Plastic Injection Molding Service

We excel at managing large, complex projects; however, we also serve small to mid-sized companies with growth prospects. Our 90 machines range in clamping force from 55 to 1,650 tons with maximum shot sizes up to 470 oz. Finished part weights can range from 4 grams to 24 lbs.

Elimold Is Your Plastic Injection Moulding Partner

Elimold provides custom plastic injection molding services for OEM manufacturing and consumer products. Located in China, Elimold provides product design assistance and engineering services for the development of plastic injection molded products and bring solutions to complex plastic engineering applications. We strive to be known in the markets we serve as the best partner for custom plastic injection molding manufacturing services that operates to the highest ethical standards.We strive to be known in the markets we serve as the best partner for custom plastic injection molding manufacturing services that operates to the highest ethical standards.

Our business strategy and operating plan is built upon People, Process Control, and Technology. We believe that by combining the best talent with proper technology to control the injection molding process we will manufacture consistent high quality parts for our customers. We also believe that culture is a strategic advantage and when we can foster an environment where people care for each other they will take care of the equipment, resin, customers and company.

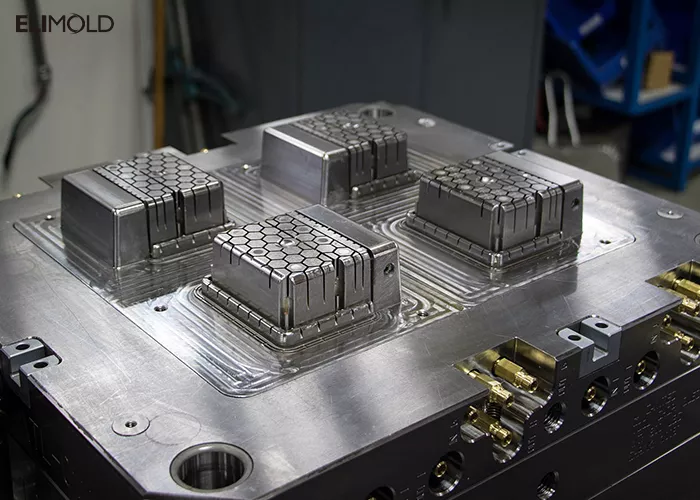

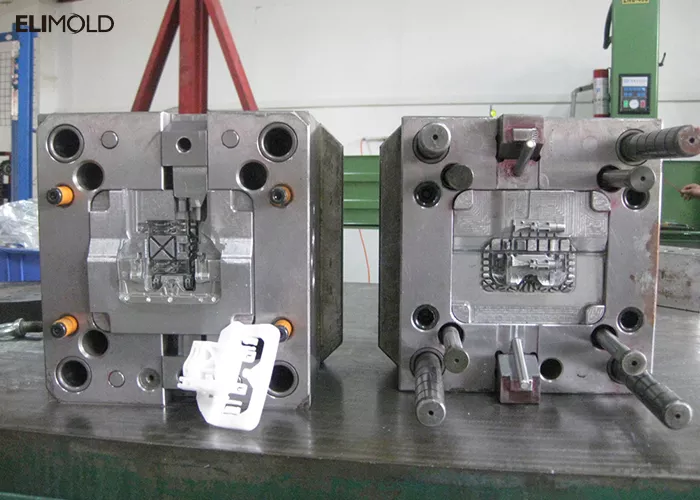

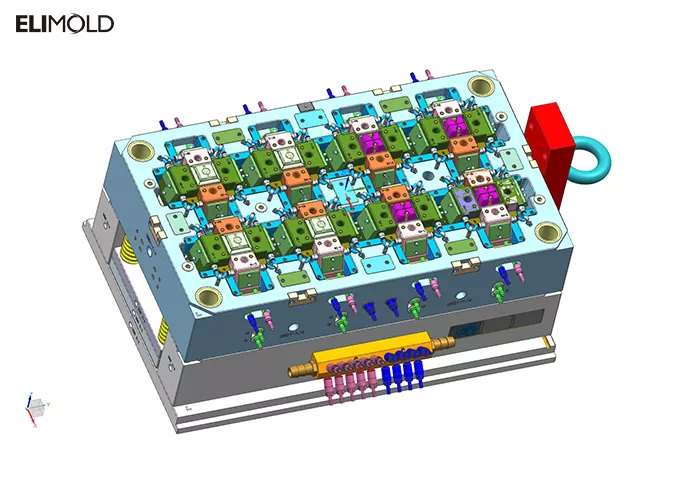

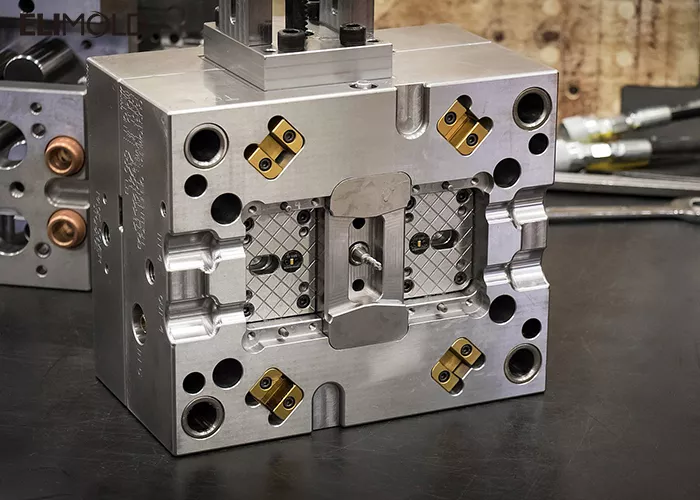

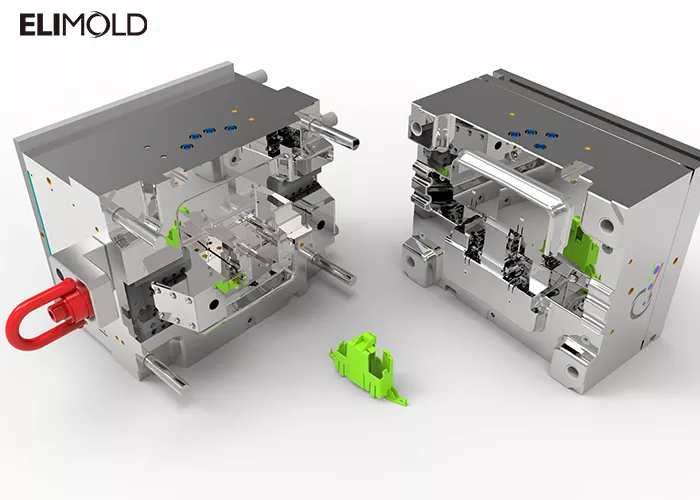

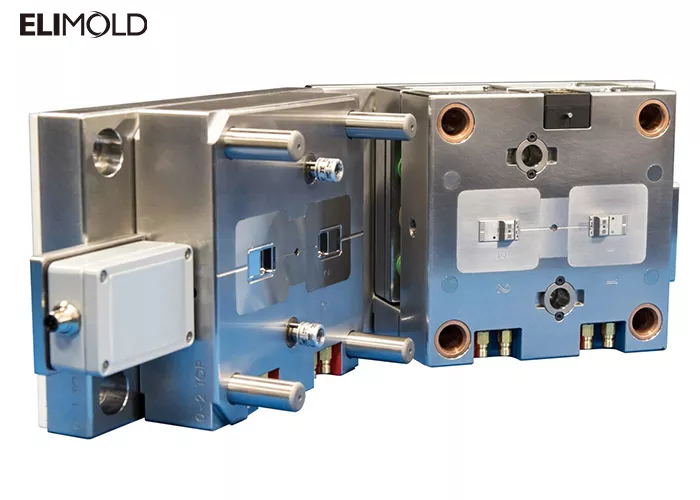

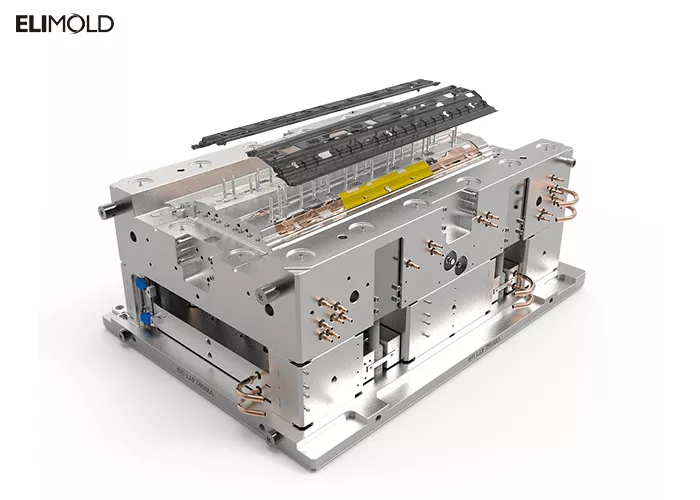

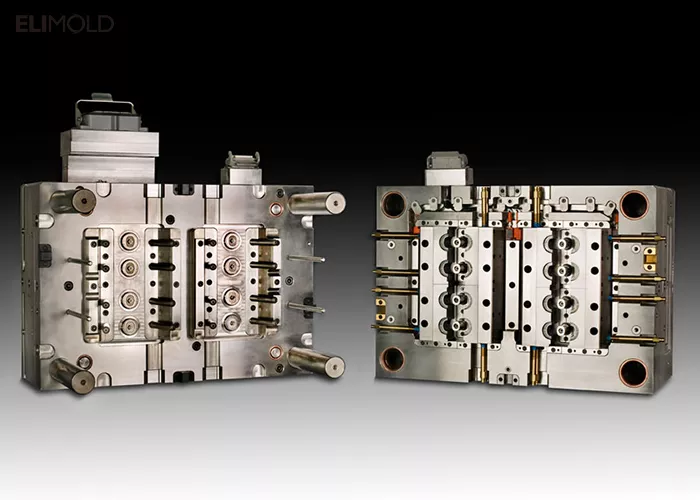

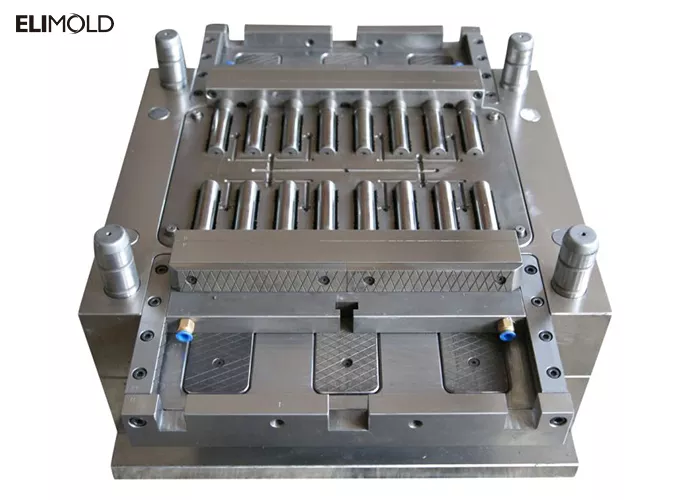

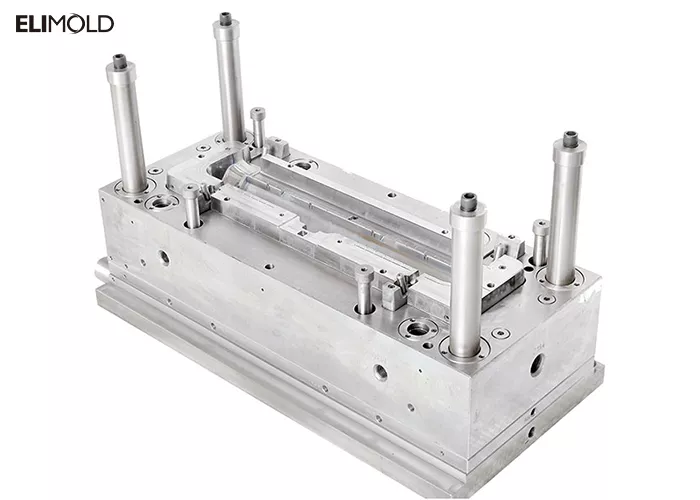

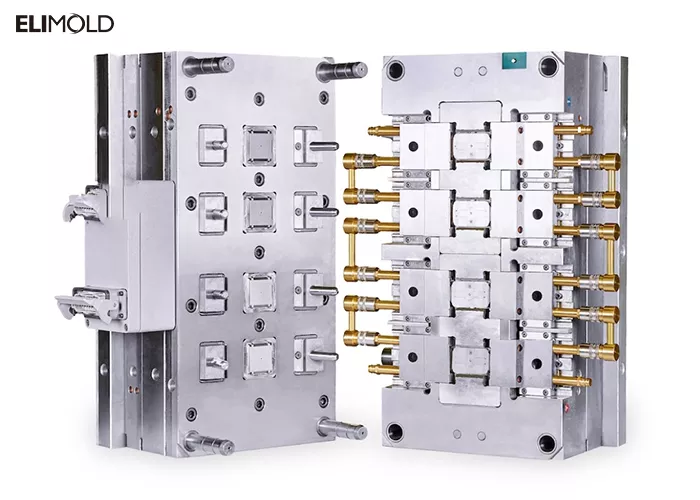

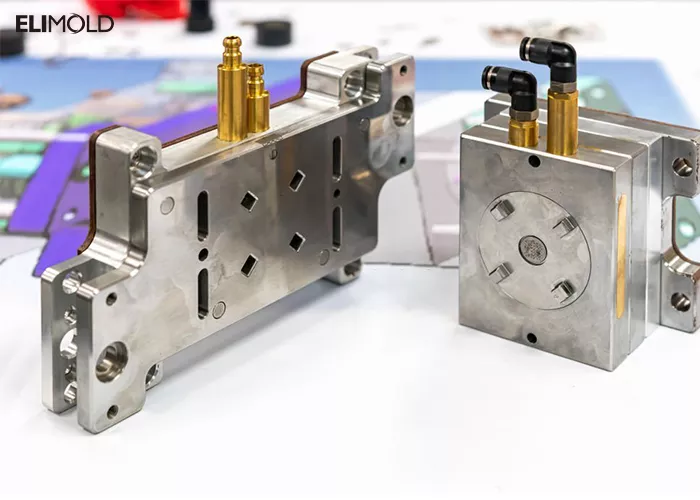

Elimold offers in-house tooling design and engineering support for new injection molds and has both in-house and outside plastic mold building resources to provide cost effective solutions to new tooling. Our in-house tooling group provides routine preventative tooling maintenance and tooling repairs to keep customer production running on-time.

Services we provide

Custom Injection Molding

Our plastic molding company specializes in production quantities from 100 to 100,000 units per order. Our free services to you on every project will include free part design advice, help with selecting a plastic material, and target cost planning for your tooling and production.

Plastic Injection Molds

As a plastic molded parts manufacturer all of our molds are made in-house and maintained by our mold making staff. Lead times to build your mold and send samples range from 5 days to 5 weeks. Our unlimited tooling life warranty means you will never see another tooling charge for the life of your project.

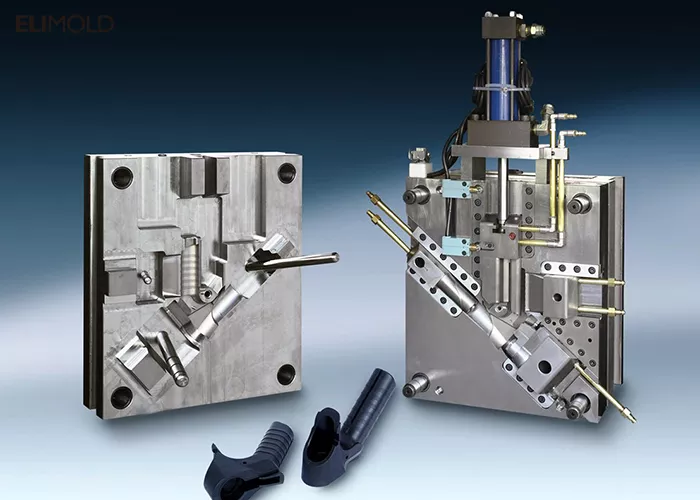

Prototype Injection Molding

Our prototype molds offer fast delivery of production quality plastic prototypes. Prototypes can help you reduce design risks before building multi-cavity molds and they can bridge low volume production quantities for low overall costs.

Design & Engineering

With our knowledge of plastic part design we offer CAD services to make 3D files from your 2D drawings or sketches. These support services are usually free to all of our purchasing customers.

Your partner at every every step with start-to-finish project management

From product design, tooling, and assembly to packaging and logistics, we can support any stage in the product lifecycle.

Our expertise in complex injection molding and mold fabrication for consumer goods and plastic packaging solutions includes developmental tooling for high-tolerance and rapid

pre-production tooling, ultra-high-precision, high-cavitation tooling, high-volume plastic injection molding, automation, and assembly.

Plastic Injection Molding Capabilities

| General Capabilities |

|

|

| Work Space Capacity | 55,000 square feet | |

| Product Capabilities |

|

|

| Mold Process Type | Custom Injection Molding | |

| Materials |

|

|

| Engineering and Commodity Thermoplastics grades including but not limited to; | ||

| Temperature Range | Melt temperatures up to 900°F | |

| Machine Maximum Velocity | Up to 12 in/sec | |

| Clamp Tonnage | Min: 35 tons | Max: 385 tons |

| Shot Size | Up to 676 grams of PS | Learn more about Shot Size in our glossary |

| Number of Cavities | Min: 1 cavities | Max: 16 cavities |

| Learn more about Cavities in our glossary | ||

| Part Thickness | .020 and up | |

| Tolerance (+/-) | ±.002 | |

| Secondary Services |

|

|

| Surface Finish |

| |

| Additional Services |

|

|

| Production Volume |

| 1 to 1,000,000 parts |

| Lead Time | Quoted on job-by-job basis Rush Services Available | Just-In-Time / Ship To Stock Kanban |

| Industry Focus |

|

|

| Industry Standards |

|

|

| Efficiency |

| |

| File Formats | Preferred format is SolidWorks, but we can also accept; | |

|

| |

Additional Information

| Industry Focus |

|

||

| Intended Application |

|

||

| Industry Standards | ISO Certified | ||

| File Formats | SolidWorks Pro-Engineer |

For Professional Custom Plastic Molding Services, Call Us Today

From medical to consumer products, Elimold has the ability and the knowledge to transform your ideas into a high-quality working part. Whether you require small to large custom parts, we have the necessary experience guaranteed to satisfy your injection molding requirements. We offer both high- and low-volume production of custom injection molded parts with on-time delivery.

Want to hear more about our custom plastic injection molding company and how we can assist your business? To learn more, don’t hesitate to contact us today and visit our FAQ page for answers to your questions.

Benefits of Custom Plastic Injection Molding Services

There are numerous reasons to consider choosing injection molding for your project. Some of the most notable advantages include the following:

- Customizability. Your tooling/mold will be custom-built for injection molding. Additionally, parts created this way can be easily colored using additives, creating aesthetically pleasing products.

- Cost-effectiveness. The automation utilized in the injection molding process significantly reduces overhead costs, allowing a sole operator to oversee the molding process.

- Accuracy. With a properly designed mold, the injection molding process can ensure tight tolerance accuracy molding to meet customer demand to print specifications.

- Efficient use of materials. The injection molding process reduces unnecessary plastic waste, as the material is injected directly into the mold during production.

- Easy reclamation and recycling. Any unused material can easily be melted down for reuse.

- Enhanced strength. Plastics have an incredibly high resistance to wear and can be injected with fillers during the molding process to create additional strength.

What Makes Us Different?

People

A business is only as good as its people. Our people provide value to our customers through delivering creative ideas and innovative solutions. As such we seek to build our team with people that share our Core Values and have strong plastic engineering, technical and interpersonal skills.

Technology

Talented people and great systems can only deliver quality injection molded parts on-time with reliable technology. We are committed to maintain modern injection molding equipment, necessary auxiliary equipment, and supporting quality laboratory and injection mold maintenance and repair.

Process Control

Controlling the manufacturing process is critical to provide for the management and reliable growth of the operation. We will employ world class systems to control and support information management, manufacturing processes, quality systems, inventory, safety, environmental and other systems necessary to provide our customers defect free products to committed delivery dates.

Culture

The “Secret Sauce” or “magic in the bottle” that makes any company a great place to do business with and a great place to work is culture. We work very hard to wrap our strategy of People, Process and Technology with a culture where team members genuinely care for each other. When we care for each other, everything takes care of itself. We care for our customers, our equipment, our facilities and create an atmosphere that is an attractive and enjoyable place to work and do business.

Our Recent Projects

Contact Elimold for Custom Plastic Molding Services Today

We are the experts in precision plastic molding! We provide turnkey service throughout your entire product development process, from design engineering to prototyping to mass production. With our comprehensive injection molding capabilities, we have what it takes to turn your designs into the high quality, high precision parts and products you need.

Request a quote on your injection molding project, or contact Elimold for more information.