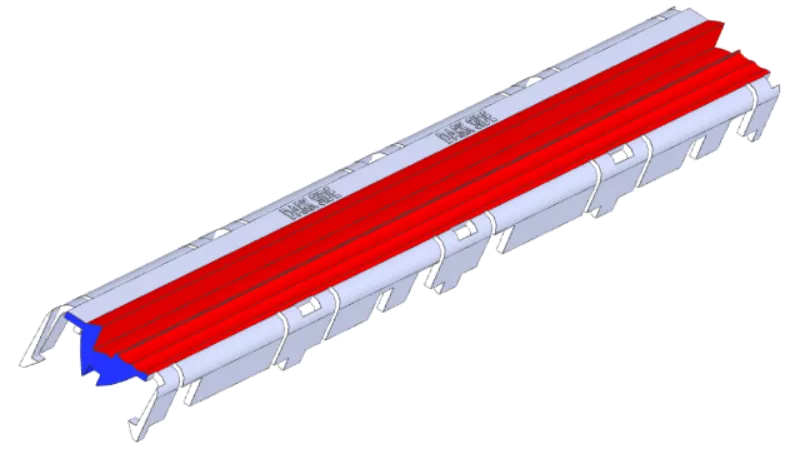

Lens For Lighting Fixture

Manufacturing Process

Product size: 11.94*1.15*0.453 (inches)

Production run: 10,000 units per month

Other Specs

Steel mold

Main Equipment for mold manufacturing: Sodick & GF EDM, Makino CNC

Main equipment for injection molding: Sumitomo

The Challenge

lighting lensA leading lighting manufacturer needed a lens. Because it is a lens, the part required very precise photometry performance and a strong validation test, creating the need for superior mold-flow analysis and very precise texture processing on the mold itself.

The Solution

Using CAE simulation, Elimold was able to fine-tune the injection parameters and achieve the right texture on the mold. By using an Electrical Discharge Machining (EDM) and taking multiple skimming passes, we created no “lay” and achieved a finish that is almost mirror-like. Although most injection factories are not equipped with instruments for IES testing, we are able to run professional IES testing to guarantee the part’s photometry performance.

Customer Benefits

The customer received a product to its exact and intricate specifications while enjoying the convenience of having the manufacturer being a one-stop provider. Having access to computer-assisted design, mold manufacturing, advanced equipment, and validation testing in the same facility, the customer realized cost savings, shorter lead time (15 days for tooling lead time and another 5 days for first articles), and guaranteed quality.