Automotive Injection Molding

At Elimold, we overcome the challenges of automotive injection molding by assisting in the design and manufacture of molds that will produce high-precision, geometrically complex molded automotive plastic parts in high volume. Our automotive injection molding capabilities include overmolding, insert molding, and in-mold labeling, among others. We can produce multi-component parts with Class A surfaces, complex geometries, undercuts, and thin walls, and easily hold tolerances as tight as ±0.001″. Contact us today for an instant free quote.

Professional Automotive Injection Molding Manufacturer

At Elimold, we have an experienced and knowledgeable team of product designers, plastic engineers, and manufacturers who work together to ensure you get the custom plastic components and automotive parts you need. Our team of engineers will sit down with you to discuss the specifications of your project, including the product you need, how it will be used, quantity, and other important details. With this information, we can help you determine if automotive thermoforming or automotive injection molding is the best choice, as well as the correct thermoplastic to use. Once the details of your project are determined, we can then make a highly detailed three-dimensional model of your product and print it out using our innovative 3D printing technology to create and test prototypes. Our team will work with you to make any necessary adjustments, troubleshoot any issues, and identify opportunities to improve your design.

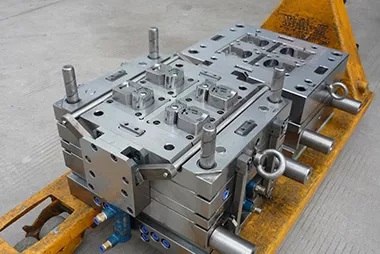

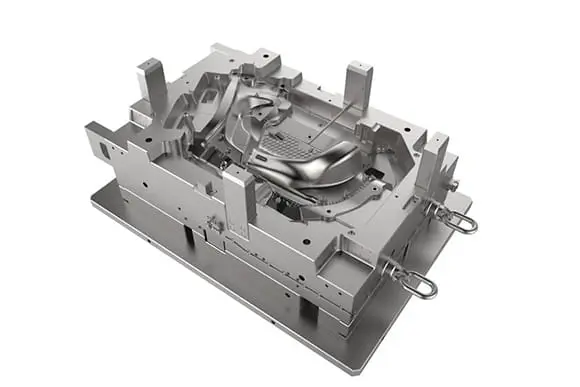

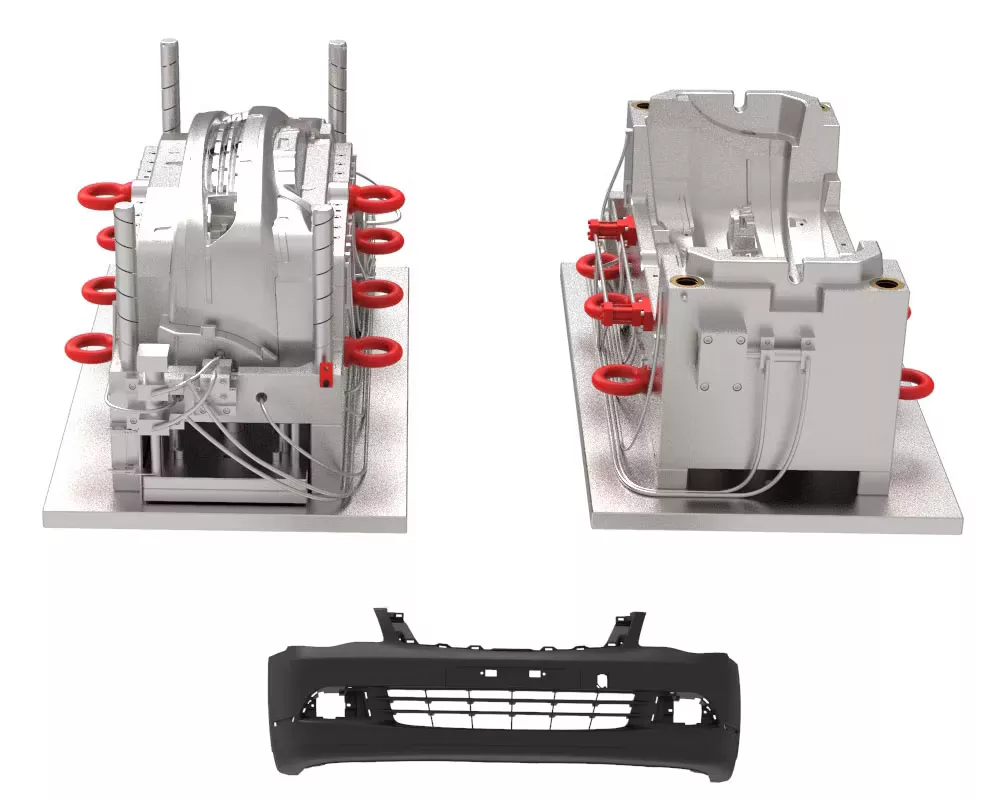

Once the prototype is complete and approved by you, we can move into the mold phase and design the automotive injection mold to produce your product, part, or assembly. In addition, because automotive plastic parts require precision and perfection, we will also produce temporary injection molds to determine the proper pressure required, troubleshoot any issues with the mold, and ensure that the end result is accurate to the design and product prototype.

Finally, our in-house mold making facility will begin to manufacture the final mold design, and once the mold design is finalized, we can begin production of your automotive part. Once the part is produced, it is sent for finishing, including sanding, painting, or assembly.

Custom Your Injection Automotive Parts by Full Processes

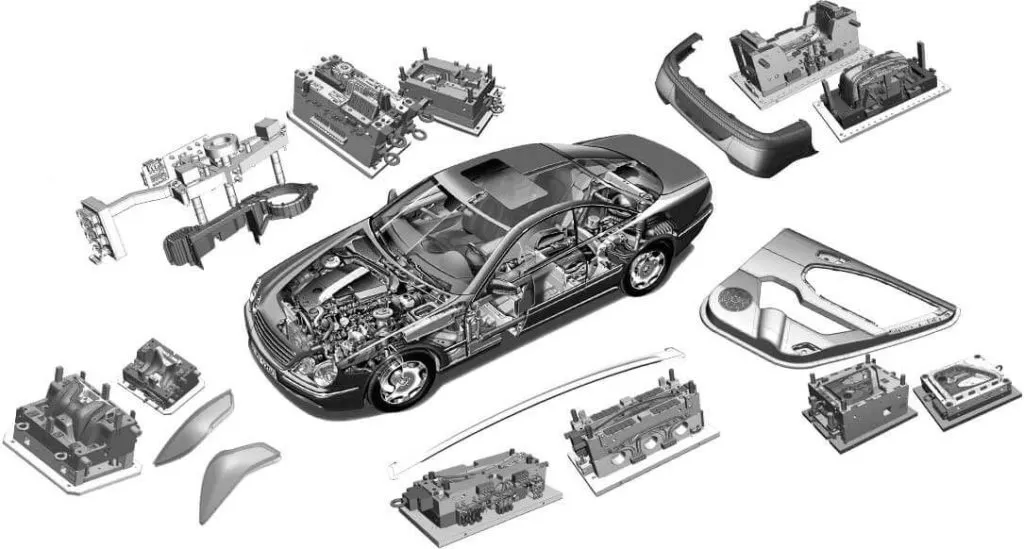

Elimold has extensive experience in serving customers in the automotive industry and is able to reduce supply chain risks. As a reliable automotive plastic parts manufacturer, we provide one-stop services including automotive parts mold design, mold processing, prototype design, material selection, sample submission, manufacturing and delivery of automotive plastic injection molded parts.

Automobile Plastic Parts Design

Custom Mold Tools

Rapid Prototyping

CNC Machining

Mold Making

Plastic Injection Molding

Various Injection Molds to Fulfill Your Automotive Plastic Parts

Insert Mold

Two-Shot Mold

Clear Plastic Mold

Large Plastic Mold

Injection Mold for Automotive Plastic Parts

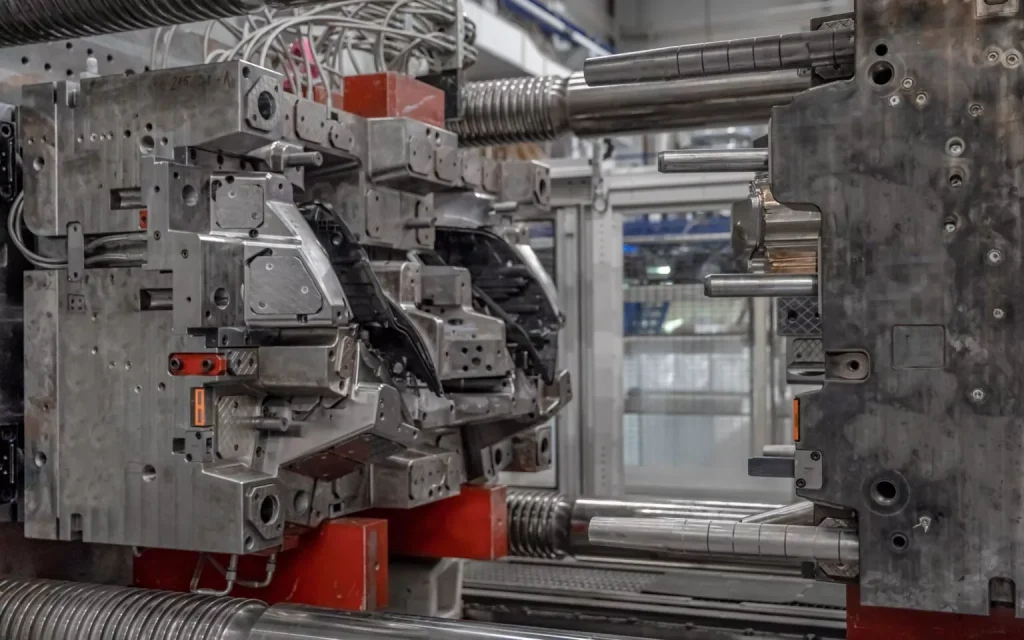

Our tooling department is the foundation of our company. We pride ourselves on being able to provide automotive plastic injection molds that produce high-quality plastic parts. By using aluminum and softer steels, we are able to meet the most aggressive project timelines. Elimold’s Tooling and Engineering department will work side-by-side with your team to ensure the best mold for the job. We can provide manufacturing-oriented design and mold flow analysis to give you an idea of what the tool will produce. In addition to projects involving new molds, we are also able to make any engineering changes in-house if necessary. If you simply want us to qualify a mold and ship it to your facility, we can also review customer-specific mold requirements and ensure we build a mold that will fit your press.

Full range of services

Elimold’s full range of services includes injection molding, overmolding, insert molding, in-house tooling, computer-aided design and manufacturing, product development, prototypes and models, material evaluation, inspection, testing, maintenance and mold flow analysis. Secondary operations include assembly, CNC machining, ultrasonic welding, milling, reaming, tapping, hot inserts, trimming, hot stamping and special packaging. Compliant with ISO 9001/ITAR/CAGE. Special mold/tool repair/refurbishment services.

Meet Your Automotive Injection Molding Rapid Manufacturing

Elimold is different from other prototype and low-volume automotive injection molding shops. We have the experience and equipment to provide unmatched speed, flexibility, and support. We leverage our superior molding expertise to provide comprehensive technical guidance and tooling options for your project. We don’t just send a price estimate for a new project; we send an intelligent quote after understanding your needs. We pride ourselves on working closely with you from the beginning to ensure the work specifications match your project goals.

We also pride ourselves on our speed, providing fast turnaround on injection molding services without sacrificing quality or precision. We are constantly improving our production processes, implementing new methods to reduce inefficiencies and shorten lead times for our customers. Whether you are looking for short-run production, rapid tooling, or prototyping services, we can help you find the best solution and deliver it quickly and efficiently.

A Better Choice for Low-Volume Automotive Injection Molding Need

Low-volume automotive plastic injection molding is driven by customers with continuous product development cycles or lower product demand. Elimold works with product developers, OEM, and tier suppliers to deliver automotive injection molded plastic parts that meet tight specifications, schedules, and budgets. Low-volume automotive part molding projects typically require less than 10,000 pieces per year, and Elimold’s in-house injection molding facility features 300-ton, 650-ton, and 3000-ton plastic injection molding machines with the ability to scale production as needed.

Our low-volume automotive part injection molding customers highly value supplier relationships, understand that price is an element of total cost, and utilize Elimold as their preferred partner in plastic product development to problem-solve, propose solutions, and share best practices in tool design and optimized processing to achieve repeatability shot after shot. We encourage prospective customers to bring their next plastic development project to Elimold to experience firsthand what our team has to offer!

Ready to start your automotive injection molding project? Get in contact with our experts.

Automotive Plastics Testing Capabilities

Our combination of testing equipment and expertise provides customers with accurate and relevant data to support automotive customers in new product development. Testing processes include mold shrinkage determination, PVT measurement, spiral flow determination and 3D measurement.

In addition, Elimold’s expertise in automotive injection molding and plastics allows us to perform tests including physical and mechanical testing under various test conditions, weathering testing and expertise, analyzing the chemical composition and performance of plastics used in automobiles.

3D Scanning

Elimold offers 3D scan-to-CAD services. We have the capability to reverse engineer your legacy parts to within 0.001 inches of the actual part. Our state-of-the-art blue laser scanning equipment provides the most accurate, high-resolution and repeatable results. As automotive injection molding experts, Elimold provides worry-free manufacturing to our customers.

3D Printed Automotive Plastic Rapid Prototype Injection Mold

If you want physical samples of your plastic parts as quickly as possible, consider Elimold as your Rapid Prototyping and Prototype Injection Molds partner. We can provide 3D printing services that can create and ship your products quickly and easily.

- Orders are available in quantities of 50-10,000 per piece; up to 100,000 per year.

- Standard tolerances are +/- .005”; tighter tolerances are available based on mathematical data review.

- Turnaround time is one day to four weeks per data review, depending on part size, geometry, and volume.

- CNC cutting focus geometry is +/- .0005”, with EDM and grinding used to achieve tight tolerances. Undercuts, holes, clip details, etc. that do not align with the mold straight line pull may require action.

- In most cases, cost and part feasibility are achieved within the same day.

High Precision Injection Molding for critical applications in the automotive industry

With our long experience in engineering precision polymer parts for critical automotive applications, we are your problem-solving partner, engineering is in our DNA and we won’t rest until we find a solution.

We support you in co-designing polymer parts that meet your application requirements for lowest leakage, low friction, high speed and precise fit. Our material experts will find the right material. Our construction engineers create a personalized plan for our high-precision tools essential for automotive precision injection molding production. We are able to produce your plastic products in large quantities. Zero ppm is not only our promise, but also the goal we create for all components.

We take the entire production process into our own hands and we strive for perfection, which is why our design, material, manufacturing, tooling and test engineering teams work closely together to keep reaction times short and be flexible to change specifications. Remember: we won’t rest until we’re done.

The automotive market is always looking for new materials and new solutions to accelerate technological innovation, meet new environmental and safety regulations and meet emerging customer needs. As the automotive industry transforms to electric vehicles, we are at the forefront of developing the most critical automotive injection molding parts to meet the precise high-volume needs of the evolving automotive industry.

Plastic Injection Molding In Automotive Industry

The automotive industry is going through radical changes when it comes to designing and manufacturing techniques. Various assembled parts and other components are being made from injection moulded plastics for better performance and enhanced durability.

Automobile engines and interior parts assembly require thermoplastic components and resins for better performance. The flexible and adaptable nature of injection molded parts makes them ideal for manufacturing parts or even complete devices for the automotive industry.Be it insert molding, micro moulding or over molding; the parts derived from these techniques are vibrant and versatile in nature. Thus they can be efficiently used for making components as per the dimensional specifications of the particular automobile device.

What are the processes for overmolding and insert molding automotive plastic parts?

While many automotive parts can be made by plastic injection molding, not all parts can be made entirely of plastic. Overmolding and insert molding are processes that can produce parts made of more than one material.

Overmolding is used to produce parts that need to come in contact with different surfaces at the same time. For example, many parts inside a car cabin. The process typically starts with a hard plastic material, such as polycarbonate or acrylonitrile butadiene styrene. Then a thermoplastic elastomer, polyurethane, or other soft thermoplastic material is overmolded onto the harder material.

In automotive or aftermarket applications, it is sometimes necessary to incorporate bushings, nuts, filters, screws, or other components made of ceramic or metal into a part. These components are added through the insert molding process. Placing a metal or ceramic component into the mold before injecting the molten plastic can create a seamless blend of two different materials.

Our Certifications

At Elimold, we strive for excellence and ensure compliance with the most stringent automotive industry standards, including ISO 9001: 2015 quality assurance standards and IAFT 16949, while meeting ITAR and IMDS requirements. We are also working towards AS9100D certification to further enhance our credentials.

By choosing Elimold as your partner, you are taking an important step toward improving your automotive plastic part manufacturing process. Our unique approach helps you overcome common industry challenges such as delays, unexpected expenses, and quality issues to maximize production efficiency. Our automotive injection mold are more than just tools, they are essential components for your product’s success in the market. By using Elimold’s solutions, we can ensure the production of high-quality automotive plastic parts.

Expertise in Metal-to-Plastic Conversion

With the help of automotive injection molding companies, metals can be converted to plastics as an effective solution to reduce vehicle weight and maximize performance. Replacing heavy metal parts with lighter, yet equally durable injection molded plastic parts can help achieve fuel efficiency goals, emissions requirements, and operating cost targets. Using advanced technologies, best practices, and sophisticated quality control systems, Elimold is able to provide cost-effective metal-to-plastic conversion solutions for the toughest automotive engineering challenges.

Automotive Parts Material Capabilities

Automotive applications place high demands on injection molded plastic parts. Designs are increasingly complex, sometimes requiring tolerances as tight as +/- .001 inches. Harsh under-the-hood operating environments are extreme in temperature, chemical exposure, and performance requirements. Designs and materials must stand up to the test.

Currently, there are more than 25,000 plastic materials engineered to provide specific physical properties such as strength, flexibility, temperature resistance, corrosion resistance, and/or UV resistance. Elimold engineers share their deep material science and injection molding expertise to help automotive OEM select the plastic that best suits performance and operating goals.

Material Options

We can design, manufacture and deliver performance-oriented automotive injection molding solutions using a wide variety of grades and types of plastics. Some of the materials we use include:

- Acetyl

- ABS

- Acrylic

- HDPE/LDPE

- PEEK

- PET

- Vectra

- Polyurethane

Surface treatment

Surface treatment of thermoplastics

- PM-F0: Non-cosmetic, finish to Protolabs discretion

- PM-F2: Non-cosmetic, EDM permissible

- PM-F1: Low-cosmetic, most toolmarks removed

- SPI-C1: 600 grit stone

- SPI-B1: 600 grit paper

- SPI-A2: Grade #2 Diamond Buff

- PM-T1: Light bead blast

- PM-T2:Medium bead blast

Surface Finish Options for Silicone Rubber Parts

- PM-F0: Non-cosmetic, finish to Protolabs discretion

- PM-F1: Low-cosmetic, most toolmarks removed

- SPI-C1: 600 grit stone

- PM-T1: SPI-C1 + light bead blast

- PM-T2: SPI-C1 + medium bead blast

- SPI-A2: Grade #2 Diamond Buff

Why choose Elimold for your automotive parts need?

Whether it is low-volume prototype and small batch injection molding, sample injection molding, or high-volume injection molding, Elimold can meet all your needs. If you are looking for high quality, high performance, and unquestionable precision in injection molded automotive parts, then Elimold is the brand you can trust. By working with us, our customers can enjoy the following benefits:

- Optimized Design: Project budget and customer satisfaction are our top priorities. We optimize designs to improve quality and moldability to meet customer goals and cost specifications.

- Strict Quality Measures: We apply strict quality measures from design to shipping, which helps to provide error-free and performance-oriented plastic parts at competitive prices.

- Fast Turnaround Time: We guarantee the fastest turnaround time in the industry. Customers can take advantage of our Kanban and inventory management procedures. We have a record of shipping within 1 to 5 days. All of this can be done extremely cost-effectively.

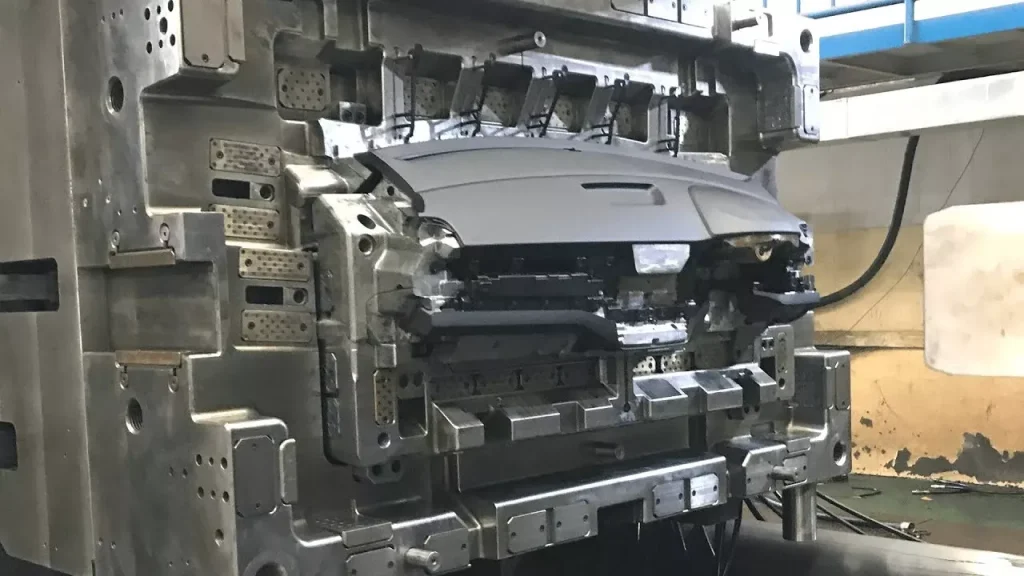

Automotive Interior Injection Molded Parts

For the dynamic automotive industry, we are a reliable partner for the production of a wide range of injection molded interior parts. In our ISO IATF certified plants, we carry out interior parts projects for leading automotive manufacturers. We are an experienced OEM, Tier 1 automotive supplier and manufacturer of automotive interior and exterior trims. Our portfolio of interior injection molded parts includes plastic automotive parts such as: instrument panel elements (e.g.: glove box, door window pillars), steering column trims, door handles, air vents, center consoles, roof modules and many more.

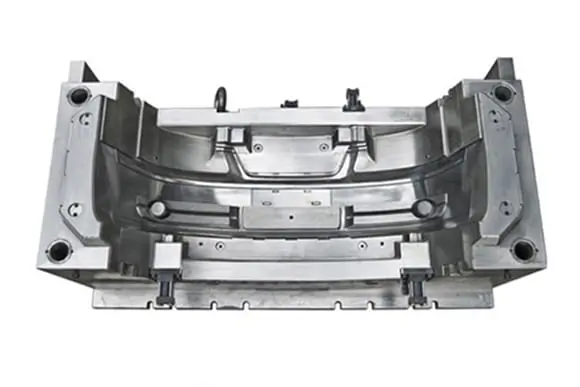

Automotive Exterior Injection Molded Parts

Injection molding is the ideal technology for the manufacture of a wide range of exterior automotive parts. Our team of experienced injection molding professionals works closely with automotive OEM and Tier 1 customers to evaluate and define all technical requirements, thus optimizing the production of impeccable exterior automotive parts. We are a plastic injection molded manufacturer of automotive exterior parts such as: fenders (mudguards), wheel arches, grilles, sensor brackets, floor rails, trunk trims front and rear lids, bumpers and exterior door trims, door panels. Our automotive injection molded plastic parts are found in a wide range of car models around the world.

Automotive Plastic Injection Molding Parts

Our team has extensive experience in designing, improving, testing and manufacturing a wide range of automotive plastic injection molding parts and electronic components, including:

- Seat Rails

- Safety Components

- Knobs and Switches

- Toner Rings

- Front-end modules

- Beams

- Brackets

- Trunk lids

- Air Conditioning Parts

- Plastic Wire Covers

- Deck lids

- Body panels

- Floor panels

- Air bag containers

- Pedals

- Seat components

- Air ducts

- Resonators

- Plastic Connectors

- Track Ways for Electronics

- Chain tensioners

- Belt pulleys

- Oil pans

- Water pumps

- Cylinder head covers

- Gear components

- Cosmetic components

Your professional automotive injection mold manufacturer

Elimold has provided automotive plastic injection molding service for primary and secondary car manufacturers. We supply a large variety of automotive plastic parts, these parts have been developed into many different specifications according to industry standards. We can provide our clients the most economical prices and appropriately meets the client’s budget constraints.

We have managed hundreds of mold design and construction and launched successful projects for the world’s largest automotive company. The first thing we have to do is to help our customers keep their vehicle launch programs on schedule, and we always provide parts within the promised time frame. From mold designing to automotive parts manufacturing, Elimold is your best partner.

Alternatives to Injection Molding for Low-Cost Automotive Prototypes

While automotive injection molding is commonly used to produce plastic parts for the automotive industry, 3D printing methods can also be employed, especially for low-cost prototypes. 3D printing can replace molded plastic parts, especially during the prototyping phase, when extreme durability or a smooth surface finish is not important. Moldable plastics can be used as fused deposition modeling (FDM) 3D printing or selective laser sintering (SLS) 3D printing, and some 3D printing technologies can also produce high-strength parts using reinforced composites. SLM 3D printing can also be used to manufacture certain end-use automotive parts. SLM 3D printing is capable of producing complex and high-quality parts. SLS 3D printing can be used to manufacture parts such as bumpers, trims, and windbreakers that are typically injection molded.

Additive manufacturing technology may expand to a wider range of injection molded automotive parts in the near future. This may involve the use of technologies such as selective laser melting (SLM) for doors and body panels and electron beam melting (EBM) for powertrain and drivetrain components.

3D printing can be a cost-effective alternative to one-off prototypes as it eliminates the need for expensive tooling, thereby reducing production costs. It offers design freedom and can be a viable alternative to producing automotive prototypes.

Customer Service

Customer service is of utmost importance, especially for the injection molding industry. You should also look for suppliers that provide excellent customer service, including clear communication throughout the ordering process and on any issues you may have. If you have any questions about the quality or safety of a supplier’s products, be sure to ask them. You should also look for suppliers that provide detailed information about how their injection molding products are made and the materials used. This will help you verify that they are following industry guidelines while ensuring that they are not cutting corners or using inferior materials.

Let us provide you with a quote for your next project.

Ready to enhance your automotive parts with state-of-the-art plastic injection molding technology? Contact us today for a free consultation to learn how our expertise can advance your next project.