Multi-Axis CNC Turning

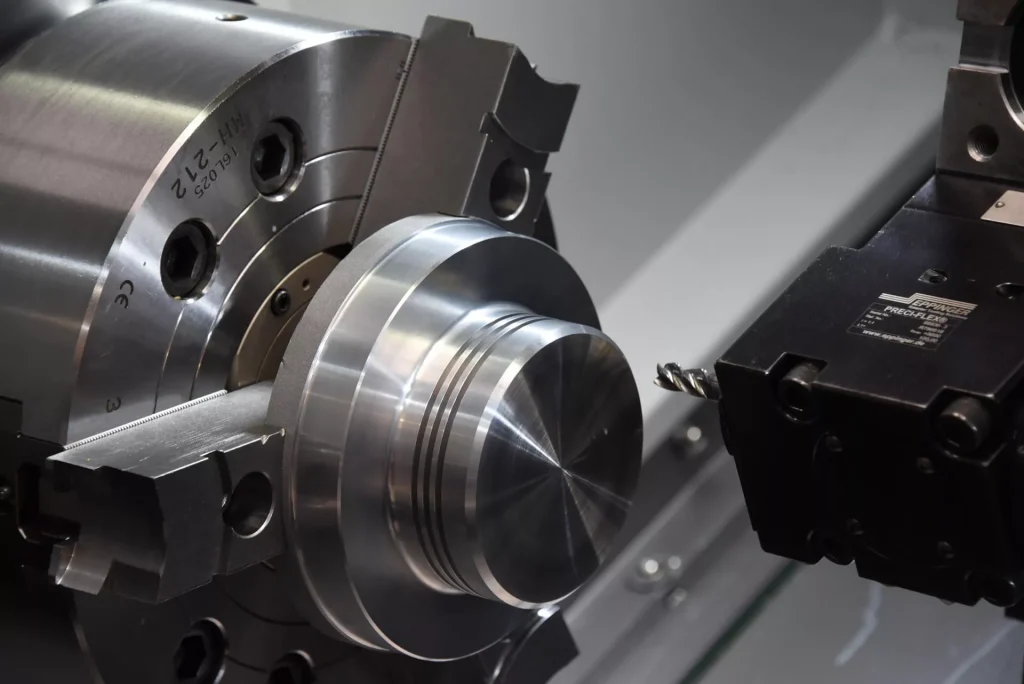

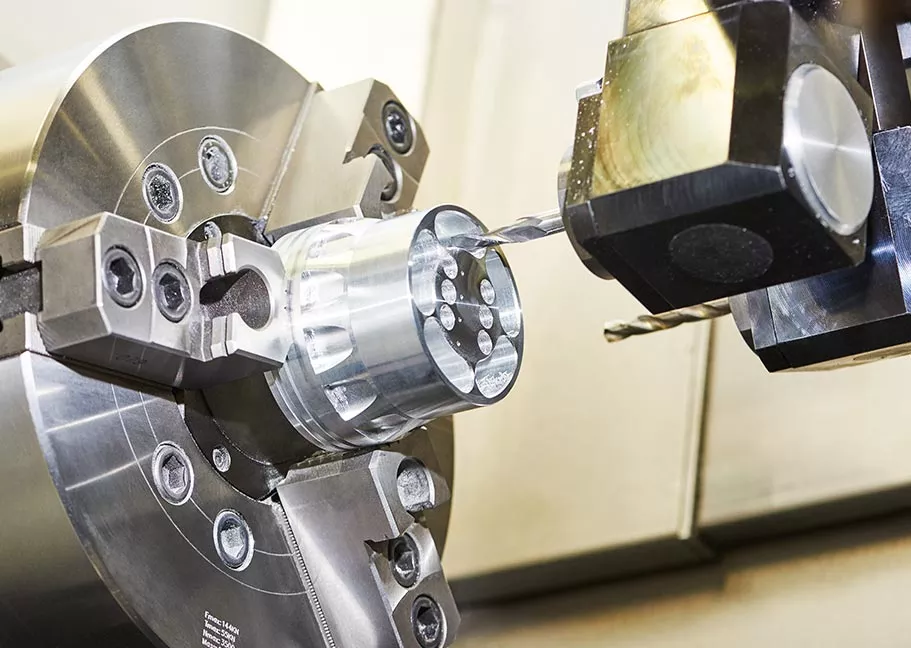

Elimold continually invests in the latest state-of-of-the-art CNC Multi-Axis Turning machinery to produce high precision parts to meet your specifications. Our machines feature 7-Axis capabilities with high-pressure coolant, spindle speeds up to 4,000 RPM and live tooling. This technology, coupled with our experienced staff ensures unparalleled service and expertise that is unique within the industry.

If your need involves larger diameter materials, or heavy amounts of stock removal we can handle the job. Beyond conventional turning tasks, our CNC lathes are equipped with live tooling allowing us to mill, cross drill, tap and mill complex shapes and features – all done in one step.

Our lathe department utilizes automatic bar feeders (up to 2.50” diameter bar) or cut blanks up to a 6” diameter. A robotic loading system increases our efficiency and maximizes production. Many of our CNC lathes can operate lights out, extending manufacturing operations and improving turnaround time.

Multi-Axis CNC turning Capabilities

Equipped with state-of-the-art CNC turning centers, our team can handle our customers’ most challenging machining projects. These versatile work centers feature live tooling, double spindles, and multi-axis (up to five axes) capabilities, which enable us to turn and mill components in the same operation. They are also arranged in cells to maximize efficiency for parts requiring multiple sequences. Other equipment capabilities include large swing lathes, automatic bar feeders, tool life management, and machine vision cameras.

- Milling

- Drilling

- Boring

- Contour Turning

- Form Turning

- Taper Turning

- Straight Turning

- External Threading

- Internal Threading

- Tapping

- Thread Milling

- Internal Forming

- Knurling

- Gear Hobbing

- Broaching

- Counterboring

- Countersinking

- Pocketing

- Profiling

- Reaming

- Parting/Cutting

- Facing

- Spline Cutting

- Engine Lathe

- Turret Lathe

- Computer Numerical Control (CNC) Lathe

- Tracer Lathe

- Computer Numerical Control (CNC)

- Large Swing Lathe

- Bar Feed

- Computer Aided Design (CAD) Design Services

- Computer Aided Manufacturing (CAM) Programming Services

- Reverse Engineering

- Milling

- Multi-Spindle (4/5/6/8)

- 3

- 4

- 5

- 6

- Live Tooling

- Three‐Jaw Chuck

- Four‐Jaw Chuck

- Pallets

- In‐House Fixturing and Tooling

- 12 in

- 40 in

- 20 in

- 0.0001 in

- 0.0025 m

- Precision

- Coordinate Measuring Machines (CMM)

- Gauges

- Inline

- Laser

- Magnetic

- Magnetic Particle

- On‐Stream

- Parts Sorting

- Penetrant

- Robotic

- Ultrasonic

- Video

- Visual

- Third Party

- Aluminum

- Brass

- Bronze Alloys

- Carbide

- Carbon Steel

- Cobalt

- Copper

- Iron

- Lead

- Magnesium

- Nickel

- Stainless Steel

- Stellite (Hardfacing)

- Tin

- Titanium

- Zinc

- Alloy Steel

- Inconel®

- Invar®

- Iridium

- Kovar®

- Molybdenum

- Monel®

- Niobium

- Palladium

- Platinum

- Silver

- Superalloys

- Tantalum

- Acrylonitrile Butadiene Styrene (ABS)

- Acetal

- Acrylic

- Fiberglass Reinforced Plastics

- Nylon

- Phenolic

- Polyamide‐Imide

- Polycarbonate

- Polyetheretherketone (PEEK)

- Polyetherimide

- Polyethylene

- Polyphenylene Sulfide

- Polypropylene

- Polystyrene

- Polysulphone

- Polytetrafluoroethylene (PTFE)

- Polyvinyl Chloride (PVC)

- Polyvinylidene Fluoride (PVDF)

- Ceramic

- Fiberglass

- Glass

- Polyester

- Assembly

- Deep Hole Drilling

- Threading

- Pressing

- Welding

- Plating

- Passivating

- Etch and Chromating

- Heat Treating

- Centerless Grinding

- Anodizing

- Laser Marking

- Metal Finishing

- Advertising

- Aerospace

- Agricultural and Farming

- Architecture

- Auto/Truck/Transportation

- Automation

- Automotive

- Biomedical

- Biopharmaceutical

- Biotechnology

- Building and Construction

- Chemical

- Commercial

- Communications

- Computer and Electronics

- Construction

- Consumer Goods

- Cosmetics

- Cryogenic

- Dairy

- Dental

- Defense Industry

- Department of Energy (DOE)

- Department of Defense (DOD)

- Electrical

- Electronics

- Government

- Heavy Equipment

- Highway Department of Transportation (DOT)

- Heating, Ventilation, and Air Conditioning (HVAC)

- Hydraulics

- Ice Making

- Industrial

- Injection Molding

- Laboratory

- Natural Gas (NG)

- Machine Tools

- Machinery

- Manufacturing

- Marine

- Material Handling and Processing

- Medical

- Medical Devices

- Military

- Molding

- Municipal

- Nano Technology Manufacturing

- Oil and Gas Pipeline

- Optical

- Packaging

- Plumbing

- Pneumatics

- Power Generation Alternative Energy

- Printing and Publishing

- Process Gases

- Pulp and Paper

- Pulp Manufacturing

- Pumps

- Railroad

- Robotics

- Semiconductor

- Specialty Machinery

- Telecommunications

- Textile

- Tool and Die

- Transportation

- Waste Management

- Appliance

- Firearms

- Food Production

- Food Handling

- Food Processing

- Food and Beverage

- Fracking

- Genetics

- Heavy Truck

- Laundry

- Liquid Propane

- Mining

- Nuclear

- Petrochemical

- Pharmaceutical

- Recreational

- Retail

- Vacuum Electronics

- ANSI (American National Standards Institute)

- AS (Aerospace Industry Standard)

- ASME (American Society of Mechanical Engineers)

- ASTM (American Society for Testing and Materials)

- AWS (American Welding Society)

- CSA (Canadian Standards Association)

- DOT (Department of Transportation)

- FAA (Federal Aviation Administration)

- FDA (Food and Drug Administration)

- ISO (International Organization for Standardization)

- Mil-Spec (Military Specifications)

- NADCAP (National Aerospace and Defense Contractors Accreditation Program)

- QS (QS is a quality standard developed by the Automotive Industries)

- RoHS (Restriction of Hazardous Substances (Compliant))

- SAE (Society of Automotive Engineers)

- TS (Technical Specifications, used with ISO)

- ITAR (International Traffic in Arms Regulations)

Advantages of Multi-Axis CNC Turning

Compared to other manufacturing methods, CNC turning offers several advantages, such as:

- Higher accuracy and precision. Since the CNC turning process uses computer software to control the operation of the manufacturing equipment, it is highly repeatable. As a result, CNC turned components generally meet extremely tight tolerances with little to no variation, even in orders of thousands of pieces.

- Faster production speeds. The use of computer software also allows CNC turning operations to be performed much faster than manual turning operations without sacrificing product or process quality, which means high-volume orders can be fulfilled in less time.

- Greater design flexibility. The CNC turning process can handle a variety of component designs when set up properly. For example, it can easily create asymmetrical features that would normally require additional sequences, which helps increase production speed and efficiency.

How Does CNC Multi-Axis Turning Work?

The CNC multi-axis turning technique requires maneuvering tools in four or more directions to shape objects and produce the necessary structure. This is accomplished by employing cutting-edge processes, such as laser or waterjet cutting, enabling accurate removal of excess material until the required shape is reached.

A CNC multi-axis turning milling center can operate on multiple axes, typically four to 12. This allows for the efficient and precise production of complex parts. In addition, it can create intricate designs and patterns in various materials, including steel, aluminum, plastics, and ceramics.

Custom Multi-Axis CNC Turning Parts

By seamlessly integrating advanced Multi-Axis CNC Turning technology, Elimold has positioned itself at the forefront of precision engineering of custom machine parts. Their dedication to innovation is reflected in state-of-the-art manufacturing processes that produce complex, custom-machined parts with exceptional precision and efficiency. The company’s responsive service is the cornerstone of its operations, ensuring that its customers’ unique specifications and requirements are not only met but exceeded. A commitment to customized solutions cements lasting relationships with customers, making Elimold a trusted partner in achieving product excellence. Additionally, their competitive cost structure highlights their commitment to delivering value, making them an industry leader in custom machined parts.

Need help with your project?

From the earliest stages of your project, our technicians at Elimold can offer their expertise to ensure your multi-axis turned parts are precisely what you need. This can include everything from design assistance to ensure low-cost manufacturability, material selection, prototyping, final assembly, and more.