Multi Jet Fusion (MJF) 3D Printing Services

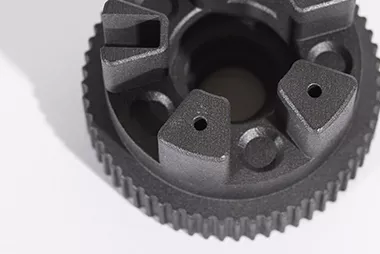

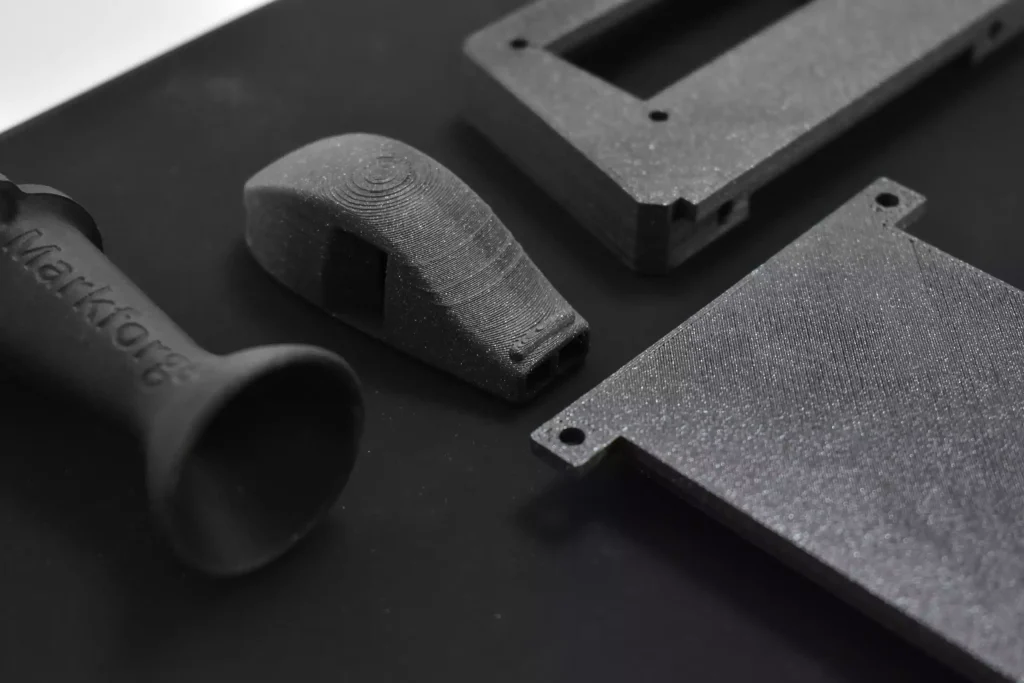

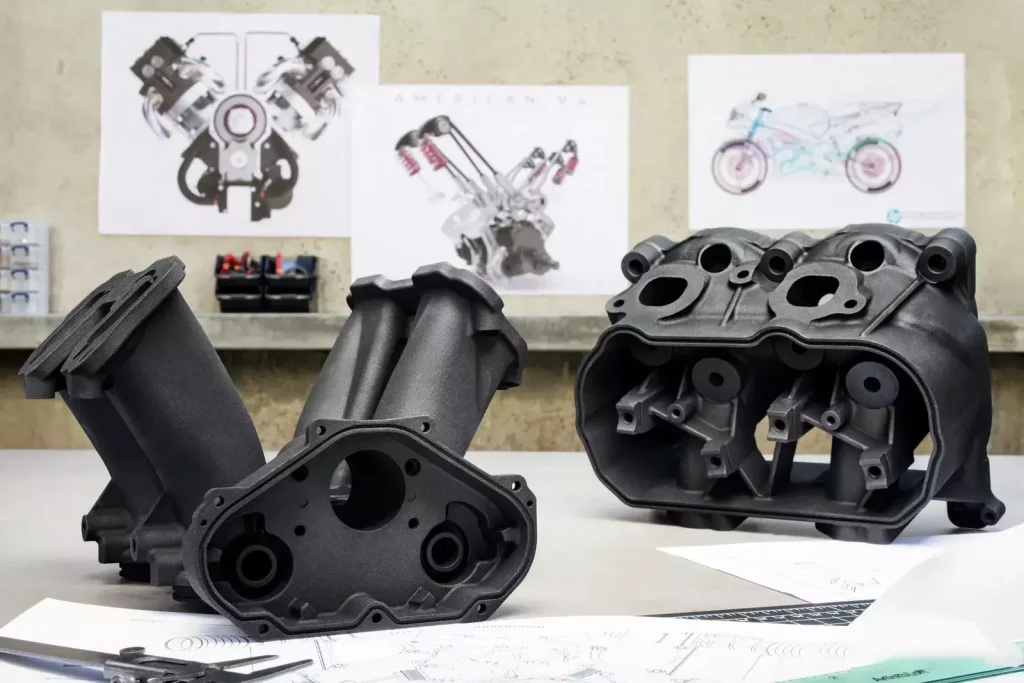

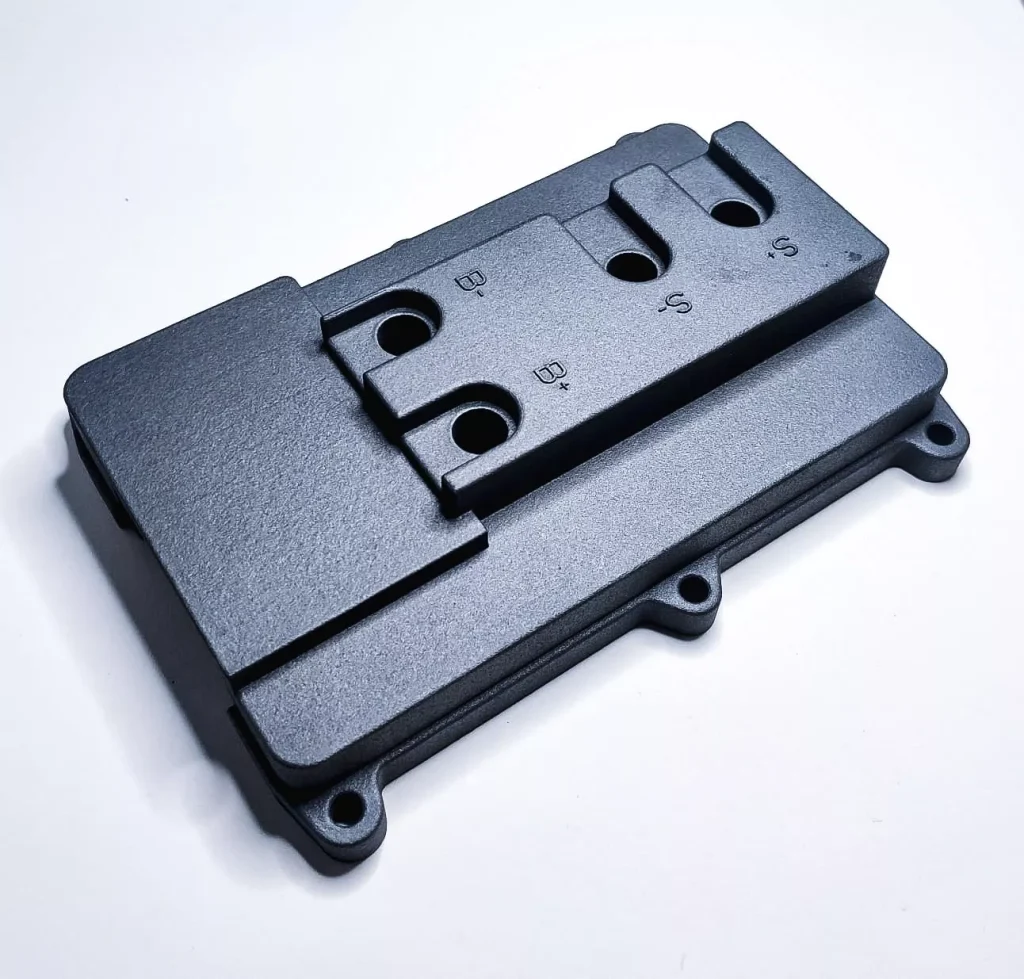

We have a strong in-house MJF 3D printing manufacturing capability that allows you to quickly prototype functional parts with high dimensional accuracy. Simply upload your STL file and get an instant quote, manufacturability review, and seamlessly move your part into production. It’s an attractive alternative to injection molding. With no support structures and minimal post-processing required on the surface, this technology is ideal for functional prototypes and low-volume production of complex end-use parts.

Expert Multi Jet Fusion (MJF) Printing Contract Manufacturer

Do you need complex parts that can be produced quickly, with high-precision features and isotropic mechanical properties? Multi Jet Fusion 3D Printing (MJF) is an excellent choice for this common scenario. It can be used to produce functional prototypes and is ideal for bridge production as well as small to medium-volume production parts. Elimold is proud to be a trusted contract additive manufacturer. We are recognized for our commitment to providing high-quality 3D printing solutions using the latest HP Multi Jet Fusion (MJF) technology. Our MJF 3D printing services meet stringent standards for quality, reliability, and innovation. As a Digital Manufacturing Network Partner, we ensure that our customers receive parts that consistently meet their stringent requirements.

Your Trusted Partner for MJF Printing Services

With over 20 years of experience in Additive Manufacturing (AM), Elimold is your partner of choice for Multi Jet Fusion (MJF) printing services. Also known as fused 3D printing, MJF offers superior performance for prototyping and end-use production parts. We have built a solid reputation with hundreds of companies across a wide range of industries who consistently choose Elimold to deliver complex and cost-effective MJF parts with exceptional surface quality, fine feature resolution, and consistent mechanical properties. With a team of over 20 manufacturing experts, we ensure that all MJF projects are executed flawlessly from start to finish. Whether you need a single prototype or thousands of serialized production parts, Elimold is your trusted partner to deliver MJF prints quickly and cost-effectively.

In-house MJF 3D Printing Facility

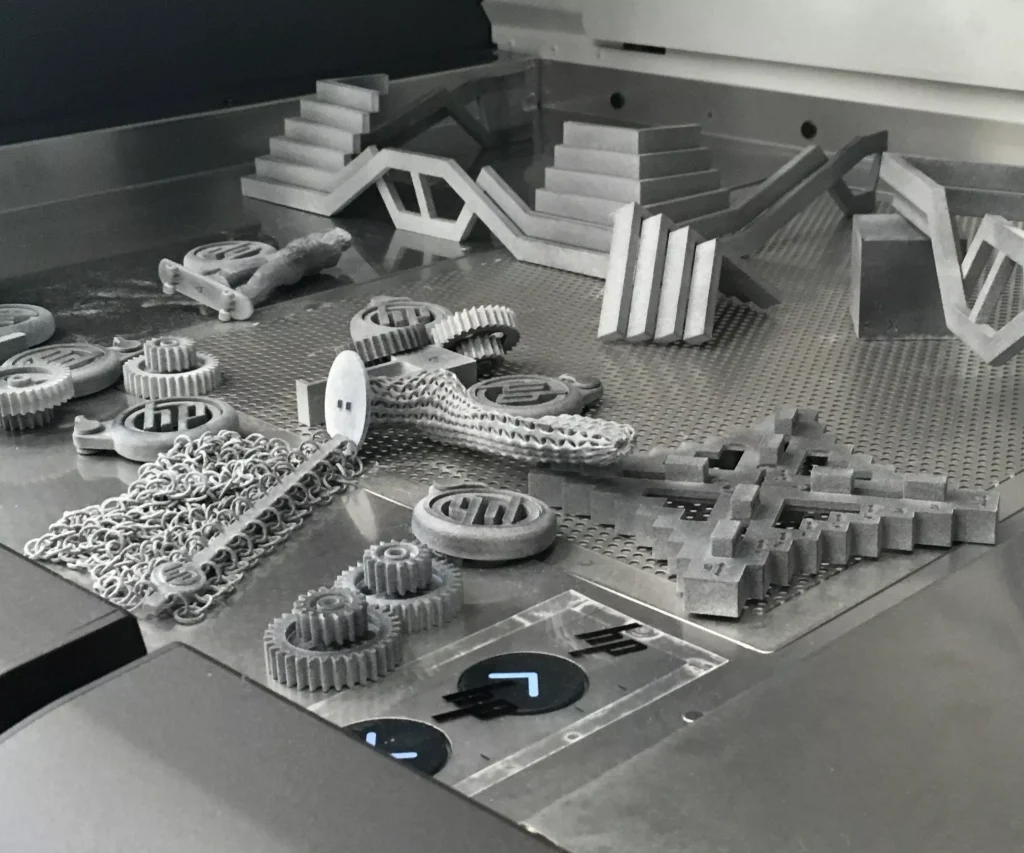

Our HP Multi Jet Fusion 3D printing services are operated from our dedicated production facility, offering both volume production and prototyping services. We chose to add HP MJF equipment over other common 3D printing equipment because we are focused on the rapid growth of 3D printing manufacturing, providing speed and efficiency for industrial-scale additive manufacturing. As a result, you can leverage the expertise of our team of engineers and over 120 of the latest MJF 3D printers in our in-house production facility, and you will be able to get faster turnaround times, the lowest unit price, and more accurate and stronger parts. Add to that the attention to detail of our engineers and our entire team’s commitment to excellent quality assurance at every stage, and you can rest assured that when you choose Elimold, you will receive the highest quality MJF 3D printed parts, as our manufacturing facility is capable of providing strong, accurate, and durable parts, whether you need a one-off prototype or a large-volume end-use part.

Our Capabilities

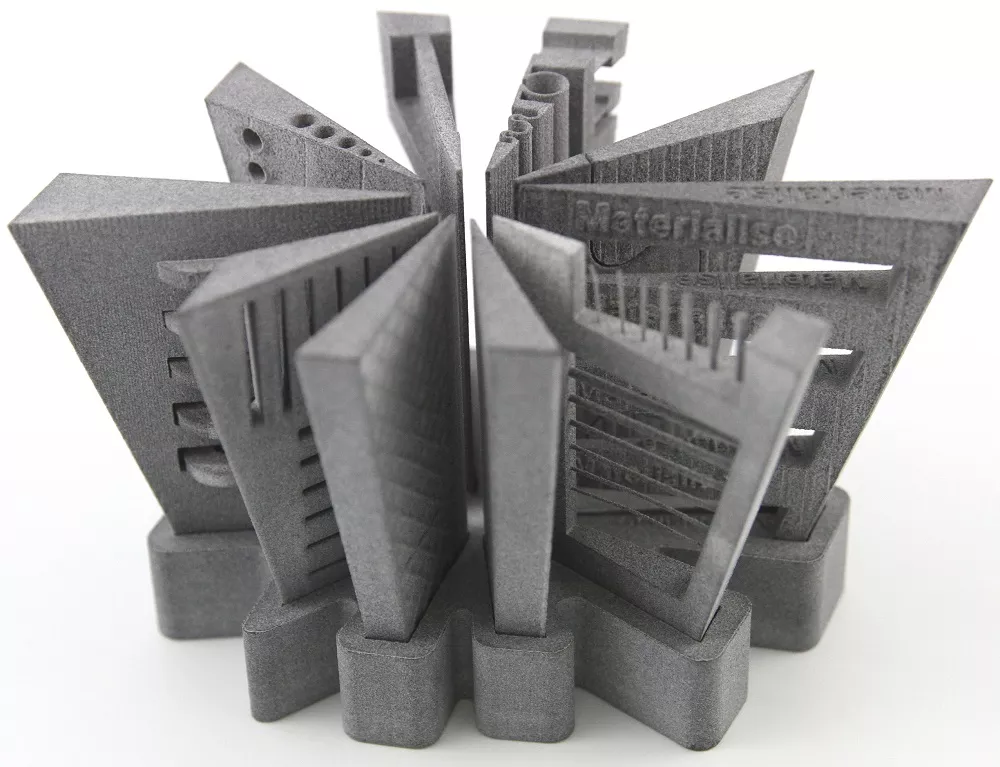

Our basic guidelines for Multi-Jet Fusion include important design considerations to help improve part manufacturability, enhance appearance, and reduce overall production time. For well-designed parts, tolerances of +/- 0.012″ (0.30 mm) are typically achievable, with the tolerance increasing by 0.1% of nominal length for each additional inch. Please note that tolerances may vary based on part geometry. Larger parts (>7″) and parts with thin thicknesses are most susceptible to warping. We recommend maintaining a uniform thickness of 0.125″ (3.175 mm) to ensure stability.

- Minimum wall thickness: 0.020″

- Accuracy: +/-0.012” or +/-0.2%, whichever is greater

- Resolution: 0.004″

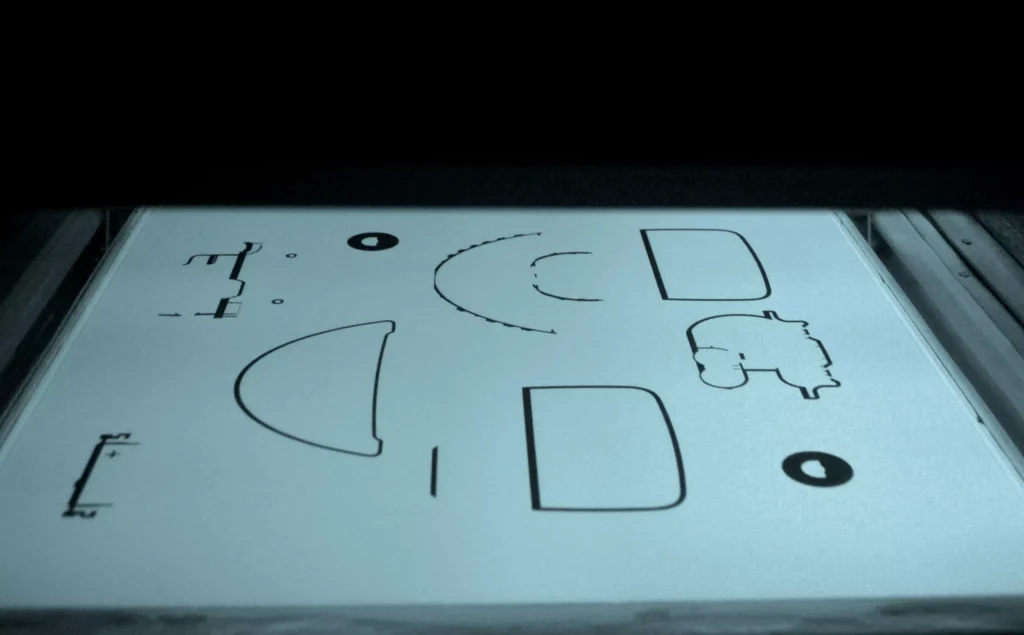

- Build unit bed size: 15″ x 11.2″ x 15″

- Large parts can be split and bonded

From Prototyping To Production

Whether you are a designer looking for a powerful prototyping solution, or a business owner or engineer looking for efficient on-demand part manufacturing, Multi Jet Fusion printing is the right choice.

Functional Prototyping

Bridge to Production

High-volume Production

On-demand Multi Jet Fusion 3D printing Services

Traditional plastic manufacturing techniques, such as cnc machining or injection molding, require tooling and other setup costs for each project. This results in higher unit costs and longer production cycles for small batches. HP Multi Jet Fusion 3D printing technology enables companies to produce plastic parts without any tooling or setup costs, saving time and money. This enables highly customizable, agile on-demand manufacturing, bringing excellent value to small and medium-sized production batches. In the fast-paced modern economy, 3D printing can help companies get products to market faster and at a lower cost than ever before, giving them a competitive advantage.

HP Multi Jet Fusion (MJF) Manufacturing

Multi Jet Fusion technology combines the design freedom of 3D printing with high-performance materials and consistent rapid prototyping to offer an attractive alternative to injection molding. With no support structures and minimal surface post-processing, the technology is ideal for functional prototypes and small batch production of complex end-use parts. Choosing Elimold for Multi Jet Fusion printing means you can take advantage of our extensive experience with this innovative technology. As a digital manufacturing service provider, we have customers around the world who are recognized for our superior 3D production and quality processes. Whether you are producing prototypes or end-use parts, we can help you get the most out of Multi Jet Fusion technology.

Traditional Technologies That Can Benefit from MJF

If you’re interested in an injection molding project, it’s a good idea to get a 3D printed “test” part before investing in a metal mold. While the SLA printing process is great for printing extremely detailed and high-resolution models, UV-cured resins aren’t as tough as traditional thermoplastics. Prints begin to degrade when exposed to UV light and moisture. Multi Jet Fusion, on the other hand, can print extremely accurate models while maintaining the structural durability of traditional thermoplastics, especially when using glass-filled nylon. This makes it a great way to test the fit and functionality of a project before committing it to injection molding.

Upload Your Parts File To Get A Free Instant Quote

Ready to get started with Elimold’s MJF 3D printing services? Simply upload your parts to our website to get a free instant quote. Our dedicated team will work with you throughout the process to ensure your components and products meet your specific requirements and adhere to our strict standards of excellence and functionality. Feel free to contact us.

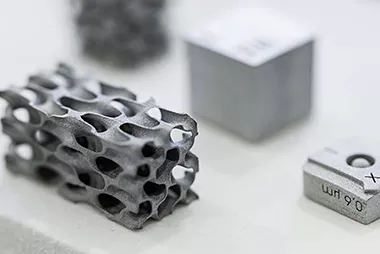

Low-Volume Production & Inventory Management

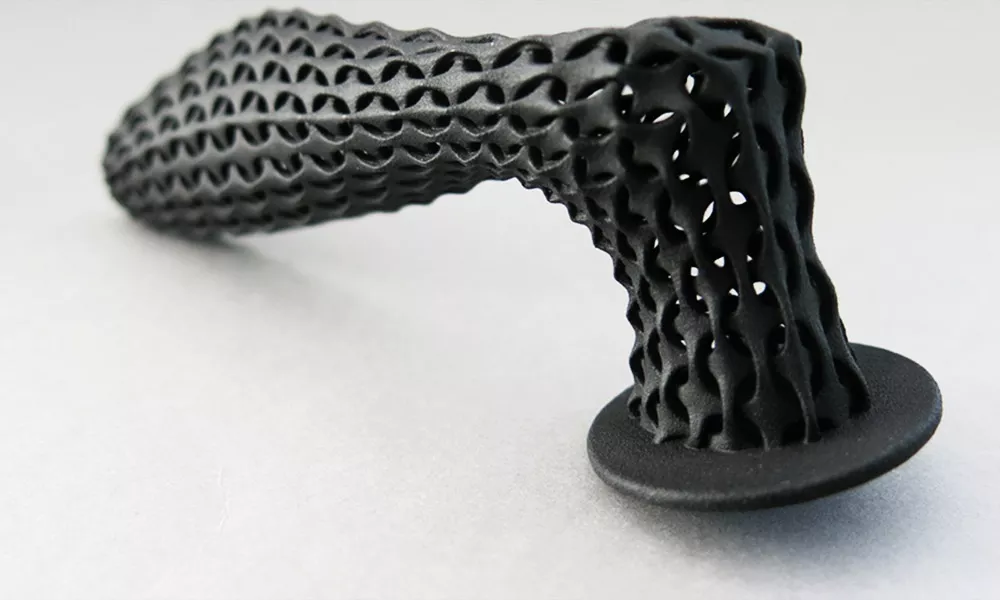

More than just prototypes, MJF is an excellent choice for initial production runs or other low-volume production runs. Due to their unique design possibilities, 3D printed parts offer manufacturers a variety of opportunities to reduce costs and improve functionality, whether by combining multi-piece components into a single part, reducing part weight with internal lattice structures, or employing just-in-time (JIT) production to reduce inventory and operating costs. MJF 3D printing can even help you extend product lifecycles by providing affordable, on-demand production of replacement parts, eliminating unnecessary large numbers of replacement parts and their associated inventory. Likewise, MJF parts can easily replace discontinued or expensive replacement parts in existing equipment. These parts can even be customized to improve their functionality.

HP Multi Jet Fusion (MJF) Manufacturing

Multi Jet Fusion technology combines the design freedom of 3D printing with high-performance materials and consistent rapid prototyping to offer an attractive alternative to injection molding. With no support structures and minimal surface post-processing, the technology is ideal for functional prototypes and small batch production of complex end-use parts. Choosing Elimold for Multi Jet Fusion printing means you can take advantage of our extensive experience with this innovative technology. As a digital manufacturing service provider, we have customers around the world who are recognized for our superior 3D production and quality processes. Whether you are producing prototypes or end-use parts, we can help you get the most out of Multi Jet Fusion technology.

3D Design and Engineering Services

Elimold’s team of engineering design experts can help your company design freely, improve product quality, and create new opportunities through advanced manufacturing technologies. Through our 3D design and 3D printing services, we ensure that 3D designs can transition seamlessly to production, helping you achieve end results quickly and efficiently. Our services integrate operations management, achieve unified workflows, and integrate with your existing design and engineering processes. This approach accelerates product development and streamlines production processes, allowing you to bring new products to market faster. Work with the Elimold Direct Design Services team to accelerate your product development. We help customers translate ideas from 2D to 3D, optimize through design reviews, and scale from prototyping to mass production by creating manufacturing tools, jigs, and fixtures.

CAD Design Services

Whether you’re looking for help making small changes to your CAD or need a more robust design solution for your application, we offer a wide range of services to ensure your project is a success. Transitioning to additive manufacturing can be challenging for your business, but our CAD design services can guide you through the entire adoption process. With decades of experience in additive manufacturing, we provide tailored manufacturing solutions to help you accelerate your adoption cycle. Work with our material and process experts to develop custom solutions and implement highly controlled additive production processes to achieve superior results. Leverage the unique capabilities of advanced manufacturing to achieve efficient production, reduce costs, and overcome the limitations of traditional manufacturing methods.

Security and Quality You Can Trust

At Elimold, quality assurance is a commitment to excellence. With ISO 9001, AS9100, and the recently acquired ISO 13485 certifications, we ensure strict compliance with regulatory standards for the aerospace and medical industries. Our certified systems provide strong process control and traceability to guarantee high part quality. Additionally, our ITAR registration, DIBNET compliance, and 110-point SPRS score ensure secure operations, while our strict adherence to NIST 800-171 guidelines keeps sensitive information secure. We prioritize the delivery of precise, high-performance parts within project parameters.

Quality Certifications

We have received several certifications for our Multi-Jet Melt 3D Printing services. Elimold’s certifications include:

- USP Class I-VI and FDA Intact Skin Surface Device Biocompatibility and Medical Applications Guide

- ISO 10993-5 and ISO 10993-10 In Vitro Cytotoxicity and Skin Sensitization Testing

- Compliant with REACH, RoHS and PAH Chemical Safety Standards

- UL 94-HB and UL 746A Flame Retardant Certification

- Ingredient Statement for Toy Applications

Quality Control & Traceability

Ensuring control and traceability throughout the manufacturing process is critical, and every step, from quote request to delivery, is closely monitored to ensure flawless production. First, we send an engineering request to obtain a quote, followed by a contract review to ensure compliance. Once an agreement is reached, we maintain full production traceability, including manufacturing, materials, parameters, and inspection. Projects are tracked throughout the manufacturing process, including tracking of the finishing process, and final inspection before packaging and shipping to ensure on-time delivery. Whether using traditional or additive manufacturing, it is critical to trace the original construction and materials of the part. From inquiry to delivery, our entire process is strictly monitored to ensure the quality of the part.

Inspection Equipment

Our commitment to quality is unwavering, and we invest in specialized inspection equipment to ensure the parts we manufacture are of exceptional quality. Single contact measurements are accurate to ±0.0010 inches, volume measurements are accurate to ±0.0019 inches, and laser line scan measurements are accurate to ±0.0010 inches. We maintain strict standards to ensure accurate evaluation of part dimensions and features.

Alternatives to MJF 3D Printing

If isotropic mechanical properties are not a primary consideration for your part, then opting for Laser Sintering (SLS) is a viable alternative. If you want parts that can be dyed or painted in a wider range of colors, SLS or PolyJet may be a better choice. If you want to choose from a wider variety of materials, SLS or FDM may be worth a look.

Multi Jet Fusion (MJF) 3D Printed Parts Provider

Multi Jet Fusion (MJF) technology helps you accelerate your project’s time to market with unprecedented speed and material selection in additive manufacturing. Each MJF printer used by Elimold is calibrated to print up to 40,000 unique production parts per week. In the past, engineers have struggled to choose between functional parts (SLS and FDM) and surface parts (SLA and PolyJet). MJF combines the best of both worlds to deliver functional, surface-finishing parts. MJF uses a fusing agent and detailing agent on powdered Nylon 12 build areas, and infrared lamps to fuse entire layers in one go, producing functional, geometrically complex parts in 0.005-inch layers at a time – with mechanical properties comparable to injection molded parts.

Order High-quality MJF 3D Printed Parts Online

HP Multi Jet Fusion (MJF) is a powerful 3D printing technology that can quickly produce high-precision, durable parts, especially when compared to other powder bed fusion technologies such as Selective Laser Sintering (SLS) or Direct Metal Laser Sintering (DMLS). Multi Jet Fusion is an affordable, fast, high-resolution technology that can be used for end-use, low-volume production, rapid prototyping, or as a transition process to injection molding. MJF enables engineers to visualize part performance with minimal upfront cost. Upload your 3D CAD file to get an instant quote with delivery time as fast as 1 business day. Easily select a different process or material if needed and get updated quotes in real time.

Start Digital Manufacturing With Multi Jet Fusion 3D Printing Today

Whether you need a functional prototype or are ready for production, Elimold Product Development can help you with your project. Our product design services and additive manufacturing solutions are available for every stage of your product lifecycle.

What is Multi Jet Fusion

HP Multi Jet Fusion (MJF) is a powder bed fusion 3D printing process similar to Selective Laser Sintering (SLS). Instead of using a laser as a heat source (like SLS), MJF uses HP’s proprietary inkjet technology to fuse layers of powder. This advanced 3D printing technology selectively applies fusing and detailing agents to deliver and control the thermal energy of infrared heating lamps. The build process is repeated for each layer of powder until the part is printed. Each layer of powder acts as support, so complex parts with lattice structures, overhangs, and undercuts can be produced without support structures.

After the build cycle is complete, the part is moved to a machining station to cool and an integrated vacuum is used to extract most of the loose powder. The part is then sandblasted to remove any residual powder. Finishing and post-processing techniques can then be applied to improve the appearance and performance of MJF parts, such as surface smoothing, DeepDye coloring, engineered coatings, or heat-set inserts.

MJF produces resilient end-use parts and functional prototypes with excellent resolution, surface finish, and edge definition. HP Multi Jet Fusion 3D Printing is ten times faster than Selective Laser Sintering, enabling production-grade manufacturing and customization without expensive tooling.

What Are The Benefits Of MJF?

Multi Jet Fusion technology offers a wide range of 3D printing materials with excellent mechanical properties. HP Multi Jet Fusion technology is an ideal alternative to SLS if you need to produce functional prototypes or low-volume production of end-use parts. MJF is ideal if you need to create components with complex patterns that also contain tiny features that must be durable. Unlike 3D printing technologies such as SLA or FDM, with HP MJF you do not need to provide supports for your parts. Because parts nest efficiently within the build volume, powder bed systems do not require supports.

Increased Competitive Advantage Throughout Product Life Cycles

The high speed and low cost of Multi Jet Fusion 3D printing makes it possible to add value at every stage of your product life cycles. Beginning with product development, MJF can quickly print functional prototypes and proofs of concept, allowing you to take your product through more iterations in less time and get to market even faster. This developmental advantage also translates to other manufacturing technologies: MJF can create durable tooling for thermoformed or cast urethane parts in a fraction of the time and cost of traditional methods.

HP MJF Build & Design Guidelines

HP MJF offers amazing part details, but each 3D printing technology ranges on what size features it can build see below for best standard practices

- Build Layers = 80 microns (0.003”)

- Minimum Walls Thickness & Feature = 0.5mm or 0.020”

- Standard Finish = Level 2 Finish with bead blast (available custom finishes)

- Standard Lead Time = 3-5 days

- Tolerances = +/- 0.010” for first inch then +/- 0.003” per inch thereafter

- Inserts = Install in post-processing

- Holes = Drill, Ream, and Tap (Print threads then chase or ream in finishing)

Multi Jet Fusion Material Selection

All materials we use are sustainable, as the process renews the powder with recycled powder, reducing production costs while maintaining part performance. Learn more about available MJF materials. HP MJF materials available from Elimold:

Nylon PA 12

An engineering grade thermoplastic for high-density parts with extreme dimensional accuracy and fine detail for functional prototyping and final parts. Nylon PA 12 has excellent chemical resistance to oils, greases, aliphatic hydrocarbons and alkalis.

Nylon PA 12 S

Nylon PA 12 S is a thermoplastic 3D printing material engineered for multi jet fusion (MJF) technology. The material offers 70% smoother surface finish compared to PA 12 along with a reusability rate of 85%. Additionally PA 12 S reduces cost per part by up to 25%.

Nylon PA 12 White

This engineering-grade thermoplastic yields high-quality functional production parts in a premium white finish. PA 12 W (Pure White) is ideal for strong, complex parts with balanced property profiles and strong structures. In addition to high consistency, this robust material has high reusability.

Nylon PA 12 FR

Nylon PA 12 FR is a high-performance, flame-retardant nylon material that meets UL94 V0 flammability standards at 2.5mm thickness, ensuring reliable performance in demanding environments. With a 60% powder reusability ratio, PA 12 FR minimizes waste while reducing overall production costs.

Nylon PA 11

This thermoplastic delivers optimal mechanical properties, and is known for producing strong, ductile, functional parts. PA 11 also provides excellent chemical resistance and enhanced elongation-at-break. Ideal for impact resistance and ductility.

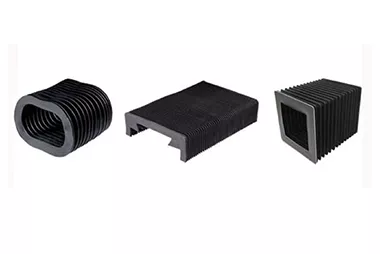

BASF ULTRASINT® TPU

This MJF specific thermoplastic from BASF offers high wear/abrasion resistance, and is ideal for applications needing rubber-like flexibility and excellent shock absorption. TPU 88A – BASF ULTASINT 3D prints with high accuracy and detail, in addition to having smooth surfaces.

Finishing Options for MJF Parts

Because MJF parts have a density that is similar to plastic injection molded parts, they can also be machined as needed. They can also be drilled to open up small holes that may be hard to produce during the printing process. Elimold offers these post-processing services for MJF parts:

- Sanded

- Tumbled

- Media blasted

- Vapor smoothed

- Painted (EMI shield)

- Painted (sand and paint, non-cosmetic)

- Painted (sand and paint, cosmetic)

- Painted (customer spec paint)

- Specialty coating

- Dyed

- Plated

- Decals

- Pad printed

- Screen printed

- Inserts

- Post machined

- Assembly

Comprehensive Multi Jet Fusion (MJF) 3D Printing Solutions

As an early adopter of Multi Jet Fusion 3D printing technology, Elimold has the experience and equipment needed to fully realize the benefits of this production method. Multi Jet Fusion 3D printing can produce finished products that are closer to the original design. It also effectively reduces errors and material waste. We can identify any production challenges early in the prototyping stage, saving you money and time in the long run. Our Design for Additive Manufacturing (DFAM) capabilities fully support your design team in the development of complex part geometries and unique end applications. In addition, we provide unparalleled post-processing services for your high-fidelity MJF parts. We can grind, polish, color match, coat, and any other special surface treatments to meet the aesthetic and functional needs of your project.

MJF vs. Other 3D Printing Technologies

HP Multi Jet Fusion is the fastest 3D printer available, with industry-leading production speeds up to 50 times faster than other 3D printing technologies and up to 50% lower costs than SLS and FDM. In addition to being cheaper and faster, HP Multi Jet Fusion 3D printing offers superior surface finish, detail resolution, and strength compared to ColorJet, Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA). Whether you are in product development, low-volume production, or product maintenance, Elimold and HP Multi Jet Fusion printing with Fusion technology will bring measurable benefits to your production from the first run.

Our Other 3D Printing Services

At Elimold, you can count on us for excellence in a wide range of 3D printing and rapid prototyping services, with precise tolerances and excellent surface finishes for our 3D printed models. We use only the most advanced rapid prototyping technologies to provide the best solutions and revolutionize the way you design and manufacture your products.

Stereolithography (SLA)

Digital Light synthesis(DLS)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Wire Arc Additive Manufacturing (WAAM)

Micro 3D Printing

Metal Binder Jetting

Selective Laser Melting (SLM)

Ceramic 3D printing

Metal 3D Printing

Laser Powder Bed Fusion Metal (LPBF-M)

Request Your Free Multi Jet Fusion (MJF) 3D Printing Quote Today

After receiving your drawings, our engineers will analyze your custom Multi Jet Fusion (MJF) 3D Printing parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.