Die Cutting Services

Revolutionize your manufacturing process with custom die cutting solutions. At Elimold, we specialize in custom die cutting services, providing unmatched precision and adaptability to meet the unique needs of each project. Our state-of-the-art technology and team of experts ensure that every cut demonstrates our commitment to excellence. Over the years, we have achieved an on-time delivery rate of 95% and a quality approval rating of 99.99998%. All production is completed in-house at our in-house facility to ensure that you receive only the best final die cut parts. Contact us now for a free instant quote.

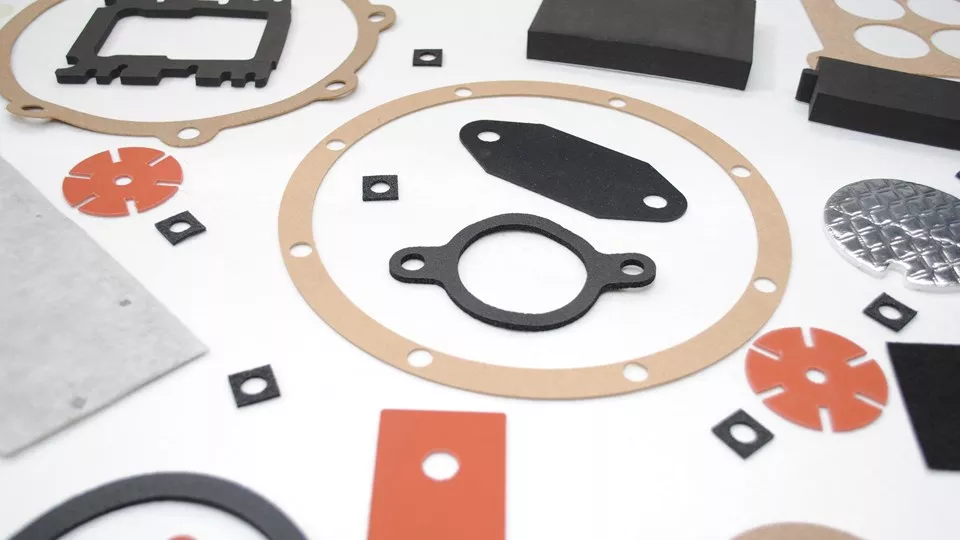

Die-cut product manufacturer

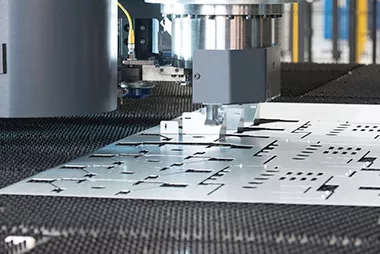

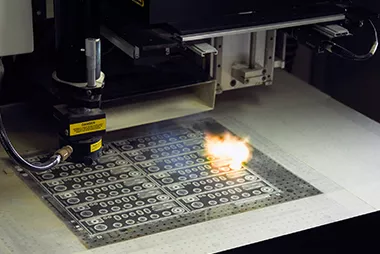

Elimold has two in-house facilities with extensive custom part production capabilities and offers a wide range of die-cutting services. Our processing services include precision die-cutting, lamination, slitting, printing, RF welding and laser, which can be performed in certified clean rooms. Labor-intensive processing, packaging and assembly are all performed in China at offshore labor prices.

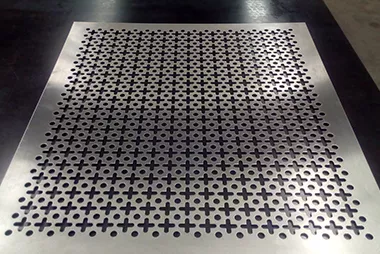

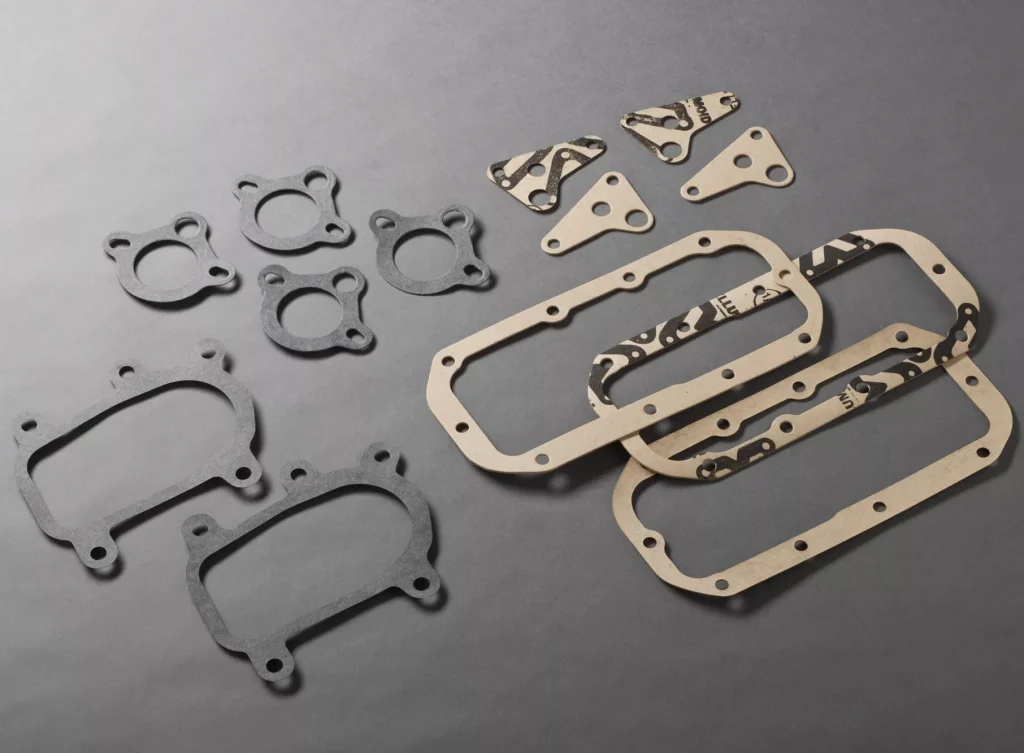

In addition, because Elimold is a leading supplier of advanced die-cutting services to a wide range of industries and applications worldwide. As a result, we are involved in the development of a wide range of products in almost all application areas. A wide variety of parts can be manufactured for our customers. From simple designs such as discs and washers to more complex and sophisticated custom geometries, we can die-cut materials into almost any shape to meet your project requirements. We have extensive experience in die-cutting a wide range of materials, and our processes are matched to yours to provide you with the highest quality products. With our team’s extensive experience and material knowledge, Elimold is often able to provide key insights to help customers avoid costly mistakes. Our engineers are experts in all areas of die-cutting and processing processes. Superior technology, a strong ISO quality system, and the ability to solve complex manufacturing challenges. Partner with us to leverage our experience, precision, consultative approach and attention to detail to lay the foundation for a successful die cutting project.

Manufacturing Capabilities at Our In-House Facility

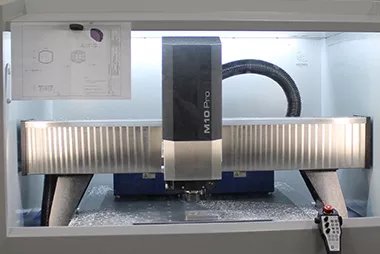

Elimold is a specialty custom die cut parts company with over 20,000 square feet of dedicated manufacturing space for die cutting services, including a cleanroom shop. Industry leading capabilities allow us to control cost, responsiveness, and quality from raw material to finished product. We offer fast turnaround while maintaining competitive pricing. We can handle any die cut order from 9,000 pieces to over 100,000,000 pieces per day. In addition, we can cut very precisely, with an accuracy of up to +/- .002 inches. This means we can easily handle projects of any size and complexity. Our machines can cut a wide range of materials, with thicknesses between .001 and 1.0 inches. With the advanced equipment we have in our in-house facility, along with our experienced team, we can ensure that your project is efficiently and precisely made to your exact needs. In addition, for special request projects, our skilled team will find the best cutting method for your project. Our goal is to provide a precise cut that meets your expectations.

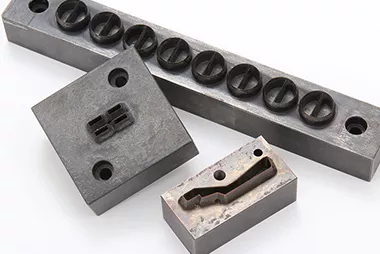

Custom Die Cut Tool Manufacturing Services

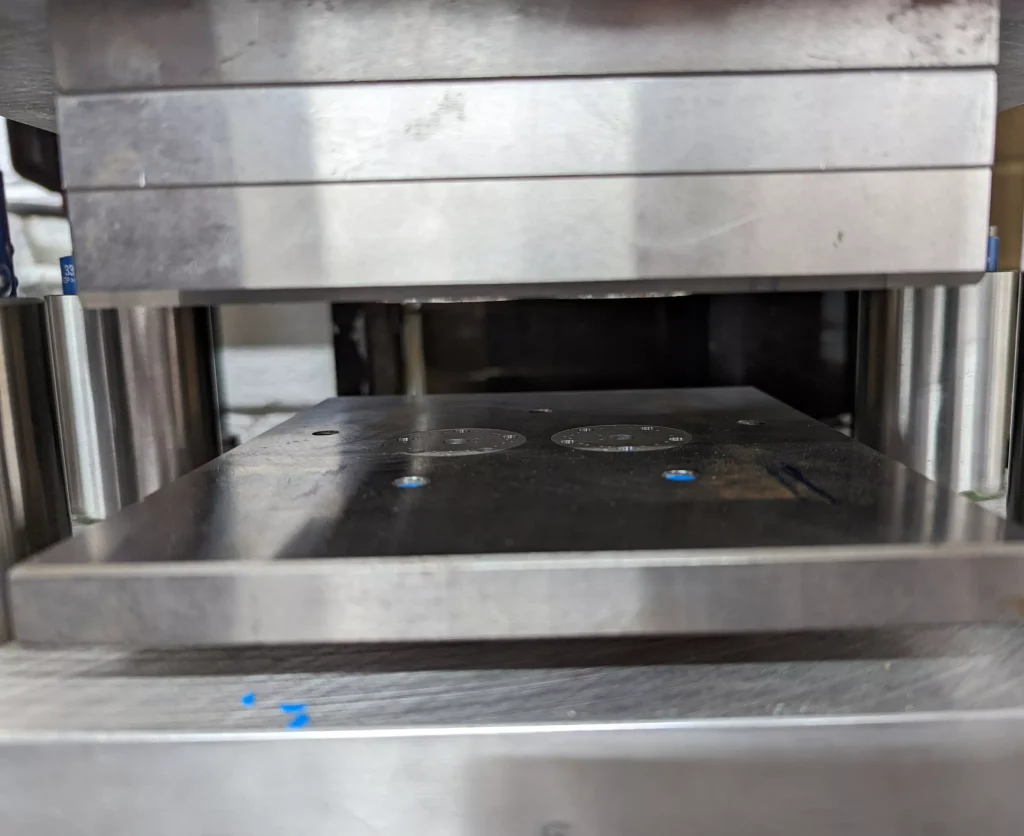

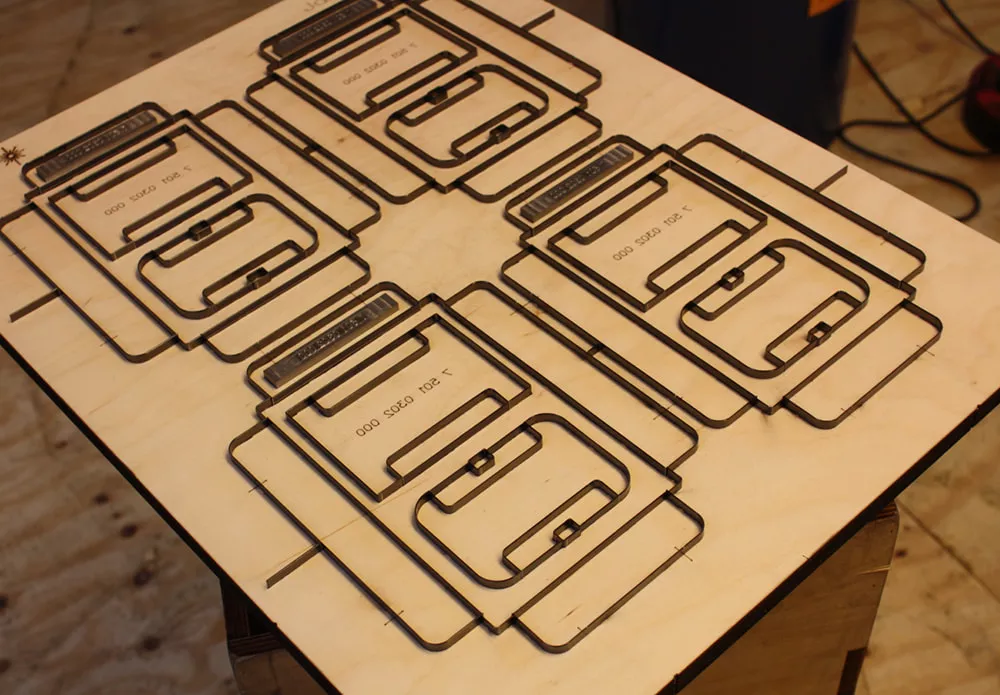

Our team can manufacture your specific custom die based on your product design while taking into account the optimal yield of your raw materials, ensuring you get the most accurate parts at the most competitive price. You can count on Elimold for timely turnaround and delivery. Custom die cut orders are typically shipped within 10 business days after prototype approval. At Elimold, we strive to understand our customers in each industry and provide quality service based on their specifications to meet their exact application.

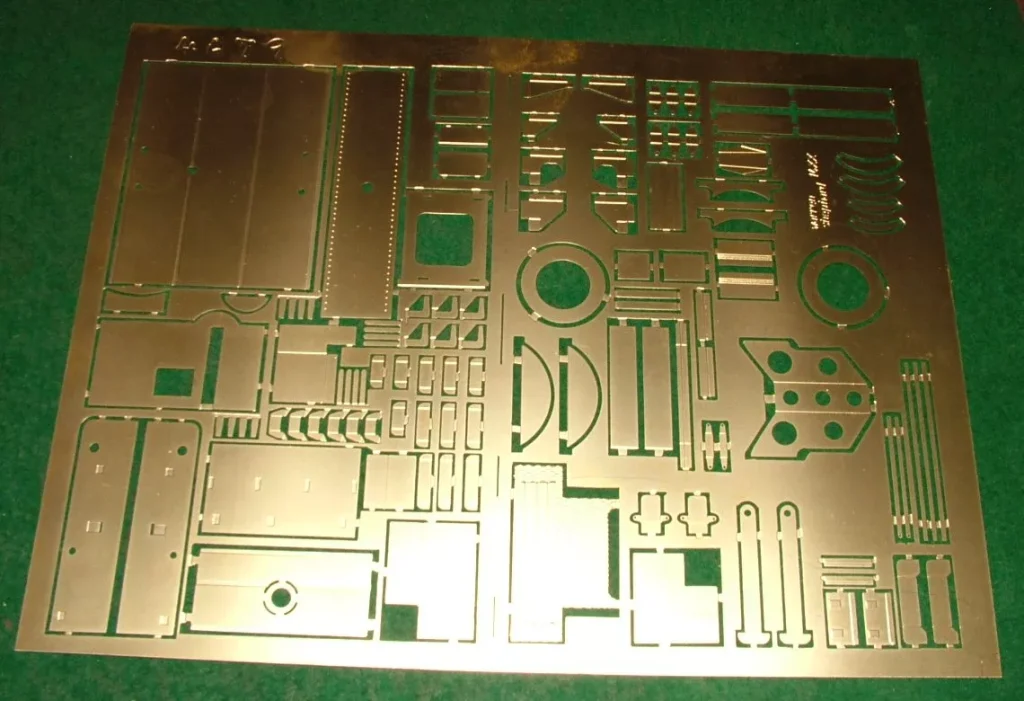

Solid Milled Dies

Steel Rule Dies

Matched Metal Dies

Part Tolerances and Precision Die Cut Part Supply Services

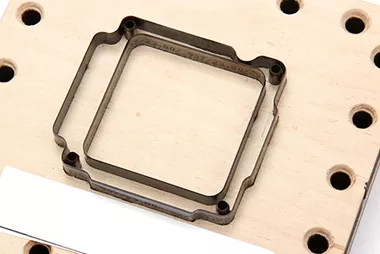

Die cutting tolerances are not simply a function of die type or part size. Material type, part features, tool type, and production technology play a role. Tooling costs, turnaround times, and specific design and manufacturing advantages also vary with precision die cutting technology. Our advanced die cutting capabilities along with our extensive manufacturing and materials knowledge will provide the highest level of support to our customers. We pride ourselves on quality, communication, and on-time delivery. Our flatbed and rotary die cutting offers low-cost tooling with short lead times and tolerances of +/- .002. Our strong partnerships with suppliers create a wide variety of material options for your unique application. Our sales, customer service, and engineering teams are second to none. Our team is here to assist you throughout your project. From prototypes to high volume production, we can custom cut products to your project requirements and specifications.

Types of Die Cutting Services

At Elimold, we have extensive die cutting manufacturing experience and a state-of-the-art equipment lineup to provide a diverse range of die cutting solutions to regions around the world. We are proud to offer a wide range of precision die cutting services, providing design and manufacturing of die cut products to companies across a wide range of industries. Our die cutting services allow us to deliver consistent, uniform shapes quickly and efficiently. Our professionals can evaluate your product needs and expectations to determine the materials and die cutting services that will be most beneficial to you. Whether your product requires a single or multiple manufacturing stages, we can find a practical and cost-effective solution.

Rotary Die Cutting

Flat Bed Die Cutting

Match Metal Die Cutting

Compound Die Cutting

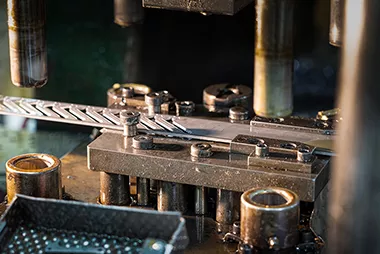

Punch Press

Multilayer Laminating

Zoned Adhesive Lamination

Kiss Cutting

Pull Tabs and Extended Liners

Perforation Die cutting

CNC Die Cutting

Laser Die Cutting

Turnkey Custom Die Cut Solutions

Elimold has a long history of producing high-quality custom die cut products. We do our work in-house and provide complete turnkey solutions that deliver your order quickly. At every step, you will work with knowledgeable team members who will strive to find innovative solutions to reduce your costs while improving the quality of the products you bring to market. Our manufacturing flexibility allows us to economically produce any quantity of custom converted products. In addition to die cutting, we also provide value-added programs to help customers manage their supply chain. Most orders can be completed within 2 weeks, depending on material availability. Elimold’s employees have many years of experience in the industry. This means we have a proven track record of manufacturing quality components for companies like yours. And, we are known for on-time delivery. We provide you with competitive pricing and quality products. Every custom die cutting job we complete begins with an initial consultation with our account manager. Request a free quote today to get started on your custom project!

Start your next die cutting project with Elimold

If you are interested in our die cutting services, the next step is to get a quote. It only takes a few minutes and one of our team’s true experts will contact you shortly to understand your needs and how we can help.

Expert Engineering Support and Prototyping

Developing new products or improving existing ones is a challenge for any business, especially a small company. At Elimold, we provide your business with the engineering support it needs to make the best product possible while controlling costs and maintaining the highest quality results. Our services include:

- Rapid prototyping & design services

- Process development & analysis

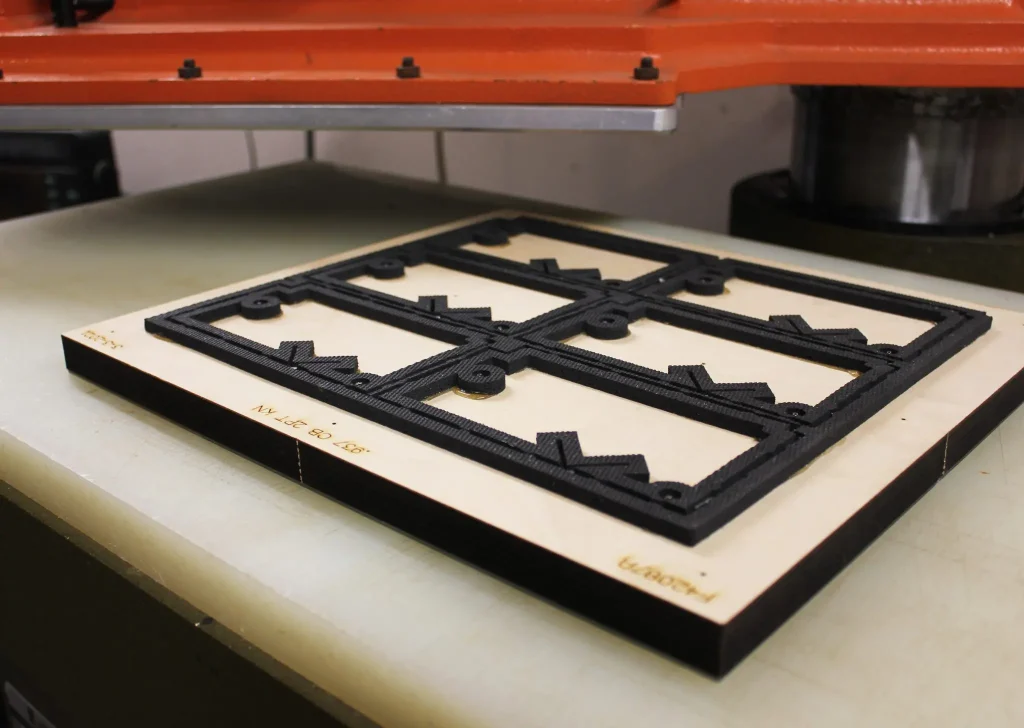

- Jig, fixture & die production

- Material recommendations

- Cost-down engineering

- Reverse engineering

- CAD file conversions

- Part nesting

- And more!

Prototyping & Manufacturing Capabilities

Elimold has prototyping capabilities and can provide recommendations based on our experience and technical expertise to meet your exact specifications. We can provide low-volume functional prototyping utilizing die-cutting technology and punching presses. With our rapid prototyping services, tooling lead times are reduced from weeks to days, allowing us to manufacture and ship functional prototypes in a short period of time. If you require medium to high volume production, our high-volume precision die-cutting services will be able to meet your production needs. Our team ensures that our products meet or exceed all applicable industry standards and ASTM, ANSI, CSA, CE, RoHS and FDA certifications. We provide custom die-cutting services using state-of-the-art servo-driven rotary presses capable of producing custom one-off products to customer specifications. We look forward to assisting you with your die-cutting project needs.

Design for Manufacturability Analysis Services

We can assist with design for manufacturability analysis and optimization to reduce overall manufacturing costs. Our experienced product development team will listen to your project requirements and source specific materials from our extensive supplier network to optimize your product performance. We can make die-cut pieces from spec sheets, hand sketches, or CAD data, so your team can work at their best. We also provide prototypes and samples to ensure the finished product is exactly what you want. We firmly believe that our customers should always be satisfied with our work, which is why we are committed to perfection. We are with you every step of the way, from initial design to finished product. It doesn’t matter if you are looking for short-run or high-volume work, or if you need a complex kiss cut or a large number of straight cuts. We focus on providing the fast turnaround your business needs at an affordable price that makes commercial sense.

Efficient Die-cut Parts Supplier

We offer precision die-cutting capabilities to provide customers with the materials they need in the exact shapes and sizes for their intended use. This improves production efficiency, increases output, and ultimately helps manufacturers control costs and ensure product quality. We can achieve tight tolerances on a wide range of materials and have the expertise to handle complex designs. We can also provide multi-stage die-cutting, meaning some materials are half-die-cut and some are fully die-cut on the same print. This helps accommodate more complex designs and further improves production efficiency. Our die-cut parts processing services are ISO 9001:2015 certified, ensuring that high-quality products are produced on every run. The value of our precision die-cutting services is that you get materials in exact formats, minimizing handling and maximizing production efficiency.

Top Materials We Offer

At Elimold we have the expertise to recommend the best material for the job and we offer world class materials from the top manufacturers in the industry, with our extensive material library and industry expertise we are able to create custom solutions that our customers have been looking for but can’t find elsewhere.

- Chipboard

- Cloth

- Cork

- Fabric

- Felt

- Fiberglass

- Fishpaper

- Foam

- Foils

- Rubber

- Silicone

- Urethane

- Medium Density Fiberboard (MDF)

- Neoprene

- Non-Metallic

- Non-Wovens

- Oriented Strand Board (OSB)

- Paper

- Plastic

- Polyesters

- Pressure Sensitive Materials

- PVC

- Textiles

- Tapes

- Films

- ABS

- Acetal

- FEP

- Halar

- HDPE

- Kapton

- Mylar

- PEEK

- PES

- VHB

PFA

PolyUrethane

PPS

PVDF

Silicone Sponge

TPX

Teflon™ Fluoroplastic

efzel

Transfer Adhesives

Udel

UHMW

Ultem

Markets and Industries Served

The Elimold team has many years of die-cutting experience and can provide the highest quality die-cutting and other custom manufacturing solutions for almost all industries in all regions of the world, including:

- Aerospace

- Agriculture

- Bioscience

- Construction

- Defense

- Electronics

- Energy production

- Food production

- Information technology

- Renewable energy

- Telecommunications

- Transportation

Common Applications

Die cutting is one of the most common manufacturing processes due to its versatility. We die cut a wide range of materials into a variety of custom parts to meet all of your needs. We can also provide laser cutting or hand-jigging to create your design. We have a large inventory of stock materials to reduce lead times for custom cut products.

- Air Filters

- Bags

- Belts

- Boxes

- Conveyor Belts

- Corrugated Products

- Decals

- Electrical Insulation

- Electronic Parts

- EMI/RFI Shielding

- Film

- Gaskets

- Handles

- Insulation

- Labels

- Magnets

- Mats

- Panels

- Plates

- Release Paper

- Rubber Goods

- Rubber Parts

- Tags, Tapes

- Washers

What Is Die Cutting?

Die cutting is a manufacturing process used to cut out precise shapes from materials such as paper, cardboard, fabric, leather, foam, plastic, and various other materials. It involves the use of a specialized tool called a die, which is a sharp-edged blade or a set of blades formed into the desired shape. The die is mounted onto a press, and the material to be cut is placed underneath it. When the press is activated, it applies pressure to the die, causing it to cut through the material and create the desired shape. The die can be custom-made to produce specific shapes, such as letters, numbers, logos, or intricate designs.

In addition to cutting, die cutting can also perform scoring, perforating, embossing, or debossing. Scoring creates creases or fold lines in the material; perforating creates small holes or dotted lines; embossing raises the surface to create a raised design; and debossing creates a depressed, or indented, design. Die cutting methods are most effective for high-volume, repetitive production runs due to the significant initial investment needed to acquire the die.

Benefits of Die Cutting

Precision

Our die-cutting tools are extremely precise and can produce consistent results, run after run.

Speed

Die cutting is known for its speed and accuracy, making it ideal for large or short runs.

Versatility

Unlike some other processes, die cutting is very versatile, capable of handling many types of materials.

Minimal waste

The die-cutting process reduces the amount of scrap that’s left over after cutting, minimizing waste (and your costs).

Cost

When a die is created to your specifications, it can be used over and over, so you’re not re-inventing the wheel. This helps keep costs down.

Rapid Prototyping

One of our key services is rapid prototyping. Customers who need prototypes want them quickly, and die cutting is a great tool for the job.

Why Partner with Elimold?

Elimold is a proud, industry-leading supplier of choice for custom die-cut parts. That means global leaders in the industry trust us to create innovative, problem-solving solutions with their premium products. It’s an honor we’re proud of. But we don’t want to be just a supplier. We are true partners to our customers, helping them innovate, create, and benefit from custom products that meet their needs. We play the long game with our customers because we know that your success is our success. With our expertise in die-cutting processes, the trust and respect of industry leaders, and our signature innovation, Elimold should be your first choice to bring your project to life.

Request Your Free Die Cutting Quote Today

After receiving your drawings, our engineers will analyze your custom Die Cutting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.