Electric Discharge Machining (EDM) Service

Elimold offers electrical discharge machining (EDM) capabilities, including CNC wire EDM, EDM drilling and EDM drilling services. Our affiliates also provide professional micro-EDM services.

EDM Machining Services Information

At Elimold, we offer electrical discharge machining (EDM) services to customers who require custom, high-quality parts with unparalleled dimensional accuracy. Because our wire EDM machines can move along four independent axes, we can create complex shapes and parts quickly. The precision of our machines and processes make Elimold the perfect choice when the highest standards of precision, fit and finish are required.

Elimold has always provided high-quality precision custom machining solutions. Electric discharge machining is just one of the many services we specialize in. Our focus on quality is rooted in our AS9100 certified quality management system. We are AS9100D/ISO9001, ITAR and Enhanced JCP certified.

What is EDM?

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges.

Electrical discharge machining (EDM) services remove metal by burning instead of cutting or grinding. This is accomplished by submerging the workpiece in a dielectric fluid and sending rapid electrical discharges through a wire or electrode (the cutting tool). EDM is one of the most accurate and versatile machining techniques; it can be used on any metal that conducts electricity, and on some ceramics. It has the advantage of being able to cut fragile or hardened parts because it does not cause the deformation induced by mechanical cutting processes.

Since EDM is a very specialized process that requires special equipment, many machining companies do not have in house EDM capability. EDM service providers supply this capability and capacity to those that need it. Part design dimensions and features are forwarded to the EDM shop or “house”. Parts are machined or cut from provided or internally purchased stock. When requirements are met the parts are returned to the client.

Benefits of the EDM Machining Process

Electrical discharge machining supplies a wide variety of advantages to both manufacturers and customers.

- Electrical discharge machining creates products and parts with highly accurate markings, angles, cuts, etc.

- EDM machines can machine even the smallest parts or smallest lines. The complex shapes that manufacturers can make with EDM tooling would be difficult or impossible with traditional tooling.

- EDM machines can accurately cut even the hardest of metals without preheating them.

- EDM does not use impact or abrasion to achieve its goals. In fact, the EDM tool never makes physical contact with the part being machined. This is a significant advantage. Because the EDM tool never makes physical contact with the part being machined, that part is not deformed, nor does it sustain heat damage or imperfections like burrs.

- With EDM, creates excellent surface finish qualities.

Types of EDM

There are three basic types of electrical discharge machining (EDM) operations: sinker EDM, wire EDM, and small-hole EDM. These processes differ based on the type of electrode used.

Sinker EDM

A sinker, die-sinker, ram, or electrode EDM uses an electrode that is fabricated into a specific shape. The inverse of this shape is imprinted on the part as the electrode “sinks” itself into the workpiece, eroding away the material. A servo control mechanism is used to monitor the gap voltage and maintain continuous sparking during the process. Oil is typically used as the dielectric fluid.

Sinker EDMs are extremely accurate and create fine finishes. They are used when parts need tight tolerances or when a tight corner radius is required. The sinker EDM process is versatile, allowing parts of many different sizes to be machined. They are commonly used to burn mold cavities for part fabrication and for internal holes and recesses.

Wire EDM

A wire EDM burns the workpiece using a very thin (typically brass) wire as the electrode. The wire is spun between two reels during machining and travels vertically through the workpiece. The cutting is done in a bath of deionized water. Computer software controls all the operations of the process, including the path of the wire.

Wire EDM machines excel at cutting very intricate and delicate shapes efficiently. They are used to machine contours, sharp corners, and tapers either internally or externally. Wire EDM is the most accurate EDM process, capable of achieving tolerances well under .0001 inches for most cuts.

Small-hole EDM

A small-hole EDM uses a small, hollow tube electrode which spins about a spindle much like a drill and drill bit. The discharge process is more aggressive than sinker EDM, and blasts small holes in workpieces very quickly. Dielectric fluid is flushed through the electrode to provide an effective “sparking” environment.

Small-hole EDM is similar to drilling, but creates very little machining residue. The process was originally used for putting in pilot holes (starting points) for wire EDM machines. They are ideal for blasting and drilling small holes in various types of parts, including those with curved or angled surfaces and those made of hardened materials.

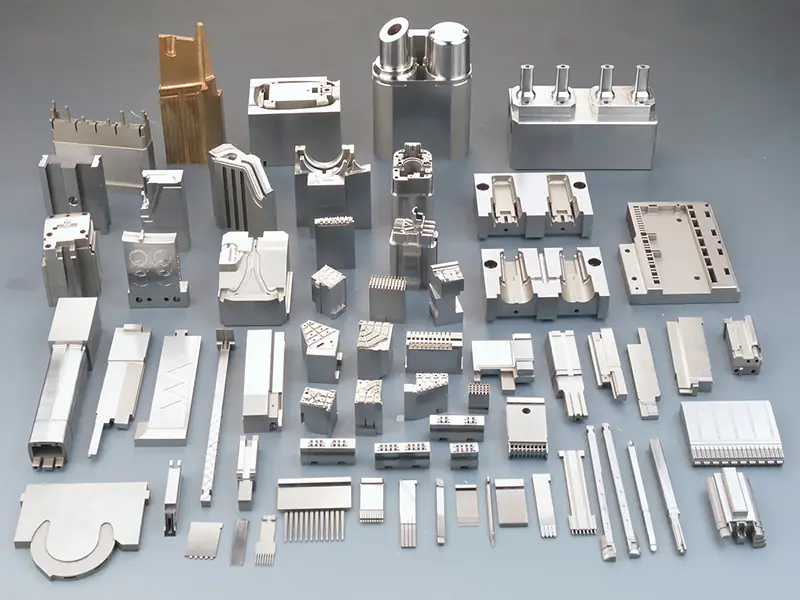

Products Produced with Elimold’s EDM Services

Using electrical discharge machining, manufacturers produce molds, tools, and dies for the forming, casting, and forging of products and parts like plastic molds, compressor blades, various engine parts, jewelry, badges, coinage, plastic mold production, compressor blade production, and the production of other engine parts. With EDM, manufacturers also make prototypes and sample parts for customers in auto, aerospace, and electronics.

Trust Elimold with Your EDM Machining Needs

Elimold is your preferred supplier of EDM machining tools. With rich experience and ISO certification, we are committed to providing the best quality products to our customers. We provide tools for a variety of industries, including the ammunition, automotive, medical, and firearms industries. We can comply with Mil-Spec, Medical and Automotive standards if required.

Our extensive manufacturing capabilities enable us to deliver demanding specifications and high-complexity products at short notice. Ready to start your next project? Please contact one of our helpful team members or request a quote on our quick quote system.