Oil And Gas CNC Machining

Elimold is a top precision Oil & Gas CNC machining services provider, our services are carefully tailored to meet the demanding requirements of the oil and gas industry. With expertise in cutting-edge CNC machining solutions, we offer a comprehensive set of capabilities specifically designed to address the challenges and specifications of this critical industry. Contact us now for a free instant quote.

Oil & Gas CNC Machining Manufacturers

The oil and gas industry requires components that can withstand harsh conditions and adapt to unexpected challenges. At Elimold, we specialize in precision CNC machining services to meet the rigorous demands of the global oil and gas industry. We have earned the trust of professionals around the world for our superior accuracy, reliability, and ability to provide components that exceed expectations, including API threads and specialized materials used in the oil and gas industry. We custom our CNC machining services to the unique requirements of the oil, gas, and gas industry. No matter which country you are in, we will machine your custom oil and gas parts and complex assemblies to ensure your operations are strong and your orders are completed on time. Elimold’s skilled CNC machinists work closely with you to custom-design the highest quality components to meet your specific project needs.

Industry-Leading Oil & Gas CNC Machining Capabilities

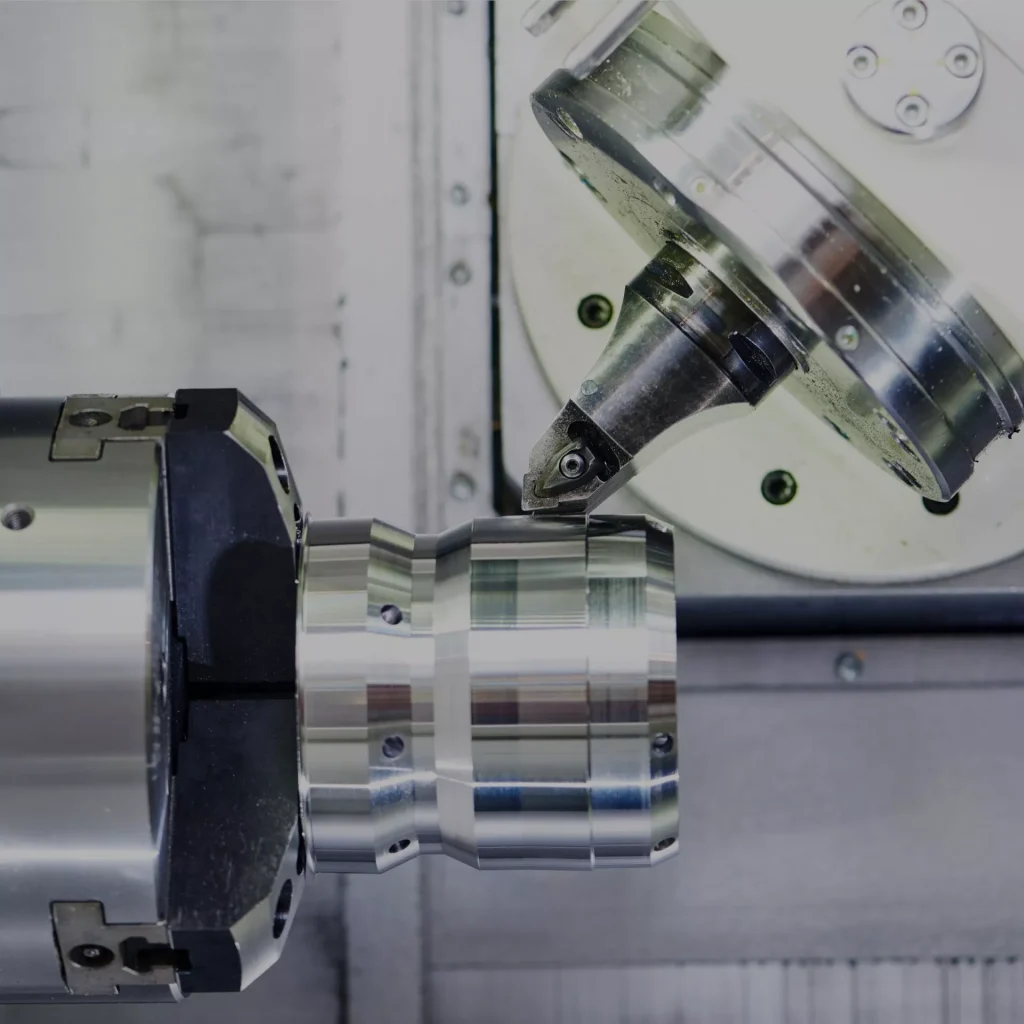

Over the years, we have continually invested in the latest and greatest technologies in the world, growing to become one of the leading providers of high-quality Oil & Gas CNC machining services and the preferred choice of the world’s leading Oil & Gas companies. We have experience machining parts, prototypes, and tools that range from 1 inch or less to over 100 feet long, performing a variety of machining operations including boring, drilling, milling, tapping, turning, threading, and more. We excel at developing and applying advanced manufacturing solutions to meet our customers’ complex needs and the precise tolerances they demand. We plan and schedule jobs to meet tight deadlines and tackle some of the industry’s largest and most challenging projects. We have a team of highly skilled machinists, many of whom have been in the industry for over 20 years, who serve as programmers and operators to reduce downtime and ensure our equipment is used to its full potential.

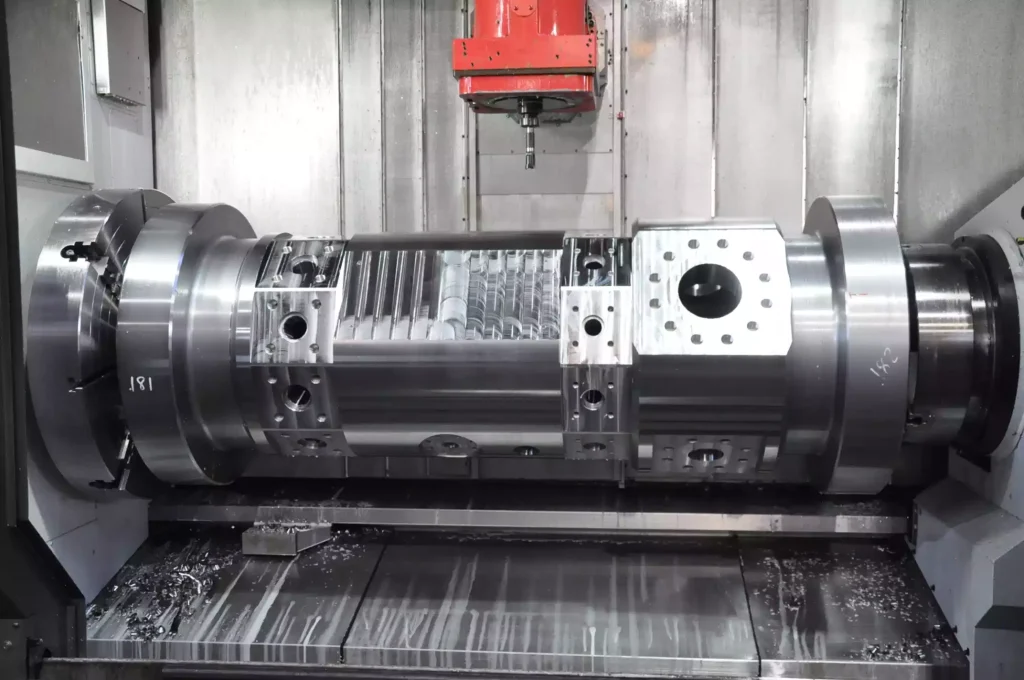

Our Oil & Gas CNC Machining Factory

With over 175,000 square feet of production and warehouse space, Elimold features some of the most advanced and diverse machining equipment in the industry, including an overhead crane capable of lifting 30 tons, multiple milling machines, lathes, and welding rooms. Our state-of-the-art CNC mill-turn machines can process parts up to 27 inches in diameter and 80 inches in length while maintaining micron-level accuracy and repeatability. Custom production machining solutions are available to meet the precision and efficiency requirements of the oil and gas industry. As an ISO 9001:2015 certified Chinese manufacturer, our quality control system ensures consistent results.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

Rapid Prototyping for Oil & Gas Precision Parts

Rapid prototyping of precision parts for the oil and gas industry is a process that requires great attention to detail. It includes the industry’s unique needs, materials, and rigorous testing to ultimately deliver components that withstand the harshest conditions. Elimold’s team of experts utilizes modern technology and simulation tools to create prototypes that reflect the real needs of the industry. We carefully evaluate materials, design, and manufacturing processes to ensure that our precision parts can withstand the extreme conditions and stringent performance requirements of the oil and gas industry.

Rapid Prototyping for Field Evaluation

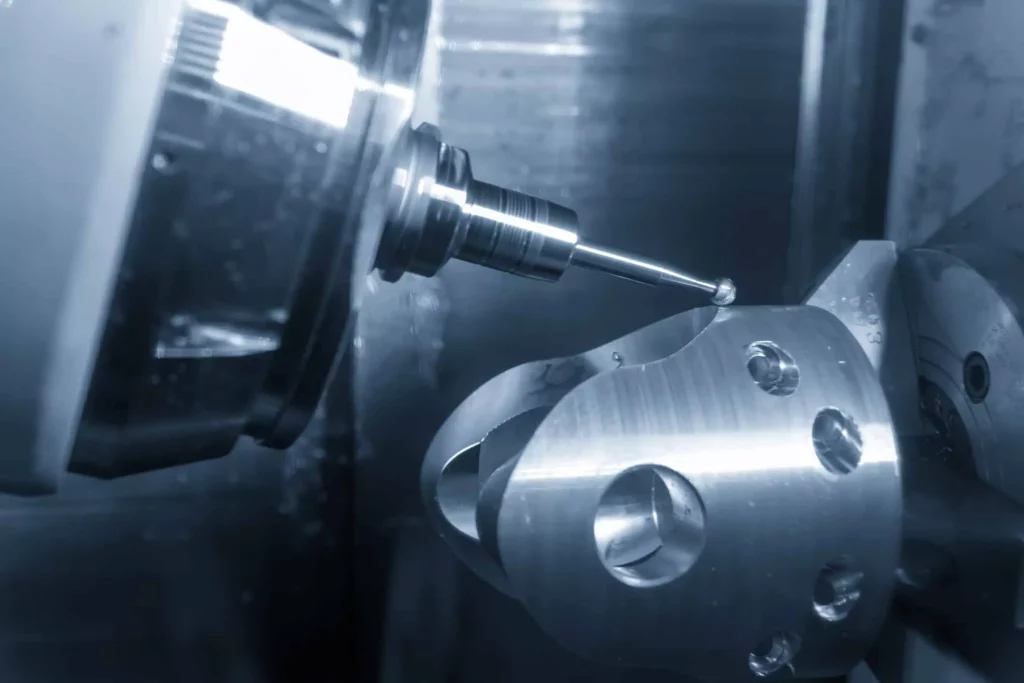

To ensure the accuracy and reliability of components, we first build detailed computer-aided design (CAD) models to simulate real-world conditions. This step helps us lay a solid foundation for the prototyping process.

Iterative Design Enhancement for Extreme Conditions

Our iterative design improvement process is tailored for the harsh conditions of oil and gas applications, ensuring accuracy and reliability even in extreme environments.

Custom Prototyping for Unique Oil and Gas Applications

Elimold excels in creating custom CNC prototype parts specifically for challenging oil and gas environments, facilitating comprehensive proof of concept in real-world scenarios.

Oil and Gas Tooling Equipment and Capabilities

Below are examples of the advanced machinery and tooling capabilities available at the Eilmold Company.

- Complete 4 and 5 Axis Milling and Jig Boring department.

- Complete Multi-Axis CNC Sinker EDM and Wire EDM including programmable “Turn While Burn” capabilities.

- Complete CNC Lathe department.

- Complete Grind and Hone department, including Jig Grind, Manual and CNC I.D. / O.D. Grinding, Surface Grinding, Centerless Grinding, and Honing.

- Optical Flat Diamond, Double Face, Single Face, Roll Lapping and, Extrude Honing.

- DP Technology “ESPRIT” CAD-CAM programming Systems supported by (6) Workstations.

- All systems capable of receiving and processing customer-supplied computer files from customers via our 265-bit AES Encrypted File Transfer Network.

- Complete inspection department with Automated Coordinate Measuring Machines.

- Highly secure, organized and state-of-the-art workspaces.

Our Diverse Oil & Gas CNC Machining Services

Our precision machining services can help companies in the oil and gas industry improve the efficiency and reliability of their operations. By using advanced computer-controlled machinery to produce high-precision parts and components, we can help our customers produce more complex, specialized equipment that is better able to withstand the harsh conditions of the environments they are designed for. In addition to improving efficiency and reliability, our precision machining services can help our oil and gas industry customers reduce their environmental impact. By producing more accurate and efficient parts and components, we can help our customers reduce waste and increase operational efficiency, which can help reduce their overall environmental impact.

Turnkey Supplier of CNC Parts Manufacturing for Oil & Gas

At Elimold, we pride ourselves on being a turnkey parts supplier. Our customers rely on Elimold’s agile capabilities to meet their contract manufacturing needs in the Oil & Gas industry. Global Oil & Gas companies can count on our talented team to provide precision, expertise, technology, and the highest level of customer service. Our in-house engineering analysis, precision inspections, and quality control services ensure the reliability of our products. We only produce the highest quality products, with services that exceed our customers’ expectations and competitive pricing. Quality control and precision inspections performed by our in-house engineering analysis team ensure that your parts meet the precise tolerances required for your project.

At Elimold, we are committed to providing a great environment for our employees who are passionate and committed to providing the highest level of quality and customer service. Together, we form a team you can trust. Our years of experience coupled with cutting-edge equipment deliver the highest quality products. We will work hand in hand with you to ensure a fast and efficient turnaround.

Our Technical Advantages in Oil and Gas Component Manufacturing

Choosing us for component manufacturing means entrusting your critical projects to a team of technical experts who have an unparalleled understanding of the industry’s unique challenges and requirements.

Responsive Manufacturing

Faced with the fast-moving nature of the oil and gas industry, we provide responsive and flexible manufacturing solutions, including low-volume production and fast turnaround capabilities to meet the industry’s changing needs, enabling timely deployment and reducing downtime for critical operations.

Reverse Engineering

Sometimes customers already have the parts they need, but don’t have the design necessary to make more. Our skilled technicians and engineers can reverse engineer existing parts and provide customers with accurate, production-ready designs. Where relevant, we can also suggest improvements to the original part.

Dynamic Testing and Simulation

Our technical experts excel in dynamic testing and simulation, using finite element analysis and structural assessment to verify the robustness and durability of oil and gas components. This allows us to identify potential weaknesses and optimize designs to ensure optimal performance in the challenging conditions of the oil and gas industry.

Environmental Compliance and Regulatory Knowledge

Elimold’s technical team has a deep understanding of environmental regulations and compliance standards in the oil and gas industry. We ensure that our components meet the required environmental and safety specifications, ensuring your project adheres to industry regulations while minimizing environmental impact.

Design for Manufacturing (DFM) Consulting

The entire process from concept to component is critical. Our engineering team works closely with customers during the design phase to provide Design for Manufacturing (DFM) consulting. This proactive approach optimizes component manufacturability, reduces production costs, and ensures timely project completion.

Extensive Part Configuration Capabilities

We are able to machine parts as small as you can hold in the palm of your hand to as large as 77,000 pounds. With in-house 5-axis machining, we can manufacture parts of complex dimensions from a variety of materials while maintaining the tightest tolerances in the industry.

Ready to get started on your next Oil & Gas CNC Machining project?

Speak with an Oil & Gas Industry CNC Machining expert today! Our team is standing by and ready to answer questions or provide a quote for your project.

Solutions for Complex Component Challenges in the Oil Industry

The Oil & Gas industry requires durable components and often encounters unexpected situations that require unique solutions. With years of experience in custom Oil & Gas CNC parts, Elimold is able to produce parts that meet stringent precision and accuracy requirements. We consistently produce reliable parts for the most challenging jobs. And most customers only need to receive service once to become lifelong partners. Our team of skilled CNC machinists works closely with you to custom design the finished product to exceed your expectations and improve your application every time. Manufacturing the perfect component and how it fits into the larger project at hand is our daily work.

Quality Assurance & Compliance

Our CNC Oil & Gas machine shop is equipped with the latest advanced machining and inspection equipment and is staffed by the most innovative and dedicated personnel in the industry. We are trusted by the world’s leading Oil & Gas equipment manufacturers. We are able to precisely machine large, complex and sophisticated components and assembly assemblies to the tightest tolerances. Our strength is our extensive machining experience in machining a wide range of metals and engineered plastics, from common to exotic materials. All of our in-house CNC machining facilities are climate controlled to ensure material stability during machining. We continually strive to achieve excellence in all of our manufacturing processes utilizing the best quality standards, ongoing employee training, and well-maintained production equipment. Our dedication to quality is absolute and uncompromising as we focus on providing you with 100% customer satisfaction.

The Importance of Precision Machining in the Oil & Gas Industry

The oil and gas industry always needs highly rugged precision components that can withstand harsh working and external conditions. Elimold is well aware of this and always pursues the demanding durability, tolerances and reliability required in this field. With rich experience working closely with the world’s top oil and gas companies, we have earned a good reputation for high levels of accuracy, precision and efficiency and are deeply trusted by our customers. We are happy to face and meet all challenges and are committed to manufacturing high-quality parts that can be used for the most challenging tasks.

With the rapid development of technology and the growing needs of the oil and energy industry, we continue to forge ahead to meet the needs of our customers and help them improve their business through our agile supply chain and state-of-the-art CNC machining services. With our excellent CNC machining equipment, our skilled engineers and machinists are ready to work closely with you to produce machined parts and components for offshore drilling platforms, pipelines and drilling equipment. Products manufactured by Elimold are widely used in the oil and gas field, such as refinery distribution networks and finished oil delivery systems. Our mission is always to innovate and develop new technologies to advance the industry and benefit customers to the greatest extent.

Materials We Machining

The oil and gas industry often deals with challenging high-temperature, corrosion-resistant metal and plastic materials. Our expertise in machining these materials enables us to process the most complex oil and gas components with precision and efficiency, ensuring optimal performance and service life in demanding environments.

Metals

- Aluminum

- Brass

- Bronze

- Chromium

- Copper

- Gammalloy

- Hastelloy

- Incoloy

- Inconel

- Invar

- Manganese

- Monel

- Nickel

- Nitralloy

- Stainless steel

- Stellite

- Titanium

- Waspaloy

Plastics

- ABS

- PVC

- Nylon

- Delrin

- PTFE

- UHMW

- Ultem

- Acrylic

- PEEK

- Teflon

- LDPE

- PCTFE

- PlexG

- Teflon

- Polyphosphazene

- Polypropylene

- polycarbonate

- polythenlene

Surface Finishes

- As Machined

- Anodizing

- Polishing

- Sand Blasting

- Tumbling

- Electropolish

- Alodine

- Heat Treatment

- Brushed Finish

- Powder Coating

- Electroplating

- Black Oxidize

Value-added Services

Our ISO-certified machining expertise and in-house capabilities range from exotic to conventional materials, from complex to standard products. We embrace a total quality culture and strive to meet our customers’ requirements for quality acceptance and on-time delivery. We are also able to perform secondary operations such as annealing, power machining, polishing, steam polishing, powder anodizing, plastic bonding, assembly, final inspection, etc. Other value-added capabilities include supply chain management with JIT, Kanban and Dock to Stock programs. We also handle MRO packaging and assembly.

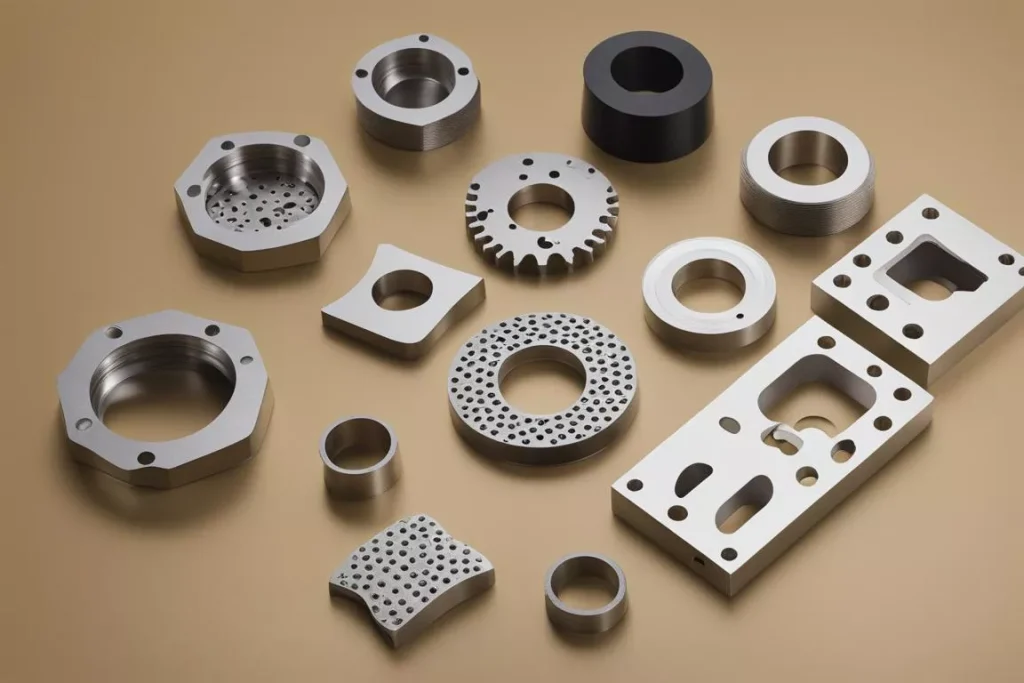

CNC Machined Parts and Assemblies for the Oil & Gas Industry

We have a team of dedicated machinists who design and manufacture components for the Oil & Gas industry. Through turnkey project management, we can move your design from prototype to production quickly and efficiently. With the latest equipment in our CNC machine shop, our technicians can handle the most challenging jobs and meet the specifications required by our customers. Typical products produced include:

- Casing Hangers

- Tubing Hangers

- Frac Valves

- Fluid Ends

- Tubing Heads

- Casing Heads

- Manifolds

- Bushings

- Surface Wellhead Equipment

- Subsea Wellhead Equipment

- Drilling Components

- Blowout Preventers, or BOPs

- Internal Components

- Riser System Parts

- Flanges

- Stab Blocks

- H4 Connectors

- Locking Dogs

- Dual Completion Block Valves

- High-Pressure Umbilical Components

- Composite Block Valves

- Tees

- Crosses

- Ball Valves

Request Your Free Oil & Gas CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Oil & Gas CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.