Metal Stamping Services

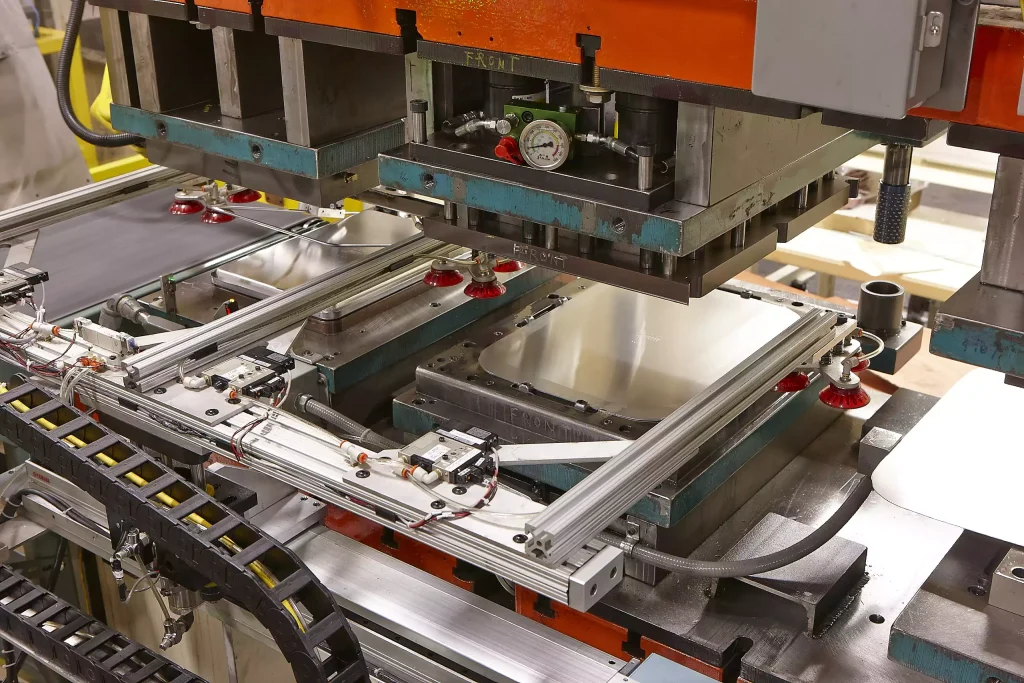

Elimold is an ISO 9001:2015-, 13485:2016-, 14001:2015-certified manufacturer of precision stamped metal components and assemblies. With engineering support, tooling design, and advanced equipment in-house, our team can overcome just about any metal stamping obstacle.

We take pride in producing stamped metal components with complex geometries. Our lines can produce precision stamped metal parts from materials as thin as .003” (or less) and maintain tolerances as tight as ± .0005”.

Custom Metal Stamping Services

Elimold is a leader in producing stamped metal parts for OEMs (original equipment manufacturers). Specializing in short to medium run precision metal stampings, we build our tooling in-house for maximum quality and reliability.Short-run metal stamping service is a cost-effective manufacturing process that fits the needs of customers with short lead times, repetitive low to medium volumes, and for customers who may require part modifications. We are committed to investing in the latest technology, to enable our experienced engineers and technicians to shorten lead times and get your part into production for quick turnaround and delivery.

Elimold provides short-run metal stamping supplies of almost any shape or size. Our pressroom equipment includes both traditional and non-traditional capabilities. In addition to our traditional metal stamping capabilities, our team will combine conventional punching methods with laser cutting, to get the best possible fabrication results at the lowest possible price.

As a leading provider of metal stamping services, Elimold manufactures complex, high-quality stampings and components for customers both domestically and internationally. Our dedication to quality paired with our extensive fabrication capabilities have earned us repeat customers across the medical component, manufacturing, renewable energy, automotive, and home improvement fields.

What can we do for you?

Elimold provides metal stamping services to a variety of industries. We run stampings up to .250” thick, but our specialty is high-volume, tight tolerance, precision stampings in a variety of materials from .003”-.060” thick. Our presses have full feed lines and are die sensor protection ready. We run nearly 60 million metal stampings per year at a 98% on time delivery rate.

Take your production needs to the next level without sacrificing quality. With CNC Machining, Fabrication, CNC Grinding, Wire EDM and support operations, WMPI can be a single source for your assembly and sub-assembly projects.

Elimold is ISO 9001:2015 certified. To learn more about our metal stamping services Contact us today.

Metal Stamping at Elimold

We pride ourselves on producing quality parts at affordable prices. We go above and beyond simple metal stamping to offer a range of services including engineering, design, welding, tapping, drilling, laser cutting and etching, and welding to take our client’s designs through the entire fabrication process from sketch to final design.

To learn more about our metal stamping, or any of our other services, contact us or request a quote today.

Elimold’s Precision Metal Stamping Capabilities

| General Capabilities |

|

| Production Method |

|

| Equipment Capability | CNC Manual |

| Maximum Press Bed Length | 36” |

| Part Thickness | Up to 1/4” |

| Press Rating/Tonnage | 18 Ton to 215 tons |

| Maximum Press Stroke | 8” |

| Maximum Press Bed Width | 36” |

| Tolerance (+/-) | ±.003 in To Customer Specification |

| Testing | Hardness Testing Material Testing |

| Additional Services Provided |

|

| Production Volume |

|

|

|

Additional Information

| Industry Focus |

|

| Stamping Product |

|

| Industry Standards |

|

| File Formats |

|

Are you ready to Tool Up, and Reduce Cost?

At Elimold. we can guide you through the process of creating one hundred pieces per year, to one million. Elimoldhas the ability to produce parts without any of these tooling options for lower quantities, and when you’re ready we are here to help you decide which option best fits cost reduction requirements, and total investment.

Stage/Form Tooling

Form/Stage Tooling is utilized to decrease the production time for bending metal. This is perhaps the cheapest form of metal stamping in which we utilize a Punch Press instead of a Press Brake to bend tabs, flanges, or Offsets. This tooling is a great option for customers looking to achieve part cost reductions without large tooling cost. This is achieved by blanking a part by laser or turret cutting and then forming with hard tooling. Estimated cost for this tooling can be as little as $250-500 and it can have substantial savings for customers looking to reduce part cost with limited tooling expenditures.

Compound Tooling

If blanking your part out by utilizing Laser and or Turret Cutting is too expensive the next step up would be a Compound Tool. With a compound tool we will Stamp the entire flat layout of your part with every rotation of our punch press. This is the fastest way to produce a flat layout, and it can be combined with Form Tooling as a secondary option if Progressive Tooling options don’t make financial sense. This tooling can vary in cost depending on thickness and size, but could be as little as $500 to $5,000 depending on complexity.

Progressive Tooling

Progressive Tooling combines forming and blanking into one process. Generally a Coil or Sheet Stock will be loaded into one side of the punch press. When the part comes out it is complete including forms, coining, offsets, and other features as required. This option is best for higher volumes. This production tooling will yield the cheapest part cost mostly due to reduced handling and labor, and higher efficiencies. Tooling can vary in cost depending on the complexity and features of the part. A general range for a simple part could be as low as $2,500, whereas an extremely complex part could vary from $25,000 to $100,000 or more.

You can trust our proven process

Request A Quote

- Receive our quote for tooling, piece price and lead time within 48 hours.

- Save money as we provide low cost quality tooling.

- Receive free storage and maintenance of all tooling.

Place Purchase Order

- Place Purchase Order

- Tooling built and sample parts manufactured to your specifications.

- Customer service notifies you with a date for your no cost samples.

- Sample delivered on time or your tooling is free.

- Approve the samples.

Production parts delivered

- Pack parts per your specifications.

- Ability to ship to one or more locations.

- Receive in tolerance, correctly dimensioned parts on time.

Customer success

- Enhancing customer loyalty and satisfaction with each order.

- Provide effortless execution.

- Receive proactive, polite, and thoughtful customer service.

- Form strong relationships through collaboration.

- Furnish best in class stocking programs.

Materials

| Low Carbon Steel | (All Grades and Tempers) |

| High Carbon Spring Steel | (All Grades) |

| Hardened & Tempered Spring Steel | |

| HSLA Steel | (All Grades) |

| Alloy Steel | (All Grades) |

| Coated Steel | (Galvanized, Galvalume, Galvannealed, Aluminized) |

| Stainless Steel | (300 & 400 Series, Alloys) (Variety of Finishes and Tempers) |

| Aluminum | (Common Alloys: 1100, 3003, 5005, 5052, 5182, 5754) (Heat Treat Alloys: 6061-0, 6061-t6) (All Tempers) |

| Copper | (Standard and Specialty Alloys) |

| Brass | (Standard and Specialty Alloys) |

| Phosphor Bronze Alloys Inconel Monel Nickel, Zinc, and Special Alloys | |

| Nylon | |

| Teflon |

Benefits of Precision Metal Stamping

- Cost Efficiency: Metal stamping produces precision metal parts quickly, making it perfect for high volume production. As the production levels increase, labor costs decrease, making it cost-effective.

- Less Scrap Material: In addition to its efficiency, precision metal stamping also produces less scrap material than other metal forming processes, making it more cost-effective.

- High Quality and Accuracy: As the name suggests, precision metal stamping produces highly detailed, complex products at the precise tolerances that your application requires. Despite multiple pieces being cut together, each product is of high quality and accurate every time.

- Highly Automated Process: Metal stamping can be easily automated and can incorporate value-added secondary services into the die or press. These services can include in-die tapping, in-die welding, or automatic nut insertion, which increases the overall value of the part.

Learn More From Our Metal Stamping Experts

At Elimold, our capabilities cover large projects to small projects and simple components to complex components. With our years of experience and commitment to excellence, we possess advanced metal stamping capabilities to meet your needs.

We understand that choosing a manufacturer is a big decision, and it’s important for you to find the right metal stamping company for your project. If you have any questions about precision metal stamping, your specific project, or what it’s like to work with us, please contact us.