Energy CNC Machining

We are a high-precision energy CNC machining total solution manufacturer, providing a full range of services to help customers stay ahead and expand market share in the demanding energy industry. Get an instant quote now to order your custom CNC machined energy parts at a better price.

Full-Service CNC Parts Manufacturer for Energy Equipment

Elimold is a one-stop machine shop that offers everything from custom machine fabrication and reverse engineering to 5-axis machining and milling. Our 72,000 square foot facility is AS9100 and ISO 9001 certified to handle the most challenging and complex projects in the energy industry. We pride ourselves on providing exceptional customer service, with highly qualified engineers and mechanical experts who can provide services ranging from design consultation to system integration.

We have extensive experience working with a wide range of metals and alloys, and our facility is capable of providing assembly, finishing, inspection, and expedited delivery services for any project, large or small. Elimold is a trusted partner to the energy and nuclear industries. Our commitment to precision, safety, and quality has made us a leader in machining for the energy industry. From concept to completion, we will work closely with you to ensure that each project is delivered with the highest accuracy and reliability. Since its founding, Elimold has been a reliable and efficient supplier of top-quality machined parts and components for nuclear equipment and all other sectors of the energy industry.

High-quality custom energy CNC machining and manufacturing services

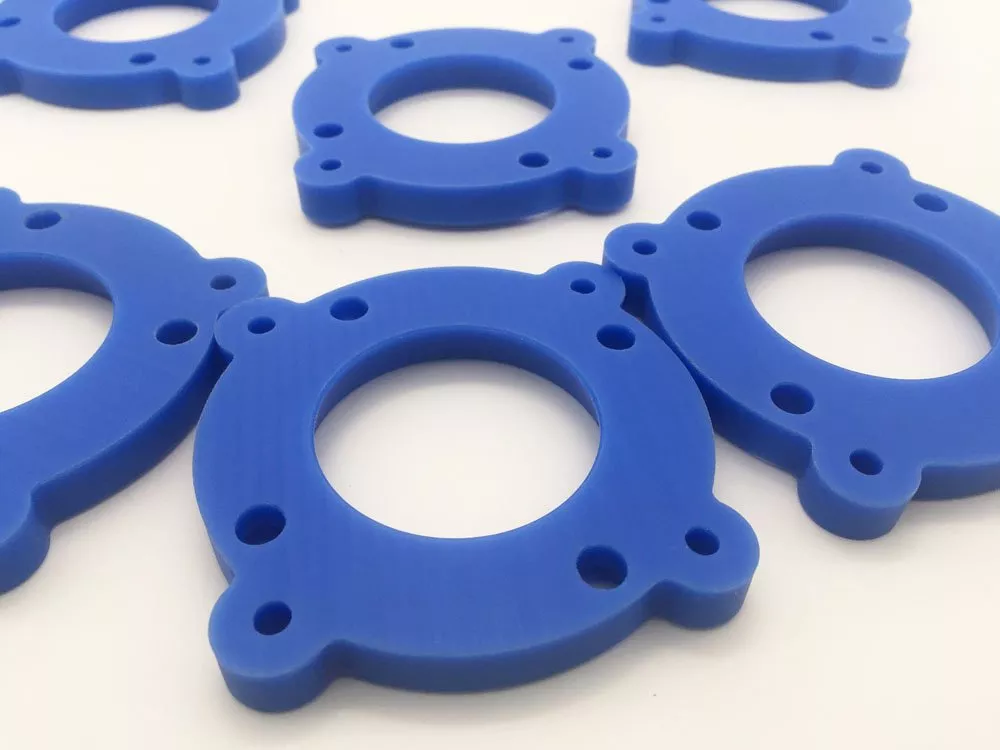

At Elimold, we provide CNC machining services to the energy industry for rapid prototyping, low-volume and large-scale production. Manufacturing in the energy industry is subject to tight tolerance controls and there is a strong need to adhere to certain specifications. From solar to wind and hydro, large components must be durable and able to withstand harsh environments. With our CNC machining services, Elimold can manufacture large parts with dimensional accuracy typically only seen in small parts. We also offer 3D printing services, a process ideal for rapid machining, custom spare parts production and complex part creation. Our total manufacturing solutions are designed to improve overall product quality, cost-effectiveness and faster time-to-market for all our customers. From commercial power to solar, fossil fuels, oil and gas, our engineers will help you deliver innovative solutions to your business’s most critical challenges.

Custom CNC Parts for the Energy Industry

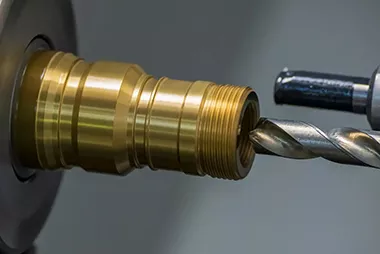

In the energy industry, machined components must perform reliably in harsh operating environments that are often subject to attack from corrosive or abrasive materials. Drilling equipment, hydraulic fracturing equipment, refineries, and now wind turbines and solar panels rely on components precision-engineered and manufactured using best-in-class CNC machine tools from Elimold.

Our CNC machining solutions deliver unmatched precision and accuracy through custom integration and automation. We develop complete turnkey solutions to reliably and accurately machine your components, no matter which sector of the energy or renewable energy industry your shop machines parts for. Whether it’s a replacement part for an oil refinery or high-volume production of precision rails and frames for solar panels, our experts can design machining applications, validate quality and improve your operational efficiency with automated infeed and outfeed systems.

We look forward to working with you on your next energy project

Elimold offers specialized CNC precision machining services to meet the needs of the energy industry. We have a team of highly skilled machinists who understand the challenges facing energy companies and have the ability to produce components with tight tolerances, ensuring consistent quality. Our services cover energy industry machining for a wide range of applications from power generation to renewable energy projects.

Precision is key in this industry and our machining capabilities are ideally suited to manufacturing high-precision, complex parts. Whether it’s a small custom component or a large assembly, we can ensure that each part meets the stringent quality standards required by the energy industry.

Our Energy CNC Machining Capabilities

We are always ready to meet the challenges of tight tolerances and complex CNC machined energy parts. Try our precision energy CNC machining services and become our next satisfied customer.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

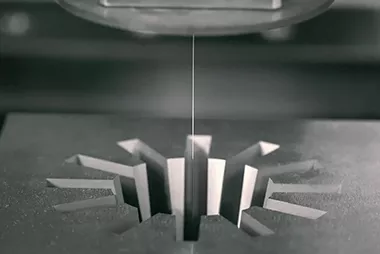

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Types of CNC Machine Centers We Offer

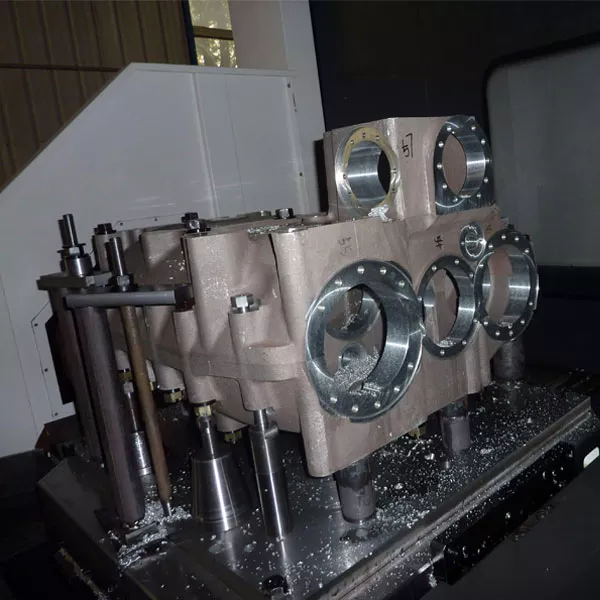

Elimold specializes in CNC machines for the energy industry. Our CNC equipment excels at producing specialized components common in this field, including heavy components that must withstand harsh environments.

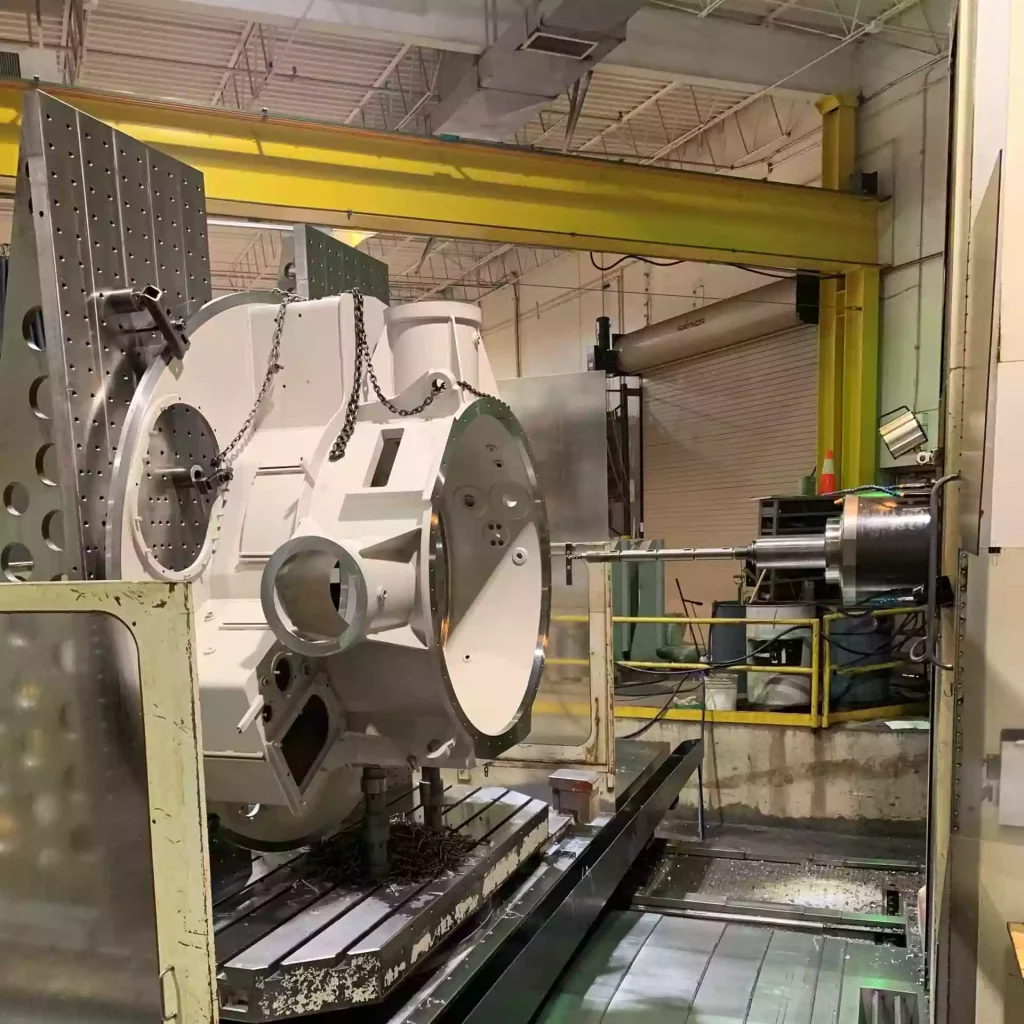

Horizontal CNC Machining Centers

Our horizontal machining centers feature a dual-spindle design that can perform milling and turning operations without multiple setups. Whether machining valves, frac blocks, or mud pumps, these machines have spacious work tables suitable for machining objects of various sizes.

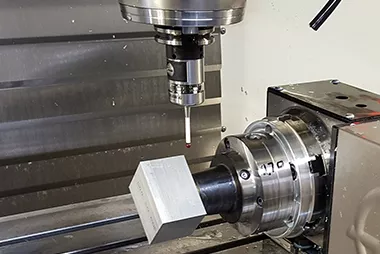

Vertical CNC Machining Centers

Our multi-tasking vertical machining centers can handle drilling, tapping, transferring, and punching. Its ability to perform multiple operations helps manufacturers increase productivity without adversely affecting accuracy.

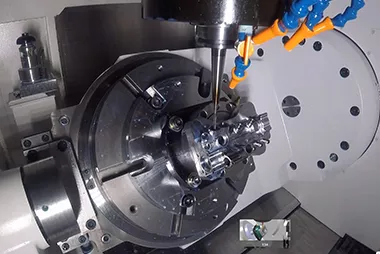

Modulo Equipe

Our Modulo Equipe units are multi-turret flexible machines that help manufacturers produce parts faster and more efficiently. We can custom each spindle to perform multiple operations simultaneously or in steps.

Advantages of CNC machining for energy parts production

CNC Machining offers many benefits when it comes to the production of parts for the renewable energy sector.

- CNC machining is capable of producing complex parts.

- Parts can be produced with high quality finishes and precision.

- CNC machined parts are consistent.

- CNC machine processes allow for the flexibility to handle high volume production or short run custom jobs.

- Its possible to produce larger parts.

- CNC machining can be used to perform fast repairs or modifications to existing parts in a timely, economical manner, helping to keep costs and downtime to a minimum.

Mastering Material Selection for Energy Sector Machining

Our team of highly skilled engineers and machinists excels in manufacturing parts that withstand the rigors of energy operations, from the intense pressures of underground drilling to the precision required for wind turbine components. Every component is built for reliability, and at Elimold, we prioritize the longevity and functionality of the parts we produce. By using materials that are strong and resistant to harsh environmental conditions, we ensure that every component contributes to the sustainable and reliable operation of your energy system. Our CNC machining services extend to manufacturing components that play a critical role in optimizing energy production, whether through traditional methods or cutting-edge renewable technologies. For those in the energy industry seeking a trusted partner for custom machining services, Elimold offers the expertise, technology, and dedication needed to move your projects forward.

Material Options

Metals

- Aluminum

- Brass

- Copper

- Steel

- Stainless Steel

- Bronze

- Titanium

- Magnesium

- Zinc

- Inconel

- Invar

Plastics

- ABS

- PC

- PCGF30

- PC+ABS

- PPGF30

- PMMA

- PoM/DelrinPA(Nylon)

- PAGF30

- PP

- PTFE (Teflon)PEI

- PS

- PPS

- PE

- PET

- LDPE

- HDPE

- PPSU

- PEEK

- G-10FR4

- PVC

Surface Finishing Options

Our finishing services further enhance our range of production technologies. Our finishing is decorative, aesthetic and in some cases functional.

- Texturing

- Anodizing

- Polishing

- Blasting

- Painting

- Electroplating

- Passivation

- Heat treatment

- Powder coating

- Custom

Tailor-made CNC Machining Solutions for Energy

We provide components specifically designed to meet the unique requirements of this industry. From valves and fittings to bearing housings, diffuser assemblies and specialized equipment. Our parts support efficient production, ensuring reliability and safety in this important aspect of energy production.

Similarly, our involvement in the gathering of natural gas both onshore and offshore reflects our commitment to supporting diverse energy production methods. We provide a variety of components for production wells, pipelines and offshore drilling platforms that are carefully designed to withstand the challenging conditions encountered in natural gas gathering operations.

We provide high-quality parts that support all aspects of this industry. Our commitment to precision and reliability ensures that our parts meet the stringent requirements of the energy production process, contributing to efficient and sustainable energy production. Therefore, our capabilities are not limited to the above-mentioned energy production areas. We are happy to take on new challenges and opportunities in the energy field and welcome inquiries for custom solutions to meet specific needs.

Nuclear Industry Machining Solutions

At Elimold, our nuclear power plant fabrication services are second to none. We offer a wide range of components to meet stringent international standards. We can produce fine and specialized components using state-of-the-art equipment and specialty materials designed specifically for nuclear power equipment.

Our extensive experience in the energy industry gives us insight into how to manufacture the safest, most reliable precision components for nuclear power plants. We understand the special demands of heavy fabrication component production and the need for just-in-time production of industry-specific custom machined components.

Our Quality Management System (QMS) is certified to AS9100 and ISO 9001 standards, and we have implemented additional requirements in compliance with ASME NQA-1 to ensure your nuclear components meet or exceed industry standards. We also conduct in-depth and comprehensive inspections of every part or component produced and assembled at our facility to ensure the highest quality products and industry compliance.

Top Energy Manufacturing Applications

- Power stations and Transformer Components

- Engineering test pieces

- Quick repair tools

- Hydroelectric power components

- Turbines – wind and water

- Blades, rotor parts, and fans

- Gears and shafts (Ram shafts, locking shafts, and bonnets)

- FRAC valve bodies

- Flowline components

- Downhole tools

- Obsolete parts, spare parts, and custom tooling

- Impellers, pipeliners, and pipe centralizers

- Enclosures and sealing accessories for explosives and perforating

- Nozzles and flow meter parts

- Pump manifolds

- Jigs and fixtures

- Turbomachinery

- Sand control screens

- Hangers

- Drill rig components

- Heavy-duty stainless, titanium, and aluminum parts

- Stators

- Pilot testing parts

- Flowmeter parts

Request a Free Energy CNC Machining Quote Now

Once we receive your drawings, our engineers will immediately analyze your custom CNC machined parts. We proactively work with you to clarify all details, then provide a quote that is both economical and accurate.