Consumer Products Injection Molding

Elimold engineers, produces and ships plastic injection molding consumer goods. Our engineering capabilities include mold designing, prototyping, product designing assistance and machine designing.All the plastic injection molding produced at Elimold conforms to ISO 9001:2015 requirements. This together with our work ethic ensures that our products are of the highest quality. Furthermore, we provide manual and automatic manufacturing as well as ultrasonic welding and custom packaging. This wide range of services allows our customers to find the solution that best suits their needs.

Manufacturer of Consumer Injection Molded Products

Elimold focuses on where we can compete in the growing demand for globally manufactured consumer products by continually reinventing ourselves to meet the needs of the current consumer market. Our engineering services include DFM, mold design, and mold fabrication. Our range of injection molding machine tonnage allows us to take on entire product projects with multiple part sizes. With many value-added features, the entire product can be inserted, machined, welded, assembled, painted, labeled, and packaged here. By centralizing more processes in one location, we can help our customers save on shipping costs and lead times.

The components we produce are on the critical path for pre-production testing, limited market release, and in many cases, final production. Because of the importance of this role, we work closely with our customers’ design and procurement teams on each project to ensure we deliver high-quality components on a schedule they can rely on. We also follow a streamlined production process to ensure the right people are in place from design to part.

Meeting Modern Demands with Seamless Workflows

Elimold’s production processes utilize a lean and agile operating philosophy, allowing our customers to source consumer plastic parts at the highest quality without costly delays. We maintain strong in-house manufacturing capabilities and supply chain partnerships to maintain additional capacity, providing support when necessary to support and expand our in-house production capabilities. This flexible approach allows our operations to scale easily to meet any level of customer demand. By manufacturing even complex molded products to consistently maintain high quality standards, we provide you with confidence and enable you to pass on the best results to the end user.

Comprehensive Consumer Product Injection Molding Services

Elimold provides one-stop injection molding services for consumer goods manufacturing, covering design, prototyping, production, surface treatment, testing and assembly. We specialize in high-quality, precision plastic parts for consumer products and more.

Plastic Consumer Parts Design

Prototyping and Testing

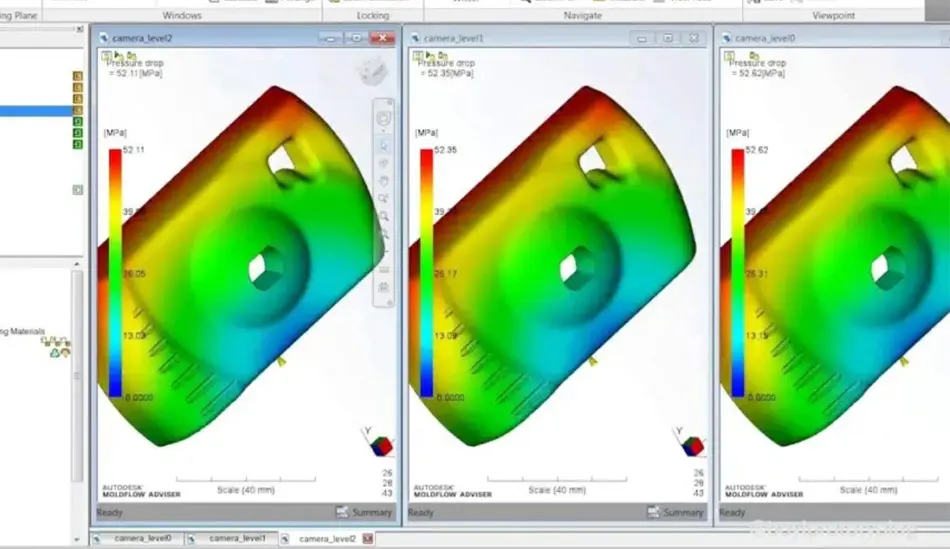

3D Mold Flow Analysis

Advanced Machining Capabilities

Mold Manufacturing & Assembly

Material Selection Assistance

Your Trusted Plastic Injection Molding Partner for Consumer Good

Elimold utilizes innovative processes and technologies, including overmolding, insert molding, and cleanroom capabilities, to deliver high-quality plastic injection molded products in small to medium batches. We offer product development, assembly services, and everything in between. We are truly a one-stop shop, serving you from project conception to inspection.

In-house mold design and manufacturing gives us full control over the quality, reliability, and performance of molds and tools. It also saves you valuable time and money on your projects. Plus, we use a wide variety of high-quality standard, custom, and engineered plastic materials. If you’re unsure which plastic is best for your injection molded consumer product, our experts will work with you to determine which material will best suit your performance and application requirements.

Diverse Consumer Goods Molding and Manufacturing Capabilities

Elimold has been a top injection molder in the consumer plastics market, providing manufacturing services for cosmetics, household goods, commercial goods, and more. Our purpose-built production facilities for the consumer goods industry feature more than 30 horizontal and vertical injection molding machines, ranging from 55-ton machines to 3,000-ton machines, optimized to meet your scalable molding and manufacturing needs with flexible, personalized services.

And, our in-house moldmaking and tool shop support customers from developing prototypes to scaled production, while extensive experience with a range of molded polymers and resins ensures optimal product quality and minimizes the risk of material defects.

Elimold’s core capabilities are complemented by a range of ancillary services, including press services, complex assembly, packaging, and more. We utilize a real-time ERP system and proprietary NPL (New Product Launch) process to ensure the highest levels of quality and predictability for your injection molded components and parts.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Quality Assurance and Quality Policy

At Elimold, we prioritize quality assurance to ensure that every product we produce not only meets our customers’ standards, but also complies with relevant regulations. Our quality assurance department uses a range of techniques and tools to carry out inspections, including:

- Vision systems and coordinate measuring machines (CMM)

- Optical comparators with 16-inch screens

- Calibration surface plates

- Gram scales, microscopes, gauge blocks, measuring pins and digital calipers

- Complete first article inspection (FAI) reports

- Advanced quality planning

Design for Manufacturability (DFM) Analysis

Elimold’s technical expertise can accelerate the design, development, and production of consumer products, helping brands go from prototype to finished product in as little as 10 days. It starts with analyzing your part design plan and providing Design for Manufacturability (DFM) feedback. DFM allows you to resolve design issues early in the process to avoid costly roadblocks and increase efficiency in the process, which is key to ensuring a fast time to market. Elimold will also help you figure out the best way to manufacture your product to meet your desired launch date.

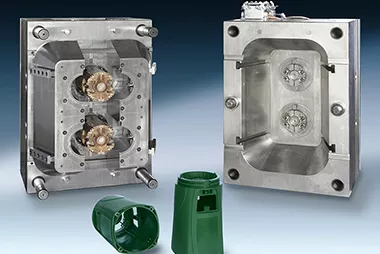

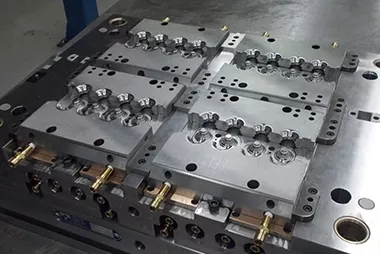

In-house Mold Manufacturing

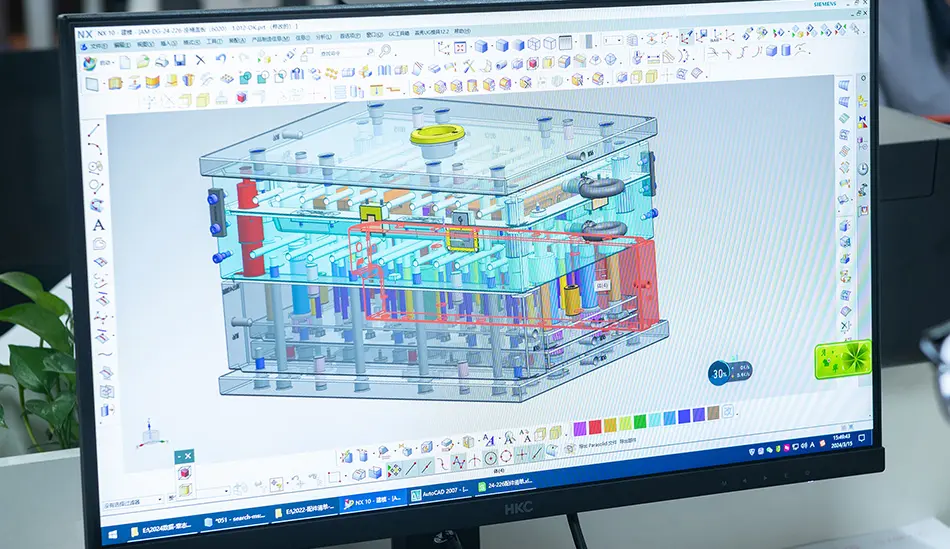

Injection Mold Design

One of our many talents is making high-quality molds for plastic consumer products. We have the skills to create unique designs and utilize our injection molding software to make precise molds that accurately maintain the shape and texture of your plastic consumer product.

Injection Mold Forming and Grinding

Our talented engineering team expertly adjusts molds to precisely achieve the intended shape. We invest a great deal of time and effort in carefully designing molds to enhance the production capabilities of your plastic consumer product.

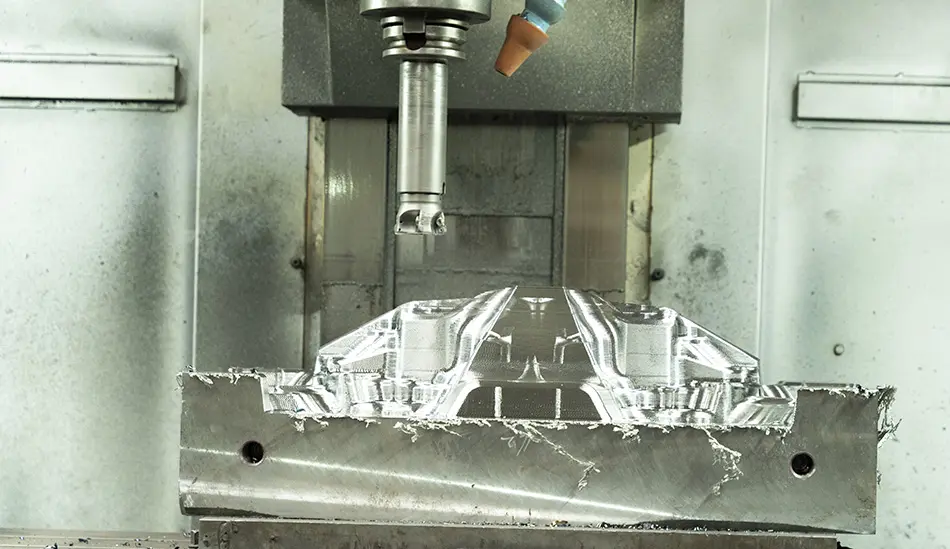

Injection Mold Manufacturing

Our CNC machining services enhance the manufacturing process of complex molds. Every detail is clearly visible, allowing us to precisely adjust the manufacturing process. In addition, it increases productivity by streamlining operations, helping to meet deadlines for large orders in a timely manner.

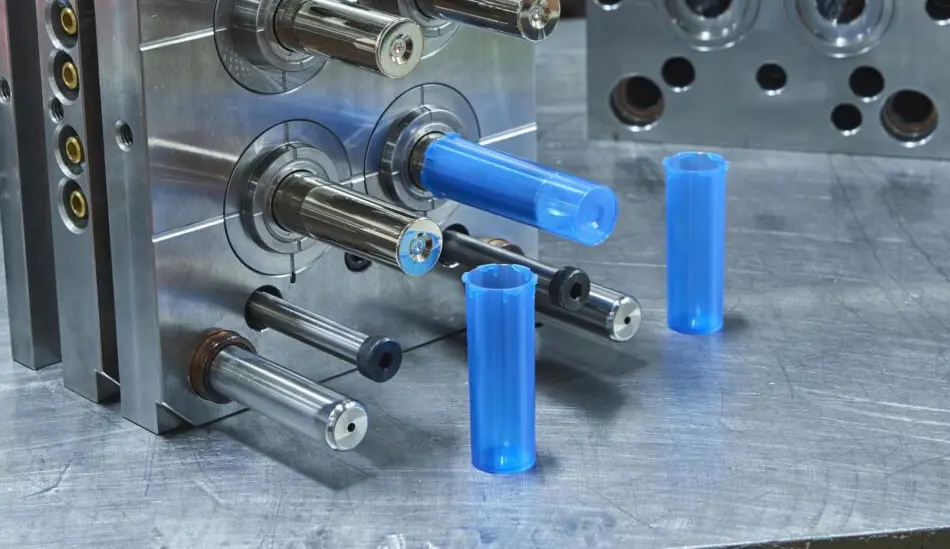

Injection Mold Assembly and Finishing

Once the mold is perfect, we assemble all the parts together, perform a thorough inspection, and verify their functionality. Making these adjustments prevents defects and promptly resolves any anomalies in the consumer product produced through injection molding.

Value-Added Services

Custom injection molding machine manufacturers bring extensive knowledge to any project. In addition to guiding decisions about the best design, tooling, and process, there are also post-molding issues that need to be considered that impact quality, cost, and time to market. OEM that work with vertically integrated suppliers gain the benefits of in-house value-added services provided by Elimold:

- Ultrasonic, spin, laser, and vibration welding

- Insert assembly

- Heat staking

- Plastic machining

- Potting/sealing

- Continuity testing

- Pad printing

- Labeling and identification

- Clean Infrared technology

- Thermal processing

- Packaging and assembly

Industry Standard Materials We Use

At Elimold, our in-house tool shop and expert technicians allow us to offer nuanced consumer plastic molding solutions. Our integrated custom injection molding services are designed meet customer driven specifications and requirements with low costs and quick turnaround times. We manufacture consumer parts and products with a range of materials, such as:

Engineering Plastics

- Polyamides (Nylon)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyesters

- Polycarbonates

- Acetals

Specialty Plastics

- Thermoplastic Elastomers

- Thermoplastic Polyurethane

- Polysulphone

- Polyarylates

- Polyamide Imide

Commodity Plastics

- Polystyrene High & Low-Density

- Polyethylene

- Polypropylene

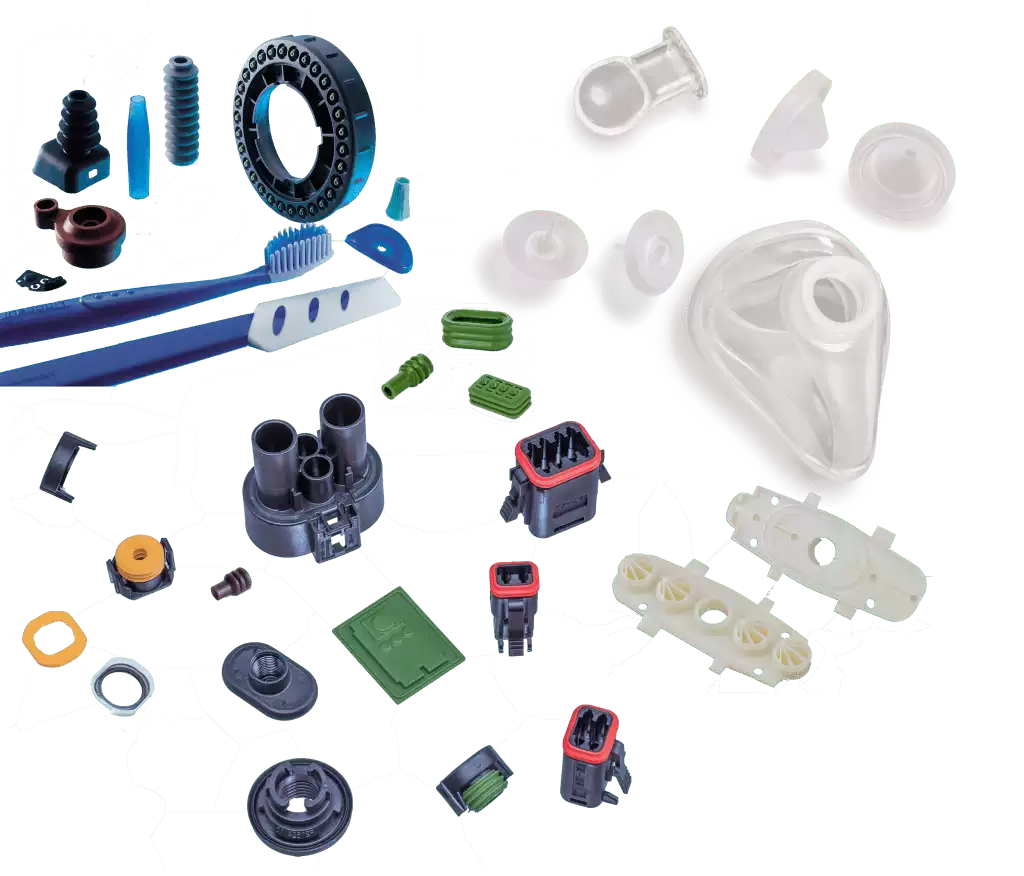

Consumer product applications

A vast range of products, components, and parts are created through injection molding. Injection molded plastic parts are used in almost every industry and in uncountable applications. However, injection molding is especially prevalent and beneficial when used to manufacture consumer products and electronic components.

- Storage Drawer Units

- Garage Door Openers

- Electric Toothbrushes

- Tool Handles and Components

- Firearm Stocks

- LED-Light Therapy Devices

- High Output Lighting Devices

- Beverage Glasses

- Letters for Signage and Crafts

- Bases for Bubble Levels

- Aquarium Filter Covers

- Accessories for Kayaks and Canoes

- Outdoor Chairs

- Retail Product Dispensers

- Floor Tiles

- Noise Machine Covers

- Medicine Cabinets

- Cooling/Insulation Sleeves for Beverage Containers

- Plumbing Parts

- In-Flight Entertainment Components

- Precision Pneumatic Chambers

- Mouth Guards and Anti-Snoring Devices

- Knobs and Components for High-End Electronics

Why You Should Partner with Elimold

The expertise and capabilities that a trusted plastic injection molding company like Elimold has are essential to supporting businesses in providing reliable, high-quality consumer components that are essential to delivering a superior product experience.

- Precision and consistency: Our plastic injection molding ensures that every detail of your consumer product is made precisely and consistently. This means your product will function as intended.

- Material quality: We produce consumer parts using top-quality materials that meet stringent quality standards. This ensures that your product is safe for everyday use, minimizing the risk of any damage or malfunction.

- Affordability: Injection molding is a cost-effective solution to manufacturing consumer products without compromising on quality. This means you get a high-quality product at a price that fits your budget.

- Customization and innovation: With our advanced molding technology, we can bring your unique product ideas to life. Whether it’s a personalized design or an innovative feature, we can make it happen.

- Quality Assurance: Elimold adheres to strict quality standards to ensure that your consumer components meet regulatory and industry standards.

- Timely delivery: We understand the importance of getting products to market quickly. Therefore, we prioritize timely delivery to ensure that you can meet consumer needs in a timely manner.

Our After-Sales Service

At Elimold, we believe that customer satisfaction doesn’t end with the completion of a project. We offer a comprehensive after-sales service to ensure that our customers get the support they need even after the product has been delivered.

Our experienced team of professionals is dedicated to providing timely assistance and resolving any issues that may arise. Whether it’s resolving technical issues, providing maintenance services, or replacing defective parts, we go to great lengths to ensure that our customers are completely satisfied with our work. We are committed to building long-term relationships with our customers, and our after-sales service is just one of the ways we demonstrate that commitment.

A Reliable Partner for Consumer Goods Manufacturing

The versatility of plastic materials makes them ideal for a wide variety of consumer-facing applications. However, the modern plastics market can be a challenging and complex one, even for experienced brands. Whether the part or product you want to create is simple in design or highly complex, there are many factors to consider before embarking on a project.

When looking for an injection molding and mold manufacturer that can deliver the products they need, businesses must balance a number of competing factors. First and foremost, businesses need reliability; they need a partner that can successfully complete each plastic project. Elimold is a viable and reliable option in a competitive market that often requires a sourcing process that operates on a global scale. Offering a wide range of capabilities, from pre-consumer production to manufacturing finished products and shipping the parts you need, Elimold has a wealth of hands-on skills and experience. This experience and our advanced technology give us the ability to deliver projects large and small to our customers on time and within budget. Elimold can meet your needs in a variety of ways and help your brand achieve new product growth with our extensive experience in plastic product molding.

Contact Elimold today to discuss your consumer product injection molding project

With design flexibility, advanced technology and superior quality, Elimold is your best partner for high-volume consumer product plastic components produced through injection molding. Contact us today to discuss your requirements.