Welding Services

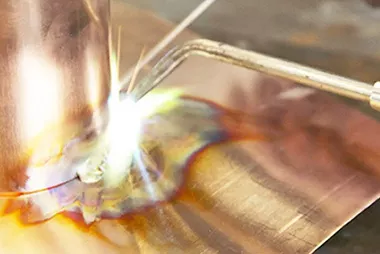

Elimold already provides comprehensive precision metal fabrication and welding services to many industries. Our team’s extensive knowledge of various metal welding properties and welding methods sets us apart from many of our competitors, helping you save time, money and hassle. Excellent welding technology and rigorous attitude are the basis for high-quality products. Trust us to meet any of your welding and finishing needs.

Professional Sheet Metal Welding Service Provider

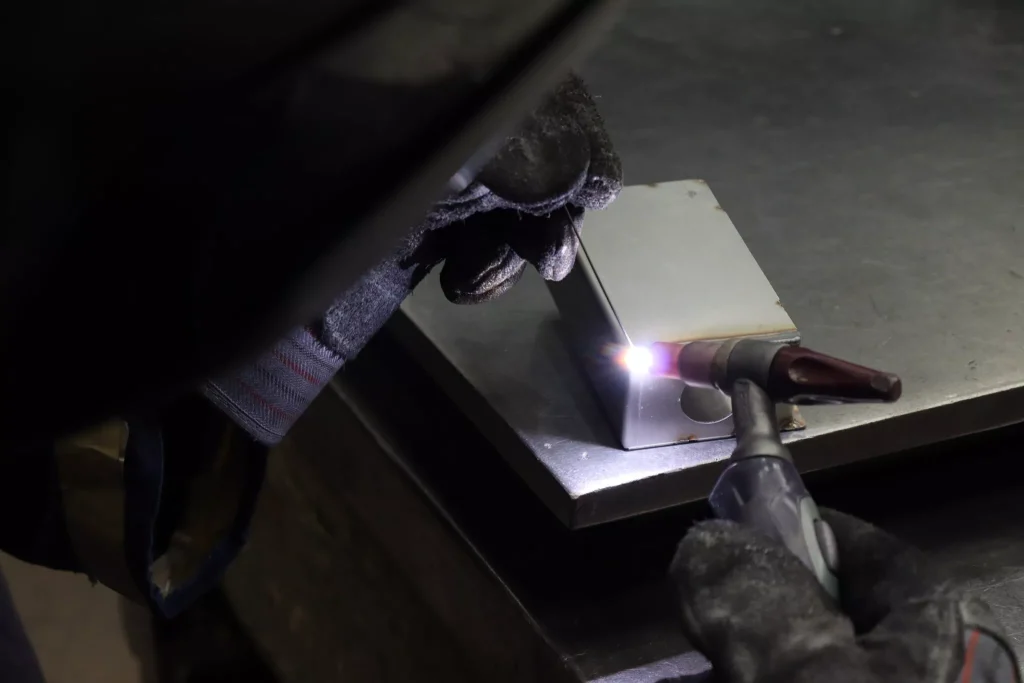

Elimold has an in-house team of experienced welding fabrication experts who provide a variety of custom fabrication solutions to meet your specific needs. We have advanced welding technology and equipment to ensure that every project we undertake can provide accurate and reliable services. With decades of industry experience, our team of skilled and certified welders have a keen eye for detail and are proficient in all welding techniques.

And, our welding team is located throughout the factory, integrating welding processes such as TIG, MIG, stud and spot welding into other manufacturing processes to reduce overall production time. They are often involved in the processing of formed or custom parts. With our passion for innovation and quality control, we ensure that every custom welded fabrication product that leaves the factory meets or exceeds industry standards. While we are able to undertake projects of all sizes, we prefer large orders because this allows us to demonstrate our superb welding technology and provide higher value to our customers. No matter the project, you can trust Elimold to meet all your welding fabrication needs and experience the precision and excellent quality of our world-class service.

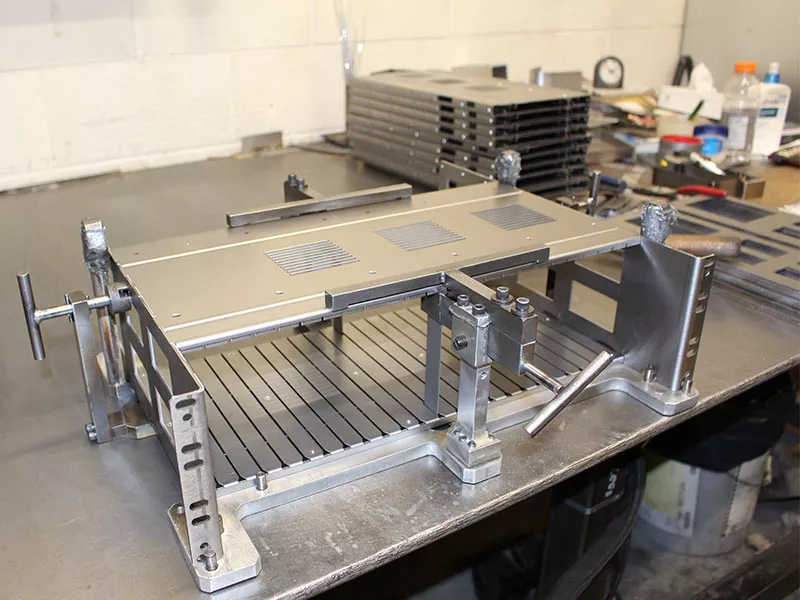

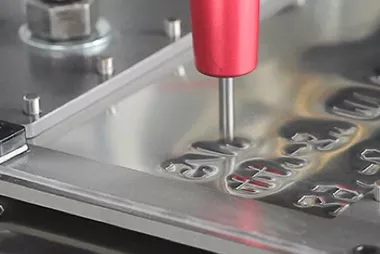

In-House Sheet Metal Welding Shop

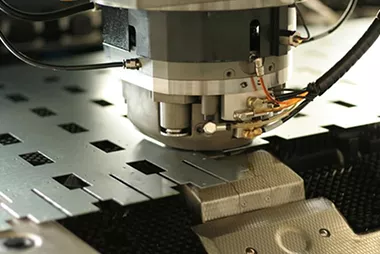

Our Shenzhen, China facility is equipped with state-of-the-art equipment and technology to provide efficient, precision manufacturing capabilities. The in-house welding facility is 31,000 square feet and is capable of meeting the demands of high-volume production and efficiently manufacturing and finishing your parts. Our engineering staff can work with you to achieve the most cost-effective design for manufacturing, and our experienced production and welding teams will manufacture your parts to your specific requirements. And, Elimold understands that the quality of your finished product depends on the quality of the components you use, and we are committed to providing you with parts that meet your exact requirements and are delivered on time and on budget. In addition, our welding services are combined with the CNC machining, laser cutting, stamping, forming, rolling, hardware installation and finishing processes required to efficiently manufacture parts. We serve customers around the world, providing custom finished parts that meet your specific requirements and tolerances.

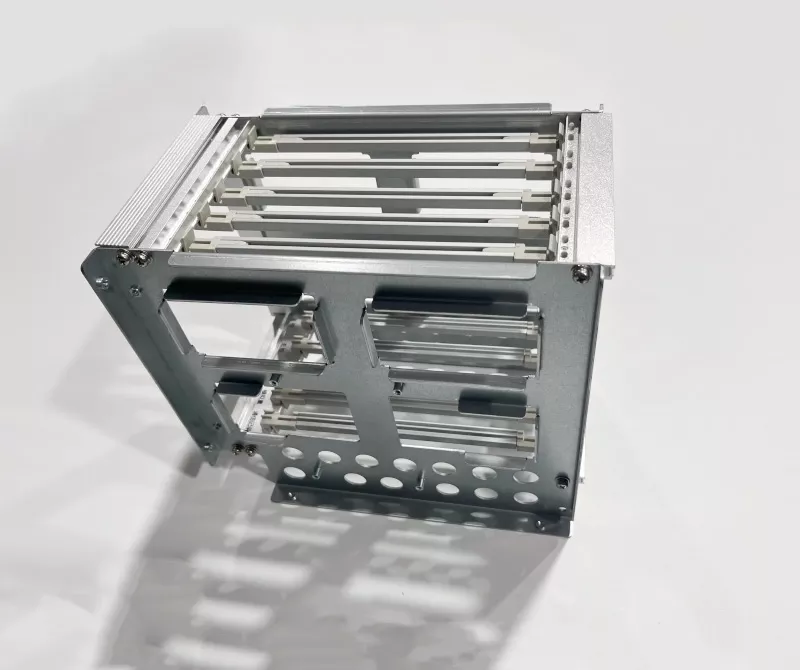

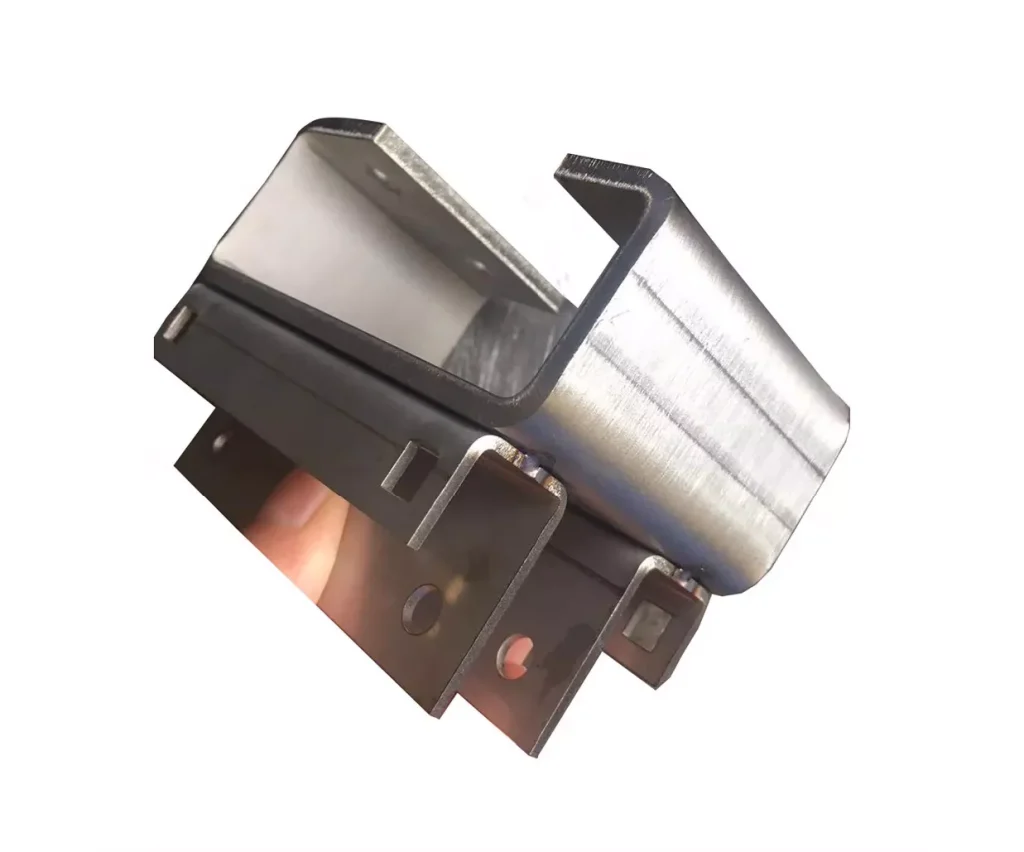

Sheet Metal Welded Parts Manufacturer

Elimold is different. We have a diverse range of talents and skills that make our services stand out from other metal fabricators. We offer our customers a full range of fabrication services at an affordable price. From small parts manufactured by robots to large, precision parts handcrafted by skilled craftsmen, we are the team you need for your project. That’s why Elimold has a training program led by a Welding Engineer/Certified Welding Inspector (CWI) to provide guidance and training to our team of welders. CWIs oversee welder certifications, administer welding trials, and perform requalifications when necessary. In addition, Elimold has a team of experienced fabricators, welders, painters, and technicians to provide full fabrication services for your project.

Get a free quote on your sheet metal welding project now

Our experts use the latest CNC technology to ensure every product is made to your exact specifications. We are committed to providing more than just a part, we provide a solution to help you succeed. Contact us now for a free instant quote.

Precision Sheet Metal Welding Solutions

At Elimold, we know that we are only as good as our team members. We know that having an experienced and dedicated workforce is the key to maintaining our success as a leading custom welding and fabrication company. We regularly invest in the professional development and skills training of our employees. We know that our commitment to quality and customer service comes from applying best practices and the latest manufacturing technologies in our daily work.

As a result, Elimold’s welding solutions use innovative materials and processes to provide higher quality products at a lower cost. Our welding solutions can improve production efficiency by eliminating multiple time-consuming and expensive manufacturing processes. Built-in flexibility eliminates downtime. In addition, our welding team and management are constantly looking for ways to improve our welding practices and equipment to meet the needs of our growing customer base. Ultimately, we are able to produce higher quality welded products that meet customer needs and provide value that exceeds expectations.

Types of Welding Processes

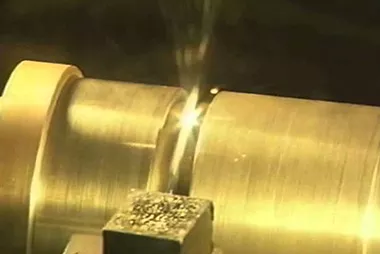

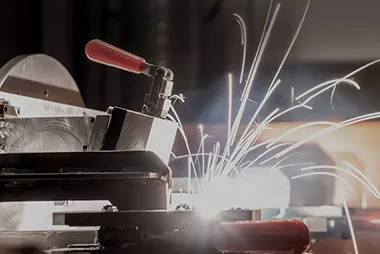

Welding processes are an essential technique in sheet metal fabrication, and there are several types that are suitable for different applications and material types. Here is an overview of some of the most common welding processes:

Gas Metal Arc Welding (GMAW/MIG)

Gas Tungsten Arc Welding (GTAW/TIG)

Flux Cored Arc Welding (FCAW)

Submerged Arc Welding (SAW)

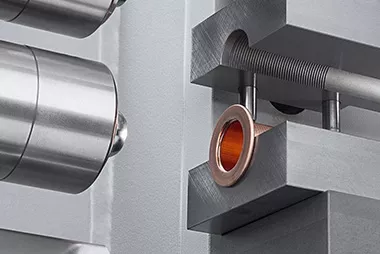

Electron Beam Welding (EBW)

Laser Beam Welding (LBW)

Stick Metal Arc Welding (SMAW)

Orbital Welding

Robotic welding

Stud welding

Remote laser welding

Spot Welding

Welding Project Estimates

The quote for your project is dependent on the estimating department providing the quote. When submitting a quote, it is important to provide accurate and complete blueprints, drawings, or documentation. The meticulous service provided by the Elimold estimating team upfront ensures that your quote is thorough and complete. Our estimating team works closely with our project managers and internal CWI to ensure that your project’s quality standards and timelines are met or exceeded.

The type of welding you choose depends on several factors, including the materials you are using, the thickness of those materials, and the required weld strength. To help you determine which type of welding service is right for your needs, please contact one of our expert engineers who can evaluate your project’s drawings and specifications. No matter how complex the project, our experienced team can provide the best welding solution.

In-House Prototyping Services

Our rapid prototyping process can get your product to market faster, with turnaround times ranging from same-day to 24 hours to 5 days, depending on the complexity of your product. And by testing with prototypes first, you stay on top of the unknown. We help you thoroughly test your design ideas, eliminate unnecessary defects at an early stage, and create working models that your project team will buy into. If you need a welding and metal fabrication supplier, Elimold is the place for you. With our expert metal fabrication capabilities, we can provide you with the high-quality manufacturing and value-added services you need.

Engineering & Design Support

Elimold’s experienced engineering department can provide conceptual design, design changes, product improvements and reverse engineering services. We will work with your team to deliver your parts at a very competitive price. And our sales, management and engineering teams have extensive experience in a variety of industries and understand the changing needs of each industry. We work closely with customers to develop and improve product design and production process planning to streamline production processes and save you end-product costs. We are able to import and unfold your 3D models (.dwg, .step, .iges, .sldasm, .ldprt, .dxf) built in Solid Works, Pro/E and other modeling software. Models can be directly unfolded and downloaded into the CAM process, reducing errors and shortening the lead time of sheet metal parts.

Assembly and Testing Services

In addition to welding services, we can also provide high-quality welding and assembly services, and we employ American Welding Society Certified Welding Inspectors (AWS CWI). Therefore, our customers can enjoy first-class quality standards. In addition, Elimold has an ISO 17025-accredited metallographic laboratory that can perform cutting and etching tests (measuring the cross-section of the weld under a calibrated microscope), tensile, compression, torque and bend tests to verify that our products meet all your requirements.

Inventory Management Services

Elimold uses a Just-in-Time (JIT) inventory strategy to schedule production based on your order requirements. We reduce costs by reducing idle inventory, thereby delivering quality products on time at a lower price. In addition, we combine JIT with Kanban technology to manage an efficient development process. We set minimum and maximum production volumes and meet customer demand through a pull system. This approach allows us to reduce customer and supplier inventory and apply lean manufacturing practices. In addition, we have a comprehensive view of your sales pipeline through an online portal to ensure that it remains efficient at all times.

Total Quality Management and Certification Standards

At Elimold, our manufacturing processes are certified to AS9100D and ISO 9001:2015, and we pride ourselves on providing top-notch quality in every sheet metal fabrication service. That’s why we offer additional services such as dye penetrant testing for weld inspection. Understanding the end application of a component is essential to achieving the best results. Our estimators work closely with our clients to determine the best welding techniques and testing procedures for each project. Whether it’s suggesting the right type of weld or recommending a testing regimen, our team is here to help. If you have any questions or concerns, please feel free to contact our team.

Quality Inspection Process

Elimold has a dedicated Certified Welding Inspector (CWI) in-house to inspect each project. This ensures that your fabrication project meets all requirements before, during, and after the project is completed. Our registered welding engineers (CWI) will check the project requirements and welding specifications before any work is completed on the project. They will also review all documents and test records of all participants before the project begins to ensure that they are qualified for the work. These measures help ensure that your fabrication project has the right personnel, materials, and qualifications before work begins. In addition, our inspection team will track the progress of the project throughout the process and help make adjustments to ensure that the project meets the industry’s high quality standards.

One-stop Welding Manufacturing Service

We have market competitiveness in the field of overall metal component manufacturing. From product design, mold manufacturing, sheet metal processing to welding manufacturing, we are able to handle high-volume and rapid prototyping manufacturing and ensure that all projects are delivered on time. Our experienced welders have the knowledge and skills needed to handle the most complex welding projects. We use the most advanced equipment to ensure the accuracy and consistency of each weld. We also have welding and manufacturing production lines for different materials to improve the welding efficiency of different products. Robotic automatic welding helps us improve our ability to handle large-scale welding projects and maintain stable quality. In addition, our commitment to quality means that we only use the best materials and techniques to create welds that are both strong and beautiful. When working with us, you can rest assured that we will meet your welding needs with the highest level of professionalism and expertise.

Benefits of Working with Elimold

One of the key benefits of working with Elimold is our ability to provide custom welding solutions. Every project is unique and we understand that our customers’ specific needs must be met. No matter what type of custom fabricated part you require, we have the flexibility to adapt our services to meet your needs. Our team works closely with our customers to understand their goals and provide a tailored solution based on their specifications. This level of customization ensures that you receive a solution that is exactly what you need, without any compromises. Regardless of the size of the project, Elimold can ensure that the end result is of the highest quality. Cost savings through streamlined production processes and greater precision and accuracy. Trust our sheet metal welding services to secure your next project.

In Need of Weldment Services?

Contact us to learn how our sheet metal welding services can support your operations.

Complete Welding Services

We offer a comprehensive range of welding services to meet all of your fabrication needs. Our team of highly skilled welders are highly trained and certified to ensure that each project meets the highest standards of quality and precision. With extensive experience and state-of-the-art equipment, we are able to handle the most complex welding jobs. Whether it is a small custom project or a large industrial project, you can rely on us to provide you with excellent results.

Sanitary Welding

Custom Welding

Metal Welding

Thin Sheet Metal Welding

Aluminum Welding

Stainless Steel Welding

Welding Iron-Based Materials

Copper welding

Welding galvanized metal sheets

What is Welding?

Welding is the process of joining dissimilar materials together, including steel, aluminum, and other sheet metals. Welders use different types of welding techniques, such as arc welding, friction welding, electron beam welding, and many more. All of these techniques use high temperatures to fuse the parts together, followed by cooling to achieve the final fusion. Some types of materials are not weldable and require additional materials (called “fillers” or “consumables”) to join them together. Parts can be joined together in different configurations, such as butt joints, T-joints, corner joints, and other configurations. Welding is one of the most common types of fabrication operations for sheet metal.

Benefits of Welding

Welding offers numerous benefits over fasteners or other methods for joining disparate components. Some of the advantages provided by welding include:

- Versatility. Welding is used across industries because it works with a variety of materials and project types.

- Permanence. Metal welding forms a permanent bond between two surfaces.

- Strength. If done correctly, the weld creates a joint far stronger than the components joined.

- Cost-effectiveness. Welding cost varies depending on the welding method and project specifications, but welding is generally a cost-effective process. Most welding projects are relatively fast, which also limits project costs.

Material Options

- Stainless Steel

- Boron Based Hot Stamping Grades

- High Strength Low Alloy

- Domex

- Armor

- Galvanized Steel

- Hot and Cold Rolled Steel

- Spring Steel

- Aluminum

- Titanium

- Copper

- Brass

Surface Finishing and Post-processing

There is no need to outsource finishing and post-processing services for your manufacturing project. Elimold has a complete range of processes in-house to complete the finishing and post-processing needs of your project. Therefore, we offer a variety of common processes as follows.

- Degreasing

- Blasting

- Pickling

- Powder Coating

- Anodizing (for aluminum)

- Plating

- Riveting and Fastening

- Adhesive Bonding

- Stress Relieving

- Annealing

- Hardening and Tempering

Industries We Serve

We can provide welding services to a variety of industries and can undertake a variety of welding projects, from simple repairs to complex assembly.

- Construction

- Automotive

- Aerospace

- Medical

- Appliances

- Transportation

- Electronics

- Furniture

- Retail

- Agriculture

- Energy

- Defense

- Food and Beverage

- Consumer Goods

- Architecture

- Mining

- Shipbuilding

- Telecommunications

- Business Machine

- Computer

- Office Equipment

- Logistics

- Government

- Marine

Welding and Fabrication Applications

Manufacturers, machine shops, fabricators, OEM and contractors across a wide range of industries trust our welding and fabrication services for their manufacturing and production needs.

- Brackets

- Frames

- Skids

- Containers

- Enclosures

- Machine Storage

- Hoppers

- Platforms

- Housings

- Pallets

- Machine Bases

- Work Benches

- Fixtures

- Racks

- Consoles

- Command Centers

- Tanks

- Structures

Diverse Welding and Fabrication Services

We specialize in custom sheet metal fabrication and processing, using state-of-the-art cutting, forming, bending, sheet metal welding and assembly processes to create structures and components. Years of experience have given us a deep understanding of sheet metal properties and how this material reacts to heat and forces during processing. This level of technology ensures that the fabricated sheet metal has superior strength and meets or exceeds design specifications. The innovative Elimold team is ready to review and guide you through the design process. Our goal is 100% customer satisfaction, providing quality and productivity in line with ISO 9001:2015 certification, resulting in timely turnaround and on-time delivery. Elimold has the ability to manage large projects from start to finish or provide support at any stage of the project. Customers can provide work materials or request Elimold to obtain them.

Other Metal Fabrication Services

At Elimold, we are committed to providing diversified services to meet more customer needs. We have three production sites to provide more integrated metal fabrication services for complete projects. In addition to welding services, we can also provide the following sheet metal fabrication services.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending

Extrusion

Embossing

Forming

Request Your Free sheet metal Welding Quote Today

After receiving your drawings, our engineers will analyze your custom sheet metal Welding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.