Swiss CNC Machining Services

Elimold‘s swiss machining capabilities allow us to produce high volume production runs of small, intricate parts for a multitude of industries. Swiss CNC machining is ideal for manufacturing small, round parts where precision matters most.If this type of machining fits you and your production needs, click to request a quote today!

Swiss Machining

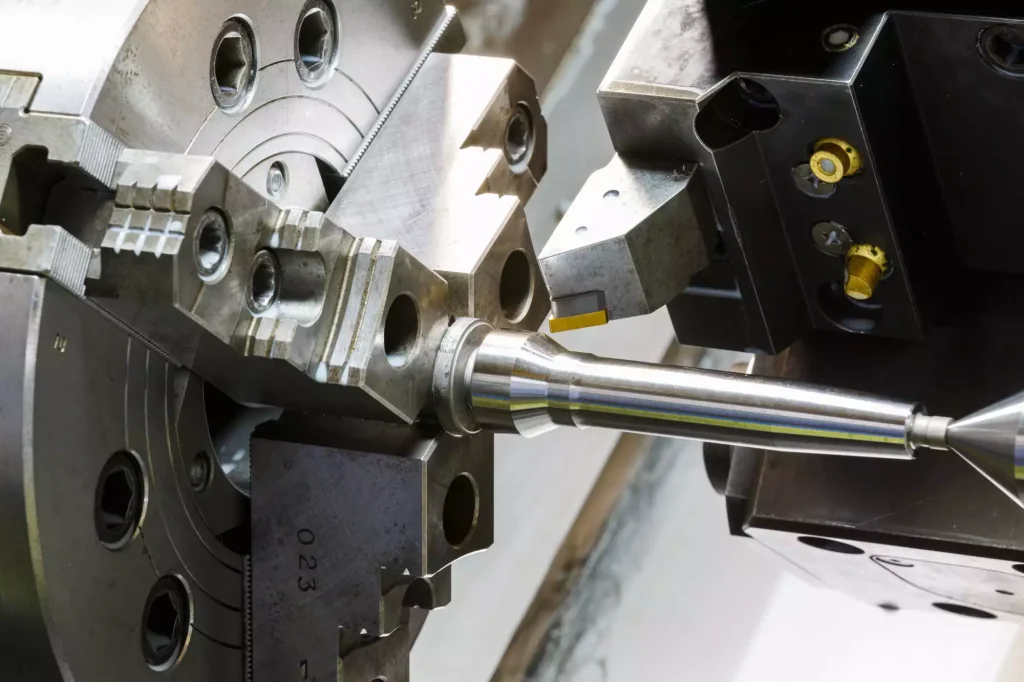

Elimold Company provides Swiss CNC Machining to a wide range of industries. We use cutting-edge Swiss CNC lathes and milling machines to produce machined parts that are precise and accurate and meet our customers’ exact specifications. Swiss CNC machining includes Swiss Turning, Swiss Automatic Machining, Swiss Lathe Machining, Swiss Precision Machining, Swiss Milling Machining, Swiss Micro Machining, Swiss CNC Programming, and Swiss CNC Design.

We provide a wide range of services, from prototyping to JIT production manufacturing. Our highly skilled and experienced machinists can handle projects of any size and complexity.

Elimold CNC Swiss Machining Experts

Our Swiss CNC turning machines are the perfect option for machining large quantities of small, complex cylindrical parts with tight tolerances. Our expertise with CNC programming allows us to quickly set-up production equipment to run your turned parts. For 1000 pieces to 100,000 piece production runs, CNC Swiss machining delivers repeatable quality for precision machining requirements. Parts precision machined with stainless steel, steel alloys, aluminum, brass, and a wide variety of thermoplastics (PEEK, Delrin, acetal, ABS, etc).

Our engineering team includes process engineers, tooling engineers and application engineers who will quickly respond to your RFQ, review the prints and collaborate with your team to determine the best way to meet your production requirements. We are ISO 9001:2015 and AS9100D registered, making parts for medical, aerospace, oil and gas, lawn and garden, sporting goods, industrial, test and measurement, and many other industries.

Our Swiss Machining Capabilities

At Elimold, our Swiss screw machining encompasses custom processes like parting/cutting, form turning, internal/external threading, knurling, and more. These processes are fine-tuned to meet your specific manufacturing needs, providing unmatched precision.Our Swiss CNC machining capabilities include machining precision parts measuring 0.050’’ to 1.250’’ in diameter with lengths up to 20’’. We maintain tight tolerances of ±0.0005’’ total on the part diameter, 0.001’’ total on the length and concentricity, and 0.005’’ total tolerance on straightness for long parts.

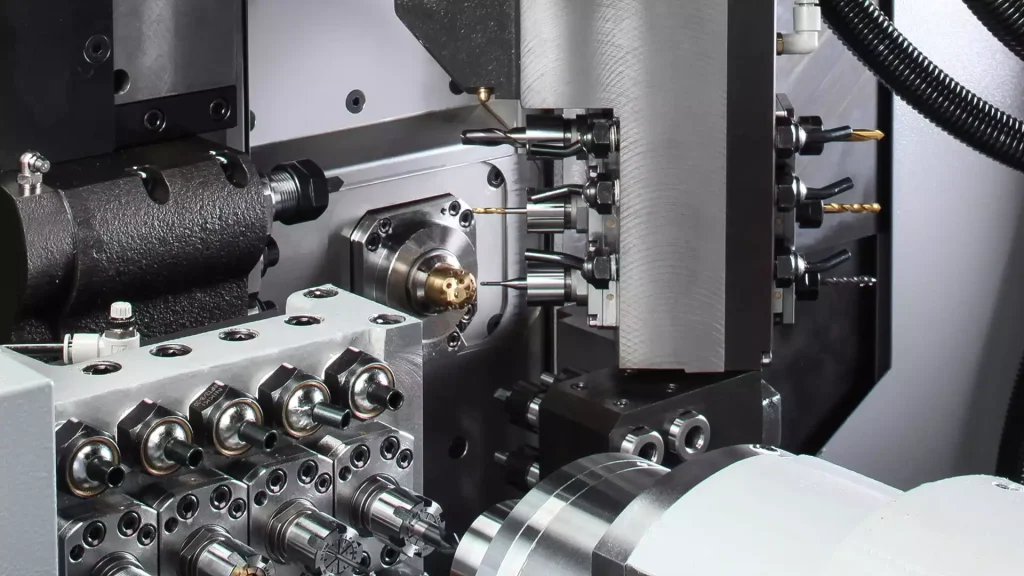

- Up to 8 Axis

- Up to 32 Tools

- 8 in. (203.2 mm) max part length per chucking

- 1.25 in max diameter

- Tolerances as close as .0005 in

- Lights-out manufacturing with bar stock up to 1-1/4 inches in diameter and 12 feet long

What Is a Swiss CNC Machine?

Swiss CNC machines are used for manufacturing small, complex parts. With Swiss machining, the cutting tools are approximately a quarter inch from the guide bushing, minimizing vibration by creating a more stable holding system. Swiss CNC machines feature exceptional flexibility and precision—making them ideal for complex, high-production applications.

One of the greatest advantages of Swiss CNC machines is their versatility. These machines can perform a wide variety of functions, including milling, threading, knurling, axial drilling and more. As a result, Swiss machines are popular across a wide range of industries in need of precision machined parts.

Swiss CNC machining also supports a host of material types, including plastics, cobalt-chrome alloys, aluminum, stainless steel and more. This advantage gives OEMs greater flexibility in choosing materials best suited to meet their functional requirements and optimize end-component costs.

In the context of medical device manufacturing, Swiss CNC machines are widely used to produce smaller components with extremely tight dimensional tolerances. The efficiency and accuracy of these machines make them uniquely suited for high-precision medical solutions, including single-use instruments and parts for orthopedic devices.

Micro Swiss Machining

The Tornos SwissNano machine was designed to produce very small parts, with extreme quality and precision. In the world of medical device manufacturing, components are getting smaller and smaller. As these components decrease in size, their dimensional tolerances become increasingly tighter. Marshall has a history of providing high quality micro-machined medical components and assemblies to our customers. Satisfying our customers is our highest priority.

SwissNano machines offer the best precision on the market for medical device manufacturers. These powerful tools are designed for workpieces requiring exceptional precision and quality. Along with their capacity for turning, cutting, deburring and drilling, SwissNano machines offer excellent ergonomics and visual access, making tool adjustment simple and efficient.

At Elimold, we work with leading Swiss CNC machine manufacturers (including Tornos and and Citizen) to provide the best solutions possible for our customers. Our performance-focused machines are tailored to meet the unique needs of medical device manufacturing, delivering fast cycle times, versatile operations and world-class part quality.

Advantages Of Swiss Screw Machining

With CNC swiss screw machining, there are various advantages to producing swiss turned parts, such as:

- Extended length to diameter ratio

- Ability to take on a wider range of bids

- Additive manufacturing for prototyping and fixturing available

- Automated inspection equipment unique to your part available with in house automation team

- PPAP compliant for all your capability study needs

- FMEA used throughout the manufacturing system – from inspection to shipment

Materials That Can Be Swiss Machined

Practically any material that can be machined using a standard lathe or mill can be Swiss machined. Some examples of materials that can be used are listed below:

| Swiss Machining Materials | Common Swiss Machining Examples |

| Alloy Steel | 4140, 8620 |

| Aluminum | 2011-T3, 6061-T6 |

| Brass | 360, 353, Lead Free Brass |

| Carbon Steel | 12L14, 12L15, 1117, 1018, 1045, 1141, 1144 |

| Copper | C14500 (TeCu), C10200 (Oxy-Free) |

| Plastic | Delrin, Peek |

| Stainless Steel | 303, 304, 316, 416, 430F |

How We Manufacture Custom Swiss CNC Machined Parts

Our custom Swiss CNC machining services rely on our in-house tooling construction and custom-built inspection equipment, which allow us to offer services at a competitive price while maintaining the highest quality. Our extensive fleet of Swiss CNC turning centers provides a range of work envelopes and features to deliver small to mid-sized parts with excellent quality.

When you partner with us for your custom Swiss CNC machining needs, we start your project by reviewing your product blueprint. Then, we review quotes from outside suppliers and generate our internal quotes. After receiving the purchase order, there is documented approval that’s sent to the customer, and then we create and distribute manufacturing prints and tooling. Next, Elimold’s Automatic Machining manufactures your parts and performs final inspections before shipping them to you.

Examples of Applications Across Industries

Our Swiss CNC machining services are ideal for a variety of industries, including aerospace, automotive, medical, and industrial. We are dedicated to providing our customers with high-quality machined parts and components that meet their exact specifications. Our team of highly skilled and experienced machinists works hard to provide the best service and satisfaction to our customers. We are pleased to be able to assist our customers with their machining needs in a cost-effective and efficient manner. Get in touch with us today to learn more about our Swiss CNC machining services and how we can assist you with your project.

Alternatives to Swiss Machining

- 5-axis CNC Milling: 5-axis milling, like Swiss machining, can be used to fabricate complex parts to extremely precise tolerances at fast speeds. Although, the parts made by 5-axis milling are often larger than the parts fabricated using Swiss machining. Additionally, however, unlike Swiss machining where bar stock is automatically fed into the work area for machining, 5-axis milling typically requires more tool changes and downtime. Consequently, depending on the production volume and part geometry, Swiss machining is often a more efficient process.

- Conventional Lathe Machining: Conventional turning and facing operations using a traditional lathe may not be as efficient as Swiss machining but can still be a viable alternative. Certain factors may justify the decision to pick a conventional lathe over a Swiss lathe. Such factors include: the part being too large for Swiss machining, tolerances are not strict, or it is a one-off part. While CNC lathes are great for these operations, they require more downtime since cutting tools must be replaced more frequently and parts must be removed and adjusted more often.

Elimold Manufacturing Capabilities From Prototype Through Production

From prototype through production, we are customer-focused and provide solutions for challenging components and assemblies. Our engineering knowledge of tool design gives Elimold the ability to find cost-effective solutions for our customer’s specific needs.