Electronics 3D Printing

From housings to sheaths and tooling, additive manufacturing is a reliable manufacturing technology if you want to innovate, evolve and bring more adaptability to your products and processes. Do you want to benefit from a production process tailor-made for your electronics project? Accelerate prototyping and production processes by implementing additive manufacturing

3D Printing in the Electronics Industry

3D printed electronics are becoming a viable alternative to traditional manufacturing processes. This is especially important as electronics become smaller, more tightly packaged, and subject to more demanding conditions. Miniaturization, increasing number and density of electronic components, and faster data speeds that generate more heat are just some of the challenges facing today’s electronics designers.

Speed is a key requirement in electronics manufacturing, and this is the biggest advantage of 3D printing. With Elimold’s 3D printing services, engineers can reduce the barriers between creativity and functional anti-static safety parts. Whether it’s shortening design cycles, conducting more iterations, accelerating tool development, or building more optimized final parts, improving efficiency has powerful downstream benefits throughout the electronics manufacturing process.

Develop your electronics projects using additive manufacturing

3D Low-Volume Production

Print strong and durable electronic parts with our engineering and ESD-safe thermoplastics. Thanks to our industrial 3D printing technologies, you can design parts with complex geometries. You can also produce small series or limited edition products or even manufacture replacement parts in no time.

3D-Printed Functional Prototypes

Test easily and quickly your electronic parts with our cutting-edge technologies and engineered thermoplastics, for a fraction of the usual cost.

3D-Printed Tooling and Jigs

Manufacture stable and lightweight tools that are easy to handle and meet the requirements of electronic applications. Our additive manufacturing experts are there to support you from start to finish, to help you obtain the result you want.

Materials suitable for electronic applications

- Nylon PA12: adaptability and versatility for housings

- Ultrasint® PA11 ESD: Electrostatic Discharge Characteristics

- Ultrasint® TPU01: high flexibility and shock absorption

- PA2210 FR: Flame retardant material for fire safety

Why choose to use Elimold?

Product compliance management

- Dimensional inspection

- Conformity of raw materials

- Conformity procedure

High-quality production

- Understanding phase

- Design and programming phase

- Production phase

- Quality phase

Quality assurance

- Continuous improvement program

- Elimold’s quality policy

- Efficient and automated quality system

- Focus on industry 4.0: innovation, automation and excellent reliability

Advantage

- Rapidly create functional parts

- Precision machines can create high-precision parts with complex features

- Geometric complexity is no longer limited, simplifying conformal tooling and workholding manufacturing

- Continuous fiber reinforcement provides metal strength parts for a variety of applications

Find your ideal solution

We’re here to help you take advantage of all the advantages of additive manufacturing in the electronics industry.

The speed and ease of use of our machines also means you can quickly move from design to manufacturing, allowing you to modify and customize your parts as needed, giving you unparalleled flexibility.

We will support you in the process of redesigning your components and selecting the materials best suited for your application.

Streamline supply chain with on-demand manufacturing

The global electronics supply chain can be riddled with inefficiencies, from inventory challenges to logistics delays. 3D printing offers a compelling solution because it enables local, on-demand manufacturing. With 3D printing services, companies can produce electronic parts on demand, significantly reducing inventory costs and mitigating supply chain risks.

On-demand manufacturing is particularly beneficial for small and medium-sized businesses that may lack the resources to invest in large-scale production. It enables companies to respond quickly to market demands or changes, providing customers with timely upgrades and replacements that would otherwise be impractical.

Customizable components for custom solutions

Engineers can customize electronic components to meet the exact specifications of a specific application, which is ideal for industries that require high-performance, custom solutions. If it’s a custom-shaped antenna to improve signal reception or a custom connector to optimize space within a device, 3D printing enables these inventions without the need for expensive molds or tooling.

Designers are no longer limited by traditional manufacturing methods as they now have the ability to create organic shapes and complex internal structures. These features contribute to miniaturization, a trend that is shaping the future of electronics. With 3D printing, producing smaller, more compact devices doesn’t mean sacrificing performance or complexity.

Application of 3D printing services in the electronics industry

Applications of electronic 3D printing can be classified based on the type of printing and the specific components being manufactured.

- High-quality enclosures housings

- PCB holders

- Electric connectors

- Jigs and fixtures

- Wire guides and organizers

- Battery holders

- Elevator buttons board

- Braille Elevator buttons

- Light Fixture support

- Lamp shades

- Lab top, I-Pad Supports

- Components, heat exchangers, electric motors

- Jet parts

- Plastic injection molds

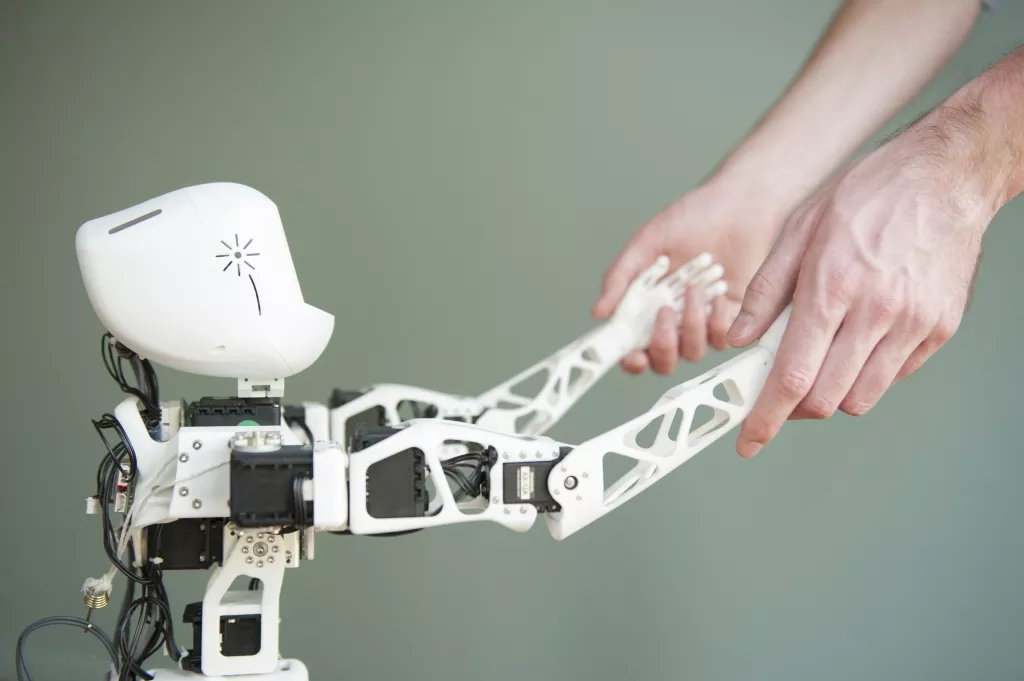

- Robot parts

- Metal printing

- Vehicle batteries

- Printed electronic circuits

- Sensors

- Tooling

Get multiple quotes for your parts in seconds

Additive manufacturing is an effective solution for the electronics industry, both in terms of material utilization and process flexibility. It can produce electronic product parts of any size from a variety of different plastic or metal materials without wasting raw materials. . Explore the potential that 3D printing has for you in the electronics industry with us and upload your files to get a quote now.