Tube Bending Services

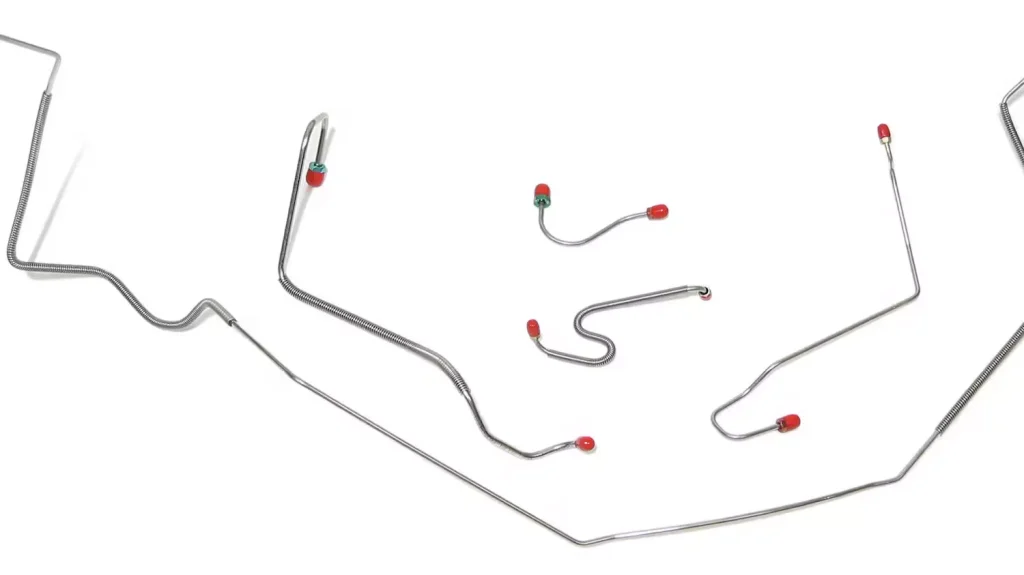

Elimold is a leading provider of tube bending services for high-volume, complex parts that require high-speed, high-precision bending. We have the experience, expertise, and equipment to meet your needs. Whether you have a one-off project or regular production, we can help you get the job done. With competitive pricing and fast lead times, we’ll ensure your project is completed on time and within budget. Get a quote for your high-volume tube bending, punching, or end forming project today.

Professional Metal Fabrication and Tube Bending Service Provider

Elimold has extensive experience and leads the market with superior tube bending and metal fabrication technology, and we are honored to have the opportunity to work with you. Our goal is complete customer satisfaction, which includes providing the highest quality products and the shortest delivery time to meet all customer needs and requirements. We serve industries that require extremely high quality and precision, and there is no room for error, so we are constantly upgrading our business with state-of-the-art equipment and software.

In addition, our tube bending team is led by our experienced owner-operators who work closely with customers at every stage of the project life cycle and personally supervise all work in progress. We are committed to providing customer-centric services at every stage of the project, and we can provide extremely fast turnaround even when customers require significantly shortened schedules.

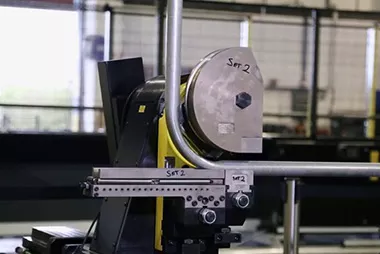

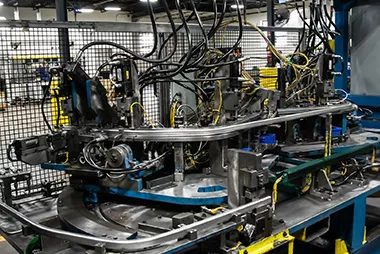

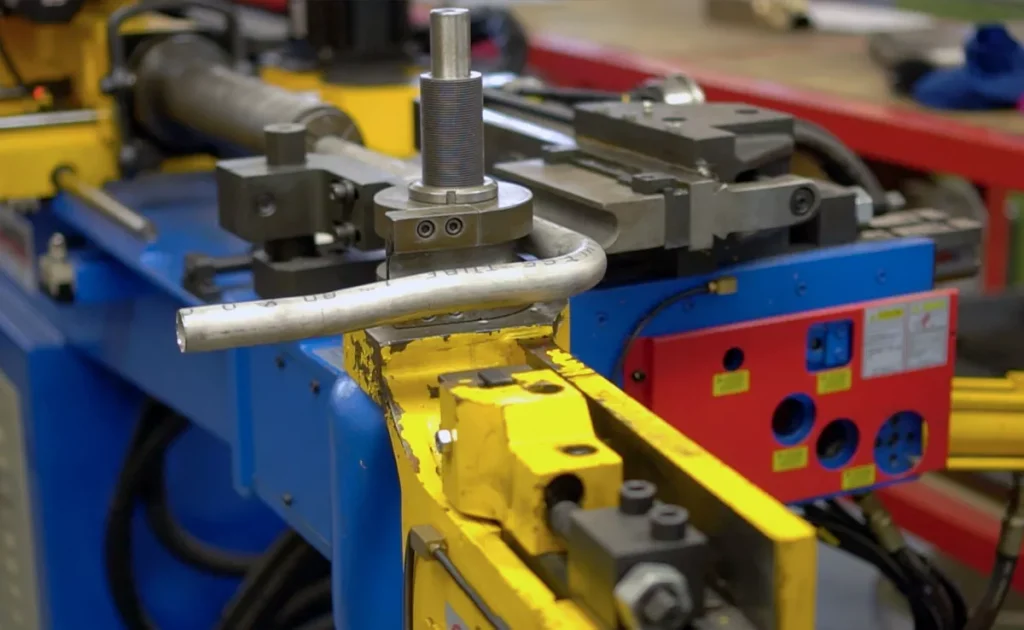

Elimold In-House Tube Bending Factory

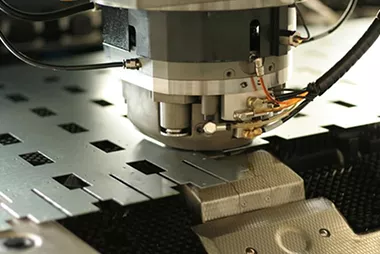

From our engineering team to our expert in-house tooling design to our 50,000 square foot production space with state-of-the-art equipment, Elimold has the experience and capabilities to complete your tube manufacturing project. Our factory floor features over 100 CNC machines of various types and over 1,300 in-house tube bending dies. Our equipment is capable of drawing, forming, flattening, and piercing tubes in a wide range of shapes and sizes to suit your project.

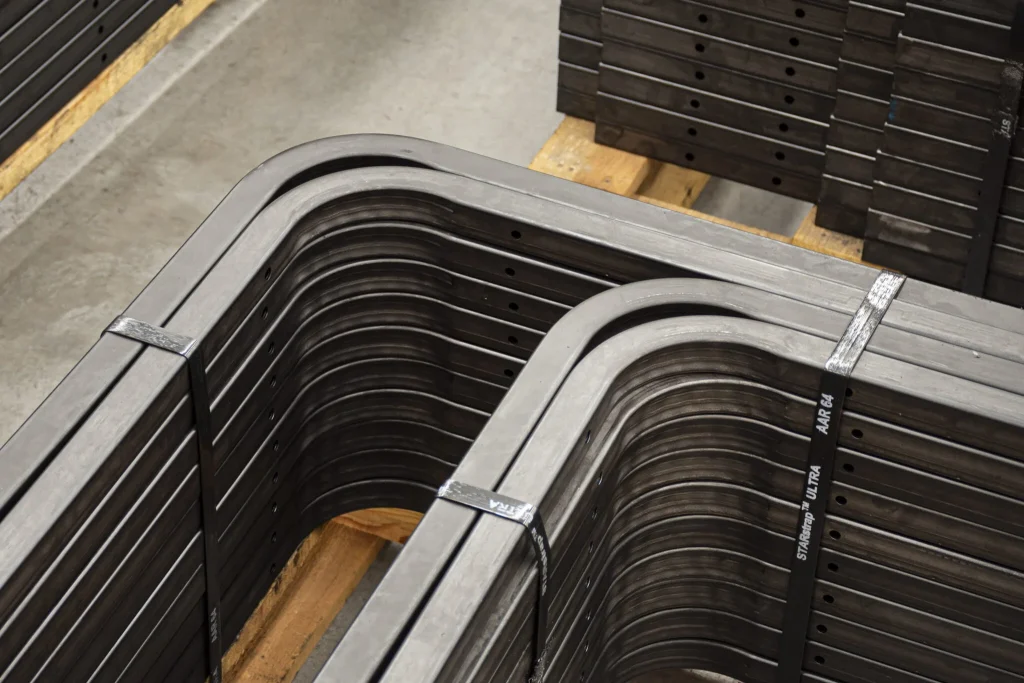

As a result, we can process tubes and hollow structural parts of virtually any shape and size. Despite the challenges of the tube bending process, our highly trained and skilled technicians consistently deliver superior products that are built to tight tolerances and meet customer specifications. Our complete process covers the entire process from initial order to prototyping and delivery.

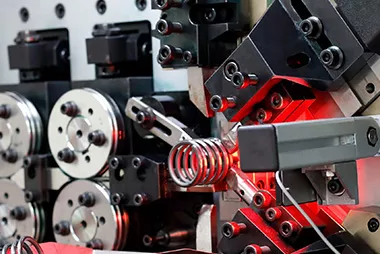

Types of Tube Bending Processes

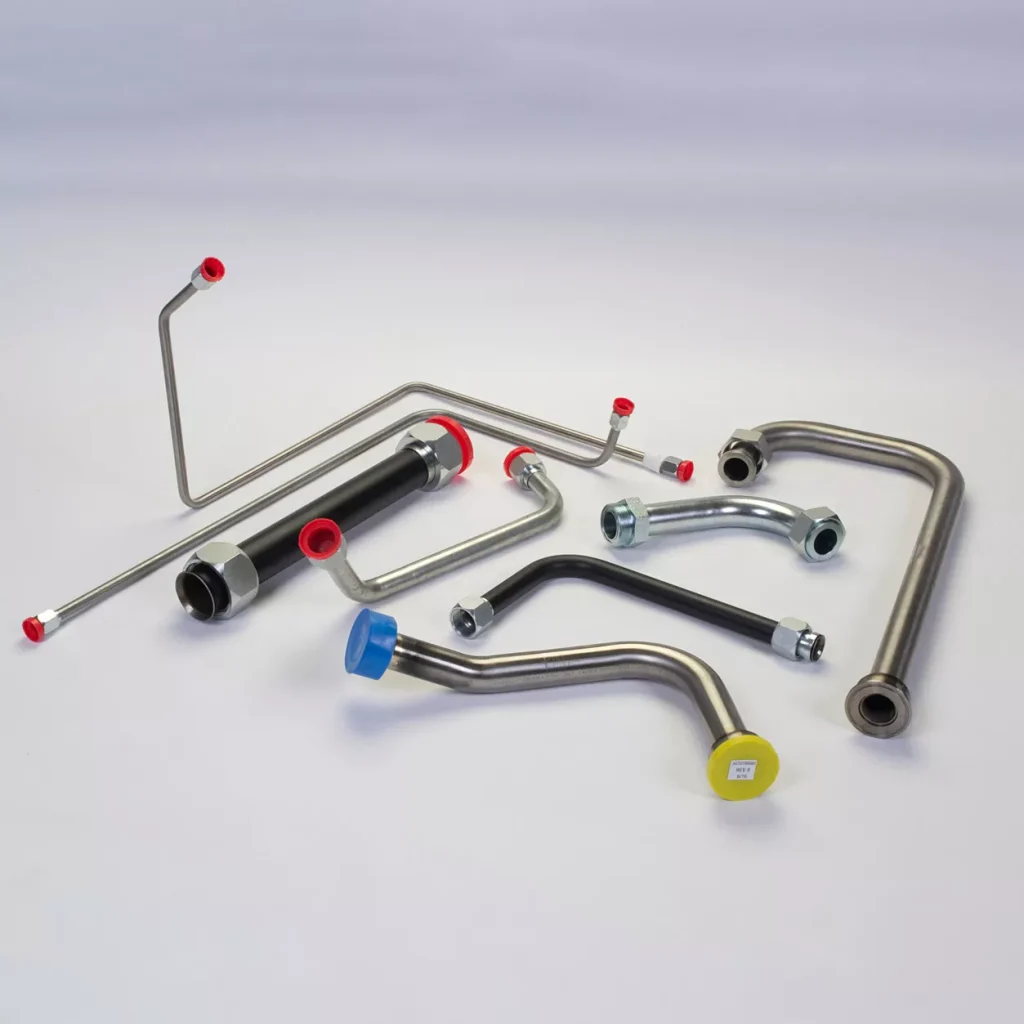

Tube bending processes utilize metal forming techniques to bend materials into precise layouts and shapes without curling or weakening the metal. Most tube bends use elbows or U-bends at different angles. There are a wide variety of tube bending methods to suit different materials, environments, and designs. Elimold offers the following tube bending processes:

Compression Bending

Rotary Stretch Bending

Coiling

Tube Bending Dimensions and Tolerances

Our tube bending services adhere to industry standards to ensure a smooth production experience. Elimold’s project engineers perform manual reviews to ensure tighter tolerances. The following list outlines the specific standards and tolerances for our stretch bending or mandrel bending technologies for round profiles:

- Minimum bendable tube diameter: .250″

- Maximum bendable tube diameter: 2.000″

- Minimum bendable tube wall thickness: .035″

- Maximum bendable tube wall thickness: .188″

- Overall tube sheath envelope tolerance is +/- 0.125” typical

- Linear dimensions (excluding locations to bends) are +/- 0.010″

- Simple, single planar bends are +/- 0.010”

- Multiple surface or multi-planar bends are +/- 0.030”

- Angularity: +/- 2 degrees

- Tube center line radius tolerance is +/- 0.125” typical

- Tube end diameter tolerancing is +/- 0.020”

- Cut edges will be normal-to-surface as a default. Normal-to-edge cuts will require agreement at the time of order.

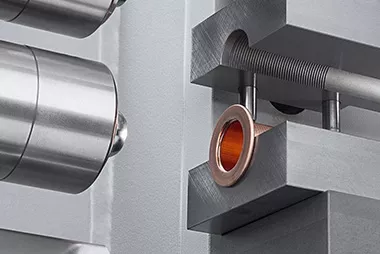

In-House Cleanroom Capabilities

Elimold is an ISO 9001:2008 and AS9100 certified company that complies with 13485 standards. Our in-house facility also offers Class 100 cleanroom capabilities and provides turnkey solutions to streamline your supply chain, reduce lead times, and lower overall costs. We are committed to providing one-stop tube bending services and other custom processing needs for a variety of metal and ceramic materials. We also offer a variety of finishing and post-processing processes, including heat treatment, cleaning, leak and vacuum testing, as well as Class 100 cleanroom assembly and packaging. In the field of high-precision tube bending, we excel in handling a variety of difficult materials, and we are willing to take on projects that other companies are reluctant to undertake.

Best Tube Bending Solutions Company

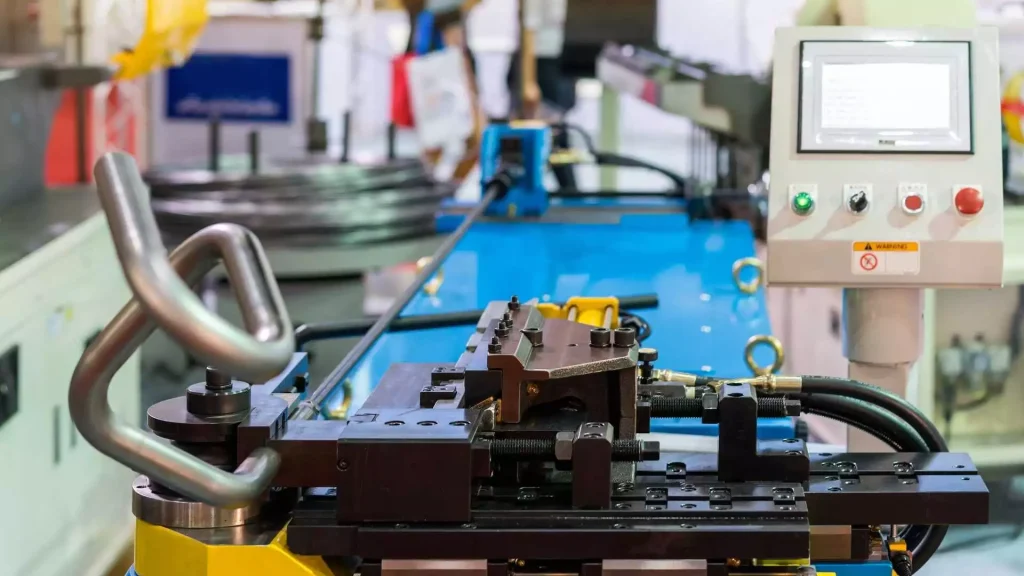

Elimold offers quality in-house engineering and tooling design, prototyping, laser tube cutting, auto-feed tube saws, and a tool room staffed with skilled tool making personnel. Our machine shop is equipped with a range of manual, CNC, hydraulic, and pneumatic tube bending machines to meet different needs. We carry a stock of mandrels and dies to process low-cost tube. End finishing machines for trimming, forging, reducing and expanding pipe components are also available. We can also handle special assembly operations such as bending, fitting, and brazing. In addition, we currently have a 187″ x 3.00″ x 114″ tube bending capability, as well as electric hybrid rotary tie rod compression die/press tube bending capability and tube forming capabilities.

In-house Tube Bending Tool Manufacturing

Elimold’s in-house tool manufacturing shop and experienced team of engineers can manufacture and design high-quality tools. Our carefully designed tools are designed to meet the most demanding tube bending projects, ensuring that the related parts can provide excellent performance, durability and reliability. We work closely with our customers to understand their unique needs and develop custom solutions to optimize their operations and increase productivity. Our commitment to excellence, coupled with our extensive industry expertise, makes us the first choice for those seeking top-notch tube bending tooling solutions, our custom solutions can drive growth and support their success.

Ready to start your tube bending quote?

The industry’s best precision tube bending and metal fabrication technologies, covering a wide range of sizes from small to large diameters with the tightest tolerances to meet any requirement. Contact us now for a free instant quote.

Full Range of Metal Tube Bending Services

The Elimold team has developed a host of proprietary technologies that no other metal tube bending shop can match. Our tube manufacturing services range from bending and processing to design, production, finishing and packaging. We offer a full range of manufacturing services and can complete welding, piercing, grooving and other secondary operations in-house. In addition, we source materials from reputable suppliers and verify compliance upon arrival. Our quality control team uses sophisticated testing and inspection equipment to ensure that each product exceeds customer specifications. Every order is reviewed for accuracy before shipping.

Do you need our assistance in determining which tube bending service is best for your needs? We are ready to provide you with a full range of services, covering all aspects of the process from engineering design to manufacturing and shipping. We can also analyze which type of tube bending service is right for your project, following practices that ensure precision and shape accuracy. But if you have tube bending needs, working with Elimold means you have one less thing to worry about, and your metal tube bending project will be handled properly.

Contract Pipe Bending Services

Elimold offers custom pipe manufacturing services. We provide the same attention to detail and precision to every customer who needs pipe bending services. Send us your design and we will provide you with a quote for a high-quality finished product. No matter the pipe size, we can meet your pipe bending project needs, whether it is small or large structural pipe, and no matter the production period.

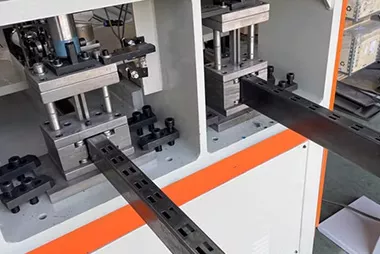

Tube Bending

Tube Punching

End Forming

Tube Bending Rapid Prototyping Services

Elimold provides customers with competitively priced prototype parts with guaranteed fast delivery. We can produce from samples, sketches or finished engineering drawings. We will manufacture parts to drawings whenever possible or provide copies with necessary deviations annotated for customer approval prior to manufacturing.

Because every bending job is unique, we consider all project factors including materials, finishing, custom work or rush deliveries. Our quotations for bending and assembly projects are reviewed by experienced engineers and estimators who fully confirm all aspects of your job.

Engineering Design Services

Our team of engineers uses a four-step service process to take customers through consultation, design assistance, prototyping and finally manufacturing and delivery to ensure smooth project completion. This process allows us to handle the most complex and challenging requirements with efficiency, expertise and flexibility.

As a result, our design team prioritizes how to best complete your project, which is why we deliver so many tube bending projects that other factories stay away from. Our service and assembly capabilities include the following, but much more. To discuss your project, please upload your files to get a quote.

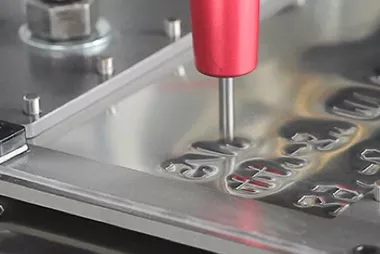

Ensuring Quality with Photogrammetry

Elimold’s in-house facility manufactures fixtures, tools and gages for production and inspection of critical part attributes. This ensures tubular parts fit and perform as designed. In addition to “hard” tooling, we use photogrammetry to collect data on samples and production batches to develop predictive models that provide insight into reasonable tolerances for any given size and type of material. AICON data can also be transferred to CNC tube bending equipment for reverse engineering of sample parts or fine-tuning tube bending programs. Additionally, X, Y, Z coordinate bend programming can interface with our tube coordinate measuring machines (CMM) and optical measurement systems to maintain the highest repeatability of production batches and ensure compliance with your design specifications.

Testing & Inspection

- CMM

- Laser Micrometer

- Air Gauging

- Borescope Inspection

- ASTM E1417 Type 1 Method A(Liquid Penetrant)

- Hydrostatic Pressure Testing Up To 10,000 lbs.

- Leak Testing

- Air Under Water

- Nitrogen Under Water

Precision Tolerance Metal Tube Production and Fabrication

At Elimold, we are used to holding very tight tolerances; all of our parts come with a quality control package to ensure your parts are manufactured to your exact specifications, and our comprehensive solutions help you improve your processes and increase profitability. If you are looking for a reliable supplier of tube bending, forming, and cutting, we are your one-stop shop for all your needs. We streamline time-consuming and costly parts of the supply chain while providing high-quality tubular parts and products that meet your specific needs. No matter the size of your tube bending project, Elimold is ready to help. We pride ourselves on having the fastest lead times in the industry. Our short lead times mean your order can be completed in days, not weeks.

Bend Requirements

Elimold can support a wide variety of bend requirements–certain parameters are helpful when building a quote, including the following specifications:

- Center line radius

- Bend radii

- Tube profile (round, square, etc.)

- Tube wall thickness

- Tube diameter (based on schedule or wall thickness)

- Type of bend (‘L bend’, ‘U bend’, ‘S bend’, ‘Coil bend’, or a combination of bends)

- Project volume (can handle thousands of pieces)

Material Options

- Steel

- Stainless Steel

- Aluminum

- Inconel

- Titanium

- Brass

- Copper

- Copper-Nickel

- Hastelloy

Surface Finishing Options

When your custom pipe bending products need surface treatment, we can provide the following surface finishing processes:

- Sandblasting

- Polishing

- Anodizing

- Electroplating

- Powder Coating

- Passivation

- Pickling

- Painting

- Brushing

- Galvanizing

Value-Added Services

Choosing one supplier for your comprehensive tube bending program ensures consistent quality control and tight production timelines. In addition to tube production and finishing services, Elimold offers the following services to streamline your manufacturing process:

- Swaging

- Flaring

- Coping

- Beading

- Drilling

- Flattening

- Flaring

- Machining

- Milling

- Notching

- Piercing

- Punching

- Slotting

- Swaging

- Threading

- Welding

Industries We Serve

We work with leading manufacturers and meet the stringent quality and delivery requirements expected by the following industries:

- Agricultural

- Alternative Energy

- Appliance

- Architectural

- Automotive

- Computers

- Construction

- Defense

- Distribution

- Electronic

- Entertainment

- Fabrication

- Furniture

- Hardware

- Health and Fitness

- Heating and AC

- Heavy Equipment

- Lawn and Garden

- Material Handling

- Nuclear

Other Metal Fabrication Services

At Elimold, we combine cutting-edge technology with decades of expertise to deliver unmatched reliability in custom sheet metal production services. No matter the complexity or size of your project, our custom metal fabrication team uses advanced tools and proven processes to ensure precision delivery. From prototypes to full production runs, we are committed to ensuring your application is a success. Experience the benefits of working with a trusted partner who understands the importance of quality and consistency. Here are the additional metal fabrication services we offer.

Laser Cutting

Plasma Cutting

Punching

Stamping

Die Cutting

Bending and Forming

Welding

Extrusion

Embossing

Request Your Free Tube Bending Quote Today

After receiving your drawings, our engineers will analyze your custom Tube Bending parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.