Petroleum And Natural Gas injection molding

Elimold works with the biggest names in the oil and gas industry, from large companies needing mass production equipment to smaller businesses seeking specialized, custom engineered parts, our expertise in plastic injection molding ensures reliable, high-quality products. Contact us today for a free instant quote.

Oil & Gas Injection Molding Manufacturer

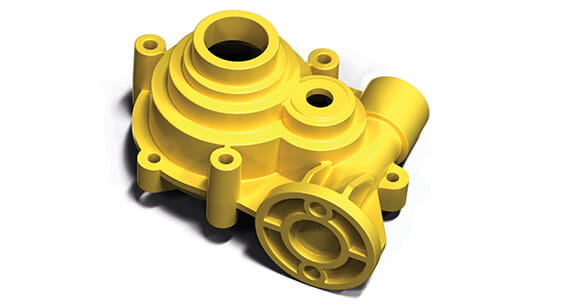

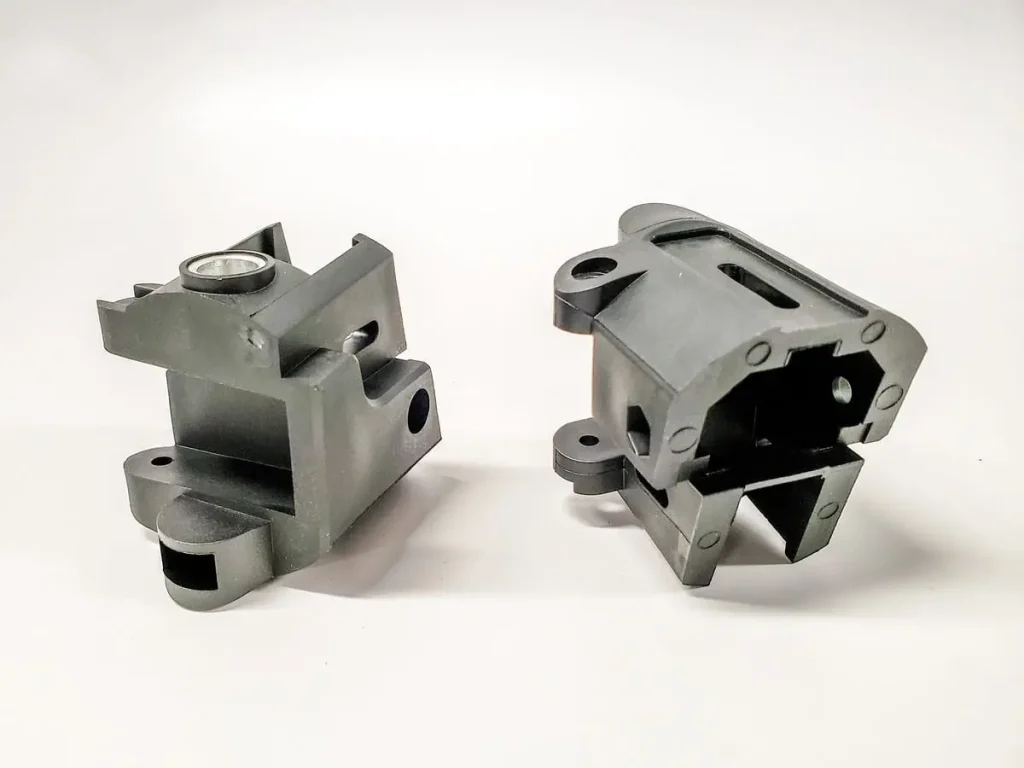

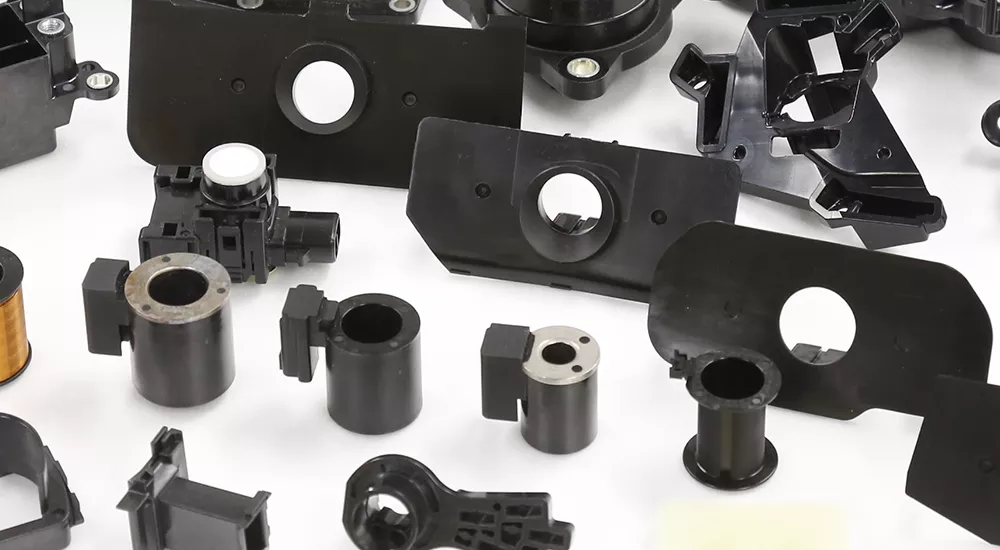

Elimold provides advanced plastic injection molding services specifically designed to meet the demanding needs of the oil and gas industry. In environments with extreme temperatures, high wear and constant exposure to corrosive chemicals, component durability and reliability are critical. With precision manufacturing capabilities and industry-specific expertise, Elimold is a trusted partner to global oil and gas product manufacturers and the manufacturer of choice when looking to create high-performance plastic parts that withstand the rigorous conditions of oil and gas operations. With decades of expertise in oil and gas plastic part injection molding, we provide durable components to meet the rigorous requirements of every stage of oil and gas production. Elimold offers complete design flexibility to meet the specific requirements of the oil and gas industry. Our injection molding process allows for complex geometries and intricate designs, allowing us to produce custom parts to your specifications. From downhole tools to pipeline components, we can manufacture parts with precise details and tight tolerances.

Oil & Gas Injection Molding Plant Capabilities

When you work with Elimold, we get involved early in product design and development projects to optimize product specifications, performance criteria, material selection, and manufacturability. By leveraging our resources during the design phase, we can address all issues early in the development cycle, helping to control expenses and reduce time to market. We can combine the design flexibility of injection molding with engineered plastic resins that offer exceptional strength and durability, and we can engineer metal-to-plastic conversions to improve component integrity while reducing weight and cost.

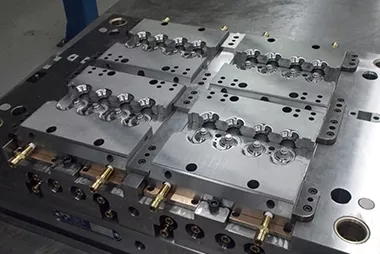

In addition, our modern, well-maintained, state-of-the-art facility features equipment rated from 60 to 3,500 tons, handling shot sizes from less than 1 ounce to 185 ounces. As a turnkey supplier for oil & gas injection molding projects, we have a team of mold and tool professionals, as well as an in-house injection mold making shop. Well-designed, precision-made, and meticulously maintained tools, combined with advanced process controls, enable us to hold tight tolerances. We also offer numerous value-added services to streamline your supply chain while providing measurable cost savings.

Furthermore, we have invested considerable time and resources in developing our ISO 9001:2008 quality management program, which places a high priority on all factors involved in the production process and fosters a culture of continuous improvement. As a result, we are able to manage both small projects as well as projects requiring tens of thousands of units on very short notice.

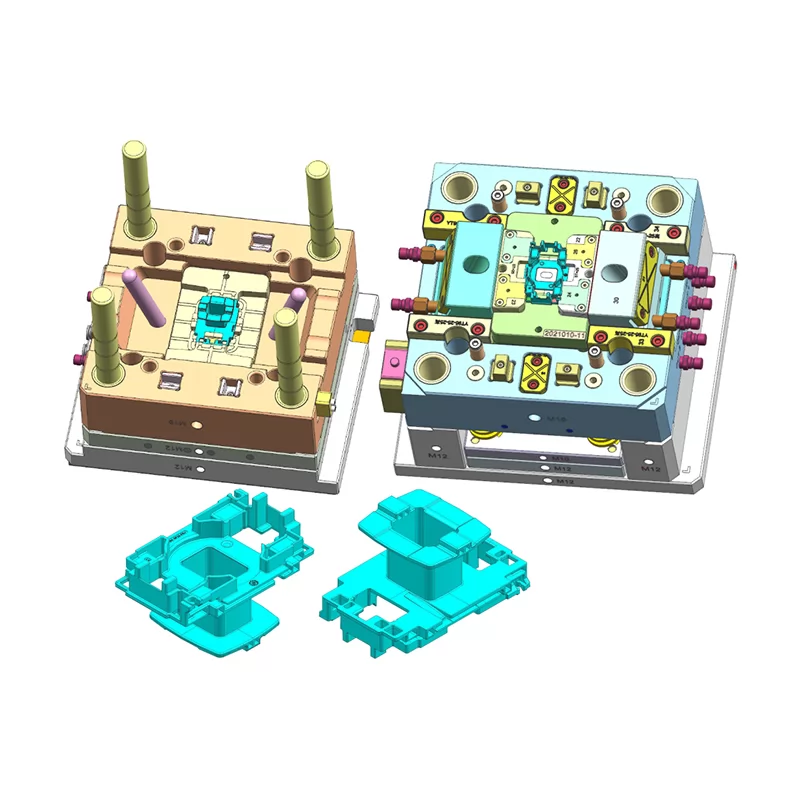

In-house mold making and maintenance

Elimold has a long history of manufacturing and maintaining high-precision production tools and small-batch prototype tools for the needs of customers in the oil and gas industry. Our fully equipped mold shop, in cooperation with our engineering team, can take your products from design to production. High-performance injection molds and handling equipment are designed and manufactured by our in-house mold and tool making department and precision CNC machining on modern CNC machines. In addition, our selected reliable external partners support us in meeting all customer requirements. Our mold experts perform intensive series accompanying and preventive maintenance of injection molds, ensuring consistent quality, flexibility and fast response times for the produced oil and gas injection molded parts series. One of our core competencies is the design and manufacturing of injection molds. Excellent tool expertise is the basis for top quality in the series production of oil and gas injection molded parts with the highest technical requirements. Our selected reliable external partners also provide satisfactory support to our customers.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

How We Can Help

Through our expertise in plastic injection molding, parts manufacturing, and metal-to-plastic conversions, Elimold is uniquely positioned to help industrial manufacturers serving the oil and gas industry, to meet the challenges of today’s market head-on. We work as a strategic partner with these manufacturers, helping them find ways to reduce cost without shirking their commitment to serving their customers effectively. Sometimes, the solution might be designing plastic parts to replace their more expensive metal counterparts. Other times, it might be merely providing more durable parts for long-term industrial use. We help manufacturers consider their costs, products, and customers, and come up with solutions that trim overheads without sacrificing quality or durability.

Strong capabilities in small series and prototyping

Avoiding errors is particularly important during product development. As early as the product prototyping phase, we use tools such as FEM and Moldflow simulation to optimize and coordinate product design and tool concepts. The consistent application of product and process failure mode and effect analysis (FMEA) ensures that any impact on the product or application is identified at an early stage. Supplier development and close cooperation on purchased materials, including the necessary qualifications, are also part of our product introduction process. We also meet requirements such as APQP, PPAP and even certificates of conformity. In addition, for many applications in the oil and gas industry, we can also use injection molding for rapid prototyping and small series production. We rely on efficient tool and mold concepts as well as flexible automation solutions that support our employees in the subsequent process steps. Elimold also offers 3D printing services for creating test samples, which rounds off our capabilities.

Ready to get a quote for your oil and gas injection molding project?

Elimold can design and manufacture nearly any type of plastic component or part needed for any oil and gas injection molding project. Contact our engineering team today for a free instant quote.

Find Oil & Gas Injection Molding Solutions with Industrial Injection Molding

We have a variety of unique OEM plastic injection molding services to meet your needs, no matter where you are in the product lifecycle. Our prototype injection molding process can help you reduce your product development cycle by weeks (sometimes months) and achieve production with injection molded parts in days. Our on-demand plastic injection molding services are designed to meet your production needs and help you quickly certify parts through scientific injection molding, in-process CMM inspection and a full set of secondary operations to seamlessly move into mass production, ensuring your parts will appear and perform as expected.

- Prototype stage and all you need is a couple of parts

- Low volume projects, 50-5,000 pieces

- Multiple programs, but low volume

- High volume contract manufacturing project with millions of parts needed annually

Serving companies in the oil and gas industry

- We are committed to procuring the most suitable materials for the Oil & Gas industry. Our advanced injection moulding machines offer a broad selection of plastics, providing remarkable flexibility in product design and order sizes, all tailored to meet the unique needs of the Oil & Gas sector.

- We will work closely with you throughout to ensure your total satisfaction.

- We will attend to the details – from initial design consultation through to prototype design and full-scale production.

- We will minimise the chance of delays in the supply chain process by arranging delivery straight from our premises to an end user’s warehouse or construction facility.

Quality assured by a strong QMS

Elimold’s Quality Management System (QMS) for the oil and gas injection molded parts it produces is based on recognized standards and includes important aspects such as statistical process control and continuous improvement programs. Our QMS complies with international quality system standards. And we confirm these standards through internal and external audits and continuously develop our work processes. Our global injection molding plants in China are ISO 9001:2015 certified. In addition, our processes are tailored to the requirements of the oil and gas industry. Our quality management system complies with international standards and we are committed to ensuring the highest quality, safety and traceability of injection molded parts. Ensuring quality for our customers is our top priority in all areas of our business. Our injection molding and plastic manufacturing processes provide your business with high-quality oil and gas parts and components by using state-of-the-art measurement and control equipment, a fully implemented quality management system and appropriate inspection services.

Measuring systems and equipment

Elimold’s quality management system ensures the quality of oil and gas products through process measurement, testing and laboratory technology. We use fully automatic optical inspection systems to monitor oil and gas injection molded parts during production. Our modern and extensive laboratory measurement equipment complements the quality assurance of our products. The systems and equipment we use include:

- Contact 3D coordinate measuring machines

- Tensile and compression testing machines

- Profile scanners/profile recorders

- Roughness measuring devices

- Other component-specific test systems and measurements

Material Options

Material selection should be based on material properties, manufacturing characteristics, appearance and cost. With over 300 engineering thermoplastic materials, Elimold’s team of materials engineers has the expertise and experience to manufacture oil and gas plastic parts using a wide variety of plastics.

- ABS

- Acrylic

- Acetal

- ASA

- Nylon

- PEEK

- Polycarbonate

- Polyester

- Polyethylene

- Polyimide

- Polypropylene

- PPO

- Styrene

- Thermoplastic

- TPR

- Stainless Steel Fiber Filled

- With / Without Glass

- Carbon Filled

Assembly Capabilities

Elimold provides top-notch assembly services for a variety of oil and gas applications, from simple part joining to complex electromechanical equipment production. Our toolmaking expertise enables us to design and manufacture fixtures that minimize costs for our customers. In addition, we often produce all components required for assemblies that require plastic and metal parts. Our team of skilled experts uses a variety of assembly processes such as manual assembly, ultrasonic and heat welding, heat staking, bonding, taping and labeling to provide a high-quality finished product that meets our customers’ exacting standards.

Oil and Gas Parts We Produce

As a global leader in oversized, void-free, custom molded products, Elimold is able to produce parts for the most demanding industries. Our experienced engineers and unique process capabilities are uniquely suited to the harsh environments and tight specifications of injection molded products in the oil and gas industry. Elimold offers a wide range of plastic injection molded parts for the oil and gas industry, including:

- Specialty Electrical Connectors

- Platform Bumpers

- Clamps

- Subsea Umbilicals

- Strain relief or bend restrictors

- Pump Impellers

- Dock bumpers

- Drill string clamps

- Fittings

- Hydrocyclones

- Ballast Protection

- Bend Restrictors

- Bend Stiffeners

- Cable Centralizers

- Cable Crossing System

- Cable, and Umbilical protection

- Centrifugal Pump Components

- Desanding hydrocyclones

- Diaphragm Pump Components

- J Tube Seals

- perforating

- Frac Balls

- Pipe Centralizers

- Corrosion protection at pipe Joints

- Extruded Pipe Liners

- High Temperature Seals

- Piggy Back Clamps

- Pipe end protection

- Pipeline strakes

- Pony rod Seals

Request Your Free Oil & Gas Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom Oil & Gas plastic injection molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.