CNC Turning Services

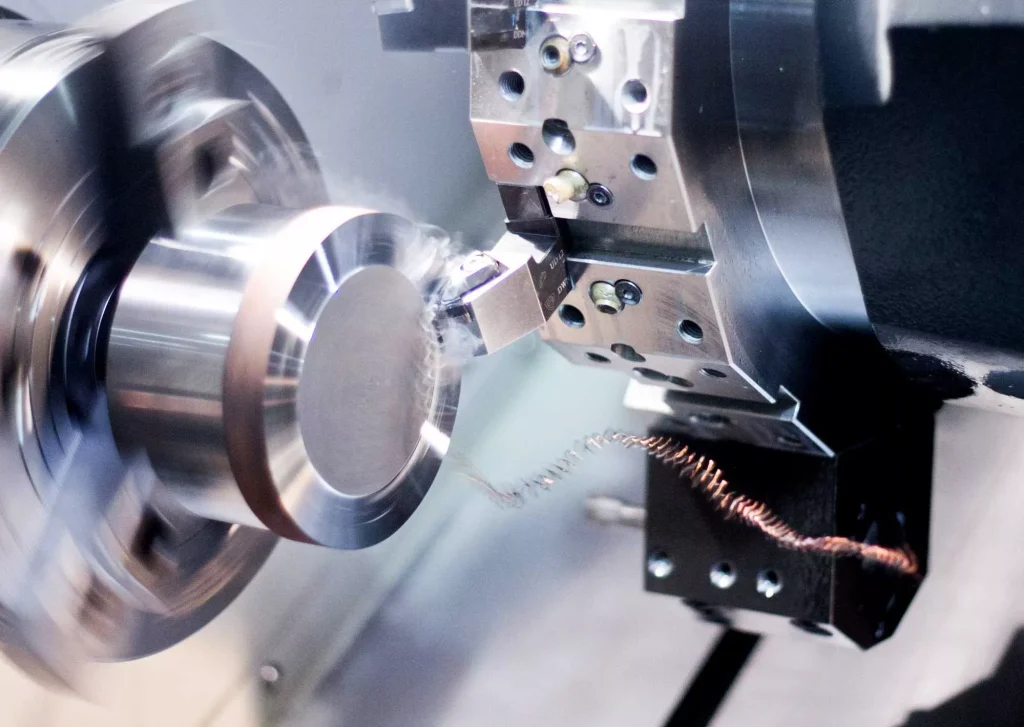

We are someone you can trust. Our ISO 9001 certified CNC turning service can machine parts to precise tolerances up to ±0.005”, standard tolerances are ISO 2768-m for metals and ISO 2768-c for plastics. We provide design advice and transition to production services to help you downsize your part designs and actual products.Our dedicated engineering team is ready to help you with rapid prototyping and low-volume machined parts.Contact us today to experience the CNC turning difference.

Online CNC Turning Services

CNC Turning manufacturing includes internal and external cylindrical surface machining, end surface turning machining, drilling machining, threading machining, complex shape and profile machining, and complex contour rotary surface, etc. Drills, reamers, taps, threading dies, knurling and CD texture tools can also be used on the CNC lathe for corresponding processing. It is the most widely used type of machine tool in mechanical manufacturing and repair factories.

Elimold is honored to provide high precision CNC turning services in our world-class factory. Our precision CNC turning service has unparalleled quality and accuracy, and is well-known and respected throughout the industry. We can ensure that every part produced can meet your requirements and even exceed your expectations. We have been working to improve our process by adding new advanced equipment and technology. With 10 years of CNC turning experience, our reputation for quality is constantly improving.

Advantages of Our CNC Turning Services

- High efficiency. We can produce 1-1000 CNC milling and turning parts as fast as one day with our equipment.

- Excellent Precision. Based on customer demands, Elimold will provide precise and accurate measurement and production for each product.

- Exact Specifications. Automatic CNC milling-turning center will perform the designed motions to get required parts with exact sizes, shapes and other parameters.

- Competitive Prices. With advanced CNC machining services and increased productivity, we can bring you the most cost-effective and affordable custom solutions.

- Quality Guaranteed. Carefully picked raw materials and strict quality control system throughout the whole project, ISO9001:2015 certification Etc.

- Fast Delivery. Average 7 days turnaround time and 99.80 on-time delivery rate.

Efficient CNC Turning Capabilities

We produce turned metal parts to tight tolerances for all applications in a wide range of industries using state-of-the-art CNC lathes. Using metal bar stock up to 2.5″ OD, we can machine surfaces and planes to tolerances up to ±0.0005″ and feature locations and profiles to ±0.0005″.

Even the most complex or sophisticated part designs can be accurately reproduced with perfect repeatability from the first to the 100,000th piece. We work from your CAD or other digital design files to provide precision turned parts to your exact specifications. DFM services are available. Elimold specializes in high-volume CNC turning. We can turn and machine tens to hundreds of thousands of parts or more. This enables us to run our CNC lathes for extended periods of time with a single tool setup, resulting in faster, more efficient production. We have non-stop manufacturing capabilities, including “lights out” production using automated CNC technology, enabling 24/6 production.

Full range of processing solutions

Elimold focuses on completing the entire process from design to production on time and within budget, but we also help customers transform ideas into fully realized products. Our experts will work with you to develop concepts, select the right materials and start full production. We can provide parts in finished, semi-finished or blank state. With our semi-finished and blank services, you can complete time-consuming tasks. Therefore, subsequent processing will be faster and more convenient.

Design for Manufacturing (DFM)

We offer DFM services to help make part production faster, easier, and less expensive. Our engineering team will work with you, as needed, to optimize your designs for better manufacturability, without altering the fit, form, or function of your turned parts.

In-House Tooling Shop

We design, build, and service all tooling for our CNC turning projects in-house. We monitor every step of the process to ensure the precision and quality of your finished parts. All tooling is custom built to each project, and we will service and maintain your tooling for the life of your program, whether you need ten thousand or ten million parts per year.

Elimold offers additional services in-house to save you time and money on your project, shorten your supply chain, and decrease the possibility of hiccups or oversight.

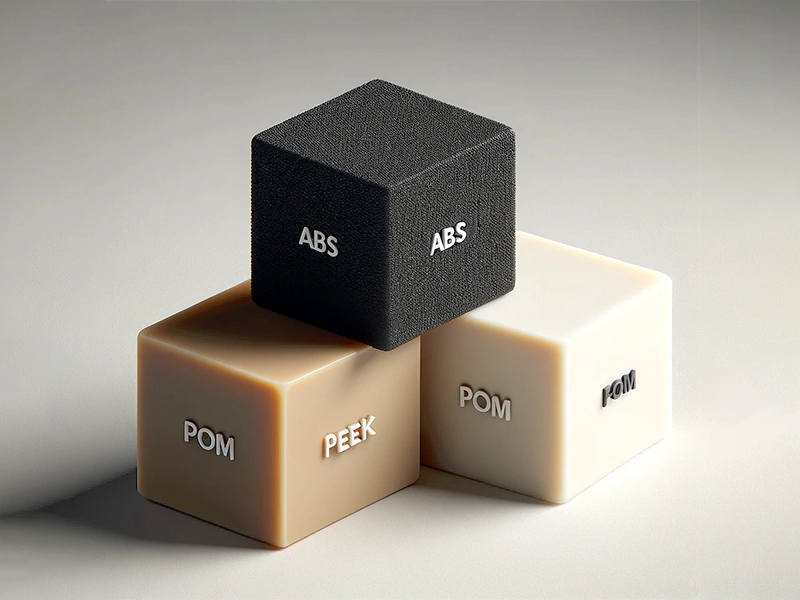

Materials We Work With

At Elimold, we hold extensive experience with diverse metal and plastic materials, which enables us to meet the complex requirements of our clients from various industries. The following are a few popular materials that we regularly work with.

Plastic CNC Turning Materials

We regularly work with the following types of industrial-grade engineered plastic materials:

- PEEK

- Ultem®

- Polyethylene

- Nylon

- PTFE (Teflon)

- UHMW

- Torlon

- PVC

- Vespel

- Acetal

- Acrylic

- PSU

- Derlin

- ABS

- G-10 Garolite

- Polycarbonate

Metal CNC Turning Materials

We perform CNC turning parts production using the following metals:

- Aluminum

- Alloy Steels

- Brass

- Bronze Alloys

- Stainless Steel and Copper

- Zinc and Zinc Alloy

- Mild Steel

- Titanium Grade 2 and 6Al-4V

Surface Finish Options for Turned Parts

Parts that are turned typically have a very smooth surface finish. The as-machined surface finish of the cylindrical areas will typically be much smoother using the lathe than the mill, so consider this when selecting the machining method for those parts that qualify for either method. Areas cut with live tooling, such as flats and slots, may have visible tools marks.

If desired, the metal parts can be lightly bead blasted leaving a fine matte finish. Hard metals like steel and stainless steel can also have edges broken (deburred) with a light bead blast to remove metal slivers, and sharp or rough areas.

Post Processing And Finishing

- Pad Printing

- Powder Coating

- Bead Blasting

- Surface Grinding

- Polishing

- Anodize

- Powder Coat Passivate

- Chemfilm

- Vacuum Metallization

- Silkscreen

- Plating

- Tumbled

Ready to get started on your CNC turning quote?

CNC turning services in China. As a leading contract manufacturer of precision-machined products across the China, the turning services at Elimold deliver not just faster parts, but more accurate and impeccable results every time.

With 10000+ of square feet to house CNC turning centers, lathes, and the most cutting-edge CNC machining technologies, we have the capacity to turn out thousands of identical components in a short amount of time, even with the most demanding specifications. Our quality management system allows us to complete every project—from prototyping all the way to shipping—in the most efficient way possible.

Let us handle your short, medium, and long-run productions as well as all of your other manufacturing needs! To talk about your CNC turning in China, project in more detail or to learn more about partnering with Elimold, please contact us or send email [email protected].

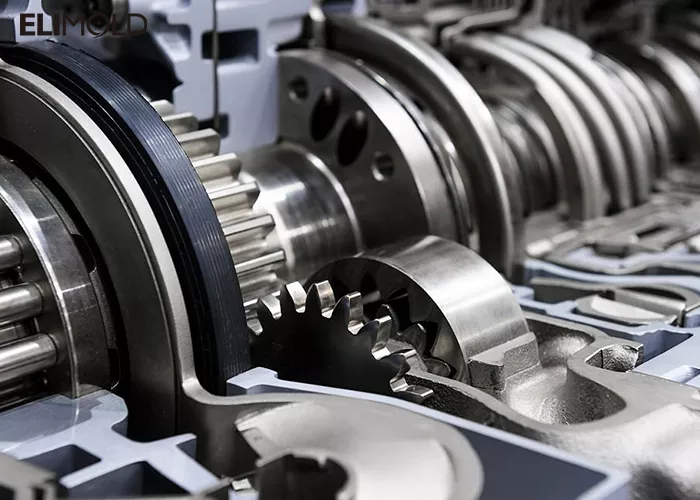

What is CNC Turning?

CNC lathes, also known as powered lathes, are ideal for cutting any symmetrical cylindrical or spherical parts. Characteristically, the lathe rotates the workpiece on a vertical or horizontal axis while a fixed forming tool moves around the workpiece in a more or less linear path. The operation of cutting a workpiece on a CNC lathe is called turning.

CNC lathes use a subtractive approach to create the desired shape. After the G-code is created, a blank piece of stock material is loaded into the chuck of the lathe spindle. The chuck holds the workpiece in place while the spindle rotates. When the spindle reaches a rotational speed, the fixed cutting tool engages the workpiece to remove material until the desired geometry is achieved.

Many operations can be performed on a powered lathe, including facing, thread turning, knurling, drilling, boring, reaming, and taper turning. Different operations require tool changes, which increases costs and setup time.

When all machining operations are completed, the part is cut from the stock for further post-processing. The CNC lathe can then repeat the operation with virtually no setup time in between.

CNC Turning vs CNC Milling

CNC milling and turning allow users to create patterns and add detail to metals that are impossible to do by hand. However, CNC Milling and CNC Turning are very different processes that usually end up with entirely different results. They both use computer programming to achieve their end results, but the differences lie in the way their finalized parts are created.

For example, CNC milling drills and turns its material along an axis to cut its materials to their specified dimensions. Conversely, CNC turning uses a single-point cutting tool that maintains a parallel insert to cut its intended material. Furthermore, the material is rotated at changing speeds at which the cutting tool traverses to make its specified cylindrical cuts. The form, shape and dimensions of the finalized product will dictate whether CNC milling or CNC turning is appropriate for your given project.

CNC Turning Project With Elimold

Design Considerations

- As the turning process applies pressure to the material, weak shapes that may flex can be difficult to machine, such as long thin structures.

- Turning generates a cut surface with fine helical feed marks resulting from the rotation of the part and movement of the cutter – consider specifying a desired surface roughness.

- Bored holes become difficult when the ratio of the depth to diameter is high.

- CNC turning is the only industrial process to choose when making production volumes of concentric shapes or threaded features. And, because of the rigid construction of these machines there is little vibration, which means CNC turning can offer high levels of dimensional accuracy with excellent surface finishes.

- Combine with our other processes, such as CNC machining, EDM, low- volume production, prototype models, and surface treatments etc., to save costs for you while ensuring quality and service.

Need A Reliable Manufacturer You Can Count On For High Quality Parts Again & Again?

Have a prototype that needs perfecting? Looking for higher quality returns on your production parts? We Can Help Your Concepts Through To Completion. Our CNC Machining services have the capacity, capabilities, and resources to provide turn-key solutions that will help you achieve your goals.

Types of CNC Turning Processes

There are many types of CNC turning operations for CNC services that can be performed on a live tooling lathe in a CNC turning factory, including Hard turning, Parting, Facing, Boring, Reaming, Taper turning, Drilling, Knurling, Threading, Grooving, etc., comes in varying tools, cost and set-up time.

1. Tapered turning: produce a cylindrical part of which diameter decrease from one end to another.

2. Hard turning: suited for materials with a Rockwell C hardness greater than 45, typically performed after heat treatment.

3. Spherical generation: create a spherical finished surface, turning around a fixed rotary axis.

4. Facing: a turning operation in which the workpiece is machined to its center.

5. Parting: create deep grooves that remove a completed or part-complete component from its parent stock.

6. Grooving: similar to parting, but only cut to a specific depth from outside or inside the workpiece.

7. Drilling: remove materials to drill holes inside a workpiece with drill bits held stationary in the tail stock or tool turret of the lathe. Boring: enlarge or smooth an existing hole.

8. Knurling: cut a serrated pattern onto the surface of the workpiece with a knurling tool to change or enhance the visual effect or hand grip.

9. Reaming: remove a small volume of materials from a drilled hole for highly accurate diameters.

10. Threading: turn standard and non-standard screw threads, which generally means single-point threading.

11. Polygonal turning: non-circular forms of machining operation without interrupting the rotation of the raw material.

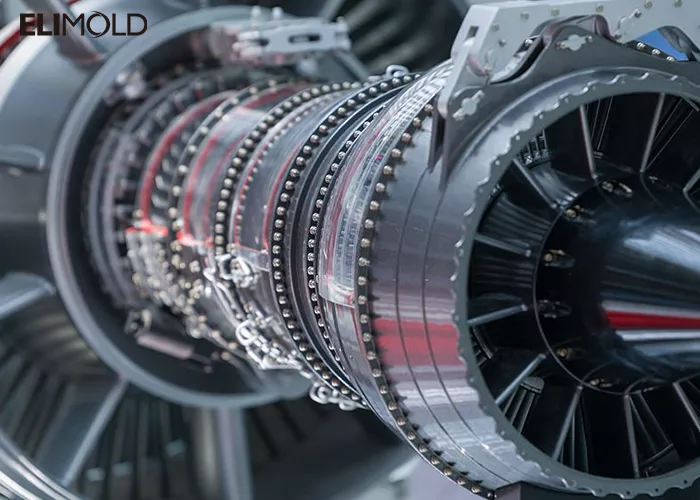

Industries We Serve

Manufacturers producing complex, critical, and precision products rely on CNC Turning capabilities to deliver the parts needed at the highest quality, greatest speed, and best comparable price.

Working with experienced and certified CNC machine shops provides a wide range of manufacturers, in a variety of industries, with the high-quality components required.

Get An Accurate Quote For Your Next Projects

Working with Elimold can help you overcome production set backs by providing support, quality, and timely delivery of CNC machined parts. Our dependable performance and quality are top notch. We have a 99.7% on time delivery record to prove it. Avoid the pricey commission fees from middlemen and hire us for all your precision CNC machining & parts needs.

As an industry leader in machining, turning, and milling services, our team knows what our clients require for long-term and sustainable success. We can choose the best machining service to meet your production targets on time and within budget.