Sheet Metal Fabrication Services

- Material thickness anywhere from 20-gauge (.0359”) through ½ inch (.500”)

- Quantities from a few to thousands of parts

- Sizes from small to very large up (14 feet deep by 7- 8 feet wide and 8 – 9 feet tall)

Our 140,000 sq. ft. facility houses multiple lasers, press brakes, manual and robotic welding, finishing stations, a conveyor engineered paint system, off-line paint system, and component assembly.

Our Service

Elimold offers precision sheet metal fabrication for industries ranging from furniture to defense. At our ISO 9001:2008 certified facility we employ modern turret punch presses and brake presses to manufacture small and medium components, and meet MIL-I-45208A inspection system requirements. Fabrication processes include but are not limited to punching, forming, shearing, laser cutting, and grinding. We also offer expert welding including TIG and Heli-Arc. We work with a range of materials including cold and hot rolled steel, stainless steel, aluminum, and brass, all of these in forms such as coil, sheet, bar stock, tubing, and plate. Our capabilities can accommodate a wide range of finishes including chrome, dip brazing, and powder coat as well as custom finishes.

Choose Elimold for Your Needs

1. Expertise

Our team of skilled professionals, with years of experience in sheet metal fabrication, is dedicated to delivering top-quality results for your projects.

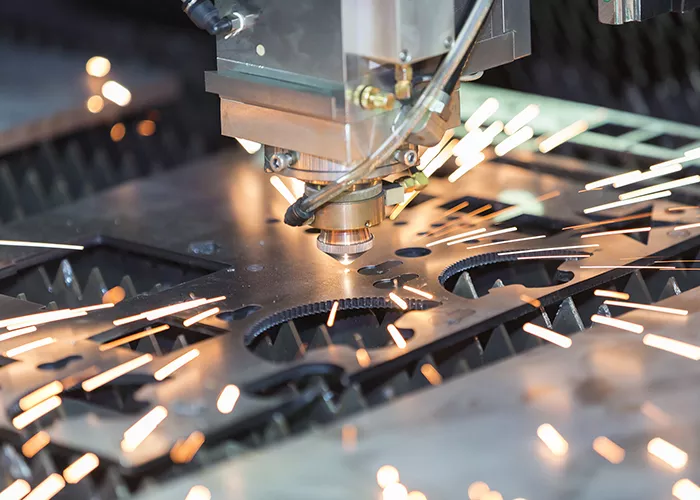

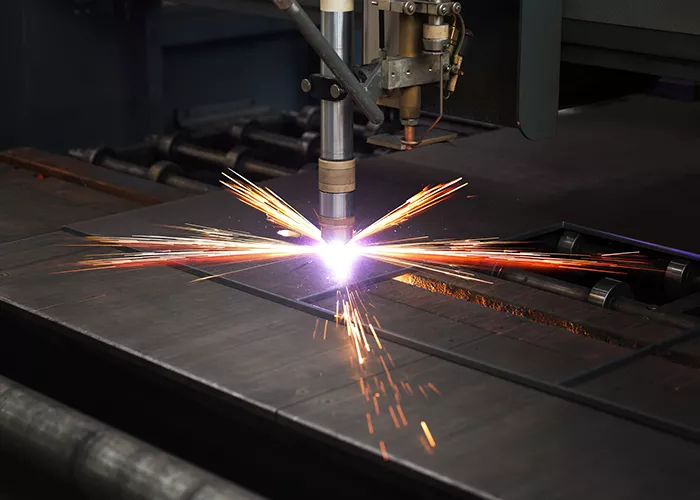

2. Advanced Technology

We employ cutting-edge equipment and techniques, ensuring your sheet metal components are produced with precision and efficiency.

3. Custom Solutions

We work closely with you to understand your unique requirements, providing tailored solutions that meet your specific needs.

4. Competitive Pricing

We offer fair pricing for our sheet metal fabrication services, ensuring you receive the best value for your investment.

5. Global coverage, Local Speed

Distance is no barrier to us. We are ideally located in the heart of China’s major shipping network, enabling us to ship products around the world, often faster than your local store. Our commitment to efficient processes and fast delivery means that no matter where you are in the world, you’ll receive high-quality custom sheet metal components right when you need them. When you choose Elimold, your location becomes an advantage, not a problem.

Get started on your sheet metal project today by contacting our expert team at Elimold, and let us help you save money, space, and time while delivering exceptional results.

What can we do for you?

We have high speed, state of the art sheet metal fabrication equipment that is best suited for repetitive, low-to-high volume and high-mix production runs. As a complete tool and die shop, we are skilled in all areas of fabrication including fiber laser, CNC punching, CNC bending, CNC forming, welding, CNC machining, hardware insertion and assembly. Many of our processes are automated, such as the material handling on our two 5000-watt fiber lasers, allowing us to run minimally attended or even lights out. We can handle any portion of your project from laser cutting flat blanks to providing you with a full assembly ready to ship to your customer. Our on-time delivery average is 98%.

Sheet Metal Services Available at Elimold

Benefits of Custom Metal Fabrication

Unique requirements necessitate custom parts that fit and perform exactly as intended. Custom-fabricated and machined parts bring many benefits, including:

- Receiving exactly the parts you need, when you need them, at a competitive price

- Precisely cut, formed, welded, and machined on specialized, advanced machinery

- Inspection with instrumentation calibrated on a regular basis in order to provide consistent quality

- Fine craftsmanship, guided by highly qualified engineers, managers and operators

- Custom metal parts made from materials that comply with your every requirement

- Custom finishes to your exact specifications

Contact with Elimold

Contact us to discuss your custom sheet metal fabrication needs and for a price quote on your next order. Our exceptional customer service team will be happy to assist you. Elimold will work with you to ensure that sheet metal components, materials, dimensions, and finishes are in line with your manufacturing requirements. Our goal is to fulfill your precise manufacturing needs with quality and consistency. For long and short runs, we offer specialized sheet metal fabrication services that you can depend on.

Tolerances

| Feature | Tolerance |

|---|---|

| Cutting feature | ±.0078″(0.2mm) |

| Bend angle | ±1.0° |

| Bend to edge | +/-0.010″(0.254mm) |

Capabilities

| Fabrication Processes |

|

|

| Laser Cutting | CO2 & Fiber Optic Up to 5’ x 12’ Laser/Punch Combination Equipment Auto Loading/Unloading | |

| CNC Punching | 48” x 96” Multi-Station Turret | |

| CNC Water Jet Cutting | 5’ x 10’ Capacity | |

| CNC Forming | Multi-Axis Gaging Up to 175 Ton & 10’ Long | |

| Welding Processes |

|

|

| Equipment |

|

|

| Equipment Axis | Up to 9-Axis Bending | |

| Fixturing | In-House Fixturing & Tooling | |

| Sheet Length | Up to 144″ | |

| Sheet Width | Up to 60″ | |

| Tolerances | ±0.005″ Typical Tighter Tolerances Held According to Specifications | |

| Materials |

|

|

| Testing & Inspection Equipment |

|

|

| Welding Inspection |

|

|

| Finishing Services |

|

|

| Plating Services |

|

|

| Coating Services |

|

|

| Additional Services |

|

|

| Inventory Management Services |

|

|

| Production Volume |

|

|

| Lead Times Available |

|

Additional Information

| Industry Focus |

|

|

| Types of Components |

|

|

| Industry Standards |

|

|

| File Formats |

|

|

What Is Sheet Metal Fabrication?

Sheet metal fabrication is the process of forming a piece of metal into a desired shape through bending, stretching, and removal of material. At Elimold, we use press brake punches and die tooling to bend and stretch flat stock into its final geometry. The sheet metal prototyping process is most often used when form, fit, and function are all a priority. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets.

Why use sheet metal fabrication?

Sheet metal fabrication provides a solution that lasts longer than other products with similar uses. For example, you may get a similar shape and function using casting. However, a cast doesn’t have the same durability and longevity you get with metal.

When you need precision, sheet metal fabrication allows you to cut, bend, and shape the metal the way you need it. Metal gives you a material that not only conforms to its new shape but holds it indefinitely.

In industries that need materials to survive impacts or harsh conditions, metal far outstrips plastics of any kind when it comes to strength. Fabricating sheet metal is also a faster and more cost-effective alternative to other methods of creating similar products.

Learn More About Contract Maunfacturing

Contract manufacturing is the process of working with a third party manufacturer to produce products for your business. Whether it’s because you don’t want to buy all the necessary fabrication equipment yourself, or you don’t feel like staffing an entire fabrication crew, contract manufacturing could be the solution you need!

Elimold specializes in working with entrepreneurs as a contract manufacturer. All you need is a good idea — even a design scrawled on a restaurant napkin will do. Bring your idea into our shop and our expert engineers will help you turn your inspiration into a fully formed design and specification.

Have a project?Get a quote

At Elimold. we take pride in being an industry-leading sheet metal fabrication company. Whether you are an established company in a global industry, or an entrepreneur looking for a contract manufacturer, we are the company for you. Contact us today to learn how our metal fabrication services can help you save costs and complete your project on time.