Multi-Axis CNC Machining Services

If you need parts created in a cost-effective manner, our multi axis CNC machining services are probably the most applicable solution. We offer a full range of multi axis machining options, providing high-grade solutions that are suitable for a range of applications. If you want to work with a dedicated team that puts quality at the center of their operations, we can help.

Multi Axis Machining Services at Elimold Company

Are you looking for a more efficient and accurate solution to your manufacturing needs? Look no further than Multi-Axis Machining!

With Multi-Axis Machining, you can achieve unparalleled precision, and accuracy in your processes. Our state of the art technology allows for complex designs and shapes to be easily produced with little to no human intervention. Plus, our machines are designed to handle a wide range of materials, from plastics to metals, ensuring that your product is manufactured with the highest quality standards.

Our team of expert technicians are highly trained and experienced in operating our Multi-Axis Machining equipment, ensuring that your project is completed on time and to your exact specifications. And with our competitive pricing, you can rest assured that you’re getting the best value for your money.

Whether you’re in aerospace, automotive, medical or any other industry that requires precision manufacturing, Multi-Axis Machining has the solution for you. So why wait? Contact us today to learn more about how we can help you take your manufacturing to the next level!

Ultra-precision machining capabilities and cost savings

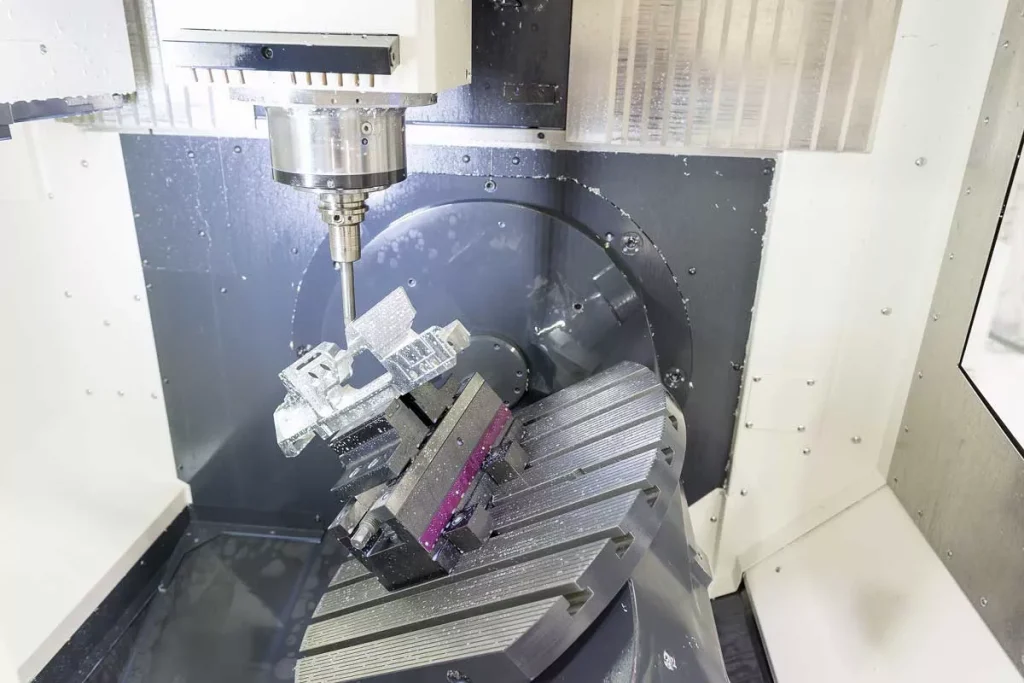

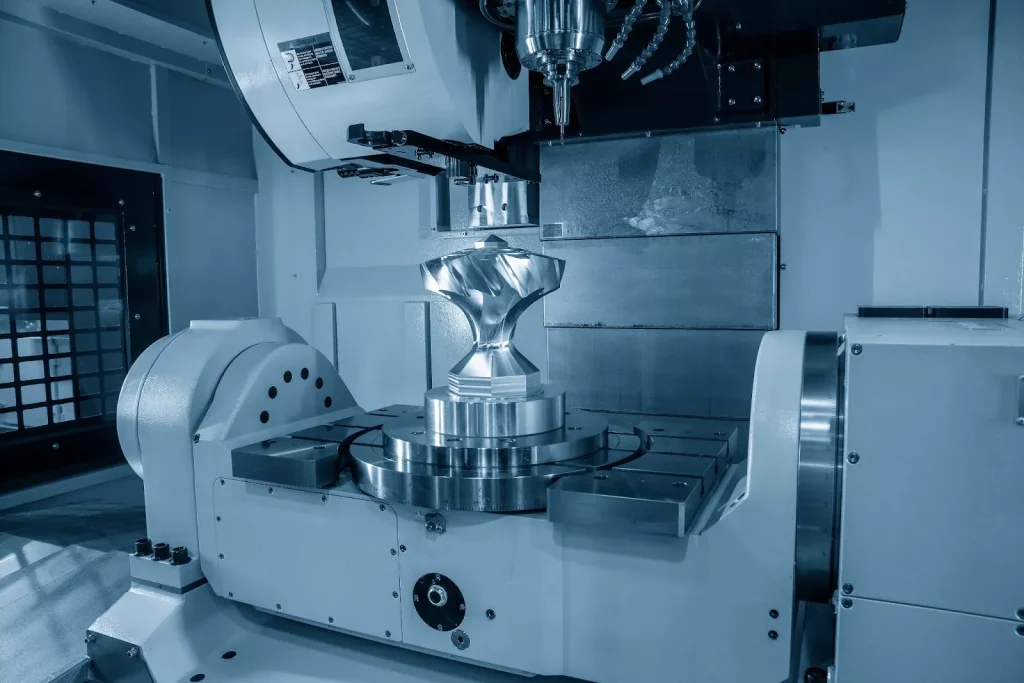

Backed by extensive experience and unparalleled creativity, the Elimold team conquers complex part manufacturing with state-of-the-art multi-axis CNC machining. Multi-axis platforms can cut part geometries and complex shapes not possible with other machining methods due to excellent mobility of the workpiece to the tool’s axis of rotation. This enhanced 6-sided machining capability improves accuracy by combining multiple independent operations, significantly reducing part handling and multiple clamping stages during machining. The spindle head operates closer to the workpiece, allowing the use of shorter cutting tools, less vibration and deflection, higher cutting speeds, tighter tool movements, and increased surface finishing capabilities.

Cost savings are another huge benefit of multi-axis technology. Consolidating 3-axis machining and other linear axis operations into a single unit increases throughput while reducing cycle times, expensive work fixtures and overall waste. It provides a more efficient and cost-effective solution with faster delivery times and production turnaround and superior quality.

Machining Capabilities

Our full complement of high-quality machinery allows us to deliver a range of services that enable precision manufacturing of complex and mission-critical parts.

Part Types:

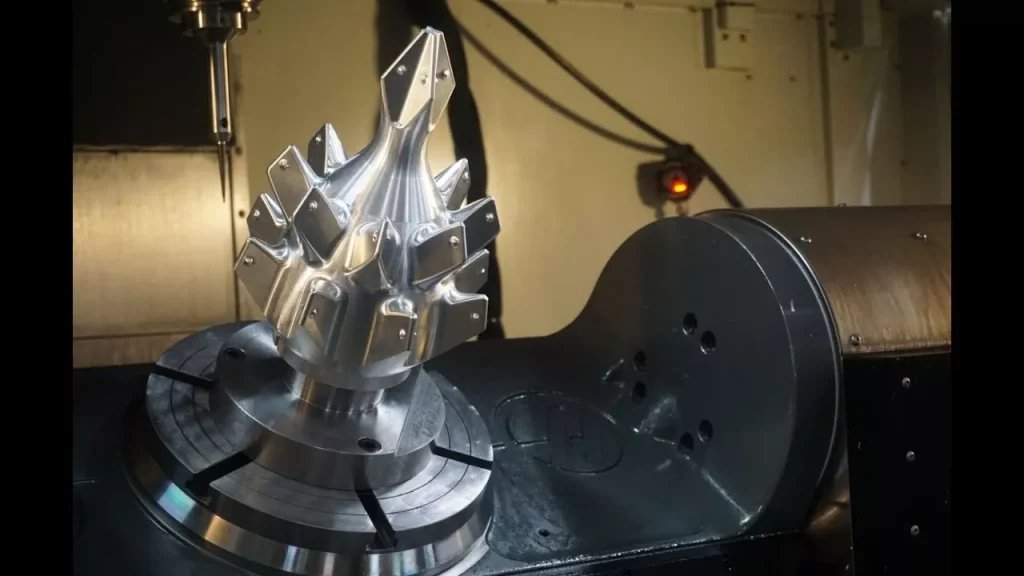

Impellers, turbines, eccentric axis, multifaceted, irregular, convex and concave parts

Part Size:

27.5” x 120”

Metal Types:

All standard metals, aluminum, armor plate, brass, bronze, chromium, copper, gammalloy, Hastelloy, Incoloy, Inconel, Invar, manganese, Monel, nickel, Nitralloy, powdered metals, stainless steel, Stellite, titanium, Waspaloy, and many other superalloys

Material Types:

Castings, forgings, fabricated weldments, billets, and bar stock

Multi-Axis Processes:

Boring, broaching, counterboring, countersinking, cutting, drilling, facing, gear hobbing, internal forming, knurling, axis milling, parting, pocketing, profiling, reaming, spline, tapping, threading (external, internal), turning (contour, form, taper, straight), and thread milling

Industries Served:

Aerospace, Defense, Food Processing, Heavy Equipment, Medical Equipment, Military, Mining, Oil & Gas, Power Generation, and Transportation

Tolerance

| Tolerance of Metal(mm) | Tolerance of Plastic(mm) | |

| Linear Dimensions | ±0.01 | ±0.05 |

| Diameter | ±0.002 | ±0.02 |

| Precise Hole | ±0.002 | ±0.02 |

| Chamfer Heights | ±0.02 | ±0.05 |

| Angular Dimensions | ±0º5′ | ±1º |

| Straightness | ±0.002 | ±0.02 |

| Flatness | ±0.002 | ±0.01 |

| Perpendicularity | ±0.002 | ±0.01 |

| Symmetry | ±0.002 | ±0.01 |

| concentricity | ±0.002 | ±0.005 |

| parallelism | ±0.001 | ±0.01 |

Complex, Critical Parts Require Precise and Tight Tolerance Machining Techniques

Behind the most complex aerospace and defense parts in the world is multi-axis machining. There is no room for manufacturing error when so much rests on the mission-critical performance of each component, and we ensure our solutions meet or exceed even the most stringent customer and program specifications.

Multi-axis CNC machining accuracy has passed AS9100D / ISO 9001:2015 quality standard certification

Our multi-axis precision CNC machine shop is AS9100D and ISO 9001:2015 certified and DDTC/ITAR registered. From the aerospace and automation industries to cutting-edge industrial manufacturing applications, Elimold thrives in processing hard materials, complex custom machined castings and forgings.

What is Multi-Axis Precision Machining?

A multiaxis machining center has a variable speed tool spindle head with a multidirectional rotary axes orientation. Raw material clamps into an indexing chuck or to a table. The spindle head assembly moves along the travel columns in unison with the chuck or index table to precisely maneuver the workpiece and cutting tool to achieve the proper cutting path required for removing material. Multi-axis machines lend themselves to a single setup, infinite geometry cutting, excellent chip management, longer tool life, repeatable manufacturing, and the speed of simultaneous 5-axis high precision machining. Like a standard milling machine, this is a subtractive manufacturing process.

Advantages of multi-axis machining

- Enhanced precision: Multi axis machining enables the production of intricate parts with complex features, such as curved surfaces and undercuts, that would be difficult and time-consuming employing more conventional production methods. We provide our Las Vegas, NV customers with greater accuracy and dimensional consistency with our ability to move cutting tools along multiple axes.

- Enhanced lifespan of our equipment: We can extend the life of our equipment and speeds of our cycle times as a result of tilting the tool/table to maintain optimum cutting position and consistent chip load.

- Lower equipment costs: Intricate parts can frequently be manufactured with multi axis machining in a single setup, lessening the amount of tool changes, boosting uptime, diminishing human error, and, in turn, the costs for your company in Las Vegas, NV.

- Expanded design possibilities: The versatility of multi axis machining opens up fresh possibilities. We can develop highly complex components with smoother transitions and complex contours and shapes, allowing for an increase in innovation and the manufacturing of customized parts.

- Achieving excellent surface finishes: Your product can be orientated to bring it closer to the cutting tool, utilizing the rotating fourth and fifth axes. When the part gets closer to the cutting tool, the tool can be shorter, allowing for less susceptibility to vibration at higher speeds, which has an impact on surface finish.

Cost Control for Machining Projects

Cost control is one of Elimold’s driving forces in producing precision parts. To ensure our customers get added value from their CNC parts program, we focus on making our machining services as efficient as possible.

We use Lean Manufacturing practices, including 5-S Workplace Organization, Cellular Manufacturing, Quick Changeover, and more, to help us identify and eliminate waste. This helps keep our costs competitive and helps us constantly improve our existing processes, while also building optimal flow into our processes from the beginning.

Why choose Elimold?

Our exceptional knowledge of CNC machines ensures that we deliver tight tolerances, greater reliability, and a higher throughput than all other manufacturing shops. We also regularly train our operators to ensure they have the skills necessary to make full use of our equipment.

As a result, Elimold offers a wide range of machining options possible, and delivers top-quality results every single time, with competitive pricing to top it off. The reliability of our service reduces maintenance costs and unplanned downtime, which will help you stay on schedule and on budget.

Your trusted partner for multi-axis CNC machining

Elimold has been a trusted processing partner for customers around the world, providing quality, precision and reliability for every job. Our multi-axis CNC manufacturing capabilities enable us to provide more solutions to our partners. Discover the difference Elimold offers and take advantage of our high precision and competitive pricing on a variety of machining operations.

You won’t find a more flexible, capable or reliable processing supplier anywhere else. Contact us today to discuss your machining needs and we will find a solution that fits your part size, complexity, volume and quality requirements.