Robotics Industry

Get high-quality manufacturing services for your custom robotic prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

On-Demand Robotic Manufacturing

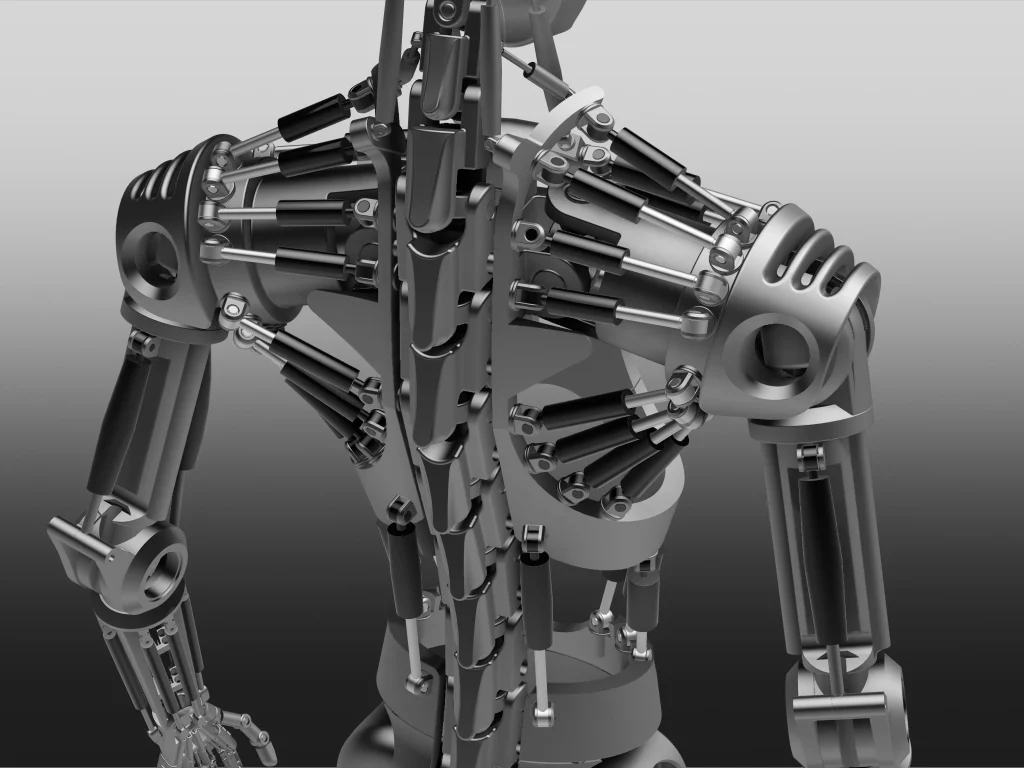

In the robotics space, we are able to work with today’s best minds who are working hard to create innovative and incredible products in both competition and production. We offer a range of prototyping and production solutions to dynamically scale and meet the needs of the global robotics industry. Our services are reliable, flexible, thoughtful and precise, designed to meet the high levels of detail, accuracy and tight tolerances required in the manufacturing of robots and robotic components. At Elimold, we offer services in different production volumes, allowing all customers to take advantage of critical production flexibility to optimize budgets and react to gaps in their supply chain.

Our robotic parts manufacturing processing technologies include cutting and injection molding, CNC machining, casting and 3D printing, etc., and all of them are done in-house. Whatever your business needs are, whether it is a full-fledged robotic component prototype or a functional robotic end effector, you can rely on Elimold to deliver quickly and cost-effectively and get you into your target market.

We take pride in our work and our products undergo extensive quality control inspections. From the initial stages of design concepts to on-time delivery of customer goods, we strive to exceed all consumer expectations. Because of this, we have a reputation for having high-quality mechanical parts. Our parts will be delivered on time, with excellent customer service and competitive pricing.

Supplier of Advanced Robot Parts Manufacturing Solutions

As robotic applications continue to evolve and improve, Elimold helps our diverse customers bring process automation and control, risk reduction and performance improvements to the forefront of industrial manufacturing. All of our solutions are designed to address functionality, precision and efficiency issues in robotic applications in costly and manually repetitive operations.

In addition, our engineers are experienced in dynamics, sensors and mechatronics, working with industry leaders who manufacture a wide range of robots, processing lines and end-effector parts to drive innovation and shorten product development cycles. Because surface textures and end-effectors are at the core of robotic performance, our production standards for machining robots and robotic components provide high precision, tight tolerances and dimensional accuracy for enhanced ergonomics and functionality. To learn how we can help your business with robotic parts manufacturing, contact our team today!

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. Our own facilities and extensive manufacturing network enable us to efficiently deliver complex, high-quality parts.

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Extrusion

Die Casting

Vacuum Casting

Wire EDM

Robotic Prototyping

Elimold provides rapid prototyping and manufacturing solutions to meet the needs of the growing robotics industry. We offer reliable production services with short turnaround times and strict quality inspections, so you can expect your parts to arrive quickly and be of the best possible quality. Whether you need to prototype a full-fledged robotic system or manufacture a complex part, you can count on Elimold for timely delivery. Not only will we help you get your prototype to market quickly, we’ll guarantee a high-quality and precise product at an affordable price.

Our Prototyping And Manufacturing Services

Are you looking for a reliable robot parts manufacturer to bring your design idea to reality? Then, you have come to the right place. We offer a range of solutions to meet different prototyping and production requirements for robot parts.

- Prototype mold design

- Prototype mold validation and testing

- Production validation and testing

- Quality verification and testing

- Precise and high quality production

How Can Elimold Help You With Your Robotics Parts Needs?

Working with Elimold starts with a hands-on, personalized approach. You’ll speak with an engineer who will work closely with you to understand your needs. For example, our detailed, hands-on DFM process can help identify and resolve potential design issues early in the product development process and recommend changes to improve part manufacturability.

We’ll help you optimize part design, production processes, and material selection to get the best results at the best price. Our experienced engineers will help you move your project from prototype to production efficiently. Our focus on low-volume, highly custom parts is a perfect fit for this fast-moving, innovation-driven industry.

We work on developing robotics solutions that include:

- Part weight reduction using exotic metals and additive materials and methods to improve robot maneuverability and agility,

- Part consolidation to improve performance and reduce cost for complex assemblies,

- Rapid prototyping to get new ideas to market faster,

- Conformal airflow for pick-and-place material handling applications, and

- Rugged parts that can withstand corrosive environments.

Let's Start A New Project Today

Difference Between Robotics and Automation

The robotics and automation industries are closely linked. Automation is a broader category that describes the use of machines, computers, and other devices to perform tasks (manual, mathematical, procedural, etc.) that would otherwise be done by human workers. Robotics, on the other hand, is the use of physical robots to perform physical tasks. Robotics and automation often go hand in hand, as in industrial manufacturing. For example, in a car factory, the assembly line often consists of hundreds of manufacturing robots performing automated tasks, sometimes with the help of machine vision. However, automation can exist without robotics (such as in software automation), and robotics can exist without automation (such as a medical robot controlled by a surgeon). As an expert in physical component prototyping, Elimold receives many orders for robotic components. But we can also produce other types of automation parts, such as conveyor belt components, automatic control equipment, and logic controller components.

Precision Manufacturing for Robotics Industry

Robotics is a diverse, relatively new industry, but most prominent in the industrial and manufacturing sectors. Applications here include robotic arms, collaborative robots (aka cobots), robotic process automation, integrated artificial intelligence (AI), predictive maintenance, and service robots. For components created for the robotics industry, dimensional accuracy is vital. Parts are complex and must be precise to work in sync with other components assembled within a robot. Surviving the stresses of repeatable actions is also essential. Other key considerations include customizability, low-friction surface finishes and complex geometries. And that’s why digital manufacturing is uniquely valuable in the production and assembly of parts for the robotics industry.

Robotics Prototyping Applications

- Robot and Manipulator Prototyping and Design (based on task descriptions or other parameters)

- Rapid prototyping of robotic devices, sensors, actuators (including web-based manufacturing/ prototyping)

- Prototyping and simulations of Micro and nano systems.

- Automated manufacturing processes, systems, and techniques

- Prototyping robot-assisted medical devices and bio-medical engineering applications

- Prototyping for Information extraction

- Other emerging paradigms and technologies that are applicable to prototyping activities in Robotics and AI applications.

Robotics Manufacturing Materials

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for robotics projects are listed below.

- Natural

- synthetic rubber

- Elastomers

- Thermoplastics

- Nylon

- Ceramics

- composites

- Liquid Silicone rubber

- Aluminum

- Titanium

- Brass

- Nickel

- Copper

- Stainless Steel/Steel

- Inconel

- Metal and metal alloy

Applicable Finishes For Robotics Industry

Elimold offers wide variety high level surface finishes. We only list some of the common finishing options. There are more finish options for custom parts for Robotics Industry.

- As machined

- Sanding & Polishing

- Sand, Bead Blasted

- Painted

- Powder coat

- Anodized

- E-Coating

- Nickel Plating

- Chromed

- Zinc Plating

The Clients We Serve

At Elimold, our range of manufacturing services can serve every player in the robotics industry. Some of our popular clients fall under the categories of:

- Direct Robot Manufacturers

- Robotics-as-a-service (RaaS)

- Aftermarket robotic end-effector manufacturers

- Robotic engineers and design experts

- University robotic and engineering departments

- Industrial and general manufacturing

- Automobile engineers

- Cartesian robot engineers

- Robotics software experts

- Medical Robotics

- Autonomous mobile robots

- Service and diagnostic centers

- Aerospace robotics

- Exoskeleton component manufacturers

- Standalone, collaborative, and production line robots

- Articulated, SCARA, Delta

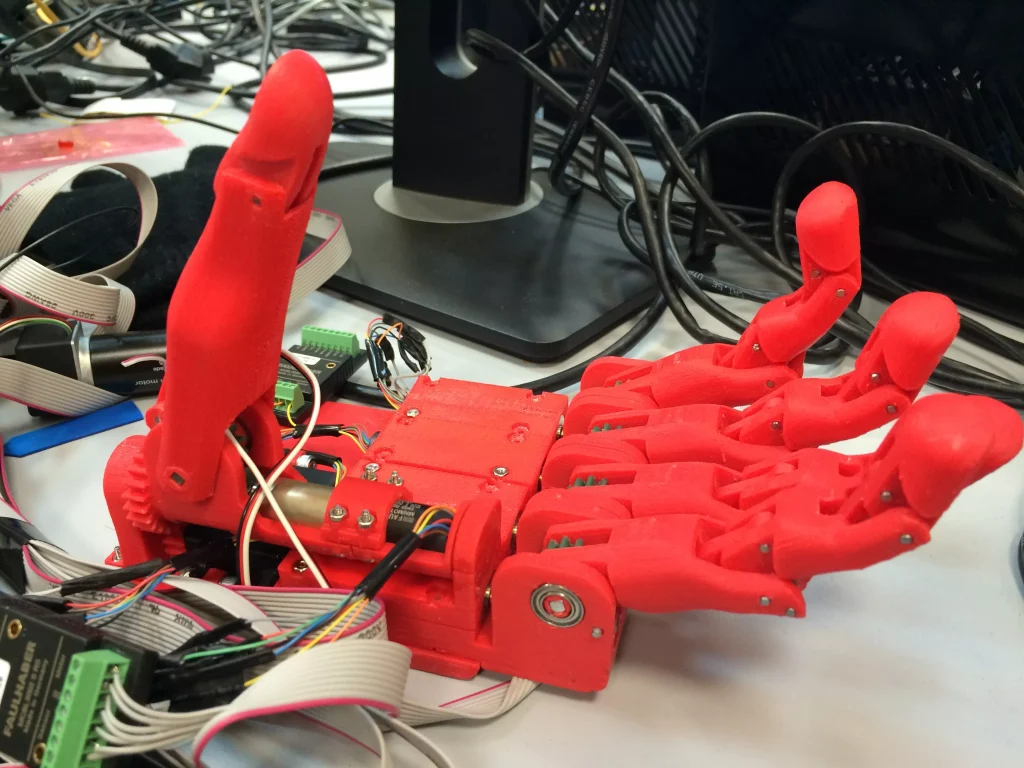

3D Printed Robots Come in All Sizes

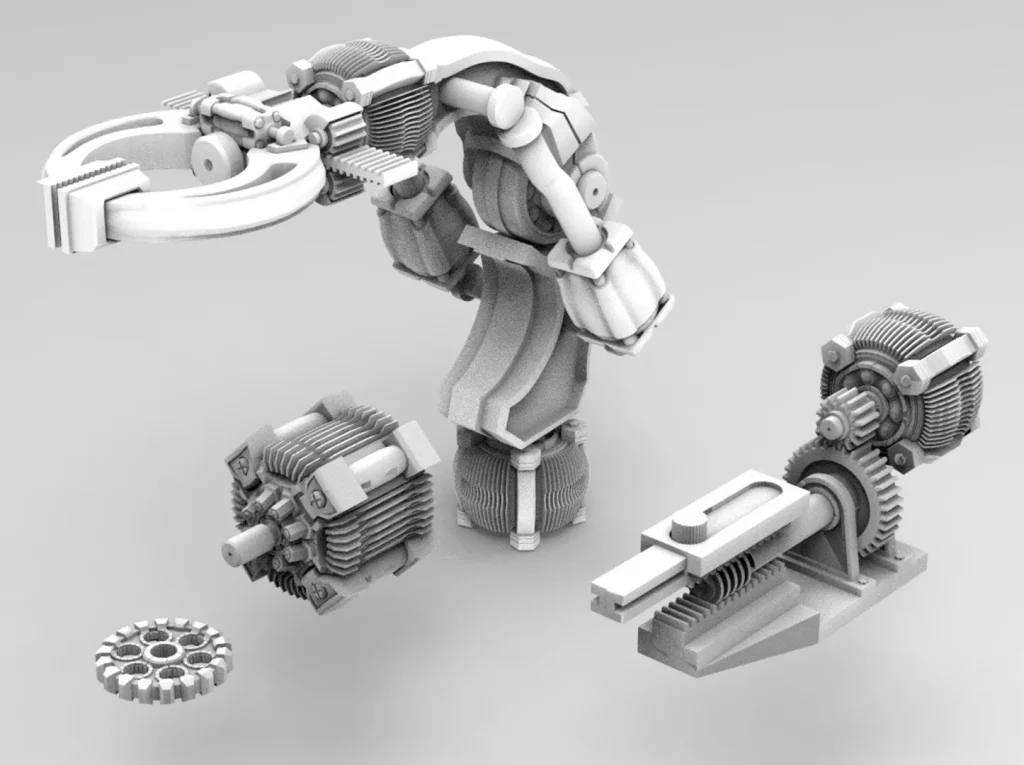

3D printed robotics encompass smaller projects like robotic arms, as well as gripping, clamping, and clasping mechanisms. Many robotics designers are also involved in 3D printing drone frames and complex drone parts with many special features.

Robotics are often created in large batches, intended to perform the same duties–on an assembly line, for instance. Elimold production ensures accuracy and repeatability in parts so that each 3D printed robot is created identically, providing consistency in every project or task.

No matter the size or complexity of the 3D printed robotics project, 3D printing makes the process faster and more efficient. Designers and engineers enjoy tremendous freedom in design, the ability to customize as needed, and unlimited opportunities to iterate during robotics product development.

Injection Molding in the Robotics Industry

When your robotics products require low-volume to high-volume production, robotic injection molding is a cost-effective and repeatable option. In Elimold’s pricing model for custom robotic parts, the price of customized parts generally decreases as the quantity increases. Injection molding is not the main manufacturing process for producing robotic parts, and is usually used to produce plastic housings, plastic frames, and plastic shells. In addition, with the introduction and development of soft robotics technology, it is becoming more and more common to use liquid silicone rubber (LSR) to mold custom robotic parts.

CNC Machining in the Robotics Industry

CNC machining technology is an ideal service for custom robotic development, as robotic CNC machining services can produce custom parts with precision and dimensional accuracy, and in a wide range of materials. In addition, robotic machined parts are often produced to tighter tolerances than other processes, and 5-axis CNC machining can produce highly complex robotic parts, which is important for robotic applications that require precise, repeatable motion. During post-processing, machining can achieve a controlled surface finish, which is necessary for low-friction components in interactive parts. Machining is well suited for small batches of custom robotic components.

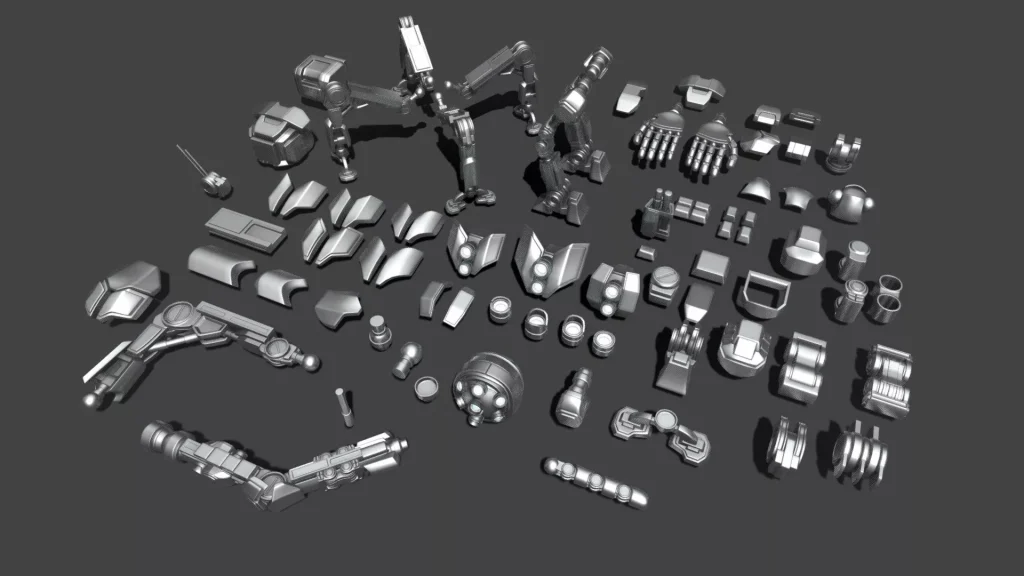

What Robot Parts Can We Make?

Robotic solutions are increasingly used in industries that require high efficiency and productivity. We can use our expertise and advanced technology to manufacture the precise robotic components you need.

- Robotic design

- Tooling and fixtures

- Custom housing and parts

- Chassis, enclosures, and brackets

- Part design and prototyping

- Generic and custom end-effectors

- Robotic modifications

- Tooling and jigs

- Custom housing and parts

- Custom robotic end-effectors

- Robotic prosthetics

- Robotic attachment and components

- Human prosthetics

- Animal prosthetics

- Robotic parts and components

- Appendages (legs, arms)

- Fingers

- Racks

- Valves

- Stands

- Control boxes and adapters

- Sensors and actuators

- Internal hydraulic and hydraulic pump bodies

- Cable routing dividers

- Robot and manipulator prototyping

- Automated manufacturing systems, processes, and techniques

- Robot-assisted medical devices

- Creation of smart factories

- Maintenance of industrial robots

Put Your Parts Into Production Today

Ready to get started? Accelerate your product development timelines, reduce risks, increase flight performance and market success by clicking here to get in touch with us and receive your free design-for-manufacturability (DFM) analysis and instant quote now.