Urethane Casting Services

Elimold is perfectly positioned to meet your vacuum casting needs. With years of expertise, we can manufacture your plastic parts to the highest standards, cost-effectively and quickly. Ideal for high-quality prototypes, functional testing, proof of concept and demonstrations. Polyurethane cast parts can be manufactured on demand in quantities ranging from a few to hundreds. Contact us today to learn more about our casting services.

Professional Urethane Casting Manufacturer

Elimold’s innovative Urethane Casting services help you go from concept to reality, creating high-quality prototypes without the limitations of traditional small-batch production. Our expertise opens up endless possibilities for you to quickly create fully functional, production-grade parts. We can transform your innovative concepts into viable prototypes, all within a cost-effective and time-saving framework. Our polyurethane casting services help you achieve this goal. With carefully crafted molds, we offer a wide range of custom parts, from small-batch production to realistic prototypes for marketing and design verification. In addition, we are not limited by any product. Whether you need a single prototype for an investor meeting or a small-batch production, Elimold is your one-stop service, providing you with excellent quality, cost-effective production efficiency and unparalleled delivery speed.

In-House Polyurethane Casting Factory Capabilities

We offer a wide range of polyurethane and room temperature vulcanizing (RTV) casting services that can be tailored to your specific project. With an 80,000 square foot in-house state-of-the-art facility, we have over 30 advanced machines running 24/7 for fast delivery. We can produce parts up to 22 feet in length, weighing over 500 pounds, and up to 8 feet in diameter with tolerances as tight as +1/16 inch. We mold polyurethane and hybrid polyurethane materials, as well as flexible and rigid polyurethane foams, to meet the specialized needs of applications across a wide range of industries. In addition, we offer design, fabrication, maintenance, and warehousing services for tooling and molds. With lead times as fast as 10 days, depending on the size and quantity of your parts, we are the ideal choice for your polyurethane and room temperature vulcanizing (RTV) casting needs.

Types of Urethane Casting

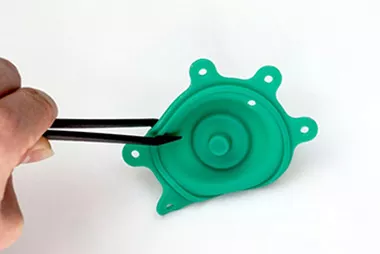

Flexible Urethane

Rigid Urethane

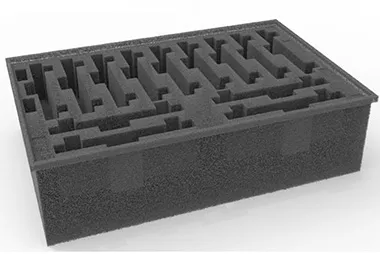

Foam Urethane

Urethane Casting Rapid Prototyping

Vacuum cast parts are ideal for rapid prototyping and low-volume production, especially for processing plastic parts from 10 to 1,000 pieces. This ensures product dimensional consistency and accuracy. The vacuum casting process uses low-cost molds, making it a more affordable and convenient method for prototyping. It is able to produce high-quality prototypes in a variety of materials and support design changes. This helps to easily test designs and prepare them for functional testing efficiently. Vacuum casting has proven to be the best choice for consumer testing, user evaluation, and concept modeling. It is able to produce prototypes using the same materials as mass production, thereby achieving comparable results with other manufacturing methods. In addition, it can accurately simulate the mechanical and functional characteristics specified in the final design, including smoothness, rigidity, and flexibility.

Common Applications of Urethane Casting

Many industries use urethane casting for their prototype and production projects. Urethane casting can be a smart choice for a lower-quantity project, as investing in injection mold tooling can be expensive. Another advantage of urethane casting is that it is optimal for use as a first production run, serving as a cost-saving measure to test prototypes before larger-scale production. Advanced prototyping is also feasible with urethane casting because the tooling and design changes cost less than other manufacturing methods. It is also possible to test various materials from a single mold. Parts made using urethane casting can also be used for customer testing, given the high aesthetic quality.

- Test Prototypes Rapid

- Prototypes Exhibit Parts

- Consumer Testing

- Products for Crowdfunding

- Lower-Volume Manufacturing

- Concept Models

- Sales Samples

- Engineering Models

- Marketing Test Samples

- Pre-Production Runs

- Bridge to Production Parts

- Point of Purchase Displays

Urethane Color Options

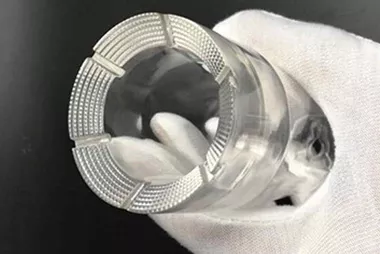

Polyurethanes can be blended with pigments to achieve a variety of colors. Naturally, a urethane may be amber to milky-white in color. Elimold’s clear urethane options are formulated to be colorless. Below are Elimold’s color options:

- Black

- Natural (unpigmented)

- Clear (colorless)

- Custom Color-Match

- Milky white

- Red

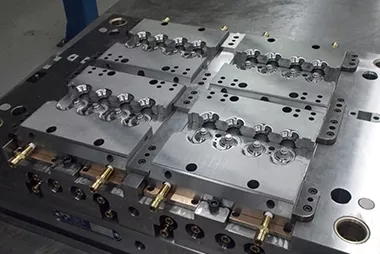

In-House Mold Making Capabilities

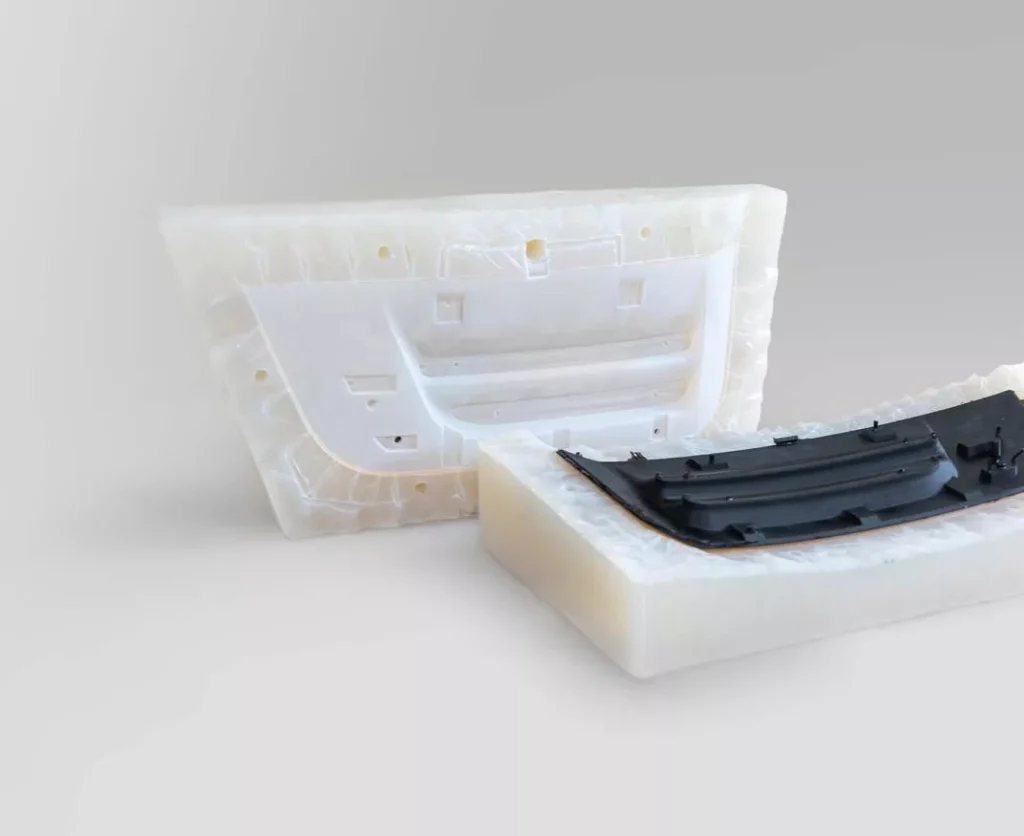

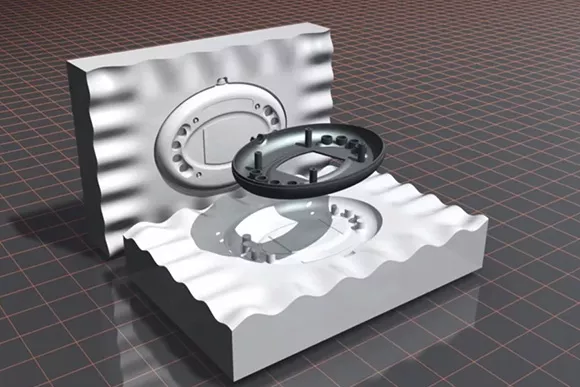

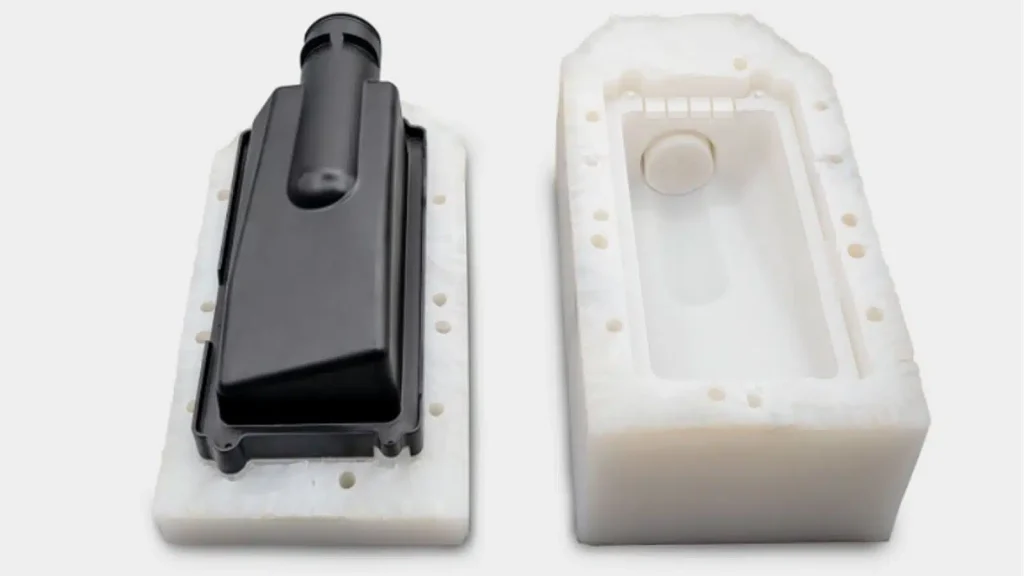

Elimold’s in-house mold making department can provide various types of molds depending on the requirements of your project. Standard molds can produce approximately 25 shots per cavity. Production molds can produce more parts per cavity, depending on geometry, quantity and material. For more complex or production-oriented parts, we will build a complete mold with cores and cavities (similar to injection molding). Each mold is custom made to the requirements of the part and project. We build single cavity, series molds, or multi-cavity molds based on the most efficient process to complete your part quickly and accurately. Here are the different types of molds we can build:

3D Printed Mold

Soft Prototype Mold

Soft Production Mold

Hard Production Mold

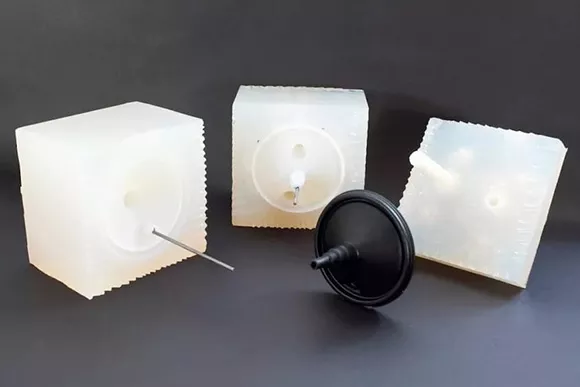

Urethane Casting Bridge Tool Manufacturing Services

Bridge tooling, or rapid tooling, refers to the molding process used between the end of product development and the start of production. Why would you use a bridge tooling? Typically, you will find yourself in a situation where your prototype has been approved and production tooling has arrived, however, traditional production tooling (usually steel tooling) is a poor fit. The problem arises when demand exists but supply is insufficient. This is when we use some of our less traditional molding methods, such as silicone molds and aluminum molds, to bridge the supply gap. We fill demand immediately before production tooling is ready. Typically, silicone molds are ideal when demand is between a few and a few hundred parts. Because of our proprietary process, there is no loss of appearance or performance when casting polyurethane parts with our silicone molds.

Custom Cast Polyurethane Parts

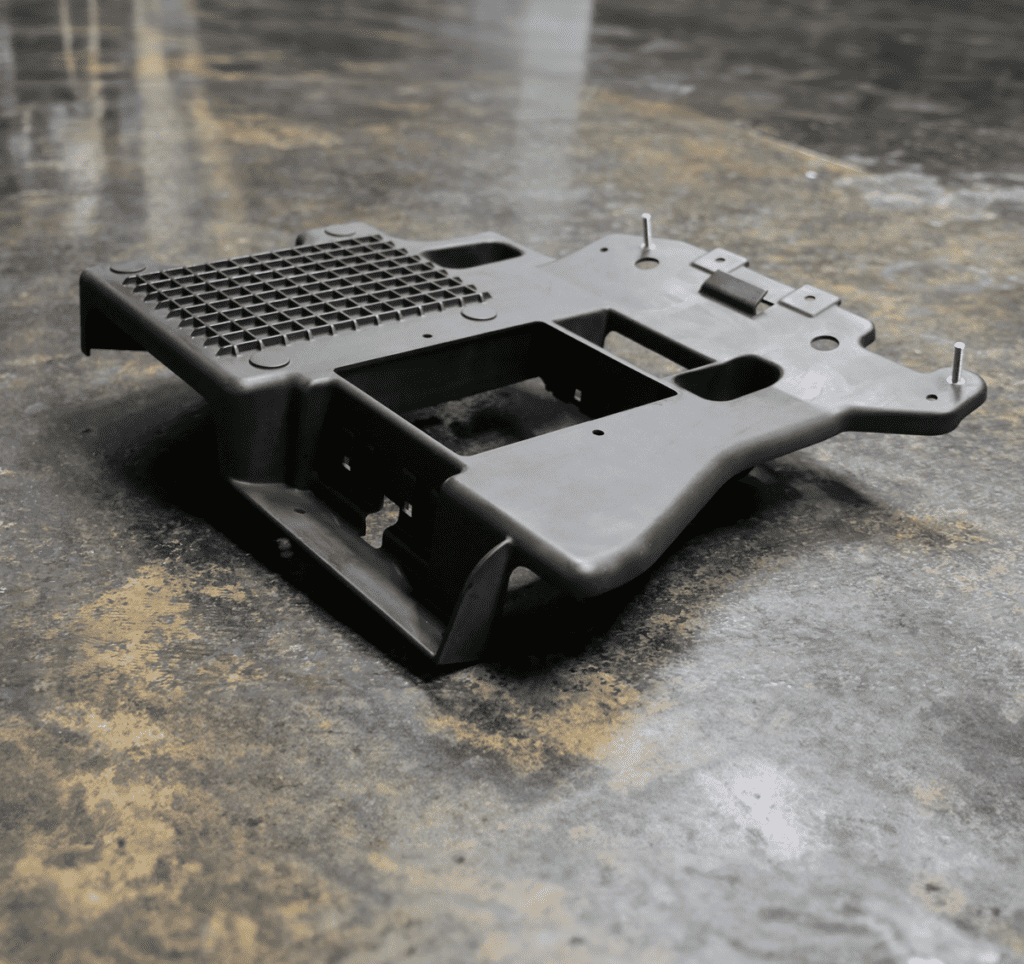

With Elimold’s extensive experience in mold design and manufacturing polyurethane products, our Urethane Casting services produce high-quality polyurethane parts to any design or specification, ensuring durability and precision. Urethane Casting parts can be clear, color matched, painted, mounted inserts, and custom. As a result, we are able to process any polyurethane casting part, support rigid, elastomeric, and silicone materials, and can provide painting, mounting hardware, and even post-machining services for your polyurethane castings, ensuring you get the exact part you need. Urethane Casting requires a high level of communication with the customer regarding design, first article approval, and balanced processing. Show our dedication to service and quality by choosing Elimold for your next polyurethane casting project.

From Prototype to Production

Elimold’s Urethane Casting services are designed to meet your unique project needs. Our advanced technology and professional team ensure high-quality, precision components that improve efficiency and performance across a wide range of industries. Whether you need precision machining, custom molds, or durable polyurethane parts, we can provide you with the solutions you need to succeed. We understand that you need a partner with the service and expertise for your critical projects. Our cast polyurethane molding department can handle projects and parts in a variety of quantities, sizes, and materials. Our project managers and engineering team will assist you in selecting the right process and material based on your specific application. When you need multiple prototypes to achieve the performance of production materials or a small number of production parts, Urethane Casting is a cost-effective alternative. Urethane Casting is a perfect process to complement rapid prototyping technology because it is relatively low cost and has a turnaround time of only a few weeks. Elimold is able to manufacture polyurethane cast molded parts and prototypes for your project.

Engineering Support

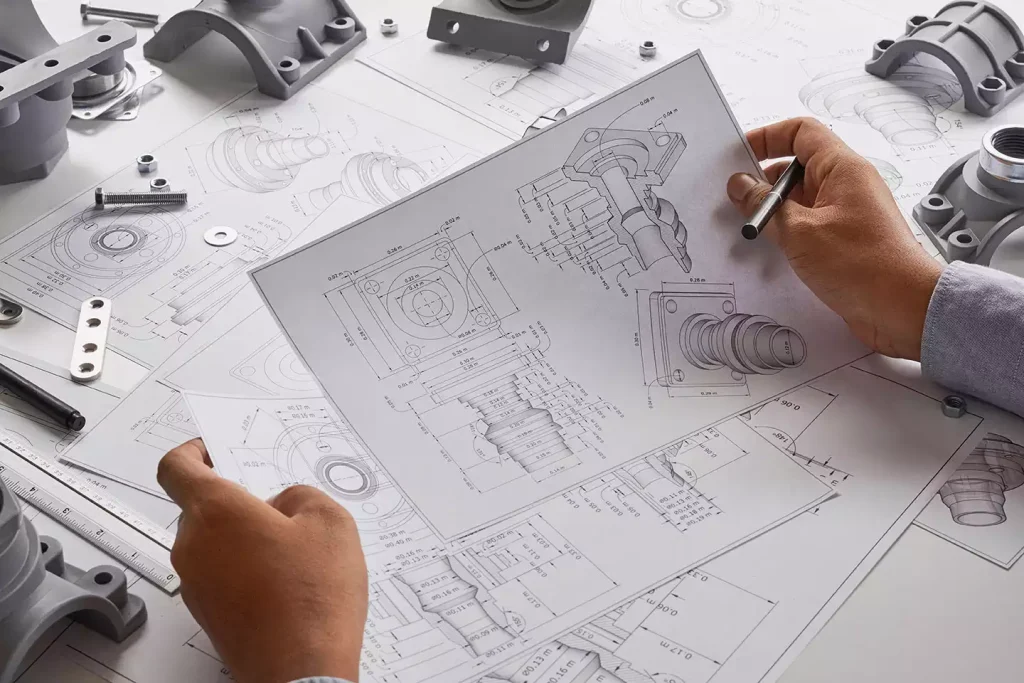

From part design to tolerance planning, our team provides quotes and technical oversight of production. We ensure your parts are ready for Urethane Casting before mold manufacturing begins, avoiding costly mistakes. That’s why Elimold’s engineers have extensive mold expertise as well as process-specific expertise, matching you directly to a vetted manufacturing process based on part complexity, material needs, certification requirements, and scale. Plus, we offer flexible manufacturing options, and our wide range of materials allows us to tailor solutions to fit specific applications and operating environments. Elimold is an industry expert in engineered plastics casting molding. As a supplier to engineering and manufacturing companies worldwide, we are committed to providing high-quality, high-performance custom parts you can trust.

DFM Services

Our experience and comprehensive technical knowledge enable us to provide advice, support and recommendations at every stage of the process, including CAD design, mold production and on-site testing. As a result, you can benefit from Elimold’s technology. First, we will send engineers to analyze your part design and understand its intended use as part of our detailed DFM process. We will then provide you with recommendations for the best materials and manufacturing solutions to meet your needs. Our employees are experienced professionals who are passionate about their products.

Quality Commitment and Management

Urethane Casting service is more than just a molding process, it is a team of highly skilled operators who ensure that every step from model to casting to post-processing goes smoothly. They work tirelessly to test and validate the process to ensure a perfect casting every time.

Elimold has well-trained technicians and experienced molders who use innovative thinking to solve any production problems that may arise in advance. We continuously test and validate the process. We implement quality checks throughout the production process, each order is accompanied by an inspection report, each part is 100% visually inspected, and if your part does not meet the specifications, we will correct it. Ensure that you receive the highest quality polyurethane castings. We will guide you to the best way to produce your product design.

Interested in our Urethane Casting Services?

If you’re looking for the highest quality custom polyurethane parts for your next project, look no further than Elimold’s polyurethane casting services. We set standards for fast customer service, quick delivery times, and high-quality parts. Contact us now for a free, instant quote.

Turnkey Polyurethane Casting Solutions

Are you planning to produce parts via injection molding, but are not ready for tooling yet? Elimold’s polyurethane casting services are the ideal way to quickly produce small quantities of parts for functional and cosmetic testing. Depending on the part geometry and the quantity required, this service can be faster and more economical than additive manufacturing. And our primary process for low-volume plastic part production is Urethane Casting because its benefits (price and lead time) exceed CNC machining in production runs of more than ten parts. The main reason is that tooling can generate huge economies of scale. Therefore, we offer a complete turnkey Urethane Casting solution, creating masters and casting copies based on your CAD design. We not only make high-quality molds, but also provide a full range of finishing services, including painting, sanding, pad printing, and more. We will help you produce the parts you need for showroom-quality display models, engineering test samples, crowdfunding campaigns, and more.

Alternatives to Polyurethane Casting

Elimold uses a variety of vacuum casting techniques and equipment to increase your prototyping and production speed and capabilities. For products and parts with tight tolerances, CNC machining or injection molding will be a better choice as an alternative to polyurethane casting.

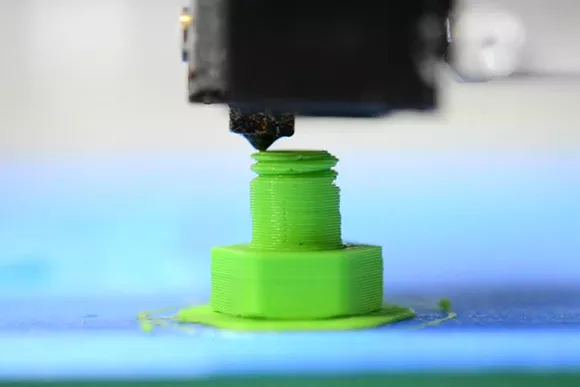

3D Printing

CNC Machining

A Low-Cost Alternative to 3D Printing and Injection Molding

The Urethane Casting process is a versatile middle ground between 3D printing and injection molding, offering the best of both worlds. Modern material advances have made polyurethane cast parts comparable in quality to injection molded parts. At the same time, these cast parts can be produced in small to medium batches, faster, and at a lower cost than injection molding.

In addition, compared to 3D printing, Urethane Casting materials have a wider range of chemical, thermal, and mechanical properties than 3D printed plastics. Cast parts are also more valuable in medium to large parts because they are not limited by the size of the print platform. Finally, cast parts have a superior finish and fine details compared to 3D printed parts, which means they can accurately create the look and feel of consumer products without any additional finishing.

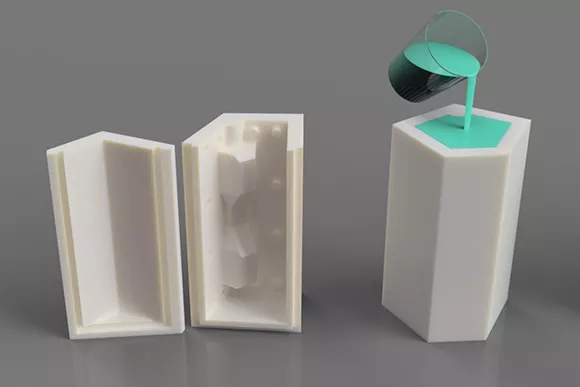

What is Urethane Casting?

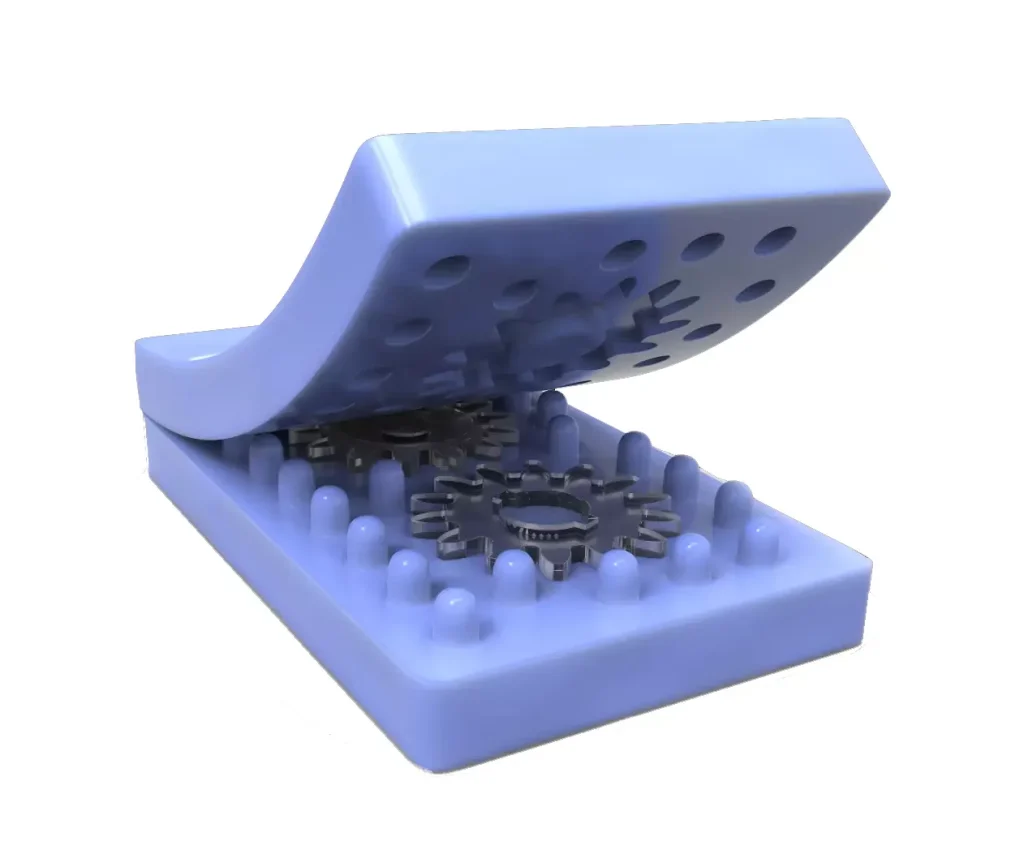

Urethane Casting or polyurethane vacuum casting is a part casting technique used to make high-quality prototypes or parts in low volumes without any tooling cost. Rather than metal molding and tooling, the parts are made from an inexpensive silicone mold and a 3D-printed master pattern.

Urethane cast parts have exceptional surface details and cosmetic appearance, bearing a striking resemblance to the master model. The process can be likened to injection molding, where the liquid plastic resin is poured into a mold tooling and left to cool, before ejecting the solidified end part. The major difference between urethane casting and injection molding lies in the type of tooling; while injection molding uses “hard” metal tooling, urethane casting uses “soft” silicone mold tools.

Due to the nature of the materials and processes, the finished part’s dimensions might experience shrinkage. The final size is, therefore, dependent on the precision of the master model and casting material.

Materials Options

Careful material selection is an important part of the design process. There are a wide variety of polyurethane materials that can be used in Urethane Casting. Material selection is largely determined by the physical properties desired in the final part. In addition, additives can be added to most materials to produce different colors, finishes, and textures. Elimold has hundreds of materials to choose from, covering hardness, color, and specifications. Most materials can be colored to match Pantone numbers. Here are some of the most common materials we use every day.

Shore D Materials

- ABS-like (80D)

- PE-like (65D)

- PC-like (84D)

- PP-like (70D)

- ABS-like, FDA Compliant (80D)

- ABS-High Impact (78D)

- ABS-High Impact, Flame Retardant (85D)

- ABS-High Impact, Class IV, FDA Compliant (85D)

- ABS-High Strength (85D)

- ABS-High Strength, FDA Compliant (85D)

- Nylon/Delrin-like (84D)

- Hi Temp (84D)

- Water Clear (80D)

- PC-like, Haze Clear (84D)

Shore A Materials

- Standard Elastomers (15A-94A)

- High Performance Elastomers (15A-90A)

- Water Clear Elastomers (45A, 65A, 70A, 90A)

- Silicones (15A, 25A, 35A, 40A, 42A, 50A, 53A, 60A, 75A)

- Medical Silicone (38A)

Most Common Materials

- TD-277-02 (durable, MRI clear, UL94V0)

- RC-79 (rigid, MRI clear, UL94V0)

- PT 8958 (tough, MRI clear, UL94V0)

- TC-851 (rigid, accurate)

- PT-8952 (impact resistant, FAR)

- TC-885 (impact resistant, UL94V0)

- TP-4051 (fast, rigid)

- OC-7086 (rigid, clear)

- Hapflex (elastomeric 20A to 90A)

Flexible Urethanes

- Adiprene L100

- F-140 (40 Shore A)

- F-150 (50 Shore A)

- F-160 (60 Shore A)

- F-170 (70 Shore A)

- F-180 (80 Shore A)

- F-190 (90 Shore A)

- F-195 (95 Shore A)

- WC-565 (Water Clear)

- WC-575 (Water Clear)

- Steralloy (FDA Approved)

- TU 89MF

Rigid Urethanes

- TC-803 (Low Cost)

- TP-4007 (High Heat)

- TP-4020 (High Strength)

- VA-273 (Optically Clear)

- Steralloy (FDA Approved)

Silicone

- M-2 (60 Shore A)

- QM-280 (80 Shore A)

- RTV 3040 (Clear)

- RTV 3460 (60 Shore A Elastic)

- Dragon Skin Series (High Elasticity)

- Sorta Clear Series (Food Safe)

Flame Retardant

- FX-8061 (UL 94 V0-60A)

- FX-8071 (UL 94 V0-70A)

- FX-8081 (UL 94 V0-80A)

- FX-8091 (UL 94 V0-90A)

Flame Retardant Heat Deflection

- TC-890FR (195°F-UL94 V0)

- FX-8575 (122°F-Clear-UL94 V0)

- FX-8585 (266°F-UL94 V0/Far)

- TP-4014 (230°F-UL94 V0/Far)

- TP-4016 (250°F-UL94 V1)

Surface Finishing Options

Polyurethane parts can be painted in any Pantone color. Elimold’s Urethane Casting services also offer a variety of textures and surface finishes. They can also be post-processed to exacting tolerances and to accommodate a variety of inserts. We offer a variety of additional finishing options depending on project needs:

- Spray Painting Texture

- Logo and Graphics

- Electroforming Plate

- Gold Color

- Spin Line

- Sputtering

- Vacuum Metalize

- Color Matching

- Painting

- Texture Treatment

- Satin Finish

- Semi-Gloss Finish

- Polishing

- Part Marking

- Light Assembly

- Custom Finishes

What are the benefits of urethane casting?

Low tooling costs

- Silicone rubber molds are created around a 3D printed model — one of Elimold’s core capabilities.

- No need for costly steel or other metal molds.

- Silicone rubber molds are created around a 3D printed

Fast turnaround times

- Elimold’s in-house capabilities mean that we control all lead times.

- Our 12-hour quoting process means no delays at any step of the way.

- 3D printed models and silicone molds can be produced in days, not weeks.

Closely reproduce the properties of other materials

- The properties of urethane allow different formulations for different properties, reducing material costs.

- Test the design and aesthetics of parts before full production runs.

- Easy color reproduction through a wide variety of paints.

Little to no finishing required

- Original 3D printed models are finished to the required specs, meaning that parts typically will not need to be finished after being molded.

- Molds are designed to minimize flash and part lines.

- Less finishing means faster delivery times.

Urethane Casting Design & Build Guidelines

Cast urethane molding is a very flexible process that can easily mold undercuts, thick sections, varying walls and parts without draft. Parts may differ depending on material, finish and geometry, but here are standard guidelines to work from:

- Minimum Wall Thickness & Features: 0.040” (1.016mm) minimum walls and 0.025” (0.635mm) minimum features. (dependent on part geometry and material)

- Standard Finish: Parts can be customized to meet your requirements for as molded or painted. (see more available custom finishes)

- Standard Lead Time: 2-3 weeks for first parts, completion depends on part, mold and material chosen. (*Parts can be delivered in as little as 1 week*)

- Tolerances: +/- 0.005” for first inch then +/- 0.003” per inch thereafter

- Parts per Mold: 25 parts per mold cavity (depending on design and material)

Is Urethane Casting Expensive?

Cast urethane molding is a relatively inexpensive manufacturing process. The lower cost is mainly due to the speed and ease of mold making for the urethane casting process. Cast urethane molding is done with silicone. The material is inexpensive, easy to work with, can quickly be modified, and will produce detailed cast urethane parts. Urethane casting can cost anywhere from a hundred to a thousand dollars depending on the complexity of the part being molded. Urethane casting is ideal for prototyping and low production runs.

Ready to Get a Urethane Casting Quote?

If you are ready to start your polyurethane casting project, fill out our quick quote form to get a free quote in 24 hours or less. Our engineers will review your project and provide a cost estimate and project analysis report.

Custom Urethane Casting Solutions

Over the years, Urethane Casting has become increasingly popular across a variety of industries, and when you look at the wide range of services it offers, it’s easy to see why. Urethane Casting services are suitable for a wide range of different applications because they are affordable, customizable, and efficient. With custom molded polyurethane, you can create a variety of parts that meet your specific needs and can be produced on a large scale without completely breaking your budget. And because Urethane Casting services are so versatile, if you can think of it, we can build it! From simple projects to highly customized and complex parts, polyurethane parts can do it. Not only doUrethane Castings come in a variety of shapes and sizes, but they also come in a variety of weight customization options, so you can choose a heavier, more rigid part or a lighter, more flexible part as needed. In addition, we have polyurethane molds that are fully food-safe, as well as high-temperature molds that can handle extreme environments.

Custom Polyurethane Casting Parts Supplier

If your project requires silicone or Urethane Casting services, consider working with Elimold. We provide high-quality casting services with fast delivery. Our experienced team excels in creating molds and castings of various sizes, complexities, and purposes. We use advanced equipment and technology to ensure accurate results. In addition, Elimold uses top-quality materials to ensure that castings are durable and can withstand a variety of conditions and environments. In addition, our team is committed to providing excellent customer service and works closely with customers throughout the casting process to meet their needs and specifications. When you choose Elimold, you will receive professional service and high-quality castings to meet your project needs.

Industries We Serve

Cast polyurethane molding has services and applications in nearly every industry. It’s versatile and effective! You can use polyurethane molds for prototypes, mass-produced parts, or anything in between. The following industries commonly use Urethane Casting:

- Automotive

- Aerospace

- Medical Devices

- Consumer Goods

- Electronics

- Robotics

- Industrial Manufacturing

- Marine

- Sports and Recreation

- Oil and Gas

- Construction

- Agriculture

- Furniture

- Art and Sculpture

Urethane Parts And Product Examples

In addition to its use in prototyping, polyurethane casting can be used to create small to medium batches of fully functional, high-quality parts. The process can be used to create a variety of parts, from scaled-down models to operational, high-quality parts, at a lower cost and faster than other materials and processes. Some common applications for cast polyurethane parts include:

- Prototypes

- Gaskets

- Seals

- Bushings

- Wheels

- Rollers

- Vibration dampeners

- Grips and handles

- Housings

- Covers

- Panels

- Enclosures

- Connectors

- Mounts

- Spacers

- Insulating components

- Decorative trim parts

- Custom brackets

- Medical device components

- Consumer product casings

- Electronic housings

- Tooling and jigs

- Bumpers

- Pads

- Structural supports

- Drive belts

- Grommets

- Conveyor belt components

- Cable jackets

- Pump components

- Valve components

- Manifolds

- Machine guards

- Sensor housings

- Robotics components

- Custom knobs

- Fixture inserts

- Pulley linings

- Mold inserts

- Shock absorbers

- Flexible couplings

- Protective boots

- Pipe supports

- Cable clamps

- Medical pads

- Orthopedic supports

- Sporting goods components

- Custom buttons

- Control panel overlays

- Packaging inserts

- Automotive trim parts

- Aerospace fairings

- Drone components

- Gaming controller parts

- Custom keys and caps

- Industrial grips

- Door stops

- Wear plates

- Tool handles

- Acoustic dampers

Professional Urethane Casting Service Provider

Elimold is a professional Urethane Casting service provider, providing international, affordable options to meet your time and budget needs. Polyurethane uses a soft tooling approach to provide professional finished products for small batch production. As a polyurethane molding company, we understand that you need a partner who can provide service and expertise for your critical projects. Our Urethane Casting services use 3D printing and silicone rubber molds, which can reduce tooling costs and shorten turnaround time. The unique properties of many production-grade materials can be accurately replicated by different polyurethane formulations. Polyurethane casting has many advantages, especially compared to plastic injection molding. Polyurethane or silicone casting can bridge the gap between 3D printing rapid prototyping and injection molding, balancing quality, cost and time. Polyurethane castings can be clear, color-matched, painted (including EMI shielding), with installed inserts, and customized surface treatments. In addition, when choosing Elimold, you will also receive guidance and support from professional designers and quality engineers, as well as fast quotes and industry-leading delivery times.

Other Custom Plastic Part Manufacturing Services

At Elimold, we use a variety of rapid prototyping technologies to produce engineering parts, prototypes, and complete working products. Since our founding, we have invested a lot of energy in building our facilities and personnel to provide services that are more competitive than many other companies in the field of rapid prototyping and manufacturing.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Request Your Free Urethane Casting Quote Today

After receiving your drawings, our engineers will analyze your custom Urethane Casting parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.