CNC Machining Services

Searching for a reliable and efficient supplier of machined metal and plastic components?If yes, then Elimold is here to cater to your requirements.We offer CNC Machining services for a wide range of industries and applications. We utilize the latest in CNC technology to make high precision machined parts. Choose from 100+ materials, 60+ surface finishes. ISO 9001:2015, ISO 13485, ISO14001:2015, IATF 16949:2016 certified.

Your reliable partner for custom CNC machined parts

Elimold provides a variety of online custom CNC machining services including milling, turning, EDM, wire EDM and surface grinding. With precision 3-, 4- and 5-axis CNC machining centers, combined with other advanced capabilities and our experienced team, we can handle all types of CNC machining parts in both metal and plastic materials.

Whether you need prototypes or production parts machining, our online CNC machining service will be your best choice.

Request your online quote today to get your machining parts done in as little as 5 days!

Production CNC Machining Services

Elimold’s in-house machining facility is over 65,000 square feet and features control systems for temperature, vibration, and more, as well as a large number of cutting-edge CNC machines. And the in-house technology is complete and experienced in machining a variety of materials, including metals, plastics, and composites.

We excel in developing and applying advanced manufacturing solutions to meet the complex needs of our customers and the precise tolerances they require. We plan and schedule work to meet tight deadlines and tackle some of the industry’s largest and most challenging projects. And, our team of highly skilled engineers, who are both programmers and operators, can reduce downtime and ensure that our equipment performs to its maximum potential. In addition, we are ISO 9001:2015, ISO 13485:2016, and FFL certified and are committed to providing excellent technology, products, and services. We believe that success comes from treating employees as assets and striving for continuous improvement. Elimold benefits from employee innovation and experience in an environment designed for them to learn and grow. We continuously upgrade our equipment and employee training to meet the industry’s ever-changing technological needs. As a result, we are able to provide a variety of services that meet or exceed your design requirements.

Our CNC machining capabilities

We can offer a wide range of high-quality machining, grinding and wire EDM operations, all under one roof. Our precision CNC machining capabilities reflect this proud tradition.

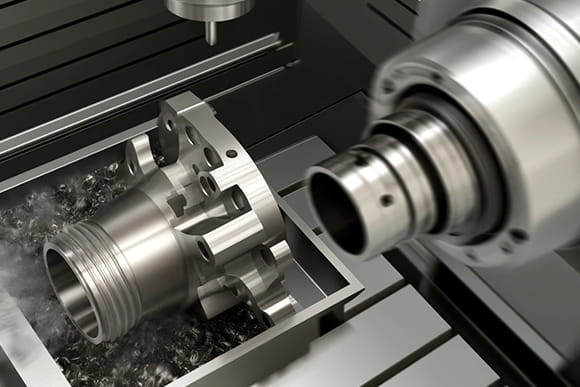

The advanced machining systems we have at our disposal allow us to offer milling, boring, turning, threading, tapping, thread milling, knurling, profiling, reaming, facing and more. Milling can produce parts up to 60 inches in length, 30 inches in width and 30 inches in height. Turning can provide parts up to 28 inches in diameter and 48 inches in length, and bar feeds up to 12 feet in length and 3 inches in diameter, all to very tight tolerances of .0005 inches. These processes are performed on 4-axis milling machines and 5-axis turning machines, using power tools, with all fixtures and tooling provided in-house. At Elimold, we specialize in prototypes and low-volume production, with expedited service available.

CNC Machining Services for Custom Parts

Our advanced milling centers and turning equipment deliver precision with tolerances as tight as 0.001 inches. Beyond standard machining, we provide value-added services like CNC routing, EDM machining, and precision grinding, perfect for designers and product developers seeking to actualize innovative ideas with top-quality custom components. Whether the project is straightforward or complex, our equipped machine shops are ready to take it on. We guarantee not only superior quality but also rapid delivery.

CNC Milling

CNC Turning

5-Axis CNC Machining

Is Your Machining Partner Reliable?

You can find plenty of CNC machining factory, but finding one you can actually count on is another story. If you’ve ever worked with an unreliable machining partner, then you know how stressful and frustrating it can be every time parts are unavailable, out of spec, or delayed.At Elimold, we believe you should be able to get the parts you need, when you need them.

Elimold provides custom online CNC machining services for engineers, product developers, designers, and more with our in-house facility. Our highly qualified AS9100D machine shop can handle any custom design, whether simple or complex. We offer quick machining, low-volume machining, and high-volume production, all with end-to-end service from our in-house facility. Send us a CAD file with relevant information or leave a message on our website to get pricing, lead time, and design for manufacturability feedback on your custom CNC parts. Our quick CNC machining capabilities include metal and plastic services and flexible production and shipping options to meet your needs at the best price and product development stage.We also provide options for part unpacking inspection, hardware traceability, material certification, and CoC to guarantee the quality of your machined parts. We accept technical drawings and have a support team to ensure you get quality CNC machined parts on time.

Gallery of CNC Machining Parts

We make cnc machining from repid prototypes and low mini order quantity for customers from multiple industries.

CNC Machining Materials

We offer a wide selection of materials for custom parts to complete prototypes and production runs of custom parts. The materials we process are very broad and include metals, plastics, and some composites.

Metals

- Aluminum

- Steel

- Stainless Steel

- Brass

- Bronze

- Copper

- Magnesium Alloy

- Titanium Alloy

- Zinc Alloy

Plastics

- ABS

- PC/ABS

- PS

- PMMA

- PA

- PC

- PP

- POM

- PEI

- PA-GF30

- PC-GF30

- PE

- PPS

- Teflon (PTFE)

- HDPE

- PEEK

Surface treatment of CNC machining service

Achieve the perfect finish with our range of surface treatments. Whatever type of surface treatment you require, Elimold can provide it (both plastic and metal parts can be post-processed). We can ensure your parts meet both aesthetic and functional specifications.

Finishes for Metal

- Standard Machined Finish

- Tumbled

- Bead Blasted (Sand or Glass)

- Polished

- Anodized

- Chemical Film

- Passivation

- Powder Coating

- Electro Polishing

- Electroless Nickel Plating

- Silver Plating

- Gold Plating

- Painting

Finishes for Plastic

- Standard Machined Finish

- Flame or Vapor Polished (Acrylic Only)

- Powder Coating

- Tumbled

- Painting

CNC Machining Design Guidelines

| Feature | Description |

|---|---|

Internal corner fillets | Design internal corner fillets to be 0.020” – 0.050” greater than a standard drill size for the radii. Follow a drill diameter to depth ratio of 1:6 (1:4 recommended) as a guideline for internal corner radii. |

Floor fillets | Design floor fillets smaller than corner fillets to allow the same tool to clear material from the interior. |

Undercuts | Always design undercuts to standard sizes and away from corners so they are accessible by the cutting tool. |

Tapped/threaded hole depth | Provide tool clearance slightly beyond the tapped hole depth to ensure complete threads. |

Complexity | Keep the number of small cuts to a minimum to reduce CNC machining costs; only design in the necessary features to balance function with aesthetic. |

Start Your Project With A Free Quote

Elimold provides high quality, low cost and fast delivery CNC machining services . Whether you need low-volume prototype parts or high-volume production, Elimold is ready to be your manufacturing partner.A wide range of metal and plastic materials are available to make CNC milling parts easy. Our factories have the scalable capacity and unrivaled capabilities.Get started on your CNC machining project today with a quick quote within 4 hours!

Elimold CNC Machining Solutions

Rapid Prototyping

Accelerate product development with our rapid machining services. We offer fast turnaround times and specialize in quick production of high-quality prototypes and mold tooling, aiding your design verification process.

Low and High-Volume Production

Whether you need small batches or large-scale production, we can offer you both. With stringent tolerance controls and comprehensive capabilities, we adapt to your volume requirements without compromising on quality.

Why use Elimold for custom online CNC machining services?

Fast and Reliably Delivery

Iterate part designs quickly and accelerate product development with quick-turn parts. Our automated design analysis will help spot any difficult to machine features before your design is sent to the manufacturing floor and save you from costly reworks further down the product development cycle.

Advanced Capabilities

Get anodizing, tighter tolerances, and volume pricing options through our network of manufacturers at Elimold. You’ll find plating (black oxide, nickel), anodizing (Type II, Type III), and chromate coating in larger part quantities; tolerances down to ±0.001 in. (0.020mm); and cost-efficient machined parts at higher volumes to lower piece-part price.

Manufacturing Analysis and Online Quotes

When you upload your 3D CAD file to request a quote, we’ll analyze your part geometry to identify any features that may be difficult to machine such as tall, thin walls or holes that cannot be threaded.

Infinite Capacity

Eliminate downtime spent waiting for parts and safeguard in-house machining with on-demand relief and infinite manufacturing capacity.

Material Selection

We stock more than 130 engineering-grade plastic and metal materials that are suitable for various part applications and industries. Materials range from plastics like ABS, polycarbonate, nylon, and PEEK to aluminum, stainless steel, platinum, and copper.

Domestic Production and Support

Work with a trusted USA-based manufacturer and eliminate the risk of sending parts overseas. You can also call or email us at any time and we’ll help with ordering parts, design feedback, material recommendations, and answer any questions.

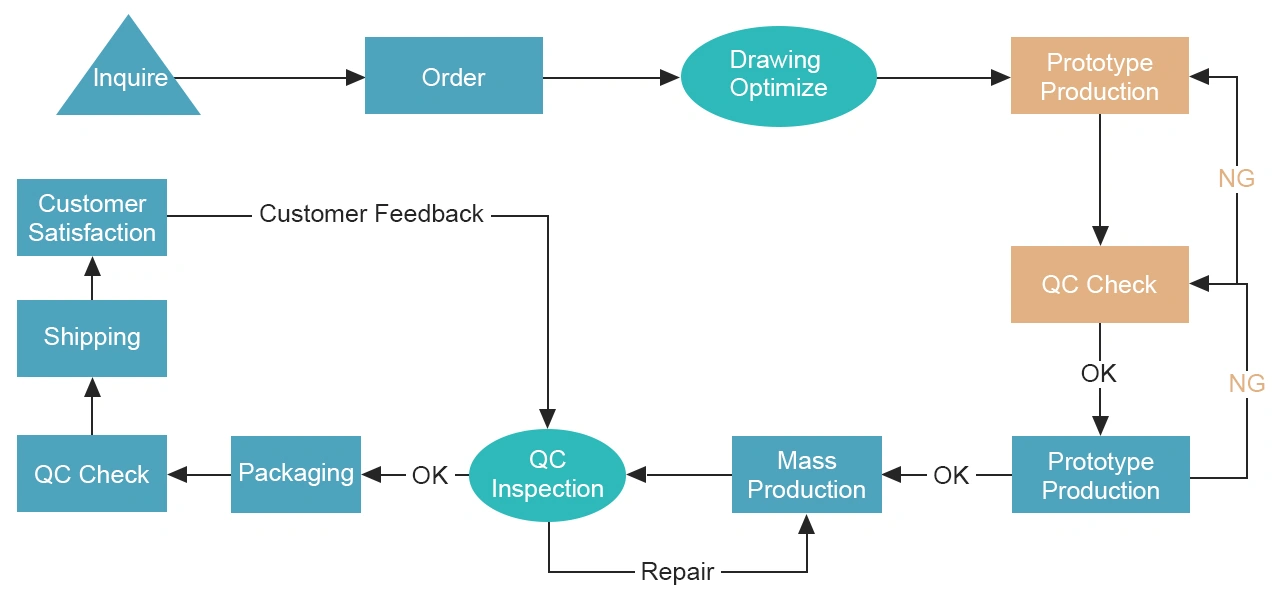

Elimold Standard—Consistently Quality Control Through The Whole Production

When you send us an enquiry with an X_T, STEP or IGES CAD file, we check it, raise any queries, then prepare a quote. We do not need 2D drawings unless you need to highlight critical dimensions, tolerances or other special features. If you accept the quote, we schedule the job, prepare the CNC program and reserve the material from our stocks or source it as necessary. Machine setups are quick thanks to the paperless process we have developed, so we can start cutting material as soon as possible. Finished parts are deburred, cleaned, degreased and inspected. Any additional finishing operations are then carried out. Finally, your parts are packaged and despatched, using our own vans for local delivery or a courier for customers further afield.

Guarantee High Quality Machined Parts

Elimold holds multiple international certifications. Our internal procedures also define the level of quality. We hold ourselves to the highest standards to ensure your high-quality CNC machined parts.

Our equipment allows for high-precision machining from one installation. Each machine is equipped with a probe to ensure quality control also is internally adjusted to the current situation on the machine.

Our team also provides documentation such as dimensional reports and first article submissions to validate the processing and data that parts meet all necessary specifications. We also decide the rework requirements and ensure that parts are made to specification.

Our Quality Promise:

- ISO 9001, ISO 14001, ISO 45001

- Material certifications

- Full report with every order

- Intermediate measurements on the machine

- Final inspection of parts by the quality control service

- Rework & refund policy

Ready to Get a CNC Machining Quote?

Online CNC machining service for rapid prototypes and production parts in metals or plastics. Get instant quotes today, and order your custom CNC machined parts at a better price.

What is CNC machining?

CNC, or computer numerical control machining, is a widely used manufacturing process that uses automated, high-speed cutting tools to form a design from metal or plastic stock. Standard CNC machines include 3-, 4-, and 5-axis milling machines, lathes, and routers. Machines may differ in how they cut CNC parts – the workpiece may remain in place while the tool moves, the tool may remain in place while the workpiece rotates and moves, or the cutting tool and workpiece may move together.

A skilled machinist operates a CNC machine by programming the tool paths based on the geometry of the final machined part. Part geometry information is provided by a CAD (computer-aided design) model. CNC machines can cut nearly any metal alloy and hard plastic with high accuracy and repeatability, making custom machined parts suitable for nearly all industries.

Alternatives to CNC Machining Services

While a CNC machining service is appropriate for creating many types of parts, it does have some limitations. For example, it can’t be used to create internal features such as internal cavities or conformal cooling channels. These are easily made using additive manufacturing methods like DMLS.

For certain types of flat workpieces, laser cutting, water jet cutting, wire EDM cutting, photo chemical etching or metal additive manufacturing may be more efficient.

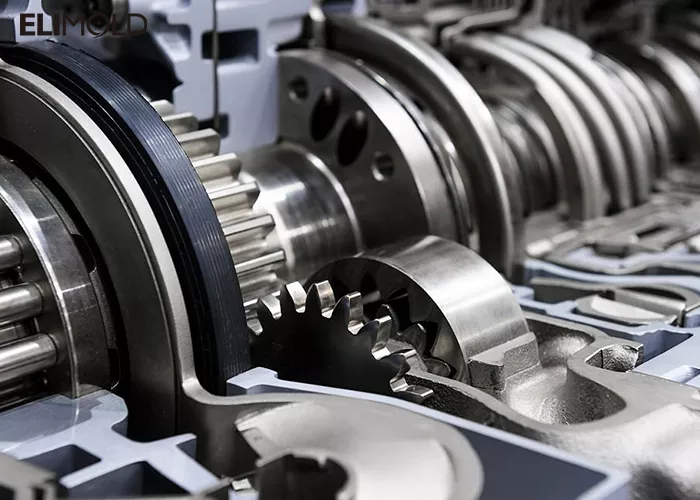

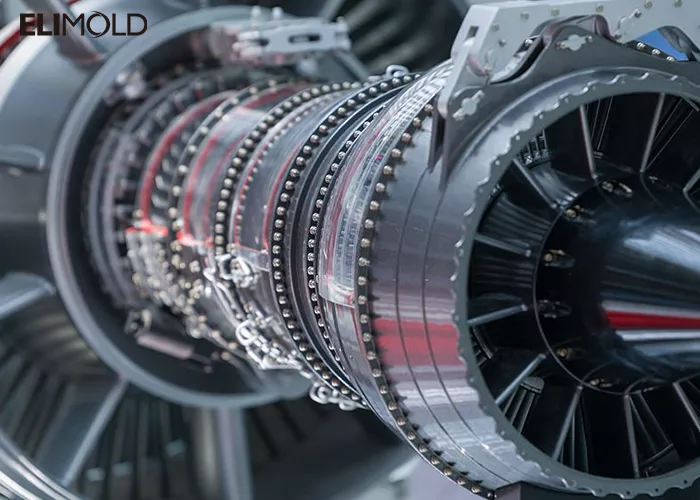

CNC Machining for Various Industrial Applications

CNC machining services are available for a vast array of applications across many industries, including:

F.A.Q.

CNC machining is a process used for designing machine parts that may either be prototypes or ready to be put into mass production. As one of the most popular processes for custom manufacturing, CNC machining can handle irregular geometries of intricate parts and is even used to produce mass production of parts once a prototype is approved.

We support many file formats to ensure we always meet the requirements of our clients. This includes popular formats of .stp, .sldprt, and .psm/.par. Moreover, we work with our clients to the end, so they get their desired results designed to perfection. This is the value we stand for.

At Elimold, not only do we have 3 axis and 4 axis CNC milling, but we also have 5 axis(HAAS) CNC milling services. These services provide excellent results, except when you need finer quality results. We suggest 5-axis CNC milling service instead of 3 axis or 4 axis milling service. Moreover, our CNC turning service employs a variety of tools and state-of-the-art software that ensures your desired components are created with accuracy and precision.

CNC machining has many benefits, including accuracy, precision, fast turnaround, the versatility of solutions, the ability to work with many materials, and being an overall economic solution compared to other solutions present in the market.

The following four factors determine the cost of a CNC machined part. 1) the time required for machining, 2) the type of material selected, 3) the geometry of the part to be machined, and 4) the startup cost of the project. Besides the client’s stated requirements, we try to make sure we take a course of action that leads to low cost without compromising the product quality. To determine the cost of your project, you can request a free quote.

Almost any rigid solid can be machined, including mild and stainless steel, aluminum, brass, copper, magnesium, titanium, and many engineering plastics. Check out our list of frequently used materials.

Our standard tolerances are 0.05 microns, which is suitable for most commercial and industrial applications. Consult with us if you need closer tolerances for special projects.

At Elimold, we offer CNC milling (3-axis, 3+2-axis and 5-axis) and turning. Milled parts can be machined up to 2000 x 1500 x 200 mm (78.7 x 59.0 x 7.8 in.) for 3/3+2 axis CNC milling. For 5-axis milling, the maximum part size is 650 x 650 x 300 mm (25.5 x 25.5 x 11.8 in.). The maximum diameter for CNC turning is 431mm (17 in.), length is 990 mm (39 in). The minimum part dimensions recommended are around 0.39 x 0.39 x 0.39 in. (10 x 10 x 10mm). The minimum for feature dimensions is 0.5 mm.

We are limited to a 1000 mm (39 in.) maximum size for parts on our platform. You can place the request through your account manager if you need higher dimensions.

Request Your Free CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.