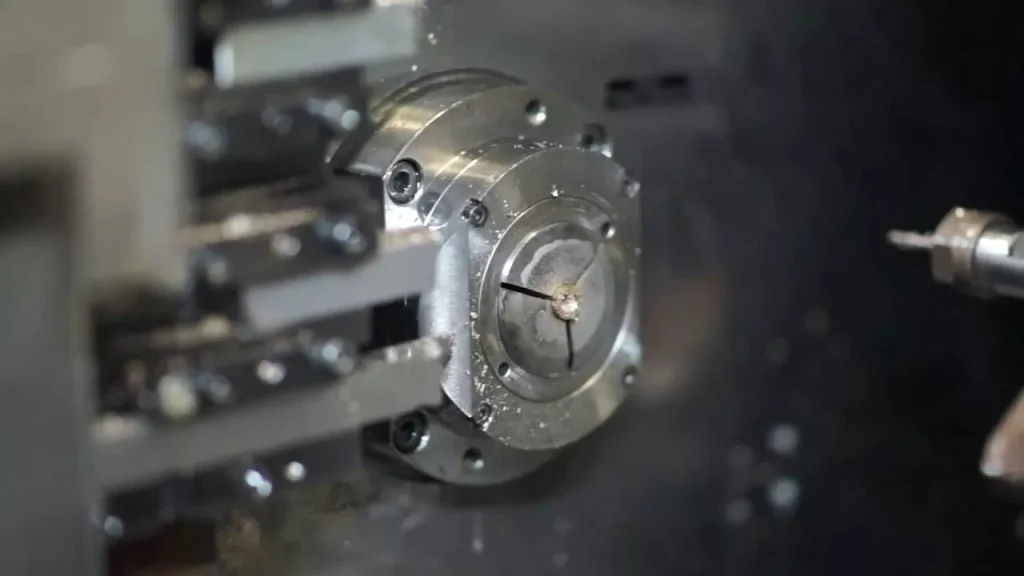

CNC Swiss Turning Services

Our precision machine shop’s state-of-the-art equipment ensures your Swiss turned tooling is manufactured quickly and built to tight tolerances. Elimold employs an experienced team of CNC machining professionals who are dedicated to providing you with the highest quality Swiss turning services.

Swiss Turning Services

From high precision CNC Swiss Turning services to high precision multi spindle production, Elimold matches the machine to your specific requirements optimizing cost effectiveness and ensuring quality.

Our CNC Swiss Turning equipment and service is a cost effective way to provide precise accuracy for small parts, long slender parts, and screws. Since CNC Swiss operations can produce complex parts in a single operation, production time is shortened. With our Swiss CNC equipment, we can perform multiple complex operations through computer controlled programming, resulting in tighter tolerances, high-quality surface finishes, and improved consistency.

Have a really unique precision requirement? Elimold can adapt a machine to make your specific part in high volumes. We are committed to providing our customers with the highest level of quality and customer satisfaction.

Swiss CNC turning capabilities

- Lights-Out Machining

- Multi-process Machining

- Broaching

- Hard Turning

- OD/ID Threading

- Tapping

- Thread Milling

- Thread Rolling

- Thread Whirling

- Ultra Precision: ±.0001″

- Diameter: ±.0001″

- Length: ±.0001″

- Roundness: ±.00008″

- Stainless Steel ( for example 303, 304, 416, Heat Treat SS, 17-4)

- Carbon Steel (for example 12l14, 1018, 1144, 1215)

- Aluminum

- Brass

- Copper

- Tool Steel

- Plastics (Delrin)

- Tubing, solid bars, hex bars, run special extrusions

- Light Mechanical Assembly

- Micro-deburring

- Vibratory finishing

- Prototype

- Low Volume

- High Volume

- Plumbing/HVAC – valves, housings, fittings, connectors, valve stems and other custom fittings.

- Automotive/Power transmission – shafts, spindles, valves, housings, standoffs, components for: powertrains, steering, braking, climate control and fuel systems

- Pumps/valves – sensors, valves, shafts, housings, fittings, stems and other precision metal components.

- Electrical/Electronics – steel, SS, brass housings, pressure sensors, pins

- Pneumatics/Hydraulics

- Custom Fasteners – Precision metal components made to order

- Engine Components – bushings, brackets, mounting studs

- Fire Suppression – brass, steel and stainless steel shafts, fittings, pivots, hubs, sensors, handles, rods, spools, pins

- Oil and Gas

- Work Holding

- Material handling

- Ag-Con – components for tractors, sprayers, dusters, harvesting equipment, etc.

- Outdoor Recreation/Lawn and Garden – shafts, housings, valves, fuel systems, brakes, steering, suspension components, pins, nozzles, etc.

- Fire Arms/Custom Knives – firing pins, nuts, barrel nuts, standoffs, pivots, bushings, studs, ejectors, pins, plunger, set screw, knurled nuts, swivel adapter

- Medical – custom/prototype, machined parts for respirators, pumps, dialysis equipment, specialty valve components, beds, wheelchairs

- Brass Stems

- Bleed Valves

- Worm Gears

- Specialized Screws

- Shafts

- Fittings

- Nuts

- Contact Pins

ISO Certification

Elimold is proud to be ISO 9001:2015 certified, allowing us to give customers complete confidence in our control over materials and processes.

Elimold ’s success is brought about directly from the success of our clients. As an ISO 9001:2015 certified CNC Machine Shop, you are assured our services meet industry quality standards. We exceed these standards with a dedication to precision demonstrated by our experienced and talented employees, cutting-edge CNC machines and a facility designed to handle high-volume productions. For services such as CNC Swiss turning, 5-axis CNC milling, CNC turning, CNC milling and CNC quality & inspection – rely on no other Machine Shop than Elimold .

Parts and components that flawlessly meet specifications

We constantly work with industries where extremely stringent quality specifications are an absolute must. By combining our ability to deliver machining close tolerance in the 40 to 50 millionth range with advanced quality controls and a firm dedication to lean manufacturing, our CNC Swiss machining services have met the needs for some of the most exacting requirements. This commitment to quality has helped us develop a significantly strong reputation for our ability to provide Swiss machining for medical components and other small precision parts.

By using concurrent engineering and exhaustive quality inspection, our technicians ensure that every CNC Swiss machining project can be completed as effectively and efficiently as possible—increasing part quality, decreasing production cost, and reducing lead times. Regardless of size or specification, our Swiss machining services provide a worry-free solution for precision Swiss machined parts and components that meet every quality and performance requirement.

How to meet your needs?

At Elimold, we understand that customers from a number of industries need CNC machined parts that are unique to their specific industry, business, and application. We learned early on that offering a wide range of services to suit a similarly wide range of needs was the best way to remain competitive. As part of this effort, we’ve complimented our state of the art CNC machining capabilities with high precision CNC Swiss machining capabilities.

What is CNC Swiss Turning?

The main difference between normal CNC lathes and CNC Swiss turned ones is how the part is manipulated in the machine. In the normal process, the workpiece remains stationary as the tool moves. In the CNC Swiss lathe process, the tools remain stationary as the lathe moves long the Z-axis.

This method of lathe operation offers greater versatility, producing parts that are complete without any need for secondary finishing. Complex and intricate profiles are easily programmed into the machine and completed in small or large volumes.

What are the advantages of CNC Swiss turning?

Complex Designs — CNC Swiss Turning machines can produce components with delicate and complex designs. Since the bar stock is well-supported during the tooling process, Swiss Turning can produce thinner walls, deeper cuts, and higher precision features than other manufacturing machines.

High Accuracy — Tight support of the bar stock virtually eliminates any extra force on the component that would impact the final manufacturing specifications. Even with extremely small components, CNC Swiss Turning can create products within tight tolerances.

Multitasking Manufacturing — In traditional CNC manufacturing, the bar stock typically rotates rapidly in a fixed position while individual tools are introduced one at a time to create the final product. CNC Swiss Turning moves the bar stock in and out of the work zone based on computer-generated manufacturing commands, allowing the machine to perform several tooling operations on the component simultaneously, including, milling, threading, drilling, boring, turning, and other custom finishing.

Optimal Cost — CNC Swiss Turning’s high precision machining and multitasking manufacturing enable our team to create higher quantities of products in shorter time frames. This makes the process more efficient from start to finish, which gives us the ability to save our clients time and money.

Contact US For A Quote

Our Quality Assurance engineers use the latest in inspection equipment and training to uphold uncompromising standards and enforce your specifications.