Oil & Gas Industry

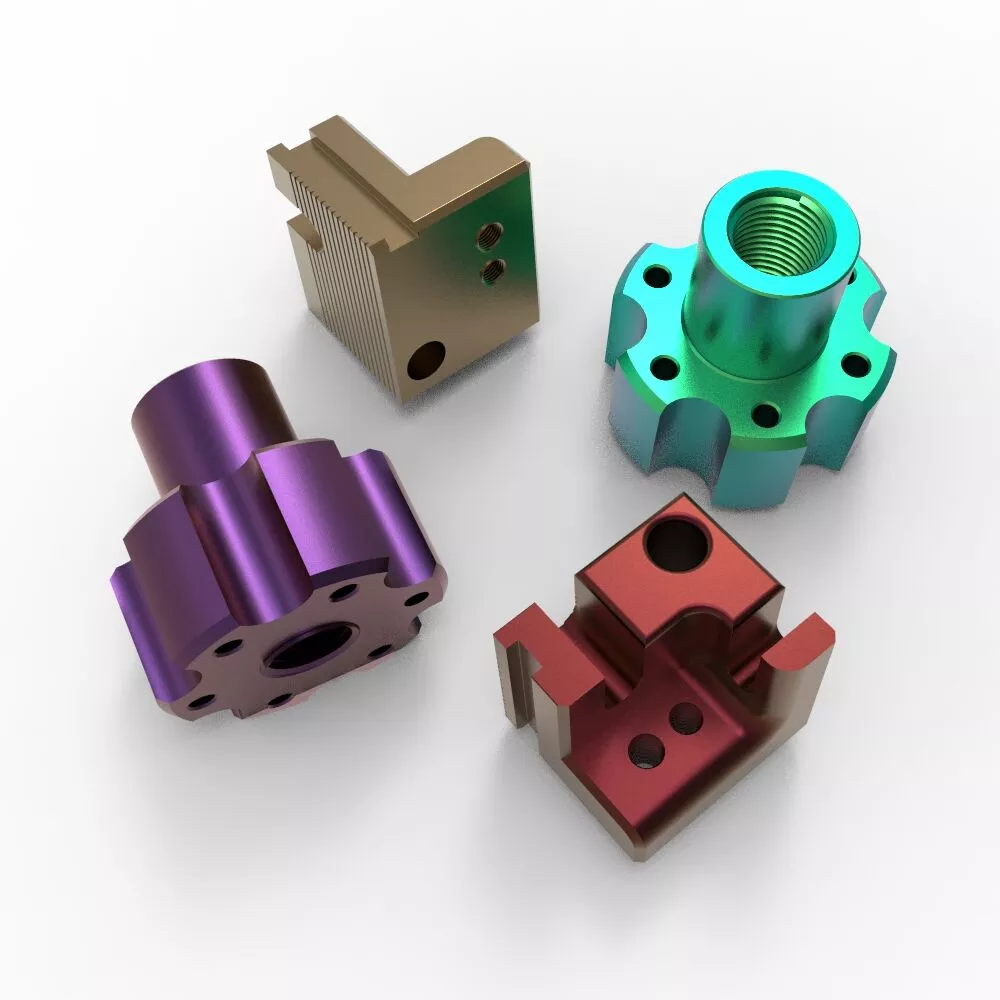

With a reputation for unmatched quality and exceptional customer service, Elimiold provides precision machining of custom parts and stock components to the oil and gas industry. Our parts provide superior performance and reliable integration into the high-speed, high-volume and corrosive environments common to this industry. Contact us now for a free instant quote.

Oil & Gas Custom Parts Manufacturers

Are you in the oil and gas industry looking for precision machining services for the oil and gas industry? If so, you’ve come to the right place. Custom parts manufacturers in this field require a team of professionals who specialize in custom components, specialized equipment, and systems that meet strict safety regulations and quality standards. Finding a reliable manufacturer with the knowledge needed to develop an efficient and cost-effective solution to meet your specific needs can be challenging. Elimold offers a full range of manufacturing capabilities, from custom machining to machining inspection and quality control, making it a leading full-service machining company you can fully trust. Elimold offers all types of custom machining services required by the oil and gas industry, making us a good partner for your oil and gas projects! And we have the skilled machinists, technicians, cutting-edge equipment, and experience you can trust.

Oil and Gas Equipment Manufacturing

At Elimold, we provide custom manufacturing for the oil and gas industry. With over 30,000 square feet of manufacturing space, state-of-the-art equipment and a dedicated team, we provide the necessary capabilities to provide you with high-quality, reliable and safe products that meet your exact needs. Serving the oil and gas industry includes designing and manufacturing the parts, products and components required for safe use in the industry. Elimold can provide custom solutions that meet and exceed your expectations. Not only do we have a variety of advanced equipment, our team has over 20 years of valuable experience in providing quality custom manufactured parts. Our team of experts will work directly with you to create a product or part that meets your exact needs.

Comprehensive Capabilities

We specialize in low-volume, highly custom parts, which is exactly in line with the needs of the oil and gas industry. In addition to CNC machining, injection molding, sheet metal fabrication and other services, we also provide industrial 3D printing services, and we help many customers re-make old service parts that they no longer have CAD drawings for through scanning and reverse engineering. We can then produce limited quantities of parts to keep important production equipment running and minimize expensive downtime.

In addition, some of our advanced manufacturing technologies do not require additional tooling. Parts can quickly go from CAD to finished metal or plastic, ready for use in your equipment. All of this is done in weeks, not months. Our service system can help you simplify your supply chain! Because Elimold specializes in short-run, high-mix production of highly custom parts, we are exactly what you need. We also provide a comprehensive portfolio of solutions to help you simplify parts procurement.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. Our own facilities and extensive manufacturing network enable us to efficiently deliver complex, high-quality parts.

CNC Machining

Injection Molding

Sheet Metal Fabrication

3D Printing

Extrusion

Die Casting

Vacuum Casting

Wire EDM

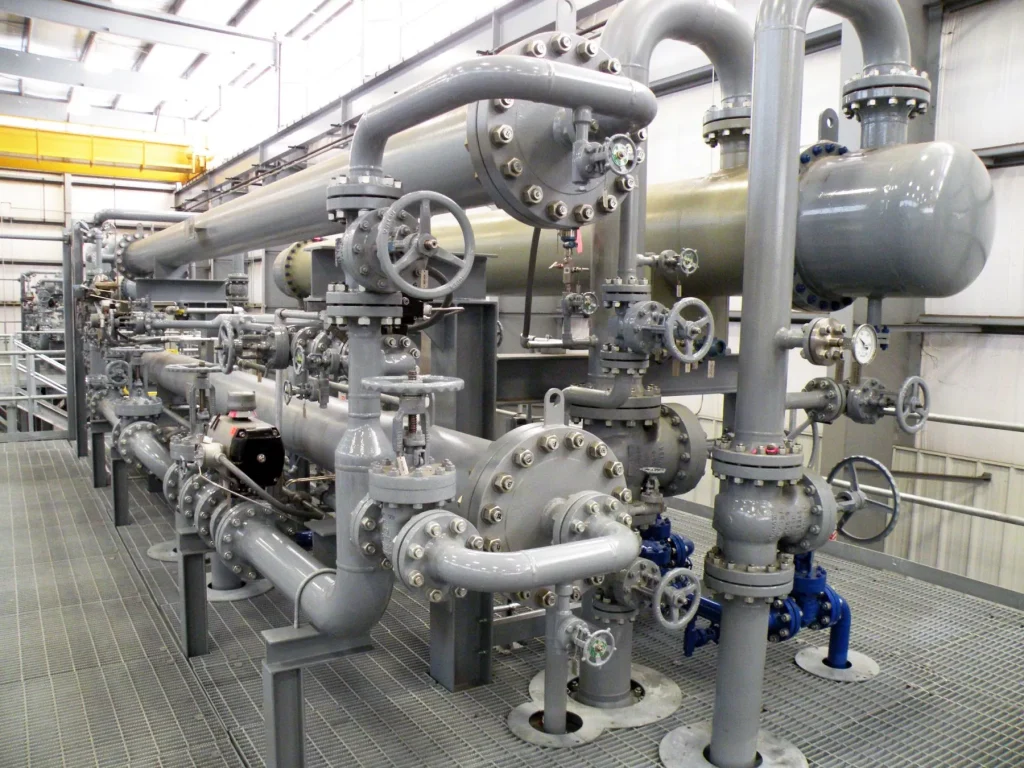

One-Stop Supplier for Oil and Pipeline Heavy Component Machining Needs

By working hand in hand with experts in the energy sector, we have found ways to create efficient manufacturing solutions in the fields of refining and oil well operations. Because of this, we have the ability to manufacture high-quality heavy-duty components for the energy field such as oil.

The oil and gas industry requires products or components that can withstand harsh working environments. Therefore, choosing a custom component processing company with extensive experience in this field is crucial to ensure the success of your manufacturing project. From drilling and exploration to production and refining, the oil and gas industry requires a variety of components and products used.

Our team of skilled engineers works closely with you to custom design the highest quality components to meet your specific project needs. And, we consistently produce reliable components for the most challenging jobs. Most of our customers only need one service to become lifelong partners. Precision manufacturing capabilities and the skills of our dedicated employees mean that the end result will exceed your expectations and improve your application every time.

In addition, the oil and gas industry requires durable, reliable components and often encounters unexpected situations that require unique solutions. Our perfect service system can ensure that the parts will be delivered on time, and provide excellent customer service and competitive prices. We provide custom engineering, in-house manufacturing and repair services to provide you with oil and gas equipment parts that perform extremely well in the field.

Oil & Gas Custom Parts Fabrication

The mechanical parts we provide to the oil and gas industry are built to last and withstand the rigors of busy field schedules and the inclement weather that often accompanies projects. Durable, high-quality tools, parts, and prototypes are the foundation of every successful oil and gas project, as are the suppliers you rely on to produce them. With years of experience serving the world’s leading OEM and Tier 1 manufacturers in the oil and gas industry, Elimold has a deep understanding of the industry and the needs of our customers. This, coupled with our unrivaled collection of the world’s largest equipment and hundreds of dedicated employees, enables us to provide precise, flexible, and tailored manufacturing solutions that ensure reliability, efficiency, and ongoing satisfaction. We can manufacture your most complex oil and gas parts using powerful CAD/CAM programs, state-of-the-art machinery, and experienced professionals. Our custom MRP system helps ensure clarity in communication, expectations, reporting, and forecasting, as well as on-time delivery, allowing you to focus on what’s important. Whether you’re pumping or drilling for oil and gas, we should be your first choice if you need custom mechanical parts for your oil and gas industry projects.

Oil & Gas Engineering Team & Capabilities

Elimold’s in-house Oil & Gas Engineering team works with your team to design and produce high-quality parts. We strive to deliver outstanding work on time and at a reasonable cost, but our strengths go beyond that, we are committed to ensuring customer satisfaction through our unique four-step risk reduction process. Our process minimizes cost, time, and frustration; while our Oil & Gas Engineering and Custom Fabrication ensure on-time delivery and quality. We believe it is important to provide every customer with the opportunity to use our custom fabrication services. Elimold’s custom fabrication services can meet your every exact need and specialized requirements while maintaining our high quality commitment to our customers.

Customization and Flexibility

Our team provides fully custom solutions based on the unique needs of each project. We have the materials, skills, equipment, and flexibility to meet highly specific design requirements and provide fast turnaround. In addition, our engineering capabilities allow us to assist customers in optimizing product designs to provide top performance and cost-effectiveness. The team at Elimold always puts customer satisfaction first, providing responsive and personalized service throughout the manufacturing process. From the initial call or consultation to post-production support, our team is committed to understanding customer needs, providing professional advice, and ensuring a smooth, worry-free experience.

Ready to Drill Into Your Project?

Speak to an oil and gas industry expert today! Our team is standing by, ready to help answer questions or get started on a quote for your project.

Value-Added Services

We embrace a Total Quality culture and strive to meet our customers’ requirements for quality acceptance and on-time delivery. Our processes and products meet the stringent standards set by ISO 9001:2015 and AS9100D. Other value-added capabilities include supply chain management with JIT, Kanban, and Dock-to-Stock programs. We also handle MRO packaging and assembly. Elimold’s experienced team takes pride in manufacturing high-quality assembly parts and components, and this pride is reflected in the craftsmanship of their manufacturing and assembly processes. Elimold’s team of experts provides the highest quality and most meticulous service in the industry.

Compliance & Quality Assurance

Elimold has a rigorous Quality Management System (QMS) that oversees every aspect of production. Our team is committed to adhering to industry standards and regulations through all of our services. Our compliance and quality assurance measures include material traceability (to track the materials that go into each product), dimensional accuracy checks (to ensure that each component meets all specifications and industry standards), and inspection procedures prior to each delivery. To provide our customers with the solutions they need, we are an ISO 9001:2015 certified company and incorporate lean manufacturing practices. Our service team will ensure that each customer receives the service and results they need. Our quality management system goes to great lengths to detect and prevent problems before you even know they exist. This multi-layered approach recently received an award for Outstanding Customer Service.

Why choose Elimold?

We have the systems, processes and technical expertise to deliver short-run, highly custom parts that meet the stringent requirements of the oil and gas industry.

- We have extensive experience reverse engineering and rapidly remanufacturing old service parts to keep your older machines up and running and help you minimize costly downtime.

- We specialize in new product innovation, rapid prototyping and bridge/short run production.

- We can support your needs throughout the product development lifecycle, from early design validation prototypes to production.

- We offer unmatched manufacturing expertise in-house, rather than through third parties, to meet all of your needs.

- We are problem solvers. We can solve complex geometries, short-run/high-mix parts and projects you thought were “impossible.”

Materials We Use

We frequently use the following materials when machining products for the oil and gas industry. These materials have different machining characteristics and require high finishes and tight tolerances.

Metals

- Alloys

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Stee

- Titanium

- Special Alloys

Plastics

- PVC

- Nylon

- UHMW

- Ultem

- Delrin

- PTFE

- PEEK

- Aceta

Surface Finishing Services

Elimold offers a variety of high-quality surface treatment processes to provide your products with aesthetically pleasing appearance and part performance.

- Standard

- Shot Blast

- Powder Coat

- Zinc Plating

- Chemical Coat

- Hot-Dip Galvanizing

- Heat Treating

- Wet Paint

- E-Coating

- Custom Finishes

Parts and Components We Can Produce

We provide high-quality products and services to our customers. Some of the oil and gas components we produce include:

- Piston, chevron and gland seals

- Anti-extrusion rings and back-up rings

- Valve seats

- Packings

- Bushings, bearings

- Lantern rings

- Frac balls

- Labyrinth seals

- Down-hole electical insulators

- Gaskets

- Lifting systems components (sheaves, rollers, guides)

- Drilling Bits, Stabilizers, & Collars

- Downhole Tools

- Flanges

- Valves

- Manifolds

- Couplings

- Choke and Kill Hubs

- Subsea Connectors

- Gas-Fluid ManifoldBlock

- Cylinder Block

- Shrouds

- Sight glasses

- Pipe and pipe support systems (saddles, carrier rings) grating/stairs

- Pumps and Compressor Components

- Wellhead Equipment

Ready to get started on your next Oil & Gas custom parts project?

Elimold’s dedicated team works with each customer to fully understand their needs, requirements and specifications. Our in-house team of engineers can provide expert design support to prevent potential defects, increase production efficiency and reduce costs. Contact us now for a free instant quote.