Drone(UAV) 3D Printing

With our advanced 3D printing technology, we can quickly and efficiently produce 3D printed drone parts that meet your specific needs. Whether it’s printing a single part, quickly repairing a damaged component, or the complete production of a drone, Elimold always provides a tailor-made solution. Contact us now for a free instant quote.

Advanced 3D Printing and Additive Manufacturing Solutions for UAV

At Elimold, we understand the complex product development cycle of the UAV industry. Whether you need a functional prototype for testing and validation, or an end-use part for a defense or commercial UAV, our additive manufacturing solutions support you from concept to production. Our focus on quality, precision, and efficiency ensures that our UAV solutions meet the rigorous standards of UAV manufacturing.

Elimold is your trusted partner for additive manufacturing solutions for the UAV industry. With our advanced technology, expertise, and commitment to quality, we enable UAV manufacturers to accelerate design iterations, reduce production costs, and bring innovative products to market faster. Contact us today to discuss your UAV 3D printing needs and learn how Elimold can advance your UAV innovation.

3D Printing Increases Drone Part Production

The use of 3D printing in drone manufacturing allows designers to create parts themselves in days instead of weeks, while potentially saving millions of dollars, producing better products at higher volumes. With Elimold’s in-house 3D printers, drone manufacturers can work with customers on specific design projects, ensuring accurate part production through rapid design changes and part iterations. 3D printing enables drone manufacturers to easily try out different versions of part designs, and as projects change, new designs can be easily printed with minimal effort and downtime. Eliminating the middleman in part production also enables drone manufacturers to work more efficiently and closely with customers to meet their exact design needs in less time.

3D Printing Reduces Drone Part Production Costs

Elimold’s 3D printing services can reduce drone part production costs by streamlining internal workflows, using affordable desktop 3D printers and affordable materials to produce durable parts. Using in-house 3D printers allows manufacturers to increase part production and optimize material usage. It also enables them to produce plastic parts without the need for injection molds, which are costly and significantly increase completion time.

Improving UAV Design with 3D Printing

3D printing improves drone design by enabling rapid prototyping of complex parts and achieving a high-quality finish for unique designs. Drone add-ons such as brackets can be prototyped and tested for strength, feel, weight, fit, and usability to ensure the final solution delivered to the customer is of high quality. Elimold’s 3D printing workflow enables manufacturers to address unique customer needs, develop new products, and improve designs at a faster pace. In-house 3D printing can speed up development timelines, allowing teams to work more closely with customers to complete unique projects for them.

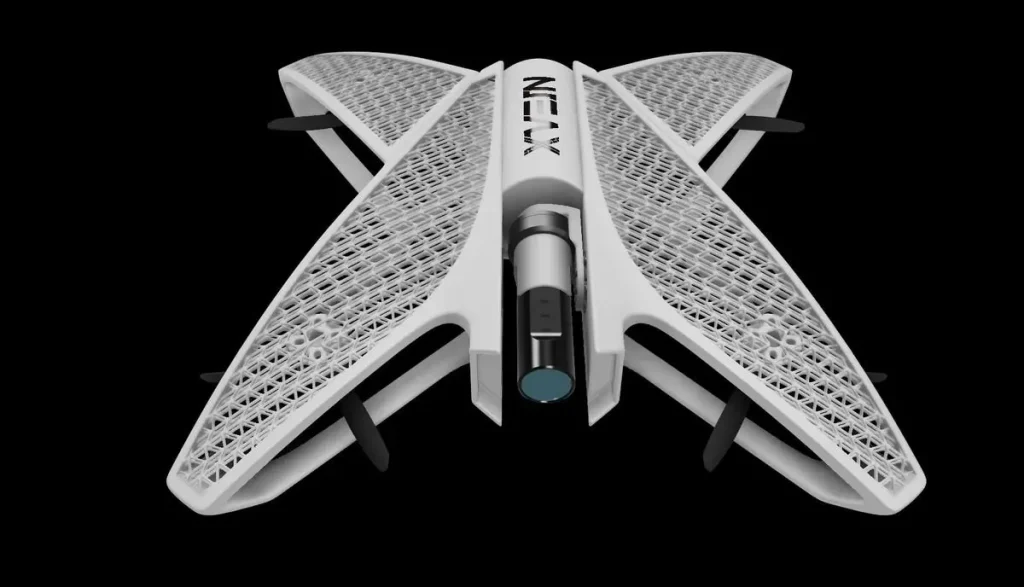

Accelerate UAV product development and production with on-demand manufacturing

We specialize in a variety of UAV projects designed to enhance the capabilities of drones, providing on-demand manufacturing services that are cost-effective and globally available. Our on-demand 3D printed drone parts enable users to quickly and independently assemble a drone anywhere in the world. We provide custom design services, project support, parts manufacturing, and CFD analysis, while maintaining a diligent design approach that prioritizes aerodynamic optimization and real-flight testing. We focus on providing customers with reliable, high-performance 3D printed drone parts to meet their unique needs, allowing professionals and enthusiasts alike to unlock unparalleled capabilities.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Stereolithography (SLA)

Selective Laser Sintering(SLS)

PolyJet

Multi Jet Fusion (MJF)

Digital Light synthesis(DLS)

Fused DepositionModeling (FDM)

Direct metal laser sintering (DMLS)

P3 technology (DLP)

Solidscape (wax deposition)

Rapid drone prototyping with 3D printing

With Elimold’s drone 3D printing rapid prototyping service, designers no longer have to spend hours analyzing the potential risks and drawbacks of new design features. High-resolution 3D printers can quickly produce new prototype parts for testing, minimizing waste. Drone manufacturers can produce replaceable modules with precise geometric accuracy without the need for expensive, time-consuming molded parts. 3D printing drone parts can shorten lead times, with the production of a new part taking only a few hours. Therefore, drone 3D printing not only has the advantages of greater design freedom and time savings, but it can also save a lot of money. Using shareable, easily modifiable CAD files during the design phase also makes it easy to replicate designs.

3D printing services enable efficient manufacturing of drone parts

Drones and 3D printing are a perfect match! The benefits of drones are becoming more and more attractive to many drone manufacturing companies as it can allow you to create your own drone, a perfect way to custom your drone to suit your needs. Additive manufacturing technology is cheaper and the product development process is faster. It is possible to make truly lightweight drones, small or large drones, and even faster drones. 3D printing can be said to be a wise choice for developing drone projects. If you’re not going to use 3D printing to mass-manufacture your drone, you can at least use 3D printing during the prototyping stage.

Develop Your Drone Projects Using Additive Manufacturing

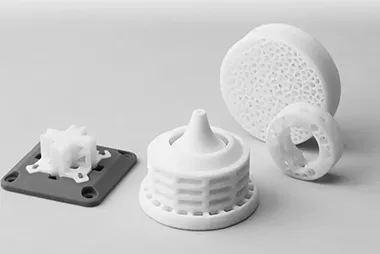

Creating lighter, stronger, and more functional drones, requiring less assembly and fewer parts is not a dream anymore. You can now use additive manufacturing to make tailored fixtures and lattice structures to reduce the weight of your drone parts. This technology is also the ideal solution to manufacture iterations to adapt your products to your client’s needs. Get the opportunity to manufacture light and reliable drones, with a perfect finishing, integrated features.

How 3D Printers Work For Drone

- 3D printing is used to create 3D printed UAV and also help you with your drone project.

- Drone parts such as the propellers, frame, antenna mounts, the prop protectors, landing gear, etc can all be printed with the drone 3D printer. You can carry out rapid prototyping at the same time and produce a finished product while saving printing material.

- As a large commercial company like agriculture or entertainment, you can use the drone 3D printer to develop your drones. The printer can also be used by hobbyists.

- The 3D printer allows production costs to be reduced unlike traditional production methods.

- Crashing and breaking parts of your drone can be expensive. Instead of buying new ones, you can 3D print your own spare parts as needed.

- You can also print optional drone accessories to add-on protective equipment like a prop guard.

- Printing your 3D drones saves you more cost than the traditional drone.

3D Printing Solutions Infuse Innovation into Your Robot and Drone Projects

At Elimold, we use the latest 3D printing technology to bring your drone designs to life. Our printing technology can easily produce a variety of components for robots and drones, including frames, housings, sensor mounting points, and complex gears and linkages. We can quickly produce precision parts that match your exact design, shorten product development cycles, and thus accelerate your time to market. And complex molds and tools are no longer required during the design process, which greatly reduces the cost of prototyping and small-batch production. Design changes can also be easily handled, increasing the flexibility of product iterations.

Are you curious about how to use 3D printing to improve your drone project? Our team of experts is always ready to provide advice and guidance. No matter the size of your project, no matter how complex your design needs are, Elimold is confident that we can provide you with a satisfactory solution.

Ready to get started on your next drone project?

Discover the seamless, turnkey process of working with Elimold. From contacting us to understand your requirements through a detailed consultation, to design, recommending materials and finishes, and moving into production. We offer a state-of-the-art manufacturing lab, paint booth, design and engineering teams, and 3D scanning capabilities to ensure high-quality results and exceptional customer satisfaction every step of the way.

Drone Development

Develop drones that meet specific functional and operational needs using Elimold’s 3D printing technology. Create detailed models of various types of drones to increase performance, reliability, and customization for a variety of applications. Our team of engineers and designers evaluate your specific needs for drone functionality and performance, creating detailed digital models that focus on the precise requirements of each application. In addition, we use advanced 3D printing technology to manufacture custom drone components and detailed models. This ensures that the drone meets specific operational needs and operates reliably.

Elimold's 3D Printed Drone Parts

Elimold offers the world’s finest drone parts manufacturing, providing precision-engineered components tailored to enhance drone performance. Our state-of-the-art 3D printing technology ensures unparalleled accuracy and durability, delivering custom parts that meet the highest industry standards. Whether for recreational use or professional applications, our carefully crafted drone parts guarantee superior functionality and longevity, setting a new benchmark in drone manufacturing. Elevate your drone experience with Elimold’s superior drone parts.

3D Printing Solutions for Drones

For drones, high-precision and lightweight components are essential to ensure optimal performance. However, manufacturing these components using traditional methods can be challenging and time-consuming. With our 3D printing solutions, you can easily produce components and complex assemblies, providing a cost-effective and fast alternative to traditional manufacturing methods. Our technology is able to manufacture high-precision, lightweight end-use parts that exactly meet the needs of robots and drones. This allows for increased design flexibility and the ability to manufacture custom parts to meet the specific requirements of a project.

These parts are designed for improved performance, durability, and personalization. 3D printing enables precise, lightweight structures and the flexibility to create unique components that meet your specific needs. Whether you are replacing a damaged part or upgrading your drone with a custom design, our 3D printed parts provide a reliable, high-quality solution.

Benefits of 3D printing drone parts

The 3D printing industry allows you to create your own drone; custom drones can be obtained based on demand. Additive manufacturing technology is cheaper and the product development process is faster. It is possible to build lightweight drones, drones of different sizes, and even faster drones.

- Create lightweight parts: Parts made through 3D printing are lightweight and have excellent strength. These are two prominent factors required for a drone.

- Complex Design and Assembly: Designs and bodies of any complexity can be easily 3D printed, allowing new designs and variants to be easily tested.

- Maintenance management, spare parts: Any maintenance and spare parts can be manufactured using 3D printing technology and different materials at the click of a button.

- Mass customization: 3D printing technology enables faster manufacturing in less time and enables mass customization at a moment’s notice

- Optimize your parts by rethinking your designs: Highly detailed, microscopically accurate, and smooth scale models printed with 3D printing technology are often used to illustrate design ideas. These models can also help in situations where CAD models are insufficient to identify design issues.

- Get the perfect fit: 3D printing allows you to create a variety of styles that can be further custom according to customer requirements

- Custom Drones: 3D printing enables you to manufacture personalized drones as per your needs and requirements. This increases the feasibility of manufacturing custom drones. Any specific part of a store-bought drone can also be custom to suit your needs.

- Easy upgrades: 3D printing supports the upgrade of drone parts to make them more efficient. Design iterations with this 3D printing technology are very economical compared to traditional manufacturing processes. This brought scope to make many modifications to the 3D design, 3D print, and test the 3D printed parts until the desired results were achieved. Flexibility and speed don’t get in the way of experimentation.

- Improved performance: The weight of a drone affects its flight time. The lighter the drone, the longer it can fly. Lightweight drones can extend battery life and be more responsive and agile during flight. UAV components are made lighter by optimizing the design structure and maintaining aerodynamic performance. The choice of materials used for 3D printing also plays a crucial role in making parts lighter, giving designers the flexibility to try different materials during the prototype stage.

Materials

Plastics

- PLA

- ABS

- Nylon

- PET

- Carbon FIber

Lightweight Composites

- Carbon Fiber Composite

- Fiberglass Composite

- Kevlar Composite

- Basalt Fiber Composite

- Thermoplastic Composites

Metals

- Aluminum

- Titanium

- Magnesium Alloys

- Copper

- Super nickel alloys

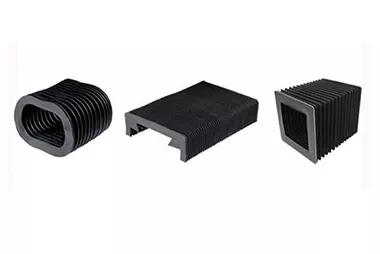

Post-processing

At Elimold, we not only produce custom parts, but also offer a wide range of post-processing services. This allows us to fully custom your 3D printed drone to your needs.

- Anodizing

- Passivation

- Plating

- Powder coating

- Insert mounting

- Heat treatment

- Shot peening

- Vapor polishing

- Part coloring

Part Type

- Bumper

- Camera Bracket

- Antenna Bracket

- Propeller Guard

- Propeller and Fin

- Arm End Assembly

- Gimbal

- Battery Compartment

- Wire Wing

- Bracket

- Grommet

The difference between 3D printing and injection molding for manufacturing drone parts

3D printing drones can create stronger and lighter parts than injection molding. These two very advanced technologies meet in a special way. We have SLS nylon production machines that can produce high quality and very precise parts. This selective laser sintering printer can print parts up to 2 feet tall in extremely durable plastic. Durability is key for drone parts. Drones are difficult to stay airborne at all times, so they need to be strong enough to survive a hard landing. This is where SLS 3D printing comes in. Since flight time is so important and light weight is a key factor, 3D printing allows the weight of their drones to be reduced through internal support that injection molding cannot provide. Unique design designed to improve efficiency and appearance. This nylon plastic is lighter than carbon fiber and does not interfere with radio signals used to fly drones.

Drone Injection Molding Services

With Elimold drone injection molding manufacturing services, injection molded drone parts are mass-produced based on fixed molds and cannot be adjusted to the customer’s needs if the design needs to be changed. Injection molding also involves storage costs because parts are mass-produced in a short period of time. However, this also means that large batches of parts can be produced at a faster rate using injection molding, with the potential to increase quantities to series production levels. Injection molding also provides higher quality parts compared to 3D printing.

Start your Drone Project Today

Professional 3D printing is at your fingertips. Create a free account and upload your 3D files, select your material, technology, and post-processing options, and order online. We’ll take care of the rest in our industrial ISO 9001 factory.