CNC Drilling Service

Elimold is proud to offer high-quality CNC drilling services to our valued clients. Our state-of-the-art equipment and experienced technicians allow us to produce accurate and precise holes in a variety of materials. Whether you need a single prototype or high-volume production, we can deliver the results you need on time and within budget.

High-Quality CNC Drilling Services for Precision Parts

We take pride in providing the best CNC drilling services for the fabrication of parts of any complexity, whether in small or large series. With our state-of-the-art equipment and expertise, we ensure exceptional results for all your drilling needs.

At Elimold, we utilize a range of advanced CNC drilling machines, including upright, bench, and radial models. This diverse selection enables us to drill holes of simple and complex patterns, with diameters reaching up to 7 cm. Whether you require precision drilling in metals and alloys such as aluminium, steel, copper, or various polymers, our services cover a wide range of materials.

We maintain strict control over the entire drilling process, ensuring that our exacting quality standards are met every time. Our integration of advanced CNC drilling equipment with our machining centers allows us to execute precise and efficient drilling operations for your parts.

Industrial Boring & Counterboring Capabilities

Our drilling equipment includes automated lathes and horizontal boring mills.

We have the capabilities to hold tolerances to +/- .0005” to depths of .250” and diameters of 3”. Our production capabilities include full production run quantities, low-volume runs and prototypes – all to our high quality precision standards.

Our custom machined parts meet the high industry standards set by the American Fastener Institute, ASME, and Mil-Spec, ensuring that your part will meet your exact requirements and perform as expected in your finished product.

Elimold has earned its reputation for manufacturing the highest quality custom machined parts for our customers and is committed to providing each customer with a custom solution for their application.

CNC Drilling Materials

- EN AW-2007 / 3.1645 / AlCuMgPb

- EN AW-6060 / 3.3206 / Al-MgSi

- EN AW-6061 / 3.3211 / Al-Mg1SiCu

- EN AW-6082 / 3.2315 / Al-Si1Mg

- EN AW-5083 / 3.3547 / Al-Mg4,5Mn

- EN AW-7075 / 3.4365 / Al-Zn6MgCu

Custom aluminium alloys are also available

Steel:

- 1.0038 / St37-K / S235JR

- 1.0503 / C45

- 1.0570 / St52-3 / S355J2G3

Stainless Steel:

- 1.4301 / X5CrNi18.10(V2A)

- 1.4404 / X2CrNiMo17-12-2 (V4A)

- 1.4571 / X6CrNiMoTi17-12-2

- 1.7131 / 16MnCr5

- 1.7225 / 42CrMo4

Custom stainless steel alloys are also available

- 2.0060 / E-Cu57 / Cu-ETP / CW004A

- 2.0065 / E-Cu58 / CW004A

Custom copper alloys are also available

- Ms58 / 2.0401 / CuZn39Pb3

- Acetal / Delrin / POM

- Nylon / Polycaprolactam

- PC / Polycarbonate

- PEEK / Polyether ether ketone

- PEEK Glass-Filled

- PTFE / Teflon

- UHMW PE / Ultra-high-molecular-weight polyethylene

Custom polymers are also available

Finishing | Surface treatment

- Coating: galvanic component coating with: zinc, nickel, chrome, etc.

- Anodizing of aluminum: in various shades or hard coatings

- Surface treatment: brushing, matting, polishing, blasting, painting, powder coating

- Heat treatment: +NT; +QT

CNC Drilling Capabilities

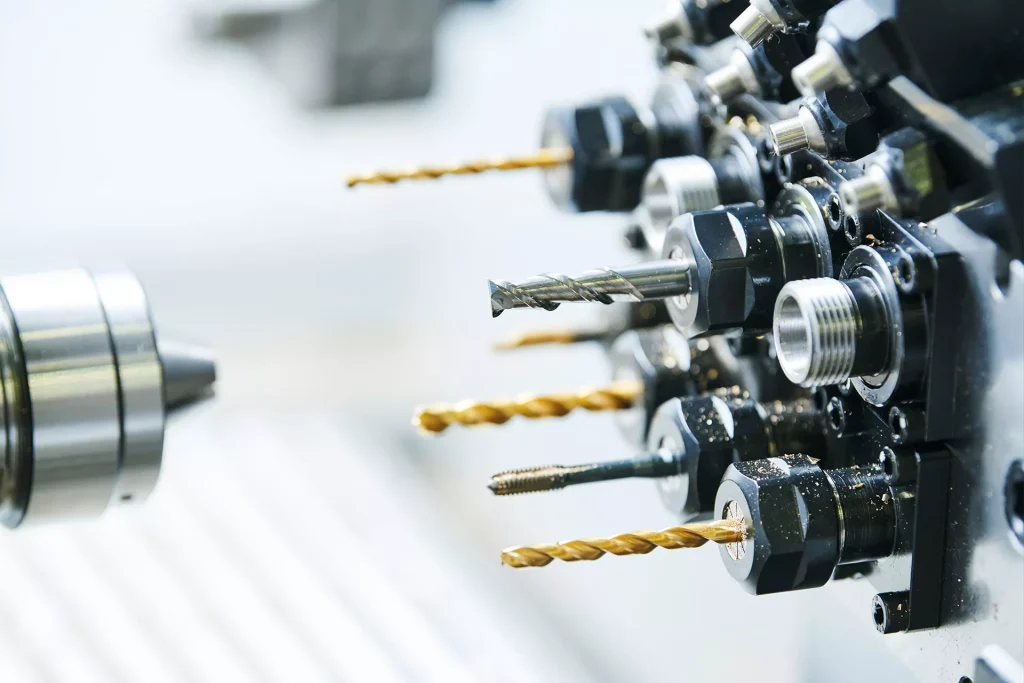

1. CNC Drilling Machinery

Our CNC machine shop has equipped with CNC vertical machining centers and lathes, including CNC vertical machining centers, Swiss automatic lathes, and multiple spindle drills, allowing for the fabrication of parts in a wide range of raw materials, shapes, dimensions, and types.

2. A Variety of Spindle Drills

A full line of spindle drills confers our operators to the advantage of being able to produce components to our clients’ exacting drawings or specifications. Our incredible in-house CNC drilling capabilities include: sub spindle, active tooling, turning, threading, and drilling in multiple axes, and a 12-foot-long bar feed.

3. CNC Drilling Shapes

Runsom offers custom CNC machining and drilling services at a rapid turnaround and competitive price for global customers. We focus on drilling and manufacturing parts with complex shapes in tight tolerance. Available shapes are square, round, flat oval, teardrop, D-shape, rectangle, and custom shapes.

4. A Wide Range of Materials

Whether your application calls for soft or hard metals, Runsom has the keen expertise to provide high-quality custom metalworking and CNC drilling services. We manufacture parts in designated materials according to your designs. We work with aluminum, stainless steel, alloy steel, carbon steel, titanium, brass, as well as plastics.

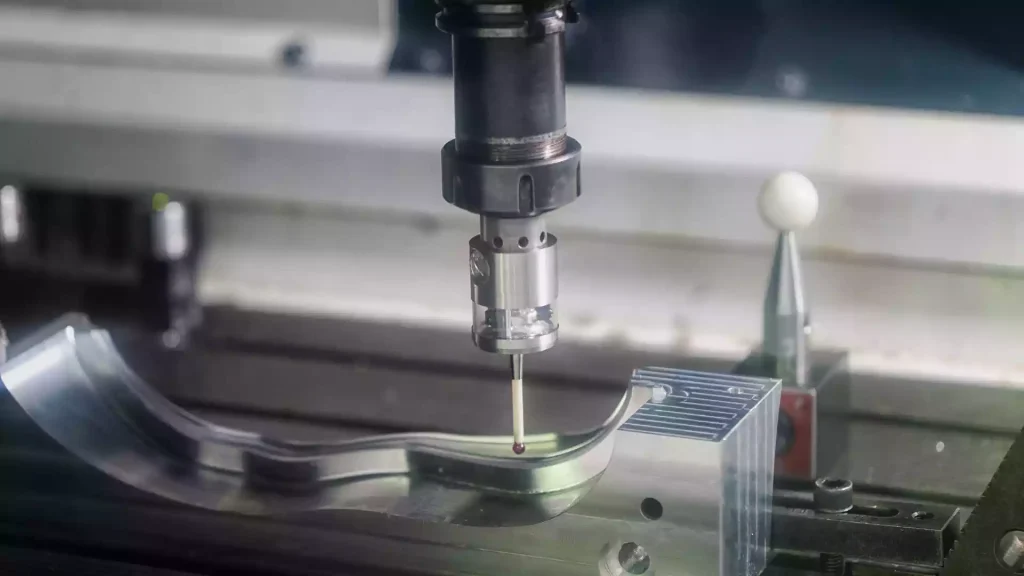

What Is CNC Drilling & How CNC Drilling Works

Drilling is the cutting process in which the workpiece does not move, making the cutter move, aligning the cutter center with the hole center, and making the cutter rotate. CNC Drilling is primarily done on CNC machines including CNC milling machines and lathes. CNC drilling service produces round holes, typically for machine screws and bolts. Drilling can process CNC drilling parts with metals, hard plastics, wood and most other rigid materials. There are several types of drilling machines available for CNC, including these drill presses: Upright, Bench and Radial. When in use, the step-by-step process for CNC drilling includes:

- The operator uploads and accesses the computer-aided design (CAD) or computer-aided manufacturing (CAM) file.

- The operator installs the appropriate drill bit and secures the designated material on the table.

- The operator starts the drilling process through the control panel or interface.

- The spindle lowers, drilling the appropriate hole sizes and diameters.

Our Advantages of cnc Drilling Service

Accuracy: The precision ofered by our CNc Driling is unmatched.It has provided companies in alindustries with many returns,including raised productivity,lowered expensesand optimized production lines.

Versaitily: i’s a sinicant advantage that our CNc driling machines are capable of aceptina multinle bits. While oerator mav ned toue a differentvpe of dhiing machine.

they can equip that machine with a series of bits. Some machine types include a tool urret for even faster shufling between bits.

Reproducibility:.A continuous chalenge for companies across markets is producing identical batches of products. This hurde becomes amplifed for custom machining projectsWith our CNC Driling service, however, those challenges are solved, leading to a consistent, imperfection-free production line.

CNC Drilling Applications

A multitude of applications requires precision machined parts with consistency, complex dimension, accuracy, and tight tolerance to function and fit perfectly into their assembly as intended. With its great precision, efficiency, and versatility, CNC drilling is preferred by various industries to make quality products, such as lighting, construction, medical, agriculture, aerospace, military, automotive, and pharmaceuticals.

Across a wide range of industries, CNC drilling is commonly practiced in machine shops and mass production facilities to create and modify furniture, brush handles, boats, shoe lasts, golf clubs, and more.

These CNC machines create parts with ultimate accuracy, precise dimensions, and high efficiency. The quality and market delivery of OEM end products will be greatly promoted by using CNC machined and drilled parts.

This manufacturing technique effectively and fast produces precise holes or threads in a fraction of the time required by manual operations. It’s for this reason that some critical industries often utilize CNC machining to enhance efficiency and productivity while lowering costs, especially automotive, aerospace, military, medical, defense, and pharmaceuticals.

Custom CNC Drilling Services

If you need any metal and plastic materials CNC Drilling and custom surface treatment services