Rapid Prototyping Services

Have a product design, idea or invention? With our rapid prototyping and manufacturing services, you can make your concept a reality. As your rapid prototyping company, our services have you covered from the beginning of product design to full-scale manufacturing. We are prototype parts manufacturers with the capabilities and expertise to assist you at every step of your development process.

Professional Rapid Prototyping Service Provider

Are you looking for ways to accelerate your new product development process? Looking for a manufacturing partner that can provide not only equipment but also design and engineering expertise to help you bring your ideas to market faster? Elimold has more than 20 years of rapid prototyping experience, has worked with more than 50 internationally renowned companies, completed more than 30,000 projects, and manufactured 400,000+ prototypes. With rich experience in prototype manufacturing, Elimold is a prototype expert you can trust. Working with Elimold, with our cutting-edge prototype design and production manufacturing technology, advanced industrial-grade equipment, and a professional team of engineers, Elimold can transform your ideas from design to market in just a few days. We look forward to working with you!

Advanced Rapid Prototyping Facility

With over 104,000 square feet of manufacturing space, 3,000 square feet of protected component storage, and an additional 5,000 square feet of storage, our rapid prototyping facility offers the highest level of flexibility and integration, allowing us to truly serve our customers at every stage of the product lifecycle. With our dedicated rapid prototyping facility and two separate mass production facilities, we are committed to building long-term, trusted partnerships based on quality, communication, collaboration, and loyalty. This allows us to work with you from the rapid prototyping stage to full production. Choosing Elimold allows for faster transitions, eliminates the hassle of finding a new supplier, and minimizes equipment retooling costs.

Complete Solutions for Rapid Prototyping

In today’s market, your competitive advantage depends on time. You need to strike a balance between speed and quality because the market waits for no one and never forgives anyone. Our rapid prototyping capabilities can help you get more done in less time, successfully achieve your time-to-market goals, and build a competitive advantage. Therefore, we provide fast and reliable complete solutions for companies looking to quickly and efficiently produce high-quality prototypes and low-volume production parts. Elimold uses a variety of advanced manufacturing technologies to provide precision custom prototype parts to accelerate your production process, shorten delivery time, reduce costs, and help you get your products to market faster. Our strong in-house factory manufacturing capabilities have lead times ranging from 10 days to 6 weeks.

One-stop Rapid Prototyping Part Manufacturing Service

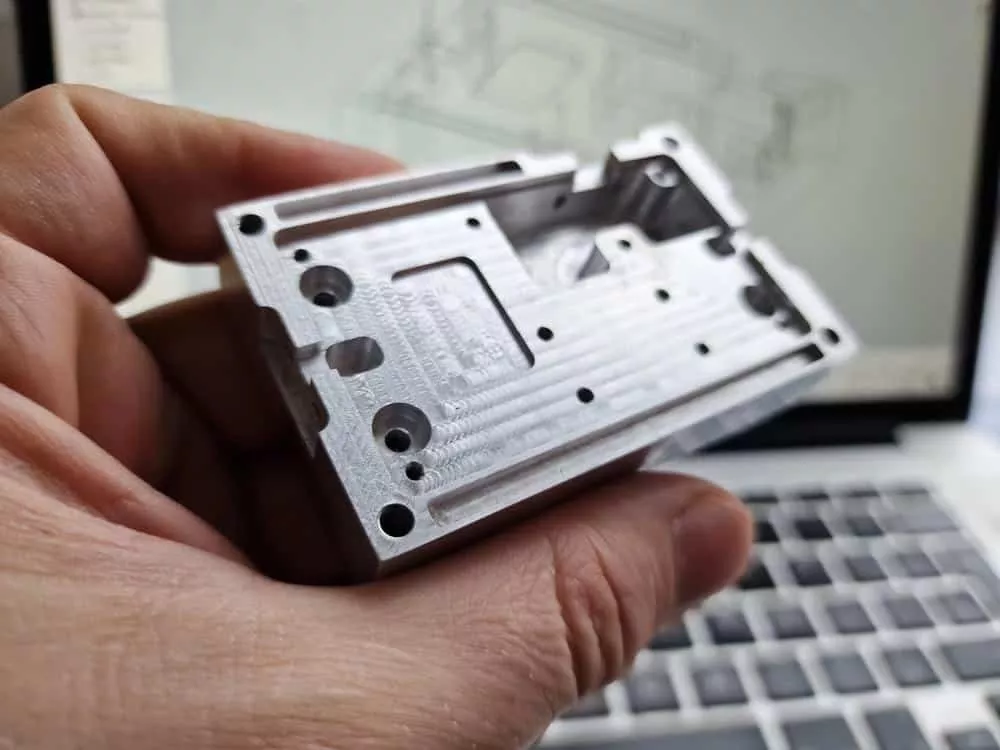

Elimold is your one-stop service provider, helping you to go from sketches on napkins to products on the shelf. With the powerful combination of our cutting-edge technology, top-notch equipment and engineering expert team, we can quickly produce your product prototypes and put them into production, saving you time and effort, helping you quickly turn product concepts into reality. Our advanced technology can quickly iterate and test prototypes before full-scale mass production. We help companies shorten development cycles, reduce costs and improve product performance through accurate and high-quality prototypes. Our expertise covers a wide range of industries, ensuring custom solutions that meet specific needs. Whether you need a functional prototype or a visual model, our team can provide innovative solutions to accelerate your product’s time to market.

From Concept To Prototype To Production

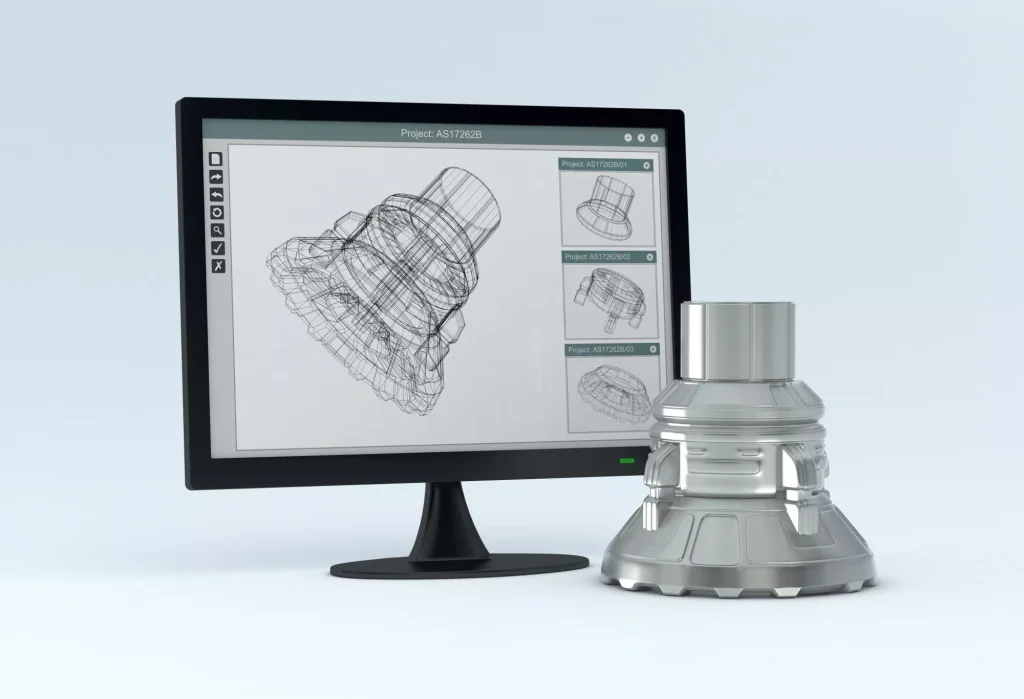

Elimold can support your design and manufacturing of prototypes, tooling, test jigs and fixtures. We have the engineering expertise and experience to assist in the design of refractory metal components. This is one of our specialties, and customers tell us it dramatically shortens the time from prototype concept to finished design.

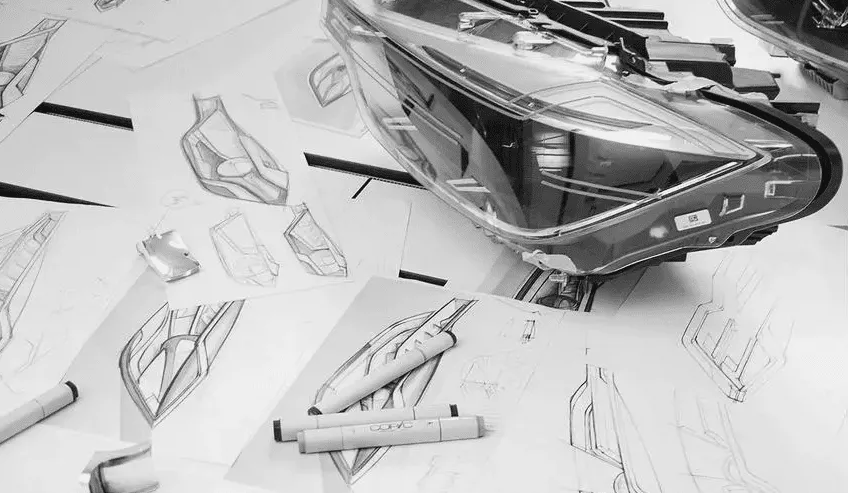

Design

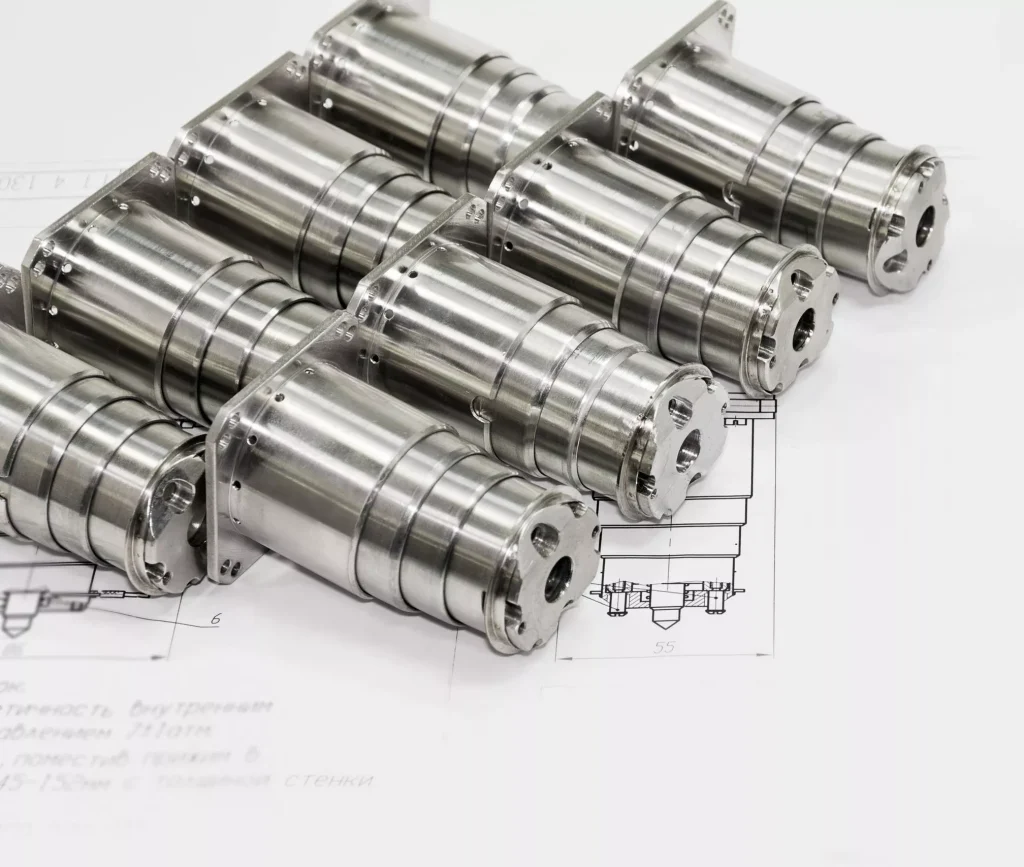

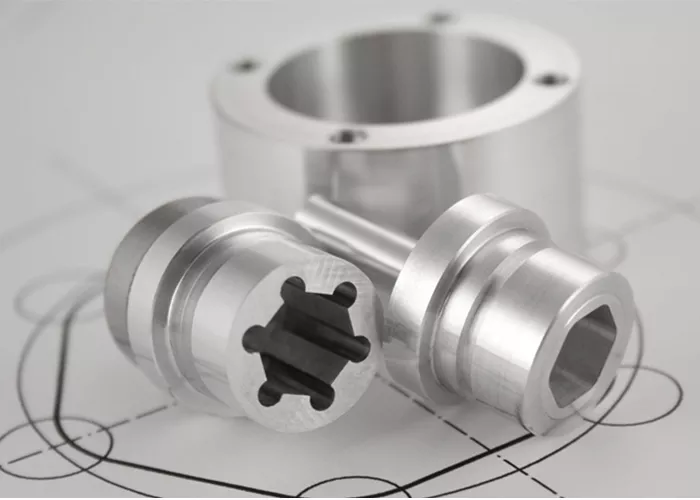

Prototype

Production

R&D and Engineering Services Capabilities

Whether you need turnkey product development or input at critical stages of the design process, we can help you advance your product from conceptualization to mass production using precision engineering. We will provide assistance throughout the R&D and prototyping stages, provide design for manufacturability recommendations, and guide you in selecting the right materials and manufacturing processes to achieve your delivery goals. In addition, when you need high-volume production, we will also provide practical guidance throughout the project, from design reviews and material recommendations to process selection and DFM feedback. Whether you are iterating quickly or preparing for large-scale production, Elimold can help you make informed decisions, avoid costly delays, and ensure that your prototype performs as expected.

Design for Manufacturability (DFM)

DFM and rapid prototyping go hand in hand. Carefully following the DFM process during rapid prototyping can save time and money. We are fully capable of manufacturing to drawings, but we also use our composites expertise to assist you in product and process design to maximize the benefits of composites. We provide DFM recommendations to help your engineers select the right materials and processes from our comprehensive capabilities to achieve cost and lead time goals. Rapid prototyping is one of Elimold’s core competencies and is backed by our unrivalled engineering expertise. We can help you develop a process that will help you test, validate and finalise your part design quickly and cost-effectively.

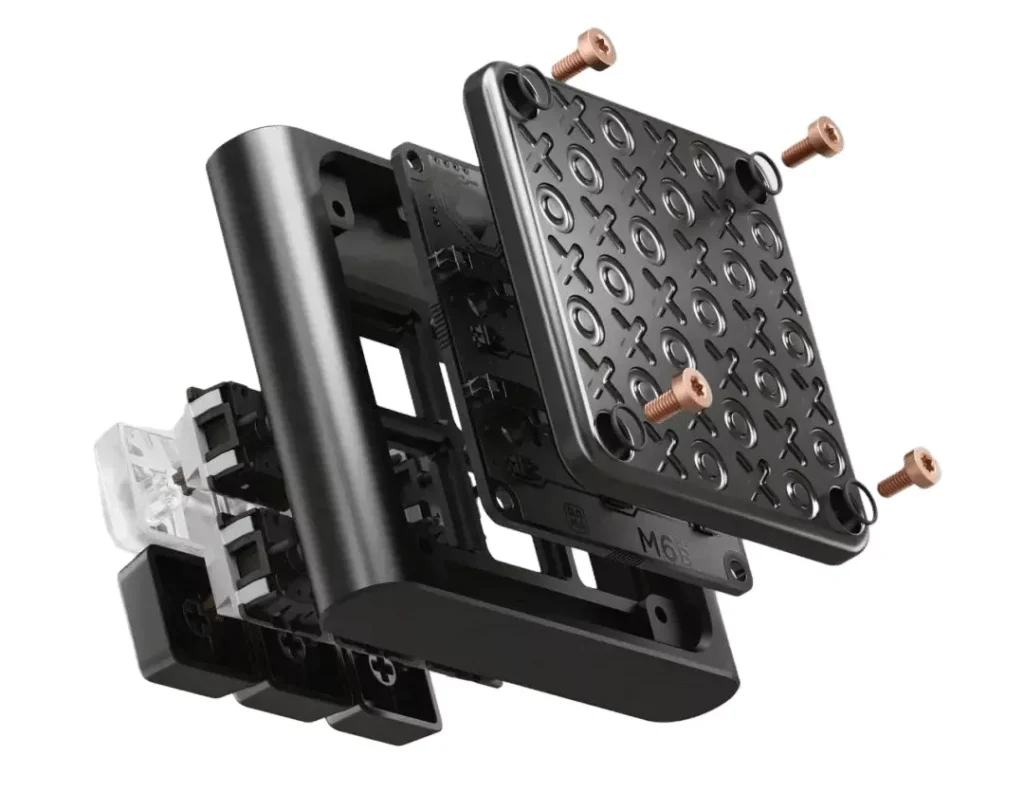

Assembly Services

Our customers are often under pressure to bring new products to market with very tight development schedules. Many customers require custom production of highly complex, technologically advanced mechanical components that need to be assembled and tested. Elimold’s technicians not only manufacture the parts, but also put them all together to provide fully assembled, ready-to-ship complete assemblies, including integrating custom sub-assemblies and assemblies manufactured in-house with outsourced components. In addition, we can support the assembly process by designing and producing custom units, and we ensure consistency and consistency from one build to the next. No matter the complexity or lead time of the project, no matter the size of the customer, Elimold can provide personalized attention and input to meet their needs.

Effectively Manage Prototyping Costs

The expenses incurred by multiple prototype iterations can present significant challenges for customers. Each modification typically requires additional resources, including materials and labor, which can quickly accumulate. When quick adjustments are needed to address design flaws or functional issues, these costs can exceed the initial project budget. Elimold addresses this issue by implementing an efficient prototyping process that minimizes waste and optimizes resource utilization. Advanced technology and streamlined workflows help reduce the cost of iterative prototyping, enabling effective design validation without compromising financial constraints.

Quality Control

At Elimold, we specialize in rapid prototyping, providing a fast and efficient way to create high-quality prototypes that meet our customers’ specific needs. Our advanced prototyping techniques allow us to produce parts with fine detail and excellent precision, allowing for faster iterations and time to market. We implement stringent quality control measures to ensure that each prototype meets the highest standards of quality and functionality.

In-Process Inspection

Our quality control begins with in-process inspection, where each part is checked at various stages of production to ensure it meets the design specifications. This proactive approach helps to identify and correct any issues early in the manufacturing process.

Final Inspection

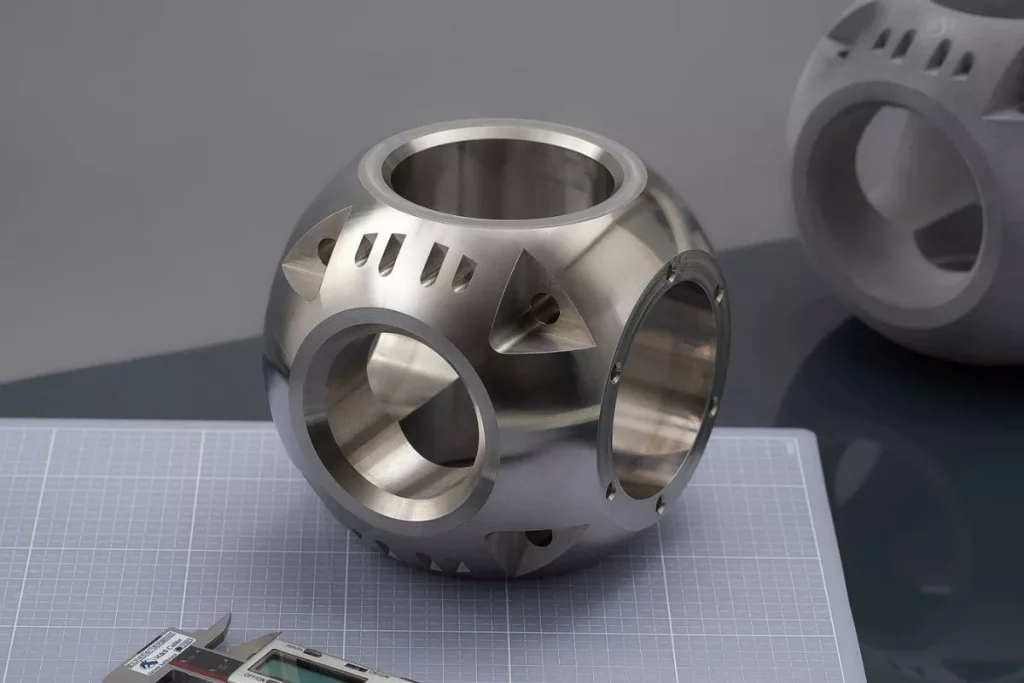

Before any part leaves our factory, it undergoes a comprehensive final inspection to verify its quality and precision. We use advanced measurement tools and techniques to ensure that each part meets the required specifications and standards.

Precision Measuring Tool

We use advanced precision measuring tools, including coordinate measuring machines (CMM) and 3D scanners, to ensure that our rapid prototyping components meet tight tolerances and specifications. These tools help us maintain a high level of precision and quality throughout the prototyping process.

Certifications

We demonstrate our commitment to quality by being certified to ISO 9001, IS0 14001, IATF 16949 and AS9100D. These international standards ensure that our quality management system is effective and continually improving, providing our customers with a consistently high quality product.

Continuous Improvement

We embrace a philosophy of continuous improvement and regularly review our processes and practices to identify areas for improvement. We work hard to maintain our reputation for quality and innovation by investing in the latest technology and employee training.

Rapid Prototype Manufacturing Capabilities

If you’re developing a new product or improving an existing one, rapid prototyping is ideal for testing, iterating, and tweaking concepts. It can speed up your design process and get your ideas and products to market faster. Do you need parts as quickly as possible to validate your project? Choose from the services below and we’ll quickly produce your parts in our certified in-house facility.

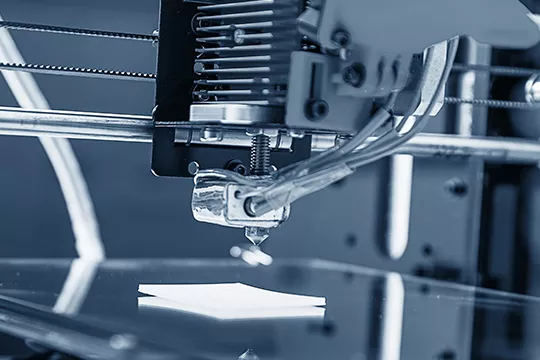

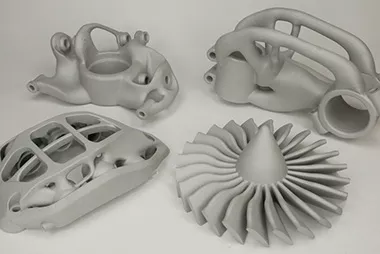

3D Printing

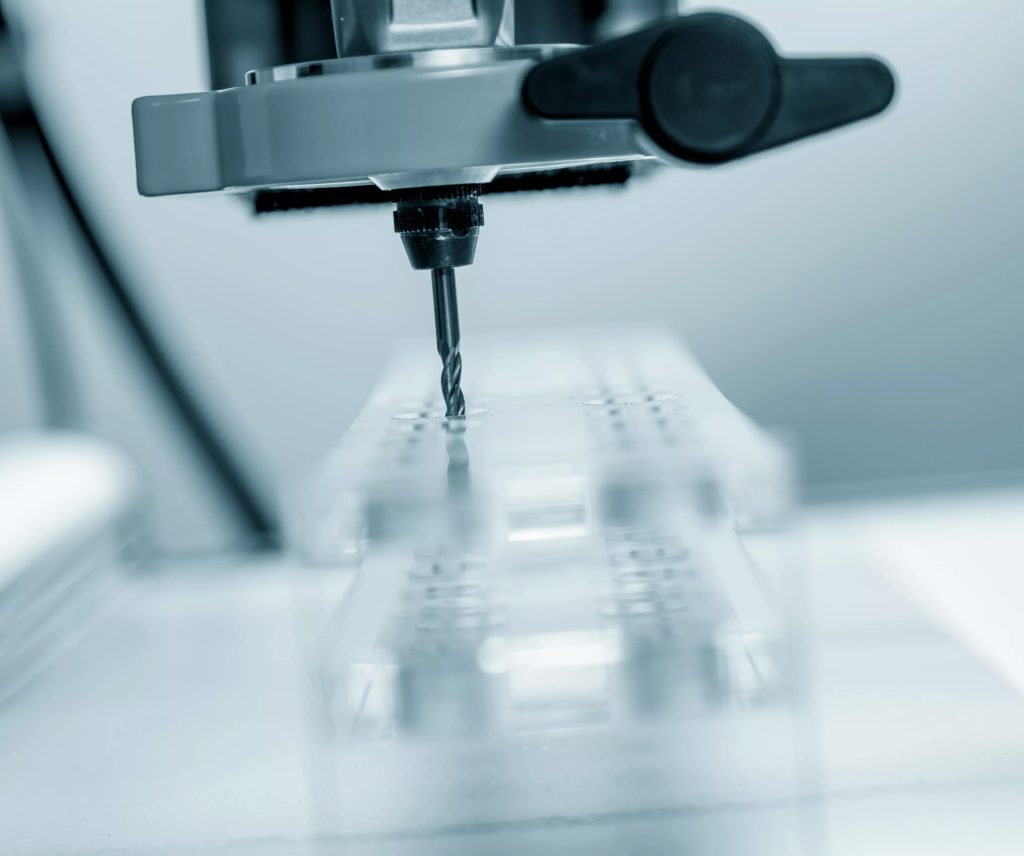

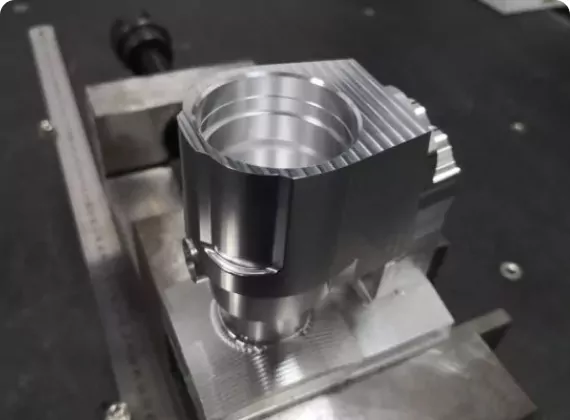

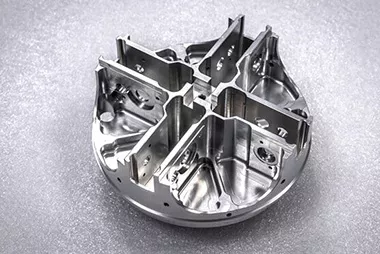

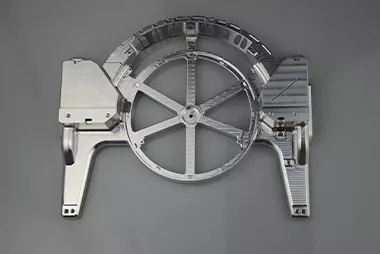

CNC Machining

Injection Molding

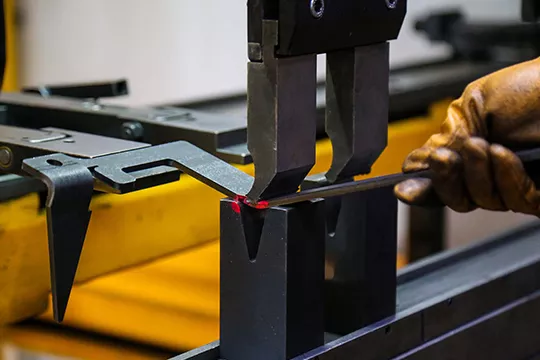

Sheet Metal Fabrication

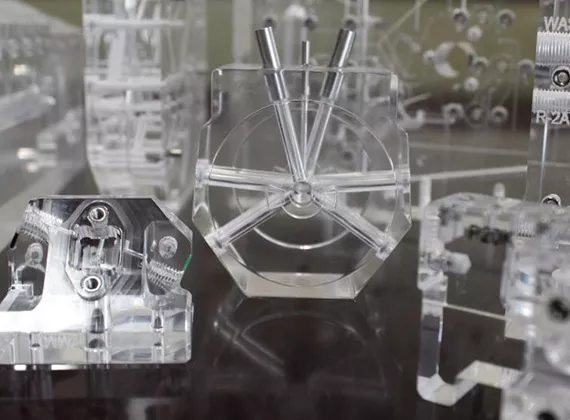

Vacuum Casting

Metal Casting

Affordable high-volume production services

When you are ready to move your design from rapid prototyping to mass production, Elimold offers a range of flexible and easily scalable solutions. We have no minimum order quantity, so our lean manufacturing services are the ideal solution for you to bring new ideas to market on schedule. Choosing Elimold for your prototyping needs means you will benefit from our expertise and commitment to precision. We offer a variety of expedited options to ensure that urgent projects are completed on time. Our market-driven pricing model ensures affordable prices without sacrificing quality. With Elimold, you will receive detailed and precise prototypes to support rapid product development from initial design to final production.

Cleanroom Rapid Prototyping Services

The purpose of a feasibility study is to prove that our customer’s task can be solved by various rapid prototyping processing technologies and to demonstrate advantages over competing technologies. Feasibility studies are followed by prototype production and series production. Whether you need one or ten products for experiments or hundreds of products for trials or validation, Elimold can help you. If your product requires cleanroom production, all production and processing services for your project are carried out in our laboratories and cleanroom facilities. All products are manufactured in-house, ensuring a faster process and protecting the safety of our customers’ projects. Our experienced team will provide you with solutions and ensure ultra-high quality results using advanced technology and fully equipped in-house workshops.

Rapid Prototyping Applications

Because of its utility and versatility, rapid prototyping has been widely adopted for these and other common applications:

- Visual prototypes and concept models

- Functional prototypes

- Pre-production prototypes

- Validate form, fit and function prior to production of tooling

- Test jigs and fixtures for accuracy

- Building molds for prototypes

- Marketing mockups for trade shows

How To Choose The Right Rapid Prototyping Technique

The right prototyping method is the one that best fits your budget, the complexity of the part, what you want the prototype to do, and your development timeline. Better prototypes cost more money and take longer to make, but they also more faithfully represent the form, fit, and function of a production part.The basic questions to ask are these:(There are many variables to consider and we cannot cover them all here.)

- Will the prototype be a static display model?

- Does it need to be fully functional?

- Are there multiple, interconnected parts?

- What is the surface texture and finish?

- What is it made from?

- How important is strength and durability?

- How closely should it match the final production version?

- Need to manufacture in small quantities after completion?

Full-Service Rapid Prototyping Shop

As a full-service shop, we can seamlessly move from prototyping to small or large-scale production to bring your next great idea to market. Because we are already familiar with the parts, the production process is efficient; and we rarely encounter problems because we have solved most of them during the prototyping process. It’s a win-win situation. That’s why we provide design, development and engineering services to assist customers from concept to CAD model, prototype to final product. Our deep technical knowledge can help customers gain the competitive advantage they need during product development, helping to validate products and accelerate time to market. Elimold’s rapid prototyping approach uses the latest technology and most advanced materials to help customers achieve their prototyping goals. We focus on fast delivery, but also provide extensive rapid prototyping engineering experience to help customers save time and money. In addition, you can quickly test and adjust the design as needed. After that, Elimold can seamlessly move into mass production.

Ready to Build What’s Next?

Whether you’re refining a design or launching at scale, Elimold rapid prototyping services brings the technology, expertise, and agility to keep your development moving forward.

Rapid Prototyping & Engineering Company

Among prototyping companies, Elimold stands out with its shortest lead times and customized development process to meet the needs of each unique project. Rapid prototyping enables clients to analyze any design flaws, compare slightly different product versions, present proof of concept to investors, or explore ways to improve manufacturing processes. As soon as a product design changes, it is easy to create another prototype with updated features at a fraction of the cost of standard tooling. Lead times can be significantly reduced. Once the prototype is complete, you can seamlessly move into production with our full range of in-house manufacturing services, saving you time and money. Since we already have your CAD design ready, it’s easy to move to full production with just the order.

What is Rapid Prototyping?

Rapid prototyping services are a widely used product development method and an important stage in the part and product development process. It is often used to create product models and is a fast and affordable manufacturing method that can easily produce multiple iterations of a part or product for testing and analysis. Due to its cost-effectiveness and extremely short lead time, engineers can often build multiple prototypes at the same time, or quickly produce and modify prototypes until the prototype meets the expected specifications. Rapid prototyping provides engineers with key data points to help them decide on any design modifications before generating more expensive models for further analysis or final production. Rapid prototyping can reduce the risk of rushing into production without sufficient quantity to confirm the data. Once you have created a product prototype and made the necessary design adjustments, you can verify whether your product is suitable for the market. After the prototype has been tested and verified, it can enter large-scale production.

Multiple Materials for Rapid Prototyping

When rapid prototyping is needed, it is essential to find a reliable rapid prototyping company that can handle a wide range of materials so that the entire rapid prototyping project can be brought together. Elimold can make your prototype parts in plastics, metals, and ceramics.

Plastics

Metals

Ceramics

Metals

- Titanium

- Steel

- Stainless Steel

- Magnesium

- Zinc Alloy

- Chromium-Nickel Alloy

- Brass

- Copper

- Aluminum

- Bronze

- Cold Rolled Steel

- Nickel

- Silver-Tin Oxide

- Cast lron

Plastics

- HDPE

- PP

- PE

- PET

- PMMA

- POM

- PPS

- PVC

- FR-4

- PEEK

- ABS

- PC

- PA

- HIPS

- LDPE

- PBT

- PPA

- PAI

- PS

- PTFE (Teflon)

- UPE

- Bakelite

Surface Finishing Options

Surface finishing in rapid prototyping is critical to quickly obtaining high-quality, fully functional prototypes. Our rapid prototyping processes can quickly produce detailed designs, and post-processing processes can enhance the smoothness, accuracy and visual appeal of the prototype part surface, ensuring that your prototype meets both aesthetic and performance requirements.

- Grinding

- Polishing

- Electroplating

- Anodizing

- Blackening Passivation

- Brushing

- Sandblasting

- Painting

- Powder Spraying

- Silk Printing

- Pad Printing

- Laser Carving

- Phosphating

- Vapor Polish

Types of Rapid Prototype

Used by customers across many industries, rapid prototyping encompasses different technologies and materials. It also covers different kinds of prototypes, including visual-only prototypes and functional prototypes used for testing a part’s performance.

Concept model

Display prototype

Functional Prototype

Pre-production Prototype

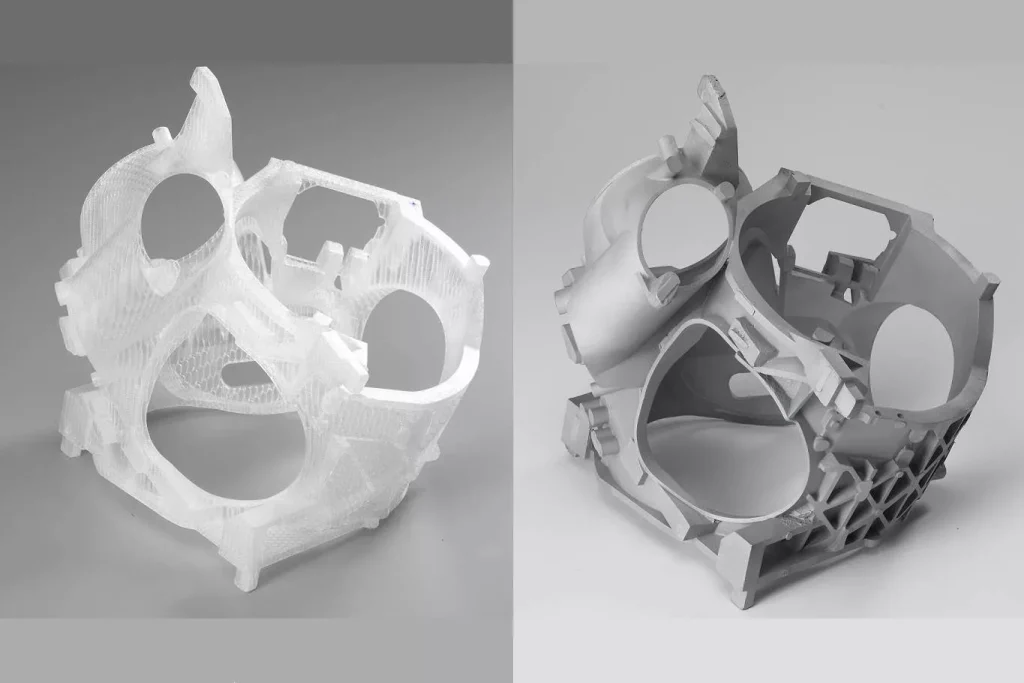

Differences between Rapid Prototyping and Traditional Prototyping

In the past, product designers and engineers were often limited to making temporary prototype parts that were not necessarily accurate in form, fit, or function. To achieve this accuracy, production-quality parts need to be manufactured, which often requires expensive tooling and can take months to manufacture. In contrast, rapid prototyping technology has revolutionized new product development. It uses digital manufacturing methods to enable designs to be transformed directly from CAD drawings to finished plastic or metal products in hours or days, without time-consuming and expensive intermediate machining steps. This allows designers and manufacturing partners to perform multiple iterations, quickly lock in a final design, or test multiple design options simultaneously.

Why Do We Need Rapid Prototyping?

Whether you are an engineer, industrial designer, or part of a product development team, rapid prototyping services can offer you distinct advantages such as:

- The ability to explore and realize concepts quickly and cost-effectively. Quick turnaround times and low costs allow teams to move far beyond the visualization of an idea, making it easier to grasp the properties and design of a product in the physical world.

- Reiterate designs and incorporate changes that allow for improved product evaluation and functional testing. This iterative rapid prototyping process provides a roadmap to developing and refining the final product before taking it to the market, ensuring that your design is optimized and foolproof.

- The ability to physically showcase concepts concisely and effectively. Rapid prototyping takes ideas, images, and concepts from an idea or two-dimensional visual into hands-on products that clients, colleagues, and collaborators can hold in their hands and see in action.

- The ability to thoroughly test and refine a concept. Minimizing design flaws with a small-volume rapid prototype run helps eliminate costly design flaws that might not be evident during an early assessment.

- Using a rapid prototyping service can save time and money by eliminating the need for setup and tooling. Since Elimold can use the same equipment to produce various prototypes with different properties and materials, our rapid prototyping services’ overall costs and turnaround time are kept to a minimum.

Advantages of Rapid Prototyping

Rapid prototyping provides significant advantages to part designers. You can use it to:

- Reduced design & development time

- Reduced overall product development cost

- Elimination or reduction of risk

- Allows functionality testing at a fraction of the cost

- Improved and increased user involvement during design stages of NPD

- Ability to evaluate human factors and ergonomics

Turn your ideas into reality quickly and efficiently

Rapid prototyping technology allows you to create product mockups or design concepts quickly and efficiently. Elimold offers a range of technologies and materials suitable for rapid prototyping. You can test and validate your ideas before committing to large-scale production. Rapid prototyping services are the shortest path to transform your ideas into actual functional prototypes and can be used at every stage of the manufacturing process. More specifically, rapid prototyping is a powerful assistant in the early stages of product development. With rapid prototyping technology, you can make as many iterations as needed and maintain high precision, thus speeding up your prototyping process.

Custom Rapid Prototyping Services

Elimold’s rapid prototyping services utilize a variety of cutting-edge manufacturing technologies to provide customers with high-quality, full-scale prototypes within hours of product design conceptualization. To achieve more robust product designs, the company’s advanced in-house workshop can quickly develop initial production prototype parts and produce them in small batches. These capabilities enable customers to quickly and thoroughly evaluate the functionality and appearance of their new product rapid prototype designs before entering regular production. While most rapid prototyping companies use traditional manufacturing methods to produce prototypes, Elimold uses the latest technology and methods, along with an advanced design team, to create the highest quality prototypes. There are many ways to create prototypes, and when you work with Elimold, our engineers will help you and your leadership team select the best prototyping process for your product development cycle using the latest technology.

Industries We Serve

We provide innovative and cost-effective solutions for prototyping and production parts for a wide range of industries around the world. Elimold has successfully delivered millions of custom parts and prototypes to our customers.

Rapid Prototype Parts Manufacturer

Prototyping is an essential step in product development. Rapid prototyping is what you need to evaluate the design and functionality of your product before committing to more expensive production. Rapid prototyping enables engineers and designers to manufacture and test their products faster and iterate as needed. Whether creating a scale model of a physical part to verify form or appearance, trial assembly, or build functional features and test them, rapid prototyping helps you achieve your goals in a timely manner. And we support both small batches for rapid testing and large batches for full production. This flexible approach enables a seamless transition from prototype to production, ensuring that products are brought to market efficiently and accurately.

Take Your Ideas From Prototype To Production

When a new product needs to be launched, the last thing you want to do is wait. Elimold’s rapid prototyping services can turn your concepts into reality in a fraction of the time. Our dedicated prototyping team selects the best prototyping technology for your needs and is committed to delivering your desired work in just a few days. Whether you need a first look, a fully functional, testable product, manufacturability testing, or something completely different, we have you covered. Our prototyping services use the most advanced technologies and techniques to turn your ideas into reality. You don’t need to have any engineering experience to bring your concepts to us. And our prototyping services cover a wide range of industries and markets, and our customers appreciate our extensive product prototyping service capabilities. With our extensive experience and excellent service, we have become the preferred provider of rapid prototyping services. From established design teams to entrepreneurs with just a bold idea, we have helped countless customers realize the potential of their designs and ensure they can be successfully launched. Whatever type of prototyping help you need, Elimold can help you. Contact us today to learn more.

Start Your Rapid Prototyping Project Today

Our improved algorithm reduces rapid prototyping quote time by up to 90%. Most quotes can be delivered in 4 hours or less, depending on the project details. Our engineers will contact you directly to ensure you have received and understood all details of the quote and to answer any questions you may have.