Large Part CNC Machining Services

Elimold provides CNC machining of large components for various industries. From prototype to mid-stage production, our expert team uses machinery to handle complex jobs and achieve consistently high-quality results.

We have expert knowledge and the right tools for precision large part machining.

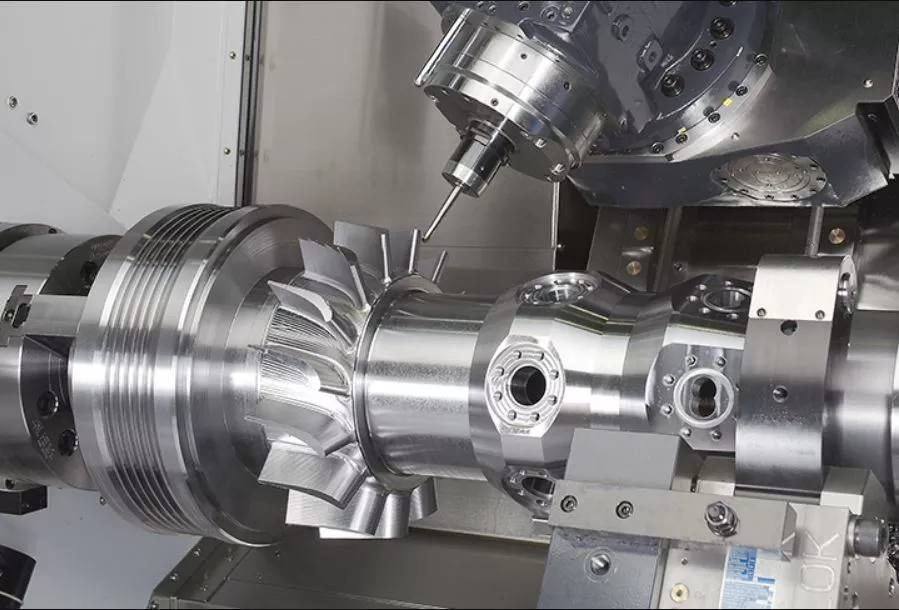

Elimold is a trusted supplier of high-quality prototypes and high-volume large part machining to leading OEMs in a variety of industries. Our state-of-the-art CNC machine shop specializes in cost-effectively machining large components in a variety of standard and specialty metals with complex geometries that meet or exceed the tightest tolerance requirements. Large part machining takes place on our large CNC lathes and turning centers with multi-axis travel and rotary table capabilities. Larger parts require CNC machining under the guidance of a strict quality management system and continuous machining process improvement, and Elimold can achieve this.

Precision large parts processing is the service that best reflects the characteristics of our factory. We have spent a lot of money bringing precision machining practices to CNC machining of large parts. For example, precision machining requires state-of-the-art tools. Therefore, we have invested in modular fixtures, magnetic workholding systems, shrink fit tools, automated probing and the latest CNC programming software. In addition, each machine is laser leveled and inspected regularly.

Finally, we have the tools you need to inspect large parts for rigorous GD&T. For example, sometimes CMM (coordinate measuring machine) inspection is not an option due to part size. Therefore, we invested in FARO Vantage laser trackers, FAROArm Quantum and Mahr Federal electronic level systems.

Large Part CNC Machining Process

At Elimold, we offer a full range of precision CNC machining, including milling, turning, routing and cutting. Our CNC milling machines are capable of complex geometries, extremely tight tolerances (+/- .001) and surface finishes as smooth as 15Ra. CNC milling can be used with most rigid materials, including advanced engineering plastics and metal.

Our CNC turning services excel at multi-axis lathe work and extremely tight tolerances. Our high-speed CNC saws combine ultra-fast cutting speed and pinpoint accuracy to cut any plastic, no matter how technical. We can process materials up to 128” in length and deliver perfectly-shaped pieces ready for the next step of machining.

Fast cycle times and consistently accurate results are the hallmark of our CNC routing services. No matter how complex the design or advanced the material, we can meet your specifications. We can handle oversized specialty parts up to 127” x 80” x 9”. And as part of our commitment to excellence, all of our parts must undergo a rigorous, ISO 9001:2015 certified quality control inspection before shipping.

Large component processing capabilities

| MACHINING PROCESSES |

|

| EQUIPMENT |

|

| EQUIPMENT CAPABILITIES |

|

| FIXTURING |

|

| MATERIALS |

|

| TURNING DIAMETER |

|

| TURNING LENGTH |

|

| MILLING LENGTH |

|

| MILLING WIDTH |

|

| MILLING HEIGHT |

|

| MAXIMUM LIFTING CAPACITY |

|

| SECONDARY SERVICES OFFERED |

|

| PRODUCTION VOLUME |

|

Finishes We Provide

As-Machined

After machining, no coating or finishing is applied to the product. This is best for parts that will not be visible to the consumer.

Black Nitride

This finish is used to improve the product’s resistance to corrosion and wear. In addition to creating a hard outer layer, it also gives the part an appealing dark color.

Heat Treat

Perhaps the oldest form of finishing parts, heat treatment enhances the color and finish of the part, while improving its durability and wear resistance.

Powder Coat

Powder coating can improve the appearance of the part by coating it in a fine powder that is typically colored, then hardening the coating. It improves durability and helps the part resist chipping with regular wear.

Bead Blast

Popular as an automotive finish, bead blasting is a way to remove surface imperfections in a cost effective manner. It does not use any harmful chemicals, making it more environmentally friendly than other finishes.

Electrolysis Nickel

This electrolysis process improves the parts resistance to wear and corrosive materials. It also improves the appearance of the part as a layer of nickel-phosphorous is transferred onto the part’s surface.

Type II Anodized

This finish comes in a range of colors and thicknesses. The paint creates a corrosion-resistant finish. Common colors available for anodization are clear, black, red, and blue, though other colors may be available upon request. Type III anodization is also typically available; this adds a layer of wear resistance to the milled parts in addition to the standard benefits of anodization.

Reduce production and operation costs

Because everything is handled in-house from start to finish, we offer a one-stop solution for large part machining. Because we work with your product from conception to final operation, we do everything we can to maximize your ROI and lower your costs every step of the way without cutting corners.

Every step of the process is optimized for efficiency, accuracy and quality. Our engineers work hard to reduce machining time, increase tool life, and eliminate material waste with every new run.

We believe in providing quality machining services with tight tolerances. Not only do we provide you with a solution, we optimize that solution to improve cost efficiency and product quality, all the way to the prototyping stage.

Provides comprehensive machinability review

During the initial prototyping phase, we provide a complete processability review to help you optimize your machining process and maximize the cost-efficiency of your design. Not only does this help align your production costs, but it can also address design elements of the product itself.

Our engineers first identify any areas in the design and production runs that may present any challenges during machining. We evaluate products to ensure parts are designed for manufacturability while optimizing functionality and cost efficiency.

By evaluating tool paths, part materials and shapes, and coating and machining parameters, we can optimize your machining process and help you shape your prototype into your final design.

At the conclusion of the processability review, we put together a detailed report outlining our findings and recommendations for your team to review. These recommendations are clear and specific, providing your team with ways to improve design inefficiencies and reduce production costs.

Once the machinability review is approved, we can move the part to the next stage of prototyping or first-run production. Every step of the way, we work with your engineering department to determine the specifications and features required for the entire product.

Quick turnaround time

We continually raise the bar on cost efficiency for our customers, and turnaround times are part of that goal. Completing tasks on time ensures the success of the project within the allotted time.

Because we’ve optimized our production lines to ensure you get the fastest turnaround times in the industry. We work tirelessly to deliver the highest quality parts on time and within budget, optimizing your machining time every step of the way.

Depending on the complexity of the project and the number of parts required for production, our lead times can be as short as 3 – 5 weeks.

Throughout the production process, we keep you updated on the progress of your order, providing regular status updates and keeping you informed of any developments during the production process.

Large Part Machining Use Cases & Applications

Many industries depend on large part CNC machining for custom and specialty parts, facilitating various technologies that would otherwise be much more difficult or impossible. The far-reaching impact of large parts machining extends across industries as broad as:

- Aerospace: Hydraulic manifolds, transmissions, fuel bodies, landing gear, electrical connectors, housings, and more utilize large part machining to expand the limits of space-age technology.

- Military: From large couplers and seat frames to helicopters, missiles, and other components, the products of large part machining can be found in technologies used in every branch of the military.

- Transportation: Large part CNC machining keeps supply chains running with freight train components, large truck parts, shipping vessels, and more.

- Oil & Gas: The energy sector operates more safely and efficiently with large part items found in pipelines, refineries, oil rigs, etc.

Most industrial manufacturing, in general, has some need for large part machining. CNC large part machining ensures companies across industries receive high volumes of precision-engineered components quickly and economically.

Stand out among many manufacturing and machine shops.

You can trust Elimold as your CNC machining and large part manufacturing partner. Our staff is dedicated to exceeding your expectations and is ready to bring you convenient, efficient and cost-effective solutions for your next project. Contact us today or request a quote.