Aerospace Sheet Metal Fabrication

As a leading industrial metal manufacturer, we supply precision metal stampings to customers in demanding industrial sectors, including the aerospace industry. We manufacture custom metal aerospace parts using advanced sheet metal fabrication and metal stamping services. We also offer value-added secondary metal finishing services. Through our direct, turnkey, customer-oriented service system, our stamped metal parts and sheet metal fabrication consistently exceed industry standards and aim to exceed customer expectations. Whether you need a small complex part for a door closure, a large (relatively) simple housing, or anything in between, Elimold is your number one source for precision stamped aerospace parts.

Aerospace Metal Fabricating Services

Elimold is a manufacturer of high-precision medium to large aerospace parts and mechanical assemblies. We provide the aerospace industry with a competitive advantage through state-of-the-art metal cutting and forming, extensive experience in welding a variety of metals, precision CNC machining, complete assembly services, on-time delivery and unparalleled customer service. Our manufacturing capabilities and inspection services meet or exceed the requirements of the most demanding projects.

We aim to provide the aerospace industry with parts that rely on precision and accuracy. In the aerospace industry mechanism these two indicators are crucial to the safety and efficiency of every aircraft. Aerospace sheet metal fabrication supports these mechanisms and can be used to create a variety of solutions that include many of the elements that make flight possible.

Sheet metal fabrication typically includes aerospace sheet metal forming and the manipulation of various types of metals that can handle high-strength environments, such as aluminum, copper, brass, bronze, titanium, carbon steel and other metals.

Elimold handles every step of the custom sheet metal fabrication process and meets your needs. From initial aerospace sheet metal design, to cutting, shearing, stamping and more, our industry experts will provide the precise OEM parts, components or formulated materials your aircraft needs to operate safely and efficiently.

Why do Companies in Aerospace use Elimold?

Companies in aerospace (including aviation and defense) work with us for our diverse capabilities and capacity to deliver consistent and repeatable parts fast. Our automated manufacturing services, including sheet metal fabrication, can be leveraged throughout the product life cycle, from early prototyping and design validation to hot-fire testing and launch.

We support customers in the aerospace industry by offering:

- application and technical expertise at every stage of development and production .

- the ability to easily pivot from sheet metal fabrication to another manufacturing service, such as 3D printing or CNC machining, without development or production delays.

- quality certifications: ISO 9001:2015.

- ability to provide durable production-grade tools, fixtures, and aids in days.

- diverse finishing options including powder coating, anodizing, welding, hardware insertion, and plating.

Capabilities

- Skilled in manufacturing of aerospace engine parts, seating and other cabin interiors parts.

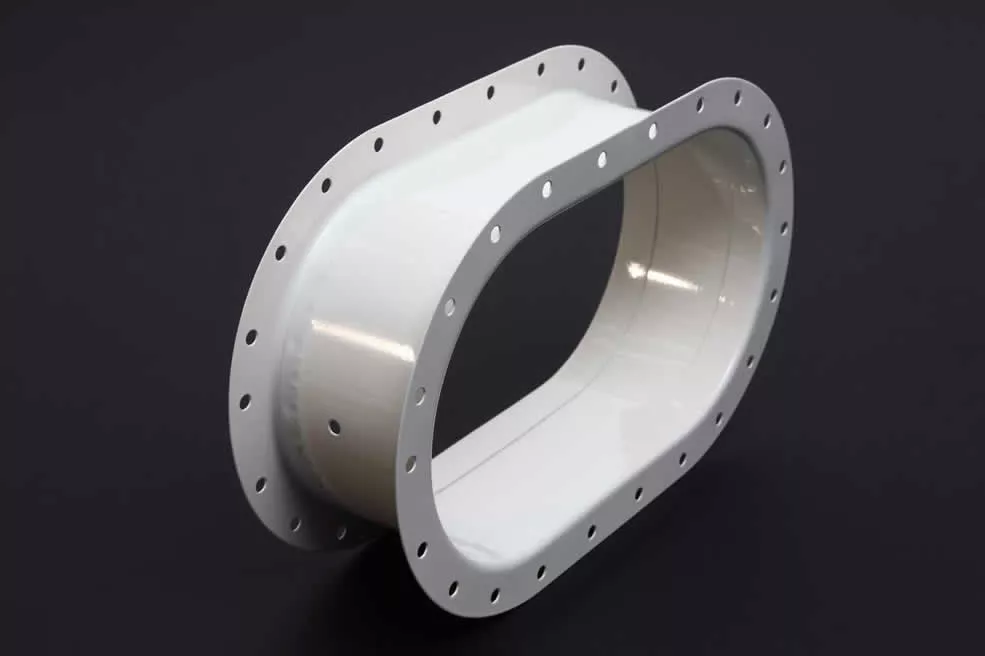

- Sheet metal fabrication (heat shields, thermal blankets, combustion liners, transition assembly, grommet & Ignitor)

- Sheet metal enclosures (power auxiliary units, power distribution)

- Precision machined components

- Sub-assemblies

- Expertise with exotic material

- Metrology/material testing

- EN & Aerospace certified welders

- Value engineering

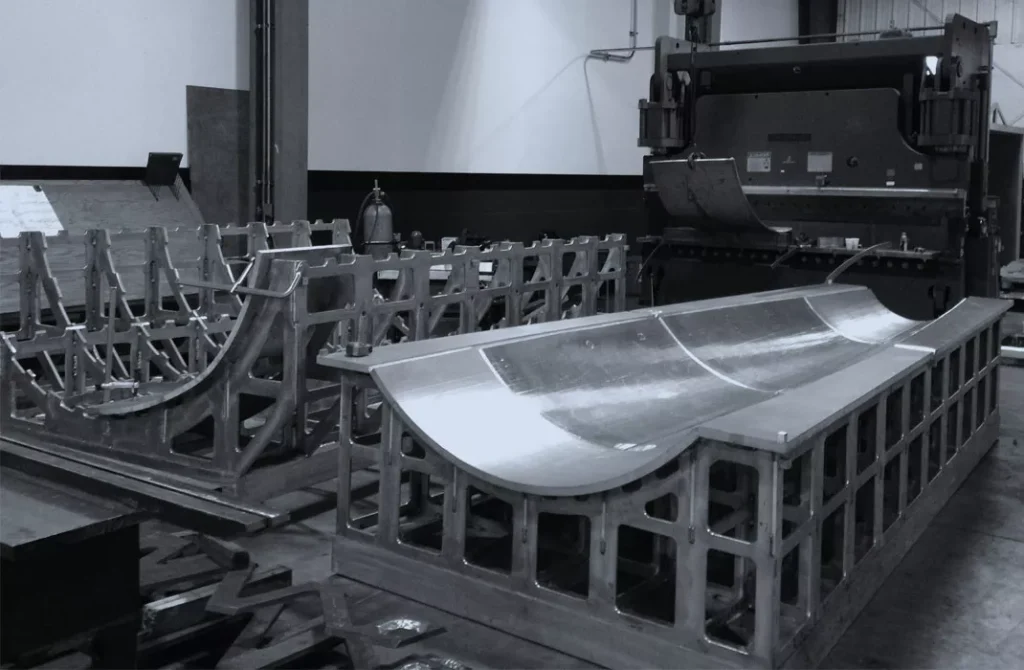

- In-house tool design and development

- Total traceability

Benefits of Precision Metal Stamping & Fabrication for Aerospace Components

Additional benefits of getting your stamped and fabricated metal aerospace components from Elimold include:

- Consistent Quality: Our metal-stamped parts achieve the consistency and quality required for aerospace components.

- Rugged Strength: Metal-stamped aerospace components are rugged and feature excellent, long-lasting strength.

- Custom Dimensions: Our metal stamping and fabrication processes create custom parts that meet your required specifications.

- Exceptional Accuracy: The metal-stamped components we produce achieve a level of precision necessary for aerospace applications.

In-House Tooling & Die Stamping Services

Our tooling and stamping dies are produced in-house. This helps us ensure that all tooling and dies match customer design requirements and meet our own high standards of quality. Since there is no waiting for the finished tooling to arrive at our location, our in-house toolmaking capabilities drastically reduce turnaround times.

Materials for Aerospace Favrication

Common materials we use include

- Aluminum

- 6061(harder aluminum, more machined parts)

- T6 (sheet metal)

- T651

- 5052- good for bending, Sheet metal

- 5052

- H32

- 7050

- 7075

- 2024

- T3 temper

- TiAl & other composite materials

- 3003-h14 (soft, thin material) used in roofing

- H-hardness

- 1100-h14 (softer material than 3003)

- 6061(harder aluminum, more machined parts)

- Nickel

- 718 (Inconel) Used in rocket and aircraft engines

- Steel

- 4140 (high carbon)

- Engines, turbines

- 4140 (high carbon)

- Titanium

- 6Al4V

- StainlessSteel

- 15-5PH

- 304

- 316L

Secondary Aerospace Metal Finishing Services

We offer a broad range of secondary services to provide added value to our precision metal parts. These services allow us to deliver more ready-to-use complete parts for your project needs. With numerous services available from a single source, your project’s production time and cost can be reduced significantly. We are your one-stop shop for complete, turnkey metal stampings and fabrications—we do more work, so you don’t have to!

Our value-added secondary services include:

- Machining

- Milling

- Drilling & tapping

- Assembly

- Finishing, painting & powder coating

- Anodizing

- Deburring

- Cleaning

- Heat treating

- Welding

Turnkey Solutions

Elimold’ full range of custom metal fabrication capabilities eliminate costly and inconvenient handoffs. Projects can be completed through Elimold, in their entirety: from 3D digital modeling, CNC waterjet cutting, welding, and CNC forming straight through hardware insertion, finishing, assembly and shipping.

Being closely tied to health and safety, medical equipment and their parts must be created with a level of precision that is completely free of imperfections and contamination. It is projects like this in which the benefits of the company’s clean facility and one-stop methodology are clearly apparent.

CNC Forming for Aerospace Fabrication

Our CNC brake press, milling, and routing capabilities ensure the utmost precision in the manufacture of all your components.These include:

- Brake press forming of complex, multi-bend pieces up to 12’

- Deep drawing with less than 10% thinning

- 5-axis milling in-house

- 3-axis and 5-axis routing

- Robotic 5-axis welding with 360-degree turn stock

Do you want to create complex assembled end products?

Do you want to receive assembled aerospace sheet metal products? Whether it’s a complex structure, strict product standards, or a small quantity order. Elimold can solve it smoothly without you taking any risks, ensuring the safety of your investment.