Military and Defense Plastic Injection Molding

At Elimold, we understand the unique challenges and requirements of the defense and military industries. Committed to providing precise, durable and reliable products, we specialize in custom plastic injection molding solutions for defense and military-grade applications. From specialized components to custom assemblies, we have the expertise and capabilities to meet the rigorous requirements of defense contractors and military companies. Contact us now for a free instant quote.

Defense and Military Plastic Molding Service Provider

As one of the top defense and military parts and products manufacturers in the world, Elimold uses science and split molding to establish a stable and reliable injection molding process. We understand the need to start with LRIP (Low Rate Initial Production) for design validation. These lower production quantities can be used to verify assembly functionality, integration, and testing before moving to FRP (Full Rate Production). To help with the move to FRP, our facilities combine automation and robotics to provide a single manufacturing solution for your military and defense plastic parts.

At Elimold, our comprehensive capabilities enable us to help you from the concept stage of your project to prototyping, implementation, and more. With years of experience in the defense and military sectors, as well as industry-leading tools and rapid product development, we have the ability to solve your highly complex injection molding problems. No matter what type of custom plastic part you need, we will approach your project with the same focus and intensity.

Our In-House Molding Factory Capabilities

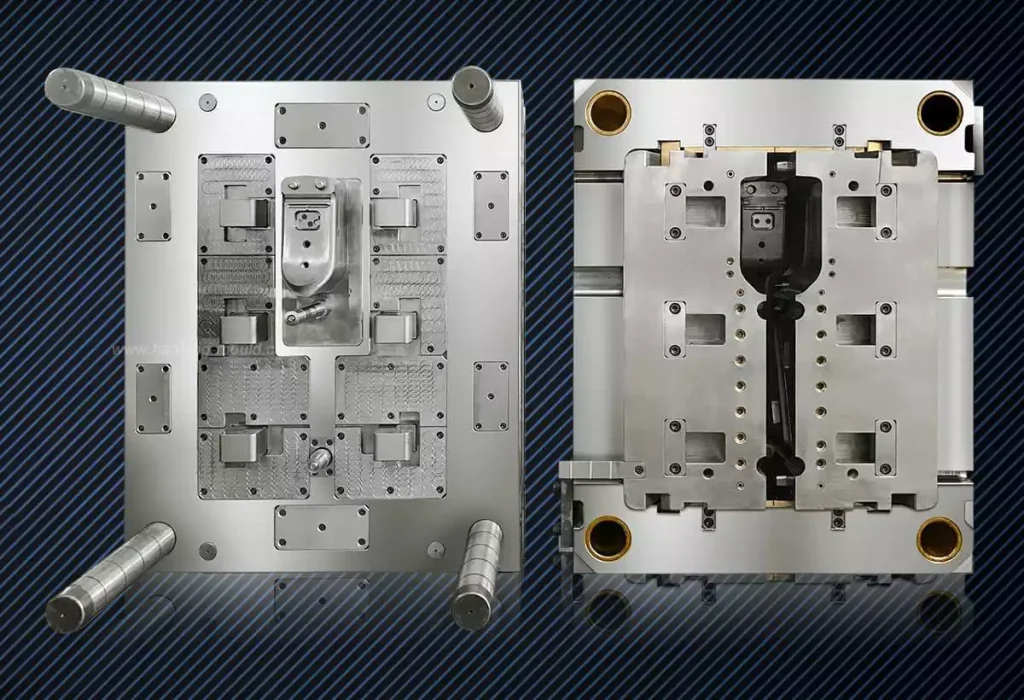

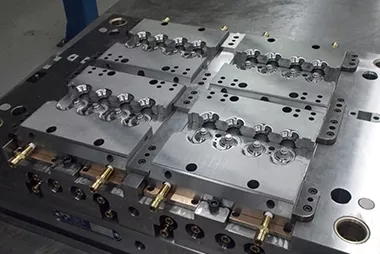

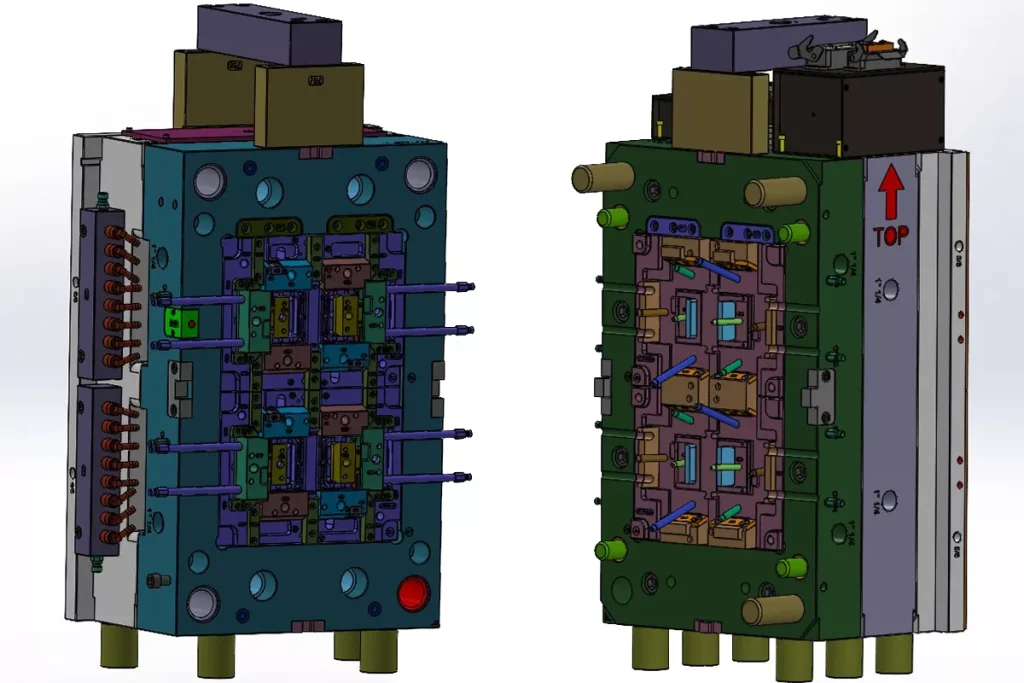

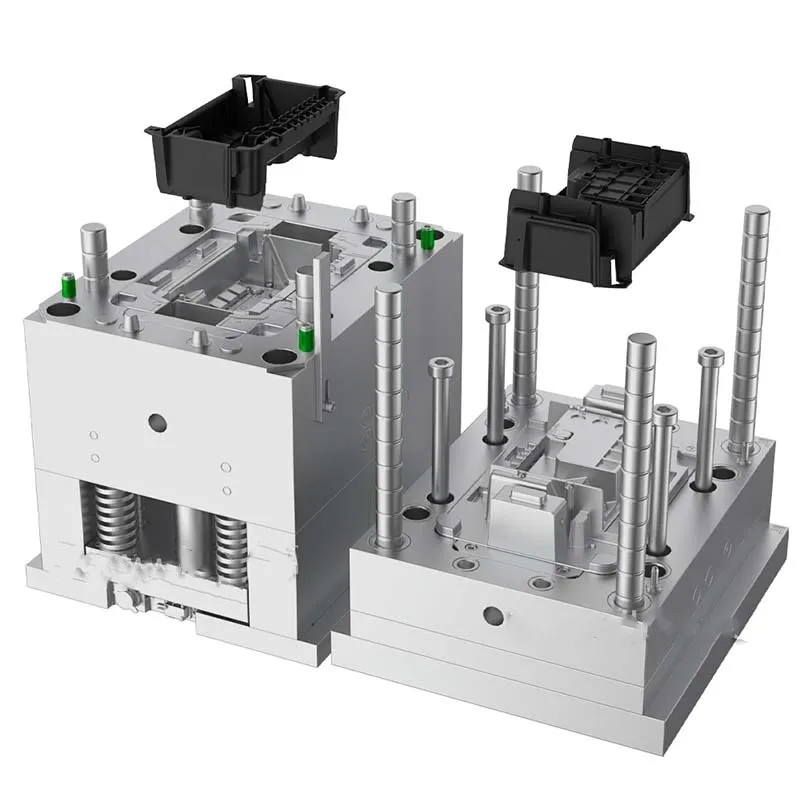

Elimold’s experienced, in-house molding facility is well-equipped to expertly meet the stringent design and material performance requirements of manufactured parts for the military and defense industries. We accomplish this through state-of-the-art 2D/3D CAD/CAM software, product design assistance, precision machining (using our multi-axis CNC machines, wire-cut and EDM technology as well as conventional mills and lathes), tool and mold design/fabrication/repair/maintenance, UHP water jet cutting, metal injection molding, and custom plastic injection molding using both commodity and advanced engineered thermoplastic resins. We accomplish this with over 100 molding machines ranging in pressure from 55 tons to 3500 tons, shot sizes from 2.8 oz to 125 oz, and silicone liquid molding.

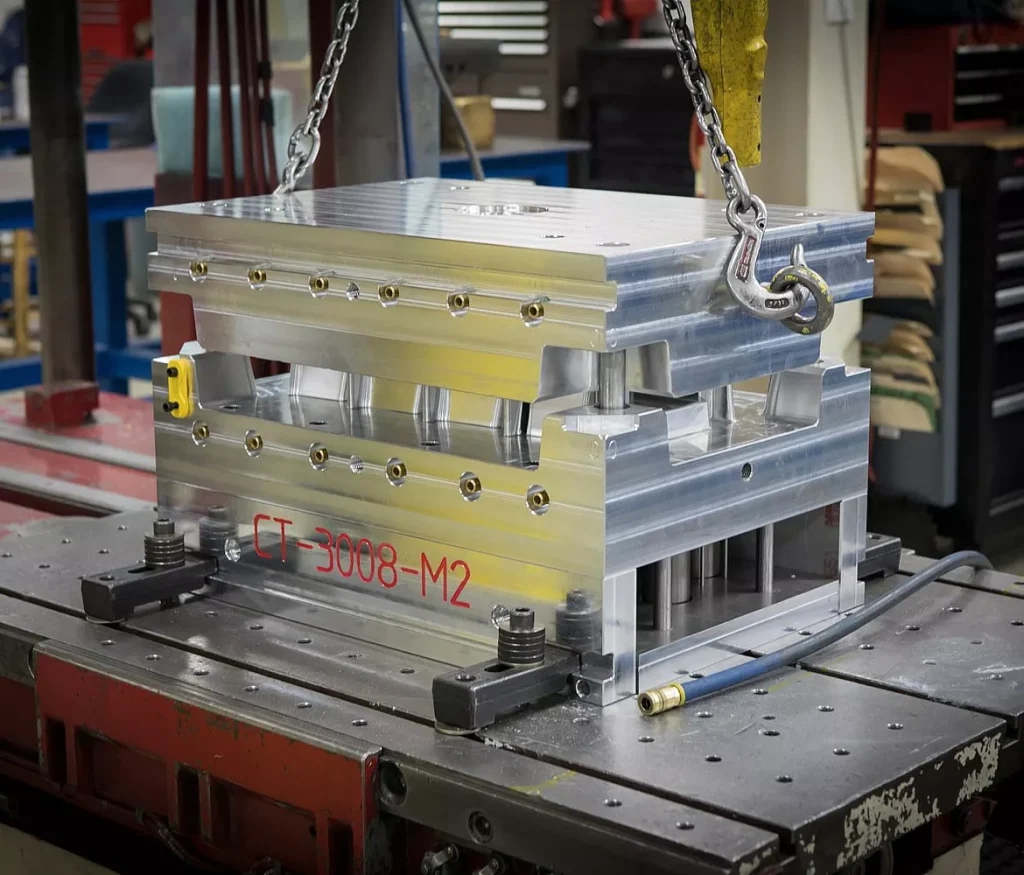

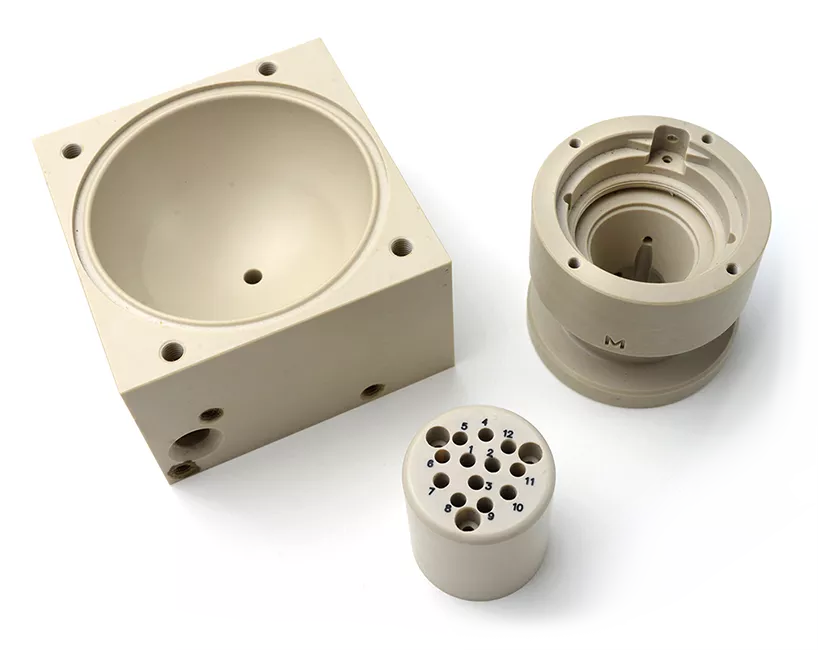

In-House Injection Mold Shop

Elimold has an in-house injection mold making shop that can meet the precision tooling requirements required for stringent defense and military specifications. With our in-house mold making department, we are able to build molds to the exacting specifications required for mission critical projects. We regularly produce ITAR restricted parts and assemblies, all done in our in-house facility. In addition, by working closely with engineers and designers, Elimold is able to help create parts that perform as expected. Many times, we are able to redesign a part to make it better, lighter, stronger, and more cost effective.

Turnkey, Cost-Effective Military and Defense Plastic Injection Molding Solutions

Elimold provides turnkey services from product concept to production. We are able to develop and deliver custom plastic parts for complex products containing electronics (PCB, shielding, wire/cable connections) and other components that are produced in-house, ensuring the delivery of cost-effective, fully assembled and tested products that are ready to deploy. Elimold’s product development value engineering focuses on analyzing design features, systems, equipment and material selections to achieve essential functionality at the lowest lifecycle cost.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Manufacturing Services for Military and Defense Contractors

Elimold’s defense and military industry customers rely on a range of critical manufacturing services, including:

- Custom Manufacturing in Engineered Plastics and Metal Components

- Engineering and Tool Design

- Prototyping

- Validation and Regulatory Compliance

- CMM and Vision System Inspection

- Automation, Assembly, and Packaging

Providing High-Quality Plastic Injection Molding Solutions for the Defense and Military Industries

Our experienced design, tooling, molding and assembly teams and the latest molding technology provide military and defense manufacturers with the ability to outperform competitors with the highest quality plastic injection molded parts in a highly demanding market. Parts manufactured for the defense industry require expertise in aesthetics and have strict and specific requirements. Our molding processes and procedures ensure repeatability for each project. The Elimold Quality Department takes careful consideration when validating documentation. Our team has extensive experience in molding commonly used engineering polymers.

Ready to start your next defense and military injection molding project?

Ready to work with a trusted leader in defense-grade plastic injection molding? Contact Elimold today to discuss your project and learn how we can help you achieve your goals with precision, reliability, and excellence.

Defense and Military Plastic Injection Molding at Elimold

Using carefully engineered polymers, including 30% glass-filled materials designed for specific applications, our engineering and production teams bring a wealth of knowledge and critical input to provide recommended solutions that improve production and performance. Tight tolerances, shot sizes, heat and pressure requirements are all critical to producing quality features and parts. Our team of experts is able to digest, evaluate and distill complex information to make the best manufacturing recommendations. Elimold’s ISO certification provides you with the assurance you need to know that we are an industry leader not only in compliance and paperwork, but also in strength and safety.

Certifications and Standards

To help you meet the unique and stringent requirements of the military and defense industries, our design team works with your product designers to make modifications to our material and machine specifications. Our goal and responsibility is to strengthen and improve your components in a cost-effective manner.

- ITAR registered

- ISO 9001:2015

- ISO 13485:2016

- UL QMMY2 standards, No. E321053

- Production Part Approval Process (PPAP) and SPI compliant

- DOWNLOAD CAPABILITIES BROCHURE

Advanced Quality Control Measures

Quality assurance is a key factor that defense manufacturing companies must consider. Elimold’s injection molding plants are equipped with in-mold sensors that monitor the production process in real time. These sensors ensure that each component produced is of excellent quality. Real-time data monitoring can check whether each part processed meets the specifications. Errors can also be picked and corrected on the spot to maintain part consistency. It is also possible to eliminate unnecessary waste in the system and improve its productivity. Defense and military plastic parts production must ensure sustainable quality assurance practices to consistently meet reliability requirements. Quality assurance is also essential. These measures at Elimold help ensure that products sold in the defense market meet relevant standards. Providing comprehensive solutions that comply with ITAR and quality control requirements is essential to ensure the safety and reliability of military and defense custom plastic parts manufacturing.

Producing Rugged, Reliable Defense and Military Plastic Parts

Defense and military plastic parts require precision production and consistent reliability. At Elimold, we understand the importance of producing critical components that can withstand the stresses of the field. Elimold’s team of engineers and manufacturing experts excel in the compliant production of high-quality, tight tolerance parts to meet the stringent requirements of the military and defense industry. Our talented team has experience producing durable, quality products for defense and military applications using high-performance engineered plastics and metals, and excels at optimizing primary injection molding services with secondary services to reduce costs and generate returns for our customers. We can also perform precision optical component injection molding, overmolding, insert molding, machining, assembly, and vacuum deposition shielding.

Your Trusted Partner in Defense Grade Plastic Injection Molding

Elimold has a proven track record of handling our customers’ defense projects with dedication, speed, quality, and military standards. With years of experience managing programs for military and defense manufacturing, we have the knowledge and expertise to ensure your products are developed quickly, efficiently, and profitably:

- Adept at handling controlled technologies (EAR, ITAR) and government contracts

- Coordination and support of projects that may involve multiple tools, technologies, and facilities

- Efficient internal and external communication with the highest level of confidentiality

- Key customer contact for overall program details

- Cross-functional team including customers, designers, engineers, manufacturing, and suppliers

Supplying injection molded plastic parts to the military and defense sectors

At Elmold, we design and deliver innovative solutions for the defense market by producing components and turnkey solutions that meet customer specifications. We provide defense product design, defense manufacturing, and prototyping services using a variety of materials and methods to meet the most stringent performance, durability, and weight requirements.

Our streamlined military product development and manufacturing processes help you achieve budgets and schedules without sacrificing quality. In addition, our secondary operations can help you successfully camouflage, protect valuable electronic transmissions, and prevent harmful corrosion of metals. Our investment in automation capabilities allows us to quickly scale up production, and during the manufacturing process of the project, your dedicated project manager oversees the entire development process and provides supply chain management, as well as full product traceability, documentation and serialization and secure data transmission and data storage in compliance with ITAR requirements.

Plastic Material Options

We have unparalleled expertise in processing high-performance and engineered polymers. Our goal is to provide injection molded parts that meet all of your strength, durability and performance requirements. We take into account design, budget, manufacturability criteria and end application.

- PPSU

- Nylons (PA/PPA)

- PEEK

- PC

- PAI

- PEI

- ABS

- PMMA

- Torlon

- PP

Value Added Services and Secondary Operations

Many of the projects we work on require secondary operations, and whatever the requirement, we can handle it for you.

- Ultrasonic welding inserts

- Spiral coils

- EMI shielding

- Assembly

- Gasket applications

- Post-molding annealing

- Machining

- Decoration

- Painting

Military and Defense Plastic Injection Molding Applications

At Elimold, we are proud to provide innovative and high-quality plastic solutions to the military and defense industries. Our expertise in precision engineering and sustainable manufacturing enables us to meet the unique needs of defense and military companies.

- Fairings

- Cable Clamps

- Lenses

- Cabin Air Vents

- Chassis Components

- Air Frame Assemblies

- Panels

- Turbine Blades

- Missile Guidance System Components

- Super Capacitors

- Highly Sensitive Electronic Components

- Components for Fighter Pilot Glasses

- Deflector Shields

- Brackets

- Barrels

- PCB Enclosures

- Battery Enclosures

- LED Marker Lights

- Magazines

- Optics

- Overmolded Wire Harnesses

We offer other services too

We understand that every project in the military and defense industry requires a unique, custom approach. Our team of experts works closely with you to understand your specific requirements and challenges. We combine your insights with our technical capabilities to deliver solutions that meet your mission-critical objectives.

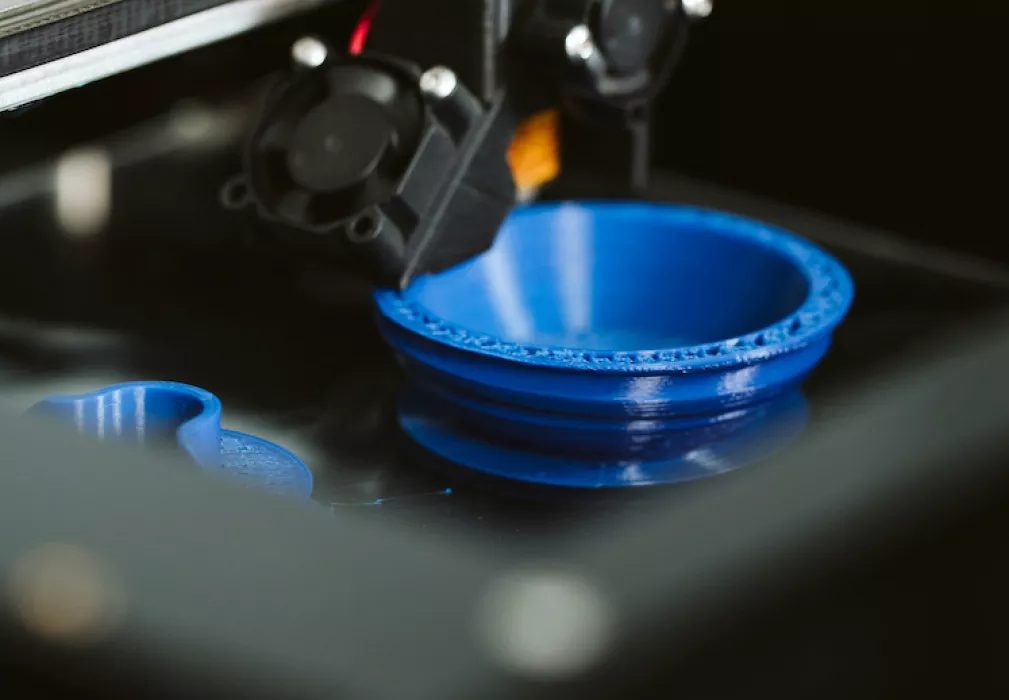

Military & Defense Product Development, Prototyping & 3D Printed Parts

Elimold specializes in custom manufacturing of injection molded parts for the military and defense industries, as well as prototype parts and custom prototype tooling. Our company has unique facilities to accommodate military and defense product development, new design concepts, and design modifications to existing legacy parts that require updated tooling. No matter what stage your project is at, Elimold can provide a lean, streamlined solution for your contract manufacturing needs. We also utilize 3D printing technology for rapid prototyping for product development and proof of concept. Whether it is Rapid Injection Molding (RIM) or Additive Manufacturing, we provide suppliers with fast turnaround and easy modifications to stay ahead of today’s military and defense market.

CNC Machining of Precision Defense and Mil-Spec Components

In addition to our full range of injection molding services, we have an in-house CNC machining shop fully equipped and equipped for machining low volume military parts and a wide variety of defense industry components. Our machine shop services utilize high precision 3-axis and 5-axis CNC machines capable of machining a wide variety of materials used in modern military and defense industry manufacturing. With decades of combined industry experience, our CNC programmers have the knowledge to ensure that every part you receive is machined to your exact precision specifications.

Request Your Free Military and Defense Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom Military and Defense injection molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.