Metal Extrusion Services

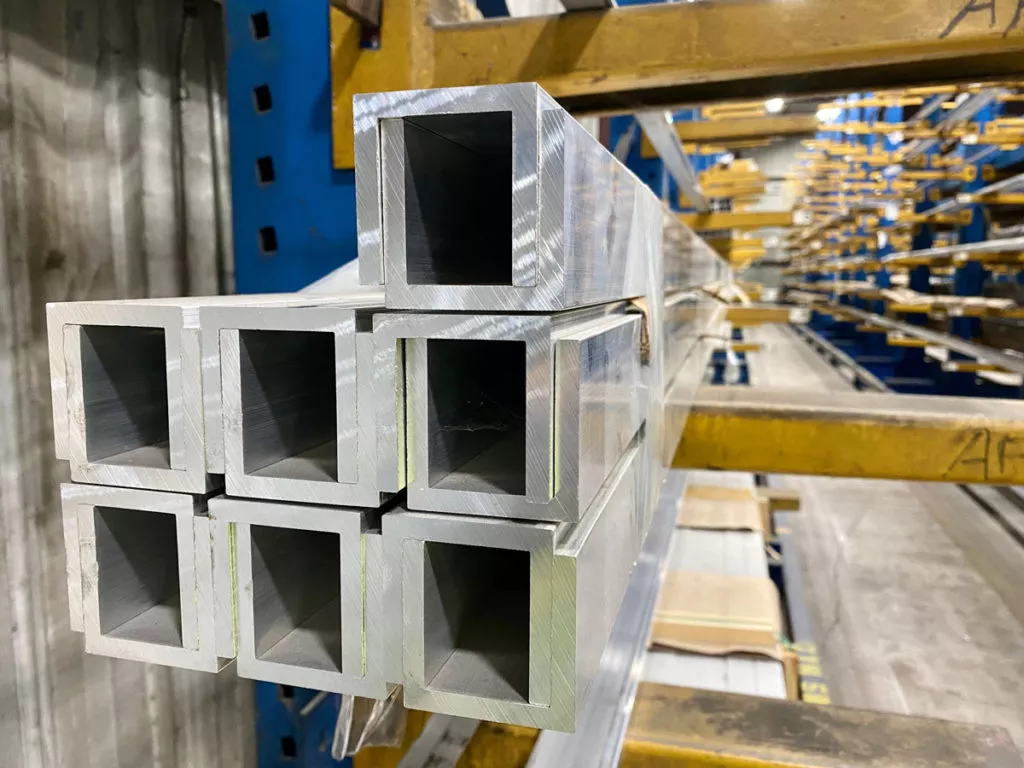

Elimold extrusion service offers high quality, cost effective extrusion parts. With our professional and experienced engineering team and advanced machines, we not only make excellent tools but we also offer complex extruded parts as a manufacturer of metal and plastic extrusions. You can be rest assured because we exercise strict quality control through the whole manufacturing process guided by high quality standards of metal and plastic extrusion technology. Regular testing and verifying at various stages of manufacturing ensure us deliver an extraordinary quality product every time.

Extrusion services China

Elimold is committed to providing quality custom extruded profiles in a variety of alloys to those with the vision to see the potential of these materials.

Elimold is proud to offer a range of metal extrusion and plastic extrusion services, serving the needs of various industries and applications. Many of our extrusions are nested, mated, or sliding-fit sets that require careful attention to tolerances and finish quality; our expert team has years of experience handling complex jobs and can easily meet even the most unusual extrusion needs.

We can handle all types of project requirements — including thin wall, complex shape, heat sink, small cross-section, co-extrusion, ram extrusion, reverse extrusion, tri-extrusion, and ultra-precision solutions — and complement these offerings with secondary operations such as punching.

Our engineers will use their expertise, in manufacturing and materials, to recommend the ideal material from both performance and a cost standpoint. We offer precise tolerances, consistency of product, reliable service and a reputation for problem-solving, all supported by extensive research and experience.

To save 10-20% over your current supplier, send us your extrusion samples or drawings.

Extrusions

Extrusion is the process by which long straight metal parts can be produced. The cross-sections that can be produced vary from solid round, rectangular, to L shapes, T shapes. Tubes and many other different types. Extrusion is done by squeezing metal in a closed cavity through a tool, known as a die using either a mechanical or hydraulic press.

Extrusion produces compressive and shear forces in the stock. No tensile is produced, which makes high deformation possible without tearing the metal. The cavity in which the raw material is contained is lined with a wear resistant material. This can withstand the high radial loads that are created when the material is pushed the die.

Extrusions, often minimize the need for secondary machining, but are not of the same dimensional accuracy or surface finish as machined parts. Surface finish for steel is 3um; (125 uin), and Aluminum and Magnesium is 0.8 um (30 uin). However, this process can produce a wide variety of cross-sections that are hard to produce cost-effectively using

other methods. Minimum thickness of steel is about 3 mm (0.120 in), whereas Aluminum and Magnesium is about 1mm (0.040 in). Minimum cross sections are 250 mm2 (0.4 in2) for steel and less than that for Aluminum and Magnesium. Minimum corner and fillet radii are 0.4 mm (0.015 in) for Aluminum and Magnesium, and for steel, the minimum corner radius is 0.8mm(0.030 in) and 4 mm (0.120 in) fillet

Types of extrusion processes

There are four significant types of extrusion processes that are used to produce objects of different quality. At Elimold, our expert team covers all operations to deliver you the best quality end products.

Direct extrusion, also referred to as forward extrusion, is the most common metal extrusion method. With this type of extrusion, a billet of material is pushed through a container by a high-pressure ram. The material flows in the direction of the ram motion and exits through the opening of the stationary die. Direct extrusion allows for larger profile designs and a higher quality surface finish than the indirect extrusion method.

There are some disadvantages to consider with this method. A large amount of friction generates between the material and the walls of the container, which results in decreased die-face pressure and temperature variances. These factors make it more challenging to control dimensional consistency and the material’s properties.

With indirect extrusion, the material is placed into a container and secured. The extrusion die moves with a hollow ram over the material, forcing it through the die opening. Indirect extrusion is also sometimes referred to as backward extrusion because the material flows in the opposite direction of the ram motion. Since there is no relative movement between the material and container, there is much less friction with this method, resulting in lower energy use and less heat generation. With less heat, indirect extrusion generally has greater control over dimensional consistency, material properties, and grain size when compared with direct extrusion.

However, the drawback to this type of extrusion is a more significant limitation on overall die profile size, as it must fit inside the hollow ram. The billet’s surface impurities can find their way into the extruded product reducing the overall surface finish and aesthetics.

These are sub-categories of extrusion integrated into the primary methods discussed above. The temperature of the billet relative to the room and material recrystallization temperature defines hot, warm, or cold extrusion. Hot extrusion is when the billet is heated well above the material’s recrystallization temperature, often associated with the direct extrusion method. The heating of the material softens it and prevents work hardening, so it more easily flows through the die, reducing wear on the tooling. Warm extrusion is when the material is heated above room temperature but remains well below the recrystallization point. The material is not heated in cold extrusion and remains at room temperature.

Warm and cold extrusion can increase the hardness and strength of the extruded product due to no excessive raw material heating. These processes work best with high-ductility materials, such as aluminum. The warm and cold processes are typical of the indirect metal extrusion method. While not drastically heating the material can provide benefits, it can be harder on the tooling and reduce the lifetime of the die. With this in mind, most manufacturers opt for hot extrusion methods.

Extruded aluminum makes up roughly 80% of all extruded metal products due to its versatility across industries, mechanical properties, diverse finishing options, and high flexibility, making it ideal for extrusion processes. Most extruded aluminum alloys are lightweight, resistant to corrosion, and have high thermal and electrical conductivity. Some aspects of each alloy set it apart from the others. To help you choose the right one for your project, we have compiled a table below of our most commonly used alloys and their unique characteristics.

Extruded Aluminum Alloys Comparison Table

Alloy NameDescriptionCharacteristicsSuitable Applications

6061

6061 is a versatile alloy that can be heat-treated to tempers such as 6061-T6. Magnesium and silicone are primary alloying elements that give the material high structural strength, toughness, and weldability.

- High strength and toughness; 40,000 PSI tensile yield strength*

- Great corrosion resistance

- Good fatigue resistance

- Doesn’t respond as well to finishing

- Heat treatable

Transportation components for automotive and marine environments

6063

6063-T5 is a very economical heat-treatable alloy with a smaller grain structure than 6061 alloys. 6063 is more common for extrusions than 6061. It can form parts with thin walls and responds well to finishing processes, making it suitable for decorative applications.

- Responds well to finishing

- Great corrosion resistance

- Easily extruded and economical

- Ideal for thin-wall applications

- Relatively low strength; 20,000 PSI yield strength*

- Heat treatable

Decorative trim, heat sinks, architectural components

* Typical minimum representative values; material temper may affect mechanical properties

If you are looking to save money and time by post-processing your existing aluminum extrusions, we can do that too! Listed above are some ready-made aluminum extrusions we can modify through other manufacturing processes, such as our CNC machining services.

Elimold's service process

After we receive your order, we will:

Step 1: Supply a complete cross-sectional drawing for you after review and discuss about your CAD files.

Step 2: Fabricate dies and extrude a sample to get your approval.

Step 3: Make the modification on the die if needed.

Step 4: Exercise process control when extruding your parts.

Step 5: Select from a variety of finishes processing to achieve the effect you want.

Step 6: Inspect finished extruded parts to avoid any dimension deviation.

Ready To Get A Quote For Your Extrusion Projects?

Do you have a extrusion part you would like to be made?Send us your drawing and we’ll send you a quote as soon as possible. We are here to help turn the order around quickly and make your project more cost effective.

Advantages of the extrusion manufacturing process

There are many advantages to using the extrusion manufacturing process across multiple industries. Whether automotive, aerospace or medical, extrusion offers a consistent and reliable method for producing high-quality parts.

The extrusion process is very versatile, allowing manufacturers to produce various products with varying shapes and sizes. Additionally, because extrusion is a continuous process, it can produce large quantities of parts quickly and efficiently. Elimold is an innovative digital manufacturing company offering plastic and aluminium extrusions in China. Some of the critical advantages of the extrusion manufacturing process are:

- The extrusion process is widely employed for manufacturing hollow pipes, tubes and more.

- Aluminium and other metal extrusion processes are used for producing prototyping structures.

- Polystyrene Extrusion is used for manufacturing complex plastic objects.

- Extrusion is also used in producing pharmaceutical products.

Extrusion Manufacturing Capabilities

| Metal Extrusion Manufacturing | Press |

| Extrusion Product FormStructural |

|

| Materials | Aluminum extrusions: aluminum alloy types: 6061, 6063, 6005, 6463, 6061-T5, 6063-T5. Plastic extrusions: Nylon, PC, ABS, PP, PVC, PS, etc. |

| Finishes |

|

| Maximum Ram Pressure | 1250 to 1675 tons |

| Maximum Circumscribing Circle Size | Up to 7 in |

| Maximum Extrusion Length | Up to 50 ft. |

| Wall thickness | from 0.25 mm |

| Weight of the profiles | from 0.003 kg/metre |

| Tolerances | Industry Standard we work with tolerances from ± 0.02 mm |

| Inspection | Material / Chemical Certifications |

| Testing | Tensile Hardness |

| Additional Services Provided |

|

| Production Volume | 500 lbs. (Minimum) More than 1000 lbs. (Typical) |

| Typical Lead Time | 2 to 3 weeks (Mil Finish) 3 to 5 weeks (Painted/Secondary Operations) |

Additional Information

| Industry |

|

| Custom Metal Extrusion Products |

|

| Industry Standards | Aluminum Extrusion Association |

| File Formats | AutoCAD |

Our Extrusion Process – A Promise of quality!

At Elimold, we understand all the factors that go into producing high-quality parts. This is why we ensure stringent quality control systems to choose the best profiles for your end-use and use other fabrication and post-production methods to improve your part’s characteristics and functionality. After receiving your order, we shall proceed to:

- Perform a free Design for manufacturing (DFM) review.

- Discuss the best aluminum profiles and design improvement options Fabricate your high-quality aluminum extrusion parts.

- Use our in-house process control systems to monitor and optimize your production.

- Perform heat treatment to improve the mechanical attributes of your part

- Engage the part in any post-processing (fabrication and finishing) to capture all desired details

- Perform final evaluation and quality control to ensure finished extrusions meet the specified dimensions, geometries, and surface finishes/details.

On-Time Delivery with Tested Performance

Working on completing projects on time and within budget, we have 2- to 48-hour response times on RFQs 95% of the time and a 90%+ OTD (on-time delivery) against our commitments. We also have robust quality control and quality assurance processes, which help ensure that our finished products work as they should.

Ready to get an aluminiun extrusion quote?

Elimold facilities are certified to ISO 9001:2000 and feature in-house die making facilities, to serve your custom extrusion needs. Using our state-of-the-art technologies to design and manufacturing extrusion tooling allows us to provide you with custom solutions for your unique applications and to ensure that our solutions surpass your expectations.

We design and manufacture extrusion tooling using the latest technology and CAD/CAM design. Our expert staff of metallurgists and engineering, manufacturing, design and marketing specialists can provide everything you need to create your custom extruded aluminum products.