Waterjet Cutting Services

Waterjets quickly cut metal and plastic parts from sheet materials using a high-pressure stream of water and abrasive. This is accomplished with the help of a high pressure pump.Elimold offers a cost-effective waterjet cutting solution whether you need a single part, batch of prototypes, or a production order. Elimold cuts materials of different shape, size, and thickness, while saving time and providing excellent finish.

Mission Statement

Our mission is to help companies and individual inventors in improving process times, saving materials, and bringing new and improved products to market. This will be achieved by utilizing the latest cutting technology to maximize machine efficiency.

These cost savings will justify our cutting technology in prototyping, as well as small to medium-sized production runs.

Some materials are more efficiently cut with waterjet than any other processes that use conventional methods. Likewise some material are cut much faster with a laser. Let us help you find the most economical process for your parts. Our values and work ethics combined will produce quality products on time and at a fair price.

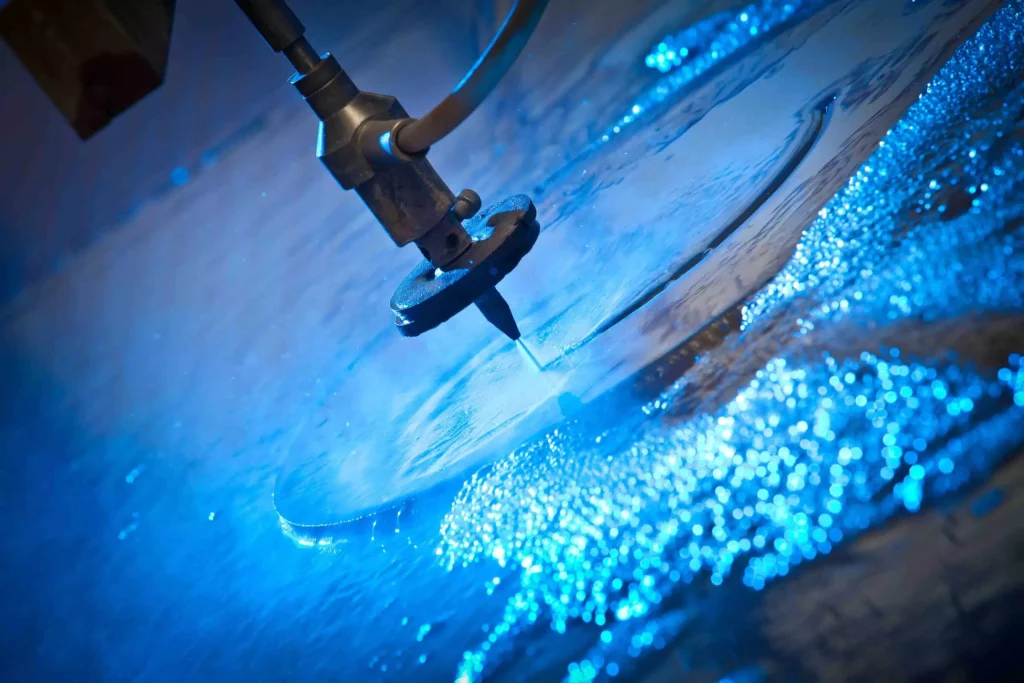

High-Velocity Abrasive Waterjet Cutting

Our state-of-the-art CNC machining and programming software, mixed with our cutting edge waterjet technology, promises the accuracy and quality your project needs.

Using a high-velocity coherent stream of abrasive mixed with water, abrasive waterjet cutting can process almost any material. For example, water passes through a sapphire, ruby or diamond orifice at 40,000 to 60,000 psi, creating momentum to pierce or drill holes as small as .030” in diameter.

Our waterjet cutting services are available to industries requiring high-quality components with a quick turnaround. We have delivered many projects ranging from detailed art and architecture to ballistic material for defense and beyond.

From manufacturing your prototype to full-scale production, we handle it all at Elimold.

Custom Metal Fabrication with Waterjet Cutting at Elimold

While waterjet cutting may be the best method for your component, Elimold recognizes that your project’s needs are specific. That’s why our team is happy to review your project’s design and determine the best method — whether it’s waterjet cutting or laser cutting, or another metal forming service that we offer.

We offer a variety of testing and inspection procedures (e.g., surface and dimensional, ultrasonic testing, visual inspection, etc.) to ensure the quality and integrity of your metal component. We also offer value-added services, such as bending, boring, centerless grinding, double disc, grinding, drilling, forming, heat treating, rolling, stamping, and trepanning, to help you produce a fully finished part.

To find out how our waterjet cutting or laser cutting services can help with your next project, contact us today, or request a quote online.

Virtually any material can be used for waterjet cutting

- Steel Hard Rolled

- Steel Mild

- Steel Tool

- Tantalum

- Tin

- Titanium

- Tungsten

- Wrought Iron

- Zinc

- Armor Plate

- Hastalloy

- Hardened Steel

- Hot Rolled Steel

- Inconel

- Magnesium

- Mild Steel

- Nickel Alloys

- Stainless Steel

- Steel Alloy

- Steel Hardened

- Alloy Steel

- Aluminum

- Armor Plate

- Brass

- Boron

- Bronze

- Cast Iron

- Cobalt

- Copper

- Exotic Alloys

Waterjet Cutting - Specifications

| General Capabilities |

| |

| Production Volume |

| |

| Lead Times Available |

| |

| Cutting Thickness | Stainless Steel:

| Mild Steel:

|

| Cutting Width |

| |

| Cutting Length |

| |

| Cutting Height |

| |

| Kerf1 | 0.006 in to 0.012 in | |

| Accuracy | 0.005 in | |

| Industry Focus |

|

|

| Intended Applications |

|

|

| Industry Standards |

|

|

| Software Used |

|

|

| 1 Kerf is the width of the cut or groove. | ||

Equipment List

| WaterJet | Flow MACH 4-4020B: 6.5′ x 13′ Table, 3 Axis, Cuts 24″, 2012 | |

| Finishing Equipment |

|

|

| Quality Control Equipment |

|

|

Application Advantages of Waterjet Cutting

- Waterjet Cutting is cheaper than other processes.

- Make all sorts of shapes with only one tool.

- Cut wide range of thickness’ to reasonable tolerance up to 3” (76mm) thick

- Up to 6” (152mm) or thicker where tolerance not important, or in soft materials.

- No Heat Generated / No heat affected zones – this is cold cutting!

- No mechanical stresses

- Cut virtually any shape

- Fast Setup means fast turnaround of your finished product!

- Only one tool to qualify / No tool changes required.

- Fast turn-around on the machine. Make a part, then 2 minutes later be making a completely different part from a completely different material.

- Leaves a satin smooth finish, thus reducing secondary operations.

- Clean cutting process without gasses or oils.

- Makes its own start holes.

- Narrow kerf removes only a small amount of material.

- Your “scrap” metal is easier to recycle or re-use (no oily chips!)

- You can trade off tolerance vs. speed from feature to feature on your part.

- Are very safe. (No, they don’t explode, thanks to the nearly incompressible property of water.)

- Draw the part / cut the part. It is that easy!

- No “scaley” edges, which makes it easier to make a high quality weld

- Machine composite materials, or materials where dissimilar materials are glued together

- Machine stacks of thin parts all at once.

Cutting Techniques Summary and How Water Jet Cutting Compares

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes | |

|---|---|---|---|---|---|---|---|

| OMAX WATERJET | Up to 6″ | 0.005″- 0.015″ | .020″/.040″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, carbon fiber, ceramics, etc. Taper up to 59 ° |

| MICROCUT™ | .0005″ – 0.5″ | 0.0005″ -0.005″ | 0.009″, 0.011″, 0.0196″ | 1 to 5000 | Low | 6-8 days | Metal, glass, plastic, stone, rubber, kevlar, laminates, carbon fiber, ceramics, etc. |

| FIBER LASER | AL: 0.250″ SS: 0.375″ CRS: 0.500″ COP: 0.250″ Brass: 0.125″ | 0.002″ – 0.005″ | .008″ | 1 to High-Volume | Low | 6-8 days | Metals – Fast |

| WIRE EDM | 0.001″ – 6″ | 0.0005″ | 0.005″ | 1-200 Is Best | Low | 6-8 days | Conductive Metals, Carbon |

| * CHEM ETCH | 0.005″ – 0.060″ | Is +/- 10% of material thickness, .002″ min. | Equal to metal thickness | 1- Infinity | $350 Min. | 6-8 days | Metal Only. No Burrs. Beveled Edges. Half Etch and Holes. |

* Inner radius should be 100% of material thickness. Outer Radius should be 75% of material thickness.

**Dependent on geometry, volume and material: Elimold options available.

Limitations of Waterjet

For all of its advantages, a waterjet service also comes with some disadvantages that should be considered when deciding if it is the best operation for a part. Depending on the thickness of the material, it may be more cost effective to have the parts produced on a laser or plasma cutter. When lead time is important other potential operations, such as laser cutting fabrication, may result in faster production times. For thick parts, the kerf will widen as the jet slows down as it travels through the part. This causes less accurate feature tolerances when cutting thick material. Other operations such as CNC milling or EDM machining can hold very tight tolerances and maintain perpendicularity on vertical surfaces of a part.

Waterjet Cutting Services for Any Material

Whether you need to cut a material that doesn’t adhere to traditional machining methods or looking for reliably accurate cutting for your product prototype design, Elimold can help! All you need to do is provide us with your CAD file, or our CAD expert can draw it up if you have a design. With our precise waterjet cutting, we can manufacture your unique product with a quick turnaround.

Contact our qualified team today for cost-effective waterjet-cutting services!