CNC Milling Services

Elimold offers a wide range of CNC milling services. We have a wide range of custom CNC milling centers that allow us to produce simple or complex part geometries with high speed and precision. Our goal is to provide you with a level of service you can’t get anywhere else. As a leading CNC milling company with many years of custom manufacturing experience, we have mastered the art of providing customized solutions to meet our customers’ unique needs.

Our CNC Turning Services Bring You Precision and Reliability

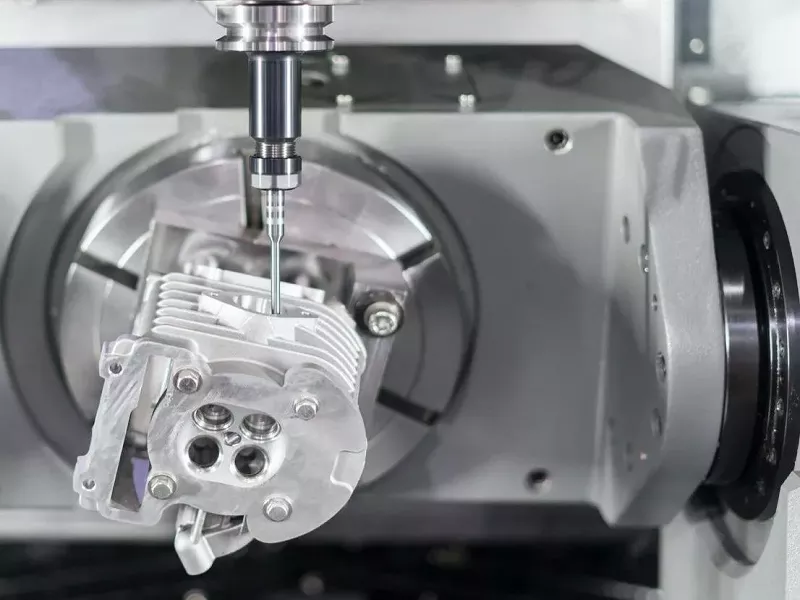

Elimold has everything you need to produce the best custom CNC milled parts to satisfy our diverse customer base. Our machine shop is equipped with all the latest and most advanced machinery. Our state-of-the-art facilities offer indexing, custom fixtures, and CAD/CAM programming. In addition, they have excellent repeatability and are able to achieve fine tolerances, ensuring that your finished product meets your desired specifications. Our automated CNC machining and wire EDM equipment integrates with our laser cutting, punching, forming, rolling, welding, hardware mounting, and finishing equipment to provide complete machining and manufacturing services.

And, a large in-house facility means that no matter what your part is, we have the shop and the machines to make it. We support 3-axis, 4-axis, 5-axis milling, and right-angle milling capabilities to help you quickly create designs from simple straight lines to complex geometries. No matter what industry you belong to, we can provide instant pricing, on-demand delivery times, and design for manufacturability feedback for materials and manufacturing processes for your custom CNC milled parts.

Elimold’s advanced quality assurance system and our experienced team of professionals are ready to take on any challenging machining job for you. We understand the challenges of producing in an environment where components must meet certain standards in order to be accepted. Everything we do is subject to rigorous quality assessments at every stage. This not only allows us to produce quality components, but it also allows us to critically examine our processes to look for opportunities to further cut costs and leverage turnkey solutions. Through a culture of continuous improvement, we are able to keep our prices competitive without compromising the product you receive.

High Quality Rapid CNC Milling Capabilities

Elimold’s high-quality CNC milling services. Our CNC vertical milling machine has a working range of 142X64X27 inches. Our vertical milling equipment is able to guarantee the precision tolerance of parts of all sizes to a tight control of (±) 0.001 inches. Our well-equipped in-house facilities enable us to provide a variety of CNC milling processes, including milling, drilling, end machining, surfacing, slotting, cutting and profiling. We can also work on a variety of projects that require tapping, countersinking, reaming, profiling, thread milling and slotting. Therefore, our CNC vertical milling services are able to meet all production requirements from prototyping to large and small batch production.

Type of CNC Milling Services

From 3-axis basics to complex 5-axis projects, our precision CNC milling brings your designs to life with unmatched accuracy and craftsmanship. Our machining team can help customers take control of their CNC milling projects and ensure custom parts meet their exacting requirements.

3-Axis CNC Milling

4-Axis CNC Milling

5-Axis CNC Milling

CNC Milling Materials

At Elimold, our CNC milling service offers a diverse range of materials, ensuring precision and durability. This vast selection empowers our clients with optimal choices for their unique projects, boosting their product’s quality and performance.

Metals

- Aluminum

- Brass

- Copper

- Stainless Steel

- Alloy Steel

- Steel Mild Low Carbon

- Titanium

Plastics

- ABS

- Acetal

- CPVC

- HDPE

- LDPE

- Nylon

- PEEK

- PEI

- PET

- PMMA

- Polycarbonate

- Polypropylene

- POM (Delrin)

- PPSU

- HIPS

- PSU

- PTFE

- PVC

CNC Milled Parts Surface Finishing Options

Gain access to quality surface finishing for custom CNC milled parts to remove aesthetic flaws and improve the appearance of your products. We also provide rigid protection and additional resistance and strength to your parts through superior surface finishes.

As machined

Standard surface finish from machine directly, variables in relation to different machines.

Heat Treatment

Using heating and cooling to immensely improve key physical properties of metal.

Sandblasting

Add uniform matte or satin surface finish against designated metal part and remove tool marks.

Coloring

Change the color of the workpiece by spray painting, baking finishing, etc.

Laser Etching

The practice of using lasers to engrave the workpiece.

Screen Printing

Process of transferring a stencilled design onto a flat surface using a mesh screen, ink and a squeegee.

Anodizing

Anodizing is an electrolytic oxidation process by coating the metal with a corrosion-resistant coating.

Polishing

Process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment.

Plating

A surface covering in which a metal is deposited on a conductive surface. It is used to enhance surface properties in multiple purposes.

CNC Milling Design Guidelines

| Description | General Tolerance or Standard |

|---|---|

Maximum Part Size | Milled parts up to 80” x 48” x 24” (2,032 x 1,219 x 610 mm). |

Distance Dimensions | For features of size (Length, width, height, diameter) and location (position, concentricity, symmetry) +/- 0.005”. |

Orientation and Form Dimensions | 0-12″ +/- 0.005″, Angularity 1/2 degree. For 24″ and beyond please consult Elimold’s Manufacturing Standards. |

Precision Tolerances | Elimold can manufacture and inspect to tight tolerances, including sub +/- 0.001″ tolerances, per your drawing specifications and GD&T callouts. |

Minimum Feature Size | 0.020” (0.50 mm). This may vary depending on part geometry and chosen material. |

Threads and Tapped Holes | Elimold can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

Edge Condition | Sharp edges will be broken and deburred by default. Critical edges that must be left sharp should be noted and specified on a print. |

What is CNC Milling?

A CNC mill is an automated cutting machine that uses a rotating spindle head to remove excess material. CNC mills come in a variety of sizes and with different axis configurations. The manufacturing process is primarily used to cut harder metals, but can handle a wide range of workpiece materials, from plastics and aluminum to stainless steel and titanium. CNC mills excel at contour cutting of harder materials. Like all CNC machines, CNC mills are controlled by G-codes created through CAM software. The Gg-codes instruct the machine where to move the tool head, how fast the tool will rotate, how deep to cut, how to move the workpiece, and other factors related to speeds, feed rates, and coordination. The complexity of the G-code depends on how many axes the mill has.

Difference Between 3-, 4-, and 5-Axis CNC Milling

3-axis milling is the most basic and commonly used method of milling parts. It involves the spindle cutting along three axes: X, Y, and Z. 4-axis milling, on the other hand, adds a rotary axis to one of the existing three on a 3-axis machine. This allows for more complex shapes to be created as the part can be rotated during CNC machining. However, 5-axis milling is considered the most advanced form of CNC milling machining services as it adds a second rotary to yet another axis on a traditional 3-axis machine. This enables even more complex shapes to be produced with greater precision and accuracy. With 5-axis milling, manufacturers can create complex geometries and intricate designs that would otherwise be impossible with other methods.

Ready to get started on your CNC milling quote?

As a leading provider of machining and milling services, we understand exactly what our customers need to achieve sustainable success. We have the ability to consistently achieve your production goals on time and within the agreed upon budget. We would be honored to work with you and help, contact us today.

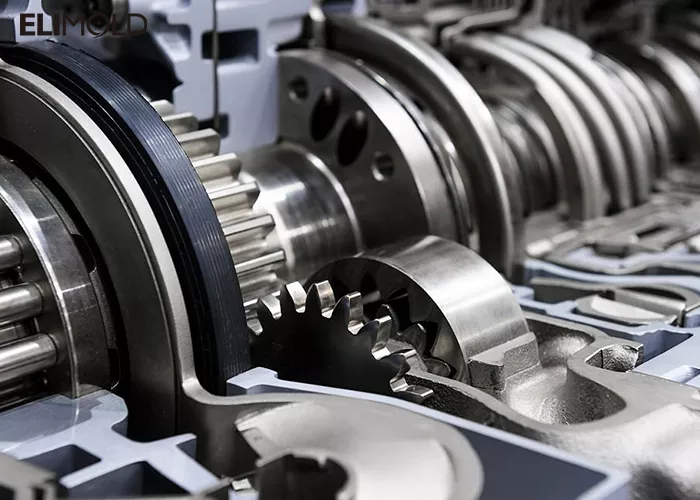

Gallery of Custom Parts

With a wide range of materials available, it is very flexible to create various end-used parts through prototypes to high-volume by fast CNC machining. Our experts can make the complex cut and CNC milled parts fast to reduce costs and improve the quality of your products. We successfully delivered millions of high-quality custom CNC milling aluminum parts to our customers worldwide. Our 3d milling service helps many customers from different industries make their parts successfully. Here are some parts we made:

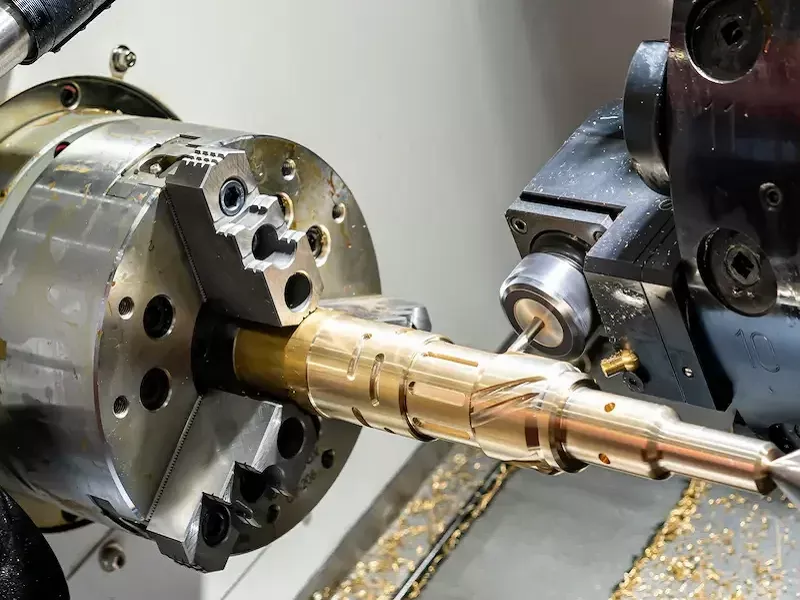

Difference between CNC milling and CNC turning

CNC milling and turning both are capable of producing accurate custom parts from metals, plastic and other materials. The main difference is that while the cutting tools rotate for milling, the raw material rotates for turning. For that reason, turning is mostly used for machining custom cnc round parts such as shafts, pins, balls, etc. Another difference is that while basic milling machines have three axes of motion, a lathe or turning machine needs only two. In a mill, the cutter usually moves up and down while the workpiece moves horizontally in two directions. In comparison, turning requires only that a non-rotating cutter move left and right on one hand and forward and back for the second axis. The fact that turning has only two axes in its simplest form, constrains the variety of shapes it can produce. For example, turning can produce a shaft, chess pawn, a cylinder with a rounded end, etc. Turning normally can’t produce even a simple enclosure box. However advanced turning centers can have more than two axes and therefore can produce a wider variety of shapes.Elimold’s services are not limited to CNC milling and include hybridized manufacturing that leverages CNC milling, prototype fabrication, additive manufacturing and more.

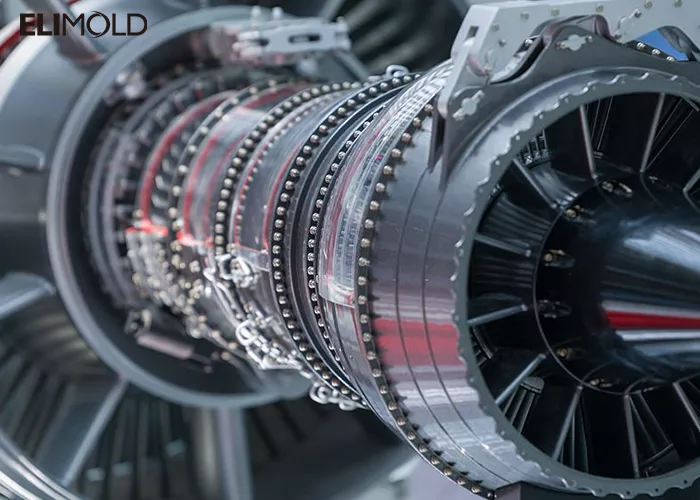

Applications of CNC Milling Services

The CNC milling process is applicable to many industries as it is highly efficient, accurate and eliminates the need for manual labor. Whether it is for prototypes or a full production runs, machine shops and their services are a critical step in the manufacturing process.

Order high-quality CNC milled parts with Elimold

Whether you are looking for 3-axis or 5-axis CNC milled parts, you can be confident that with our CNC milling services, you can produce large orders of complex parts with exceptional precision and efficiency. Plus, our expertise, combined with the power of our in-house facility and our supply chain network, will ensure your parts are quoted fairly, delivered quickly, and built right the first time, every time. Contact us today.