Agricultural Injection Molding

Growing your farming needs with quality injection molding and thermoforming solutions. Experience on-time delivery for high-quality plastic part manufacturing.

Agricultural Plastic Products Manufacturer

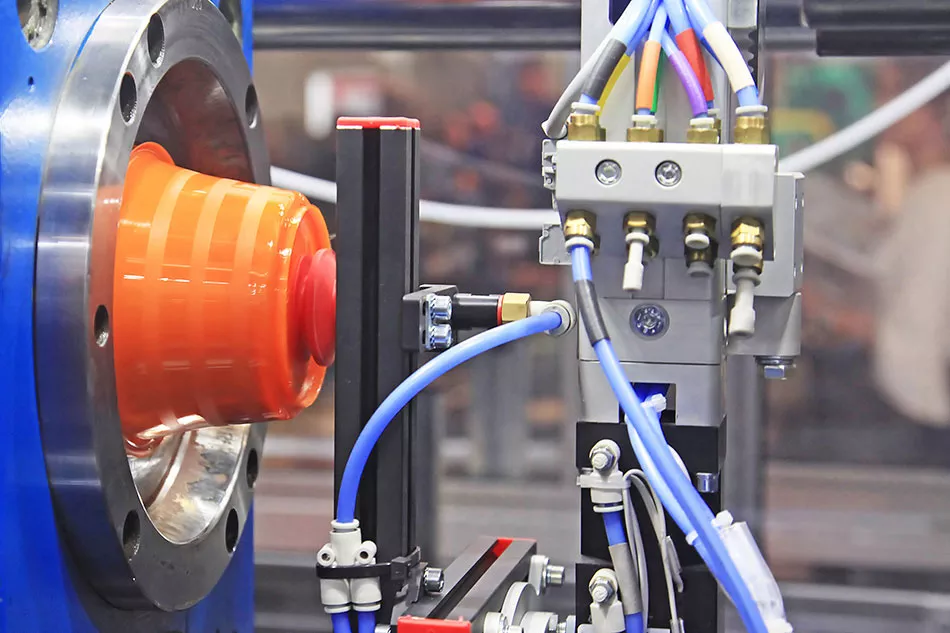

As a leading custom plastic parts manufacturer for the agricultural industry, Elimold combines innovative design and advanced equipment with decades of manufacturing expertise. Our state-of-the-art facility features 19 different molding machines and a dedicated team of designers, machinists, assemblers, and quality experts to handle projects of any size. Agricultural parts must withstand harsh outdoor conditions, frequent use, and chemical exposure, so durable part design and precise, seamless production are top priorities. Our team works closely with you to select the ideal material and manufacturing process for your custom parts, ensuring optimal performance through rigorous quality testing and final inspections.

Injection Molding Services for the Agriculture Industry

Elimold is a leading supplier of custom plastics for farm equipment and agricultural vehicles. From tools to tractors, the equipment used in agriculture needs to be durable, long-lasting, and able to withstand the most adverse conditions. With our experienced team and innovative thermoforming and injection molding equipment, we not only deliver the quality our customers demand, but also the low cost and fast turnaround time they seek. Our customers come to us knowing that our engineering and manufacturing teams will work with them to design, select the right thermoplastic materials, and select the best manufacturing methods to minimize cost and ensure accuracy for every component and consistency.

Best-in-Class Agricultural Plastic Solutions

What sets Elimold apart from our competitors is our approach to new projects. We develop custom applications and solutions for the problems our customers face. From initial design review to how the product will be used and the challenges that may be encountered in the field, we advise on the type of plastic, all the way to final product assembly. Our goal is to ensure that the end user has the best experience and gets the most out of our products. Our extensive experience as a custom agricultural injection molding service provider, coupled with our experienced team, processes, and equipment, enables us to respond quickly and produce large quantities quickly at competitive prices.

Elimold specializes in providing custom injection molding solutions for businesses involved in the agricultural industry, for the manufacture of high-end agricultural products and complex part designs. We manufacture a wide range of custom agricultural equipment injection molded parts and produce low to high volume products in a cost-effective manner. Our experience, latest equipment, technology, automation, and ability to ship directly to large agricultural equipment manufacturers sets us apart from the competition.

How can Elimold help you with your food and agriculture component needs?

- Providing you with engineering assistance to help you optimize the manufacturability, reliability, and durability of your agricultural or food processing part designs.

- Supporting your needs for iterative product development with rapid prototyping so you can bring new product innovations to market faster.

- Helping you select the best material for each component to ensure it provides optimal performance and longevity in your critical applications.

- Supporting you throughout the product lifecycle, from rapid prototyping of new part designs to bridge and production manufacturing.

Types of Injection Molding Processes for Agricultural Industry

Go from prototyping to on-demand manufacturing in just days for affordable, high-quality molded agricultural parts. Even better, once you move to on-demand manufacturing tools, your prototyping tools are free. Partnering with Elimold, which offers free design consulting services, can significantly speed up the manufacturing process, resulting in greater supply chain flexibility, more consistent parts, and easy certification.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

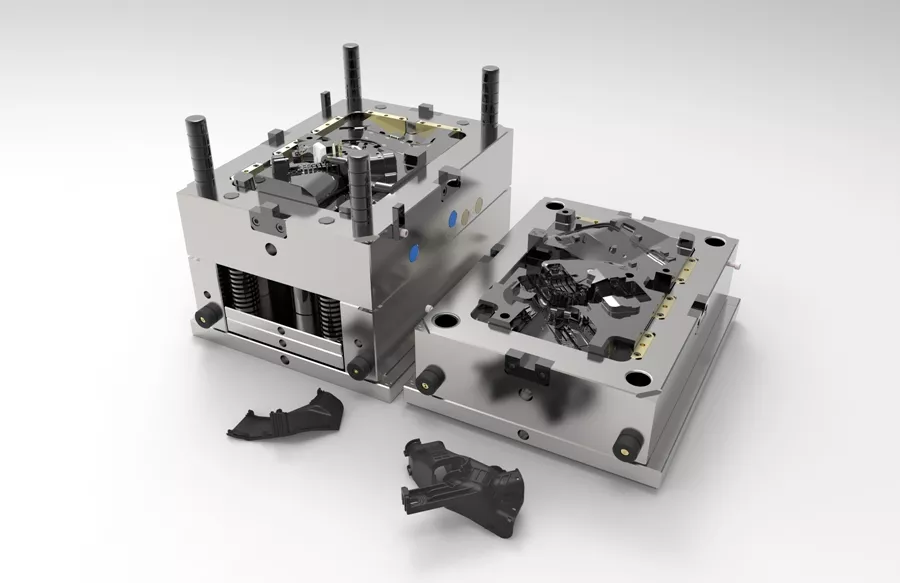

World Class Expert Designers for Custom Agricultural Product Injection Molds

Elimold’s injection mold design team is what sets us apart from our competitors. Our mold design experts will work with you to design the perfect agricultural product injection mold for your application and provide feedback on part design to overcome the most complex challenges. Whether you have a design idea or want to start from scratch, our team of expert designers will help you turn your custom agricultural equipment plastic parts into reality. Contact us to discuss the specific requirements of your application and receive a free quote!

Our Agricultural Injection Mold Processing Capabilities

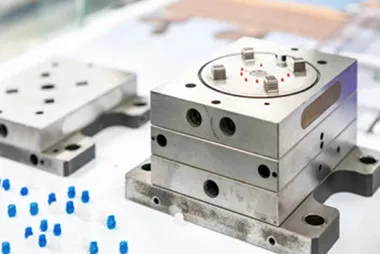

The agricultural industry relies on precision and durable plastic parts to keep farm equipment and businesses running. Elimold has the expertise and resources to produce high-quality custom injection molds for manufacturing custom plastic parts for farm equipment. Custom injection mold tooling is our specialty, and our design team will work with your engineers to develop the best design for your application.

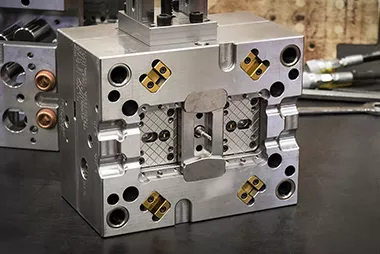

We are a top manufacturer of custom injection molds for the agricultural industry. With a design in hand, our shop can quickly produce custom injection molds to tight tolerances. Our in-house shop produces precision injection molds with tolerances as tight as 6/10,000 on a 140-inch span and 14/10,000 on a 23-foot span. We also offer value-added services such as CNC machining, mold sampling, polishing, welding, etc. to save you time and money on your agricultural custom plastic manufacturing.

Working with Elimold, you can rest assured that your custom mold will be manufactured to the highest standards and go through a rigorous quality verification process to ensure the final product exceeds your expectations. We manufacture custom injection molds for a variety of plastic and metal materials to support custom plastic parts for agricultural equipment.

Value-added service capabilities

The agricultural industry often has stringent requirements for part performance, weather resistance, durability and reliability. Elimold specializes in manufacturing high-volume OEM injection molded plastic products at competitive prices. We offer a full range of plastic injection molding solutions designed to help our partners bring high-quality, high-performance products to market:

- Low cost, high value manufacturing

- Product design assistance

- Mold making

- Material selection

- Manual and automatic assembly

- Ultrasonic welding

- Secure custom packaging

Why trust your agricultural plastic injection molding to Elimold?

You need your contract manufacturing partner to have a process designed for success. From design to quality control to logistics, we’ve developed a way of working to align with your priorities.

Robust Part and Tool Design

When optimizing design for manufacturability, these two things go hand in hand. Our engineering team and mold shop experts will work with you to evaluate your design so your project can move seamlessly to full production.

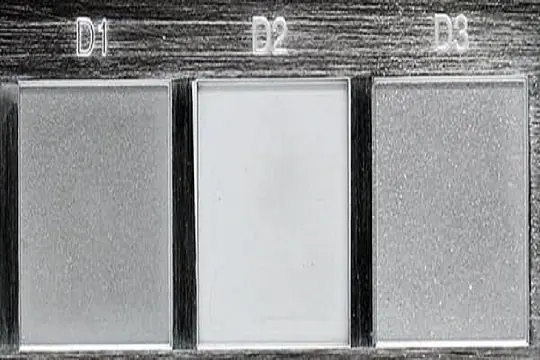

Superior Quality Control

With human and technological systems measuring tolerances, checking for flash, and verifying color, you can be sure that defective parts don’t enter your supply chain.

Equipment and Capacity

With 140,000 square feet of production space and more than 60 dedicated molding machines, you never have to worry about not being able to meet product demand. We can also custom our equipment to perform complex procedures.

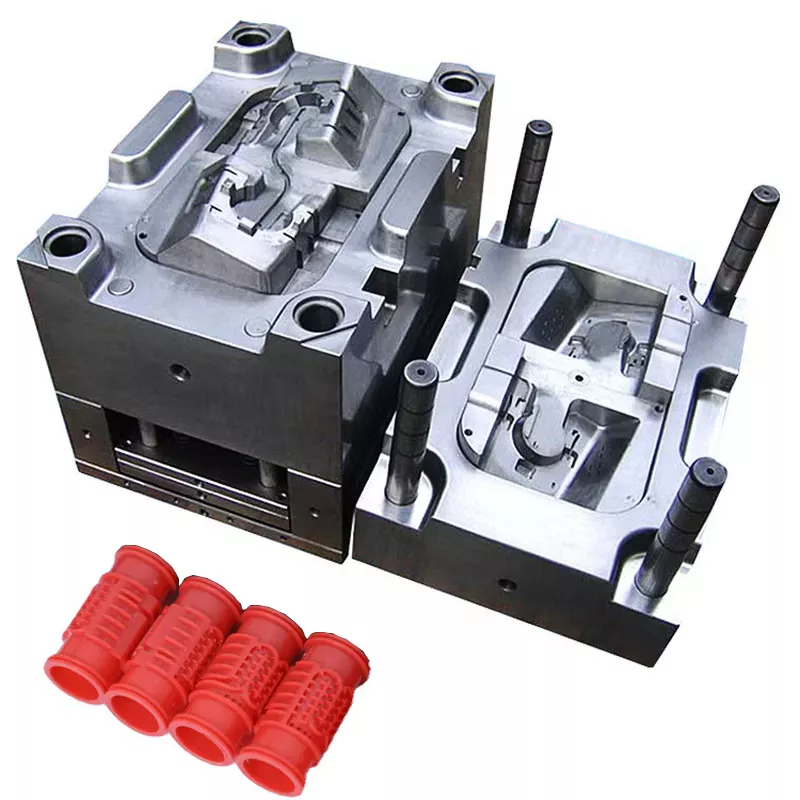

Agricultural product accessories production process

Whether it is a production of thousands or large-scale production of millions, Elimold can provide a full range of agricultural molding solutions to meet various requirements. Equipped with more than 60 injection molding machines ranging from 60 tons to 4000 tons, it can handle parts of various sizes. Elimold also partners with specialized suppliers of hot runner systems, allowing us to meet the tightest tolerances, provide design flexibility, and reduce production cycle times. However, production process control also plays an important role in manufacturing high-quality parts. You can find our production process solutions below:

- Design Preparation: Create detailed product designs and mold specifications.

- Mold Fabrication: Skilled toolmakers craft molds with precision and expertise.

- Material Selection: Choose suitable plastic material based on agricultural requirements.

- Injection Molding Process:

- Clamping: Securely close the mold halves using hydraulic or mechanical force.

- Injection: Melt plastic pellets in the machine and inject into the mold cavity.

- Cooling: Allow the plastic to cool and solidify within the mold.

- Mold Opening and Ejection: Open the mold and eject the solidified component.

- Post-Processing:

- Trimming and Deflashing: Remove excess material and refine the final shape.

- Secondary Operations: Perform additional processes like drilling, assembly, or finishing.

- Quality Control and Inspection:

- Visual Inspection: Check for surface defects and imperfections.

- Dimensional Checks: Measure parts to ensure they match specifications.

- Packaging and Shipping: Package finished components for distribution to agricultural businesses.

Properties of Plastic Injection Molded Irrigation Parts

We take a wide variety of plastics and materials and are ready to manufacture most custom injection molded plastic irrigation parts and assemblies. Different resins and plastic blends have different irrigation part properties such as:

- Strength

- Durability

- Flexibility or hardness

- Dimensional stability

- UV resistance

- Moisture, chemical or mechanical resistance

- And much more.

Material Options

Our high-out automated process lines can manufacture products from virtually any engineering, commodity and specialty plastic material. While we can work with just about any thermoplastic resin, plastics we use most often to produce agriculture industry-specific parts and assemblies include:

- ABS

- ABS/PC

- Acetal

- Acetal Copolymer

- Acetal Homopolymer/Delrin

- ETPU

- HDPE

- LCP

- LDPE

- LLDPE

- Nylon

- PBT

- PC/PBT

- PEEK

- PEI

- PET

- PETG

- PMMA (Acrylic, Plexiglas)

- Polycarbonate

- Polypropylene

- PPA

- PPE/PS

- PS

- PSU

- TPU

Additive & Fibers

If the standard materials can’t meet your custom injection molding parts requirements, the additives and fibers can improve the material properties.

- UV absorbers

- Flame retardants

- Plasticizers

- Colorants

- Carbon fibers

- Glass fibers

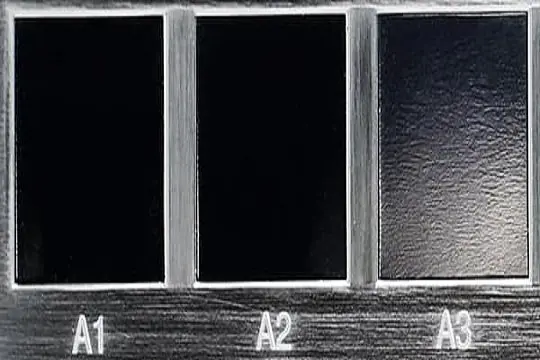

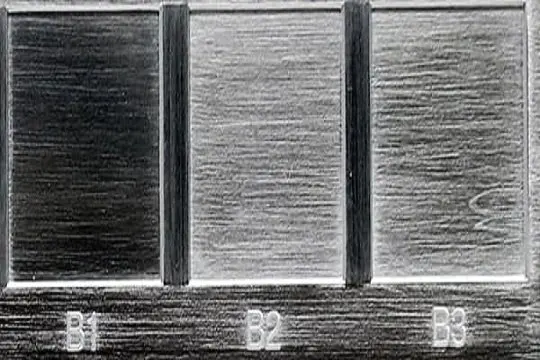

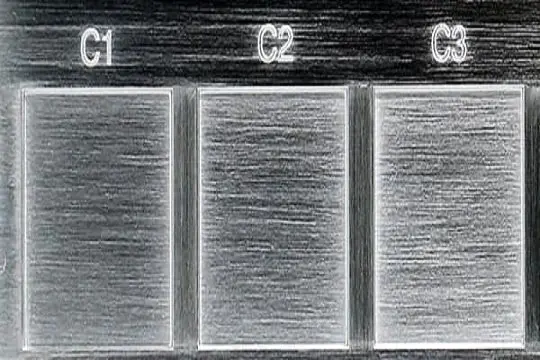

Surface Finishing

Custom Agriculture Industry Injection Molding Services Surface treatment will enhance the quality of your injection molded parts. Elimold offers a wide range of surface treatment options. These highly effective surface treatments enhance the functionality and aesthetics of your parts.

Glossy

Semi-glossy

Matte

Textured

Advantages of Injection Molding in Agriculture

- flexibility. As manufacturers, we can choose the mold design and the type of material to be melted as the main ingredients of the product. Therefore, regardless of complexity, we can supply all types of parts vital to the agricultural sector.

- efficiency. Once we set up the process with the relevant molds and materials, the entire cycle moved quickly, producing thousands of parts per hour. Our machines are also very energy efficient, so we pass these savings on to our customers.

- Quality consistency. As we mentioned before, the agricultural industry takes quality and regulations very seriously. As a result, we can tightly control the parameters of the process to ensure that even if we produce thousands of products an hour, they are all of the same high quality as Reliant.

- Great value for money. After we develop the mold for the manufacturing process, the production cost is relatively low, which is one of the reasons why more farmers are turning to injection molding to meet their operational requirements.

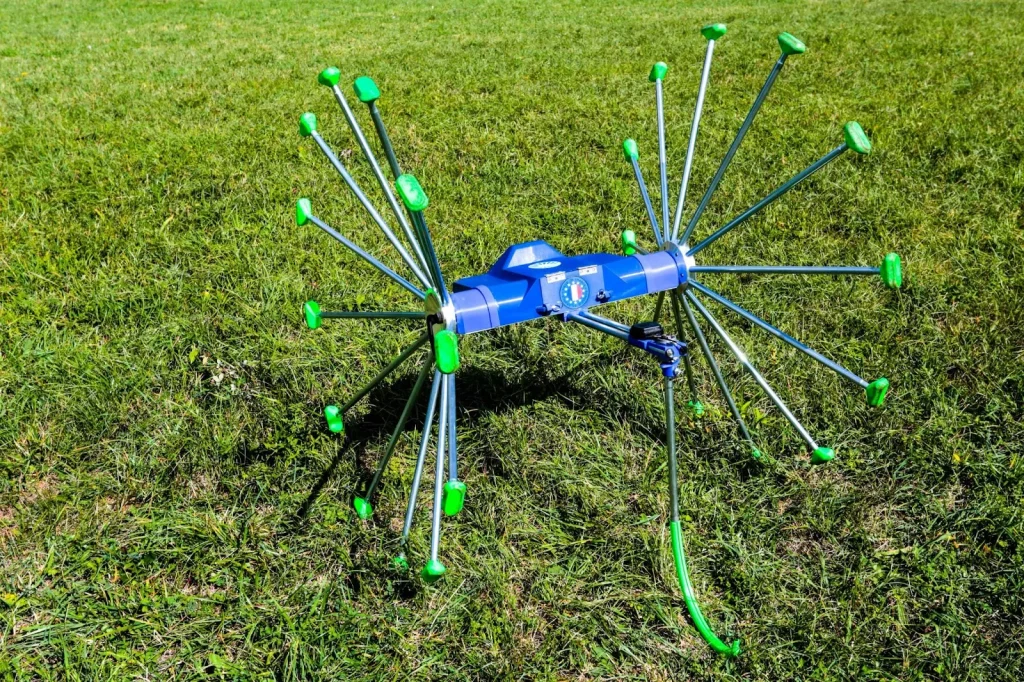

Applications in Agriculture

With years of industry experience and a strong commitment to quality, we have become a trusted partner for agricultural businesses around the world. Whether you need a one-of-a-kind component or high-volume production, we have the expertise and resources to meet your needs. The agricultural industry requires durable, reliable plastic parts that can withstand harsh outdoor conditions and repeated use. Here are some examples of parts we produce for our partners in the agricultural field:

- bucket

- Lawn mower body

- Spiral hopper

- septic tank

- poultry feeder

- Pet water fountain and chow tower

- Beef stick casings

- Stock tank

Choose Elimold as your agricultural injection molding manufacturer

We are a plastic parts manufacturer serving the agricultural sector and we understand the standards of products related to the agricultural industry. All of the agricultural related plastic products we produce are manufactured to the highest standards. To ensure that we always meet this commitment, we test each product to achieve the required quality level and ensure that they are strong enough to stand the test of time. Our main goal is to help our customers get the necessary parts at a very low cost without sacrificing quality.

Request Your Free Agriculture Injection Molding Quote Today

After receiving your drawings, our engineers will analyze your custom agriculture injection molding parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.