Electronics Plastic Injection Molding

We are an ISO-certified of engineering, custom injection molding, and contract manufacturing. Our clients bring demanding applications requiring electronics plastic injection molding services and best served by expert engineers.

Your Partner for Plastic Injection Molding of Electronics

Elimold has over 20 years of experience and a 5,000 square meter production area equipped with advanced injection molding machines. Our expertise in mold design and manufacturing enables us to provide quality plastic parts for the electronics industry. Our team of experienced engineers and technicians is dedicated to providing comprehensive injection molding services, from mold design and custom tooling to prototyping and custom plastic injection molding. We also provide a range of post-processing services to ensure your electronic products stand out from the competition. Alternatively, we offer JIT services to help you manage your supply chain with cost-effective distribution and optimal efficiency. As a leading plastic injection molding company, we provide comprehensive services covering every stage of the production process, ensuring the high quality of plastic electronic components. Our most cost-effective solutions streamline the development process and speed up your electronic products to market.

Your Electronic Plastic Parts Supplier

We provide the electronics industry with the latest plastic injection molding technology, materials, and advanced component and mold designs to provide the best quality components required for the highest quality electronic products. Our facility is equipped with in-house mold care support to repair and maintain the molds running on these machines. We can produce parts according to your drawings, specifications, or purchase orders. If you don’t have a confirmed design, but have a great idea, our team can help you make it a reality. Our team can work with your team to understand the goals of the project and its expected operating environment. We can then collaborate to develop prototypes for testing and validation. Once the final design is acceptable, full production can begin.

Elimold excels at taking on challenging jobs, no matter the size or complexity. With advanced equipment and well-trained personnel, we can handle designs with unique geometries, hold tight tolerances, produce in high volumes, and utilize materials efficiently.

Elimold specializes in electronics plastic injection molding

Elimold offers complete tooling, mold making, and plastic injection molding of high precision parts for the electronics industry. We have extensive experience working within AS9100 procedures in a Total Quality Managed (TQM) environment. Our systems are equipped to offer full traceability of products and materials throughout the entire manufacturing process.

We have a long history of providing contract manufacturing services for enterprises that require very tight tolerances, and a high level of precision.

With technology in the electronics industry continuously driving production to smaller components, it is important to work with a company that has the expertise to produce tiny parts at a lower cost and a higher speed.

Electronic Injection Molding Service Types

As an ISO9001:2000 certified plastic injection molding facility, we provide comprehensive solutions tailored to the unique needs of the electronics industry. With our expertise, advanced equipment, and dedication to quality, we deliver precision engineered components that meet the most stringent requirements of electronics products.

Plastic Injection Molding

LSR Injection Molding

Overmolding

Gas Assist Injection Molding

Insert Molding

Structural Foam Molding

Rapid Tooling

Micro Molding

Production Tooling

Value-added services

- Design for manufacturing support

- Plastic material development, testing and specification to UL, CSA, RoHS and other international codes

- Engineering and injection mold manufacturing

- Secondary services include inserts and welding to simplify assembly

- Plastic part decoration, painting, assembly, packaging

- Working with short-run or high-volume contract manufacturers

- EMI/RFI shielding

Quality Assurance and Quality Policy

At Elimold, we prioritize quality assurance to ensure that every product we produce not only meets our customers’ standards, but also complies with relevant regulations. Our quality assurance department uses a range of techniques and tools for inspection, including:

- Vision systems and coordinate measuring machines (CMMs)

- Optical comparators with 16-inch screens

- Calibration surface plates

- Gram scales, microscopes, gauge blocks, measuring pins and digital calipers

- Complete First Article Inspection (FAI) reports

- Advanced Quality Planning

Importance of Thorough Testing of Electronic Parts

During the design and development of electronic enclosures, it is imperative that the enclosures be physically tested to ensure that they can adequately protect the electronic device. In addition to the fit and layout of components within the enclosure, other types of testing must be considered:

- Thermal testing: Evaluates how the enclosure withstands temperature fluctuations and extreme heat conditions, ensuring stability and functionality in different thermal environments.

- Stress analysis: Evaluates the structural integrity of the enclosure by subjecting it to mechanical stresses and determining its ability to resist deformation or fracture.

- Environmental testing: Examines the enclosure’s ability to withstand moisture, humidity, and chemicals, ensuring its functionality under different conditions

Turnkey solutions for high-quality custom molded electronic parts

We provide complete injection molding support, working with you from conception to final finishing touches.

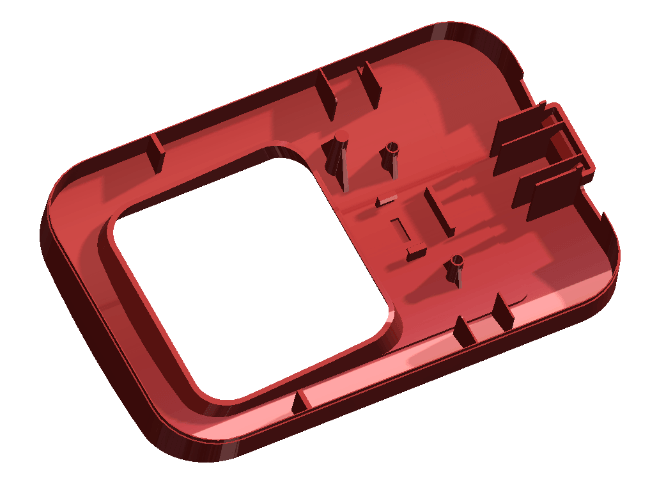

Product Development

Based on customer feedback and prototype testing, outline a development plan and select the best electronic component injection molding solution.

Prototypes and Pre-production

Prototype models can be developed in a matter of days to meet the market needs for electronic device injection molded parts.

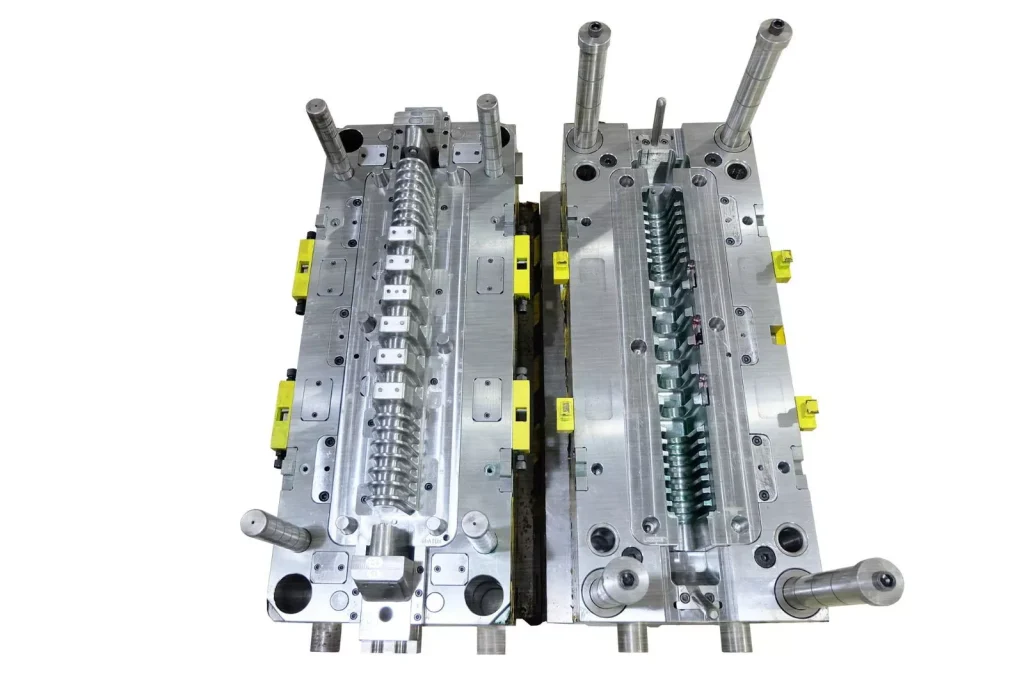

Mold Design

With full range of mold design and engineering, our experienced team of designers and engineers can help you complete any size electronic equipment accessories project.

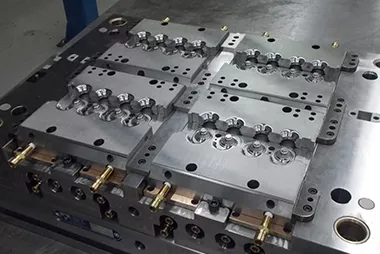

Mold making

Familiar with mold manufacturing technology, high-precision CNC machine tools, advanced 3D software, 3D inspection equipment, and mold flow analysis software. These technologies ensure the overall quality of the mold.

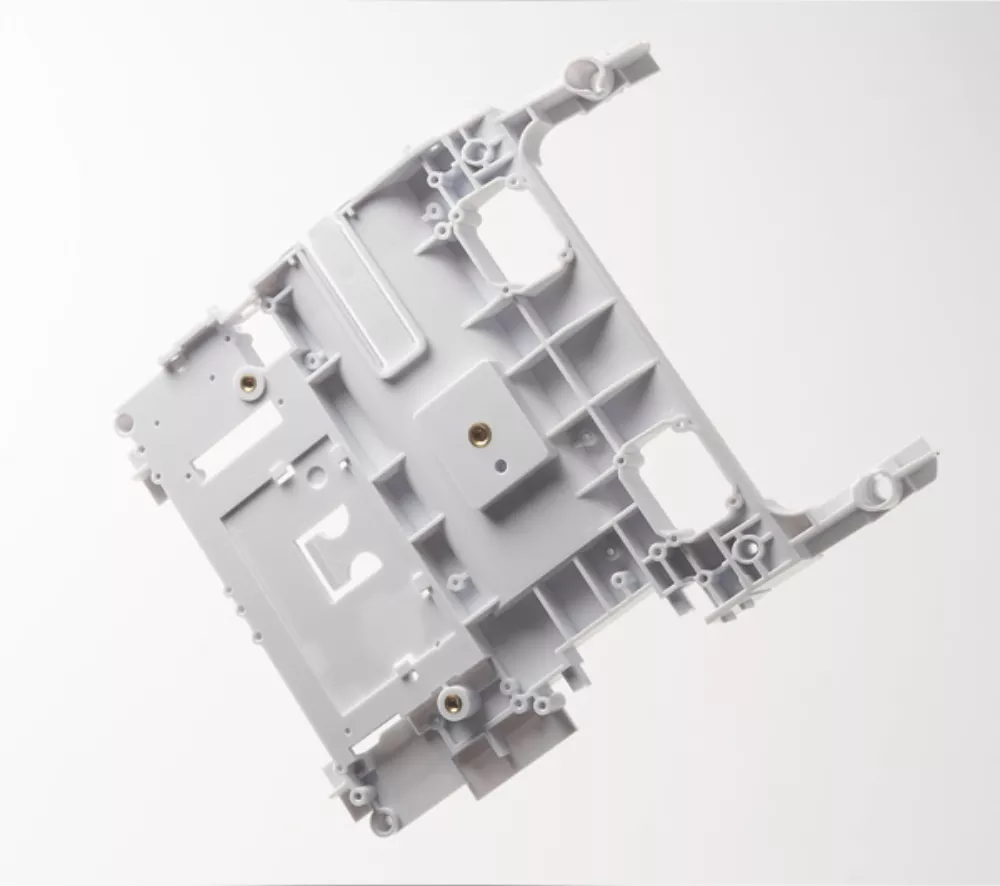

Electronic parts injection molding

Elimold has a 3,000 square meter production area equipped with advanced injection molding machines. Efficient molding of electronic parts from manufacturing to delivery.

Assembly and packaging

Whether it is a simple manual assembly or a highly automated multi-assembly process, we can provide our customers with electronic device assemblies with precise size and performance requirements.

Cleanroom Injection Molding

For those sensitive electronics applications, sometimes traditional injection molding solutions just won’t cut it. That’s why we’ve worked hard over the years to establish ourselves as the go-to supplier for cleanroom injection molding solutions. Our facilities are ISO Class 6 and 7 certified (secondary operations) and Class 8 certified (full-scale injection molding). We offer both hard-wall and soft-wall cleanrooms and have everything you need to provide you with flexible, scalable manufacturing solutions that meet your exact needs.

Advanced Injection Molding Solutions for 3D Printed Steel Mold Inserts

We use 3D printing technology to create steel mold inserts, allowing us to manufacture complex and delicate molds with unparalleled precision. This technology reduces lead times and increases design flexibility, allowing us to meet the unique needs of the electronics industry. So whether your component is standard or highly custom, we have the tools to make it happen.

Plastic Injection Molding Process Monitoring System

We have adopted the most advanced process monitoring equipment, which can process up to 32 pressure signals and 16 temperature signals in real time to reduce scrap in the plastic injection molding process. The system can record all conditions in the mold during the injection molding process. Special functions can analyze, optimize, monitor and record the injection molding process, which is a suitable and reliable tool for the 3C industry in all stages from certification and verification to production. And the system’s integrated user management and automatic recording of user activities provide maximum process security and transparency. Closed-loop functions such as our automatic hot runner balancing option Multiflow improve setup efficiency and compensate for process fluctuations during production.

Elimold Can Meet Your Microelectronics Injection Molding Need

Elimold stands out in the field of injection molded electronics, specializing in microelectronic applications. Our expertise lies in producing micron-sized plastic components. With a deep understanding of the industry, we focus on developing and molding complex microelectronic components to precisely meet our customers’ unique requirements. Our commitment to quality is supported by ISO 9001 and ISO 13485 certifications, ensuring that our processes meet the highest standards of quality and reliability.

Choose Elimold for your injection molded electronics needs and experience the unparalleled quality and reliability our micro components bring to your electronic devices. Contact us today to get started on your project.

Have an electronics injection molding project?

If your structural electronics design requires injection molding, our team can work with you to provide a custom solution that makes your manufacturing process more efficient and improves product quality. Do you have a project that requires a prototype, but doesn’t require injection molded structural electronics? We can help you with that, too.

Material options

Material commonly used for injection molding of precision electronic components include:

- ABS

- PC

- TPU

- PA

- HDPE

- PP

- PVC

- Nylon

- PE

- PPO

- Acrylic

- PBT

- PEI

- PET

- PMMA

- POM

- PPE+PS

- PUR

- TPU/TPE

- LCP

Post-Processing Services

Our mold maintenance program for projects including electronic plastic injection molding services ensures that each mold is regularly cleaned and inspected at predetermined intervals based on setup and cycle count. Mold inspections, general mold maintenance, major mold maintenance, and preventive maintenance are standard operating procedures.

Our electronic plastic injection molding product finishing capabilities include hot stamping, ribbon, pad printing, screen printing, defect coating, conductive painting, decorative painting, metalizing, and plating.

Our assembly and joining capabilities include product filling, foil/heat sealing, ultrasonic welding, heat staking, mechanical assembly, pinning and UV/hot melt adhesives, custom packaging/kitting, and bagging.

What Electrical Components Do We Currently Provide Injection Molding Services?

We provide plastic injection molding services for an array of electric & electronic components. Some of the electrical products that we currently produce are electrical housings (plastic housing that encases electrical components) timers, electrical machinery, and various electrical components & controls.

Numerous kinds of test equipment, lighting, sensors are important in electrical field. Manufacturing these parts correctly is integral in providing our customers with accurate arts that are high-performing. Electrical devices are needed for long term uses quality is key. And that is what we provide. Plastic is actually an ideal material for use in electronics because it can be either conductive or non-conductive plastic resin. When combined with watertight seals can be UV resistant with the ability to be used in flexible or rigid applications.

Applications

As experts in high-volume production of injection molded parts for the electronics industry, we manufacture plastic injection molded electronic parts for:

- Desktop and server bezels

- Custom badges and molded nameplates

- TPU overmolding of magnesium frames for laptop cases

- Mobile phone cases

- Mobile phone display lenses

- Battery covers and housings

- Home security control panels

- Test instruments

- Router housings and injection molded antennas

- Many more

Other Manufacturing Services

In addition to our electronic injection molding capabilities, our customers often require low-volume custom electronic enclosures for electrical components. Our RTV molding and casting capabilities allow us to produce very large single-piece parts at a fraction of the cost of injection molding, thermoforming, or rotational molding. For high-volume work, we offer 3D printing, and for metal parts, we offer CNC machining services.

Room Temperature Vulcanization (RTV) molding and casting, commonly referred to as polyurethane casting, is a cost-effective process for custom electronic enclosure manufacturing. Silicone molds are strong enough to create the cavities required for dimensionally accurate parts and flexible enough to remove custom parts with complex geometries and even multiple undercuts.

Are you ready to start your next project?

For superior electronic component manufacturing solutions, contact Elimold. Our team is equipped to handle the complexity of your electronic injection molding projects, providing tailored support and innovative solutions. Elimold is not only a prototype parts supplier, but also a development partner, providing expertise to accelerate your product development.