Medical CNC Machining

Elimold is a company that provides high-quality CNC machining services for medical applications. Years of business experience and skilled professionals have enabled our company to provide customers with high-quality precision parts and assemblies. No matter which stage you need, prototyping or batch CNC machining, we will meet all your needs. Contact us now to get a free instant quote and find out how we can work with you on your upcoming project.

Medical CNC Parts Manufacturer

Elimold has been a leader in CNC machining critical components for the medical industry. Our customers continue to choose us because of our deep understanding of regulatory requirements, thorough documentation and traceability of materials, and ability to deliver cleanroom-specific parts directly to our customers’ assembly lines. As a full-service medical device component manufacturer, we are well-positioned to provide a large volume of precision CNC work for the medical industry. As a complete end-to-end solution provider, we have made significant investments in non-core services for the medical industry. Our deep expertise combined with these investments delivers a unique suite of services that enables our customers to achieve lifecycle part cost competitiveness, breakthrough design for manufacturability competitiveness, and continued market share growth. We are committed to providing a full range of services that enable our customers to maintain and grow their market share in the extremely demanding precision medical device manufacturing industry.

Comprehensive CNC Machining Solutions for Medical Device Components

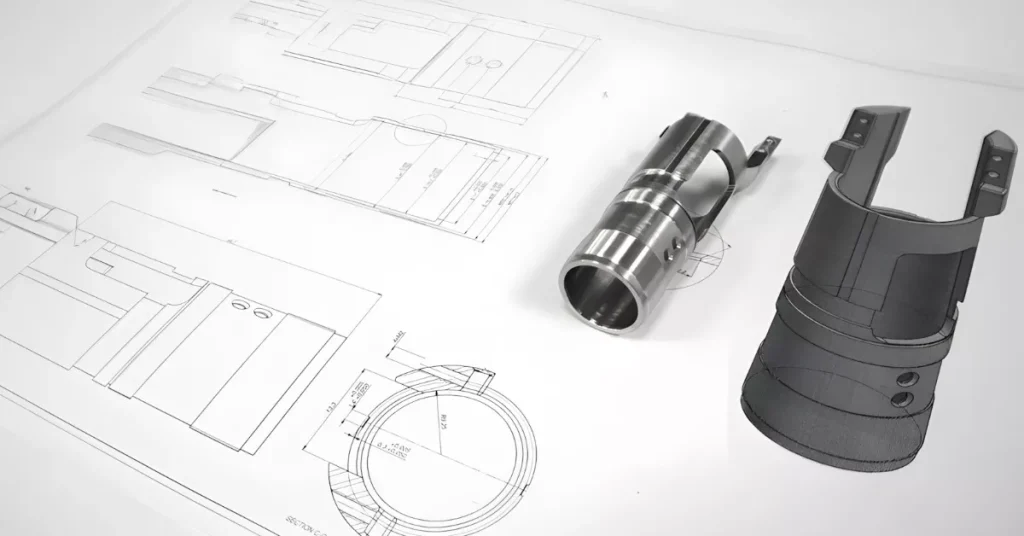

We offer comprehensive solutions covering the entire lifecycle of medical-grade machining, from initial prototyping to full production. Our knowledgeable team works with you from the earliest stages of design, providing expert guidance and feedback in order to transform your concepts into precise, functional prototypes. Utilizing advanced machining capabilities and state-of-the-art technology, we scale prototypes into high-quality production runs, maintaining the same precision and consistency at every stage. As a result, Elimold provides precision machining services to support short-term production runs for medical device companies around the world. We offer a strong supply chain for customers seeking to source production components. From prototype to production, we work with our customers on design for manufacturability to ensure we can provide a reliable and efficient supply chain. Our approach includes designing and building custom fixtures/tools to allow for machining complex geometries and cutting multiple parts.

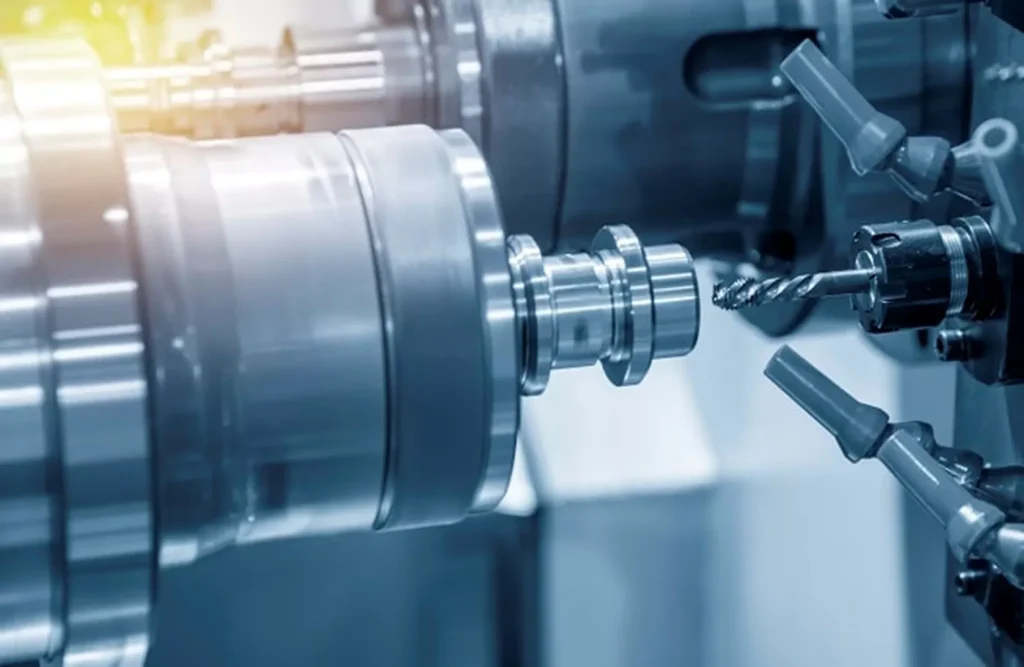

Precision Medical Machining & Medical Equipment Parts Manufacturers

At Elimold, we utilize a variety of advanced and high-precision CNC production equipment to custom produce a range of medical device parts for the medical industry. Our qualified technicians are able to operate our advanced CNC equipment with proficiency and are able to deliver medical components with tolerances ranging from 0.0001 to 0.000005 inches. In our years of operation, Elimold has become a leading medical device custom CNC parts manufacturer, capable of machining the smallest and most technologically advanced medical components. Our rigorous AS9100 Rev. D certified, ISO 13485 certified, and ISO 9001:2015 certified quality management systems ensure that all of our products meet or exceed the strict regulations and standards required by the medical industry.

So, no matter the production volume you require, from the simplest to the most complex components, we can do it. Our team is willing to accept challenges. Regardless of the requirements, we are fully committed to working closely with each customer to provide quality custom medical CNC parts. In addition to on-demand custom manufacturing, we handle all production needs from raw material procurement to final product inspection, ensuring the accuracy of each unique medical part and providing continuous supervision from concept to completion.

Advanced Technology for Diverse Prototype and Tooling Need

Elimold has worked with several medical device manufacturers to improve their supply chain and customer experience. Our rapid prototyping services and flexible manufacturing model means we can take on small batches of work and then scale up as needed. No matter how big or small the job is, we are committed to delivering high quality every time. We have the equipment you need to meet your machined medical device part needs. This includes a variety of CNC lathes, Swiss screw machines for small precision components, and 3-5 axis CNC machining centers of various sizes. This allows us to match the best machine for your part to achieve quality and efficiency. Our CNC machining experts and programmers can create quality parts and small and large production batches with high precision and the ideal materials, geometries, and sizes to meet your medical manufacturing needs.

Precision CNC Machining of Medical Components

Elimold’s CNC machining facility has extensive experience in CNC machining small, medium, and large medical components with accuracies as high as ±.0001″. We offer a full range of medical device manufacturing services from prototype to production. Whether your needs are small, ultra-precision machined parts, complex surgical instruments, or high production volumes of mature products. With a skilled, experienced, and dedicated staff, our company understands the importance of accuracy and quality. Our stringent quality control system ensures that each machined part meets or exceeds your drawing specifications, inspection reports, and documentation.

Our Manufacturing Services

Elimold offers best-in-class manufacturing capabilities, ideal for rapid prototyping and custom production orders. With our own facilities and extensive manufacturing network, we are able to efficiently deliver complex, high-quality parts.

CNC Milling

CNC Turning

3 Axis CNC Machining

4 Axis CNC Machining

5 Axis CNC Machining

CNC Prototypes

Wire EDM Machining

CNC Threading and Tapping

CNC High-Speed Drilling

Swiss Machining Service

CNC Routing Service

CNC Grinding Service

CNC Machining for Medical Applications

As a reliable and dedicated medical component supplier, Elimold provides superior precision components for a variety of medical applications. With the right tooling and high-precision equipment, our CNC Swiss machines are able to cut extremely hard materials into complex designs, including precise flanges, fillets, grooves, and radii. Tools and cutting surfaces are cooled to prevent thermal distortion, and products are thoroughly finished using grinding, polishing, and buffing techniques to achieve a smooth, blemish-free surface. The mallet shaft diameter and all critical features have very tight tolerances of ±0.002 inches.

Rapid Prototyping of Medical Parts

Rapid prototyping is another cornerstone of Elimold’s CNC machining services for the medical industry. By leveraging state-of-the-art equipment and innovative technologies, our company supports the product development cycle by producing prototypes quickly and accurately, helping medical manufacturers improve designs and accelerate time to market. This agility ensures that breakthroughs in medical technology can reach patients faster while maintaining the high quality required for life-critical applications. From concept to production, Elimold’s focus on precision, reliability, and innovation ensures that medical components meet the rigorous demands of the healthcare industry.

Need CNC machining medical parts?

Are you looking for a medical machining company or need dental parts machining? If you are looking for a quality machine shop to help you with medical machining, dental machining, or medical industry parts manufacturing, we can help. With a proven track record of precision, on-time delivery, and repeatable accuracy, Elimold is well-equipped to manufacture your precision medical components and parts. Contact us now for a free instant quote.

From Prototyping to Full Production Capabilities

Elimold understands that successful products and customer relationships are the result of creativity in designing for manufacturability, the ability to deliver tight tolerances, and expertise in gaining insights from an iterative process. Our team of engineers works with your design team to CNC machine medical devices, and our knowledge and experience with FDA regulatory requirements brings value to our relationship.

When you work with us, we begin by producing one or a few sample parts to assist your design engineers with proof of concept. We then assist with iterations during the prototyping phase, responding quickly to design changes. We can make on-the-fly changes to get your customers’ new products to market faster. And, we work directly with your design engineers to evaluate machinability and material selection to avoid potential quality issues.

When your precision medical device design is ready for clinical trials and FDA or other regulatory approval, we begin building the robust processes and documentation that will play a vital role in the future success of your product. Once your product is approved, Elimold is able to handle the high-precision, tight-tolerance, and high-volume CNC machining that meets your monthly and annual needs. We also focus on internal continuous improvement opportunities to reduce costs and shorten lead times, which will positively impact the quality of the parts we provide to you.

CNC Machining for the Medical Industry

Elimold can manufacture medical device components using our dedicated CNC machining facility at our facility in Shenzhen, China. We use CNC machining to manufacture a variety of medical device components including graspers, ligature devices, handheld surgical devices, and catheters. Whether you require 5-axis milling, wire EDM, micro machining, or precision-manufactured parts, the dedicated machining capabilities of our CNC machining lathes provide you with the best medical manufacturing services. Our equipment is carefully controlled to ensure high-precision results, and we can ensure that your medical parts are manufactured with the highest precision and strictest control. We also use the highest quality materials for EDM to ensure that your medical parts are sterile and guaranteed not to break when used in medical procedures. Many factors can affect the outcome of a medical procedure. The same is true for medical CNC machining. Our facility is temperature and dust controlled to ensure that each process is in a perfect environment to guarantee high-precision results. We believe that the best environment produces the best parts; it also allows us to achieve the tightest tolerances.

5-Axis CNC Milling Services for Medical Device Parts

At Elimold, we provide precision 5-axis CNC milling services to meet the complex geometries and tolerance requirements of medical device parts. We utilize the latest CNC milling equipment with 3, 4, and 5-axis capabilities to produce state-of-the-art components for our customers. Our team of highly skilled machinists and engineers specialize in complex parts that require careful process design utilizing design benchmarks and our own fixturing programs. We also utilize robotic manipulation in our machine’s pallet automation system to maximize throughput and minimize quality deviations.

6-Axis CNC Turning Services for Medical Device Parts

Elimold offers 6-axis CNC turning services to clients seeking to work with us on machining handheld parts from prototype to production in the medical device industry. Our Eurotech TA20Ys lathes offer a competitive advantage for “one-off” parts and unattended production. The y-axis and sub-spindle capabilities make our CNC turning services best suited for complex parts with off-center and back-facing features.

Cleanroom CNC Machining Medical Products

Elimold offers integrated assembly, kitting and packaging solutions, all done on-site. Our cleanrooms are designed to ISO Standard 14644-1 Class 7 to clean, assemble and test components before they arrive at your facility. Our strategic investments in this area are to provide our customers with a complete solution, including cleanroom assembly of components. Our customers can reduce costs, reduce supply chain risks, and improve the integration of components and sub-assemblies in their operations.

Cleanroom CNC Machining Turnkey Solutions

Cleanroom is a general term. What sets Elimold apart from other manufacturers is their strategic selection of equipment that can be installed in their facility. The first step is to offer multiple parts cleaning processes to allow our engineers to select the best solution. With assembly equipment, our operators can assemble parts by hand, under a magnifying glass, or even under a microscope. Elimold has invested in different testing equipment to verify assembly before shipment. When the parts are ready to ship to our customers, we have vacuum packaging equipment to keep the parts clean during transportation.

Additionally, Elimold has invested in industry-leading equipment in our cleanrooms. Our goal is to save time, streamline your internal assembly needs and reduce the overall stock keeping units (SKUs) of a part or sub-assembly. All of these efforts will directly reduce your part price. In addition, by leveraging Elimold’s turnkey solutions, you will see even greater cost savings. It’s all part of a custom developed solution designed in collaboration with your team. We support your product specifications and production requirements.

Our Inspection Department Ensures Excellent Quality

Elimold’s CMM Inspection Service offers best-in-class tools and technology for measuring, inspecting and verifying high precision of highly complex components. This is part of our comprehensive end-to-end CNC manufacturing solutions. Our automatic coordinate measuring machines offer high accuracy, speed and versatility. You can measure the accuracy of your parts down to 0.0001 inches. The measurement accuracy is not operator dependent and the measurements can also be fully automated and programmed. Our CMM Inspection Service guarantees a high level of accuracy while taking into account environmental differences such as temperature and humidity. This applies to single points in a 3D shape or entire shapes. This ensures stable testing and manufacturing conditions for your production needs.

Benefits of using Elimold for Medical CNC Machining

Digital manufacturing delivers the speed and precision required for prototyping and production of medical components. Our CNC machining services support engineers and device developers in the medical industry with:

- Design for Manufacturing (DFM) feedback with every quote

- Ability to prototype with production-grade materials

- Low-volume, precision parts in as little as one day

- Various materials (high-temperature plastics, medical-grade silicone rubber, and hundreds of plastic, metal, and elastomer materials)

- Quality certifications: ISO 9001:2015, ISO 13485 : 2016

- ISO Class 8 cleanrooms available

Medical Machining Materials

In order to manufacture custom designs that best suit each of our customers’ applications, we offer different metal and plastic materials depending on the part type and desired application.

Metals

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Steel

- Titanium

- Nitinol

- Cobalt-chrome

Plastics

- Acetal

- Delrin

- Nylon

- PEEK

- PTFE

- PVC

- Ultem

- UHMW

In-house Finishing

In addition to our superior precision machining capabilities, we also offer specialized finishing services for the medical industry to ensure that no defects interfere with part sterilization.

- Passivation

- Teflon Coating

- Parylene Coating

- Sodium Stearate

- E-Polishing

- Ni-PTFE Coating

- Engraving

- Polishing

- Coating

- Bead Blast

- Anodizing

- Chromate Coating

- Electroless Nickel Plating

- Part Marking

- Powder Coating

- Press Fit Hardware

- Silk Screening

- Brushing

- Polishing

- Black Oxide

- Brushed + Electropolishing

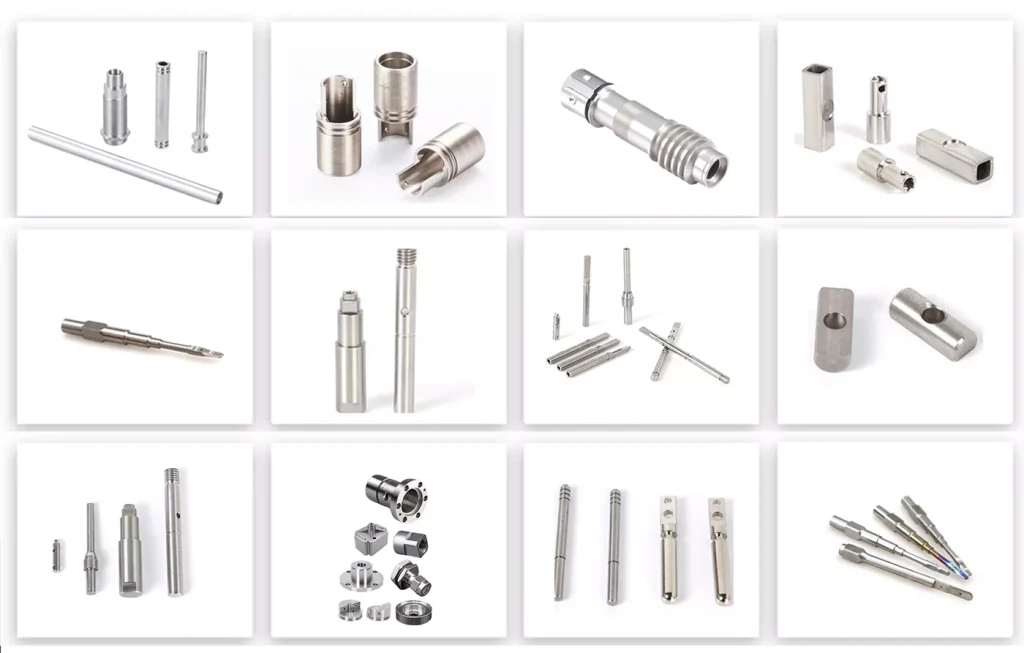

Custom Machined Components for the Medical Industry

Precision CNC machining plays a vital role in the medical industry, especially in the production of medical devices and instruments. These specialized machines are capable of producing precise and intricate parts with high accuracy, making them ideal for manufacturing medical components that require tight tolerances. For the medical industry, Elimold has produced a wide variety of CNC engineered plastic and metal material components for major medical analytical/diagnostic and medical testing manufacturers and subcontractors, including internal manifolds for analytical DNA assessments (in the DNA testing field), mass spectrometry components, manifolds that house optical fibers (for surgical procedures), and a variety of other cartridges and components with medical uses and applications. Medical components can be produced in a variety of engineered plastic and metal materials for medical devices and equipment that perform analyses in harsh environments. Elimold produces small precision medical device CNC machined parts in prototype quantities to high-volume production.

Our quality systems ensure full compliance with the quality requirements of all applicable medical industry customers. With production capabilities ranging from prototype runs to 700,000 components per year, Elimold can provide a large number of finished medical CNC machined components with high consistency and quality (with corresponding cost savings).

Medical components and parts we machine

Elimold utilizes top-of-the-line full 5 axis and multi-axis machines for the creation of a variety of healthcare-related parts, including cardiovascular and orthopedic devices, surgical instruments, and medical screws. Our six full 5 axis machines are capable of producing the highest quality precision machined parts with increased speed and superior surface finish.Additional examples of CNC machining applications in the medical industry are listed below:

- Medical implants

- Testing & analysis components

- Medical instrument components

- Respirator device components

- Ventilator components

- Drug deliver components

- Pump components

- Complex multi-component assemblies

- Precision shafts

- Brass inserts

- Spacers

- Fittings

- Valves

- Capstan

- Cough assist

- Oxygen Sensor

- Blower Mounting

- Bulkhead

- Flexure

- Precision Spacer

Request Your Free Medical CNC Machining Quote Today

After receiving your drawings, our engineers will analyze your custom Medical CNC machining parts right away. We actively work with you to clarify all details before providing a quote that is both economical and accurate.