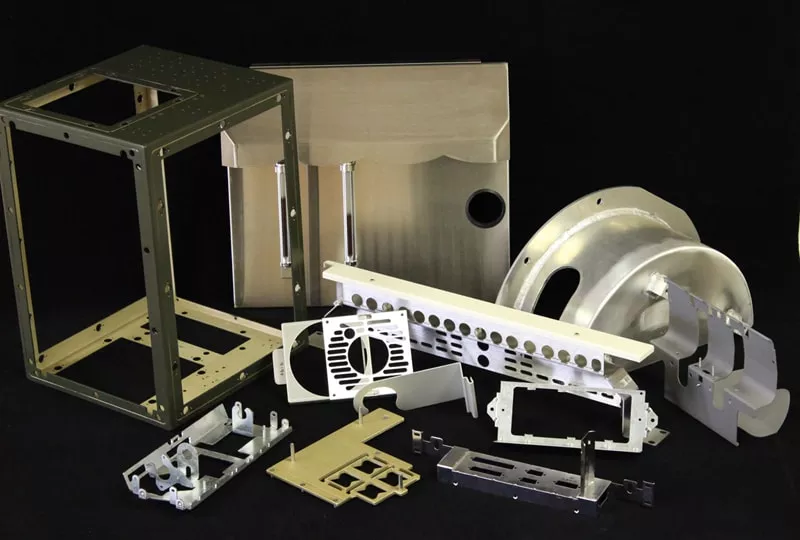

Consumer Products Sheet Metal Fabrication

Consumer product sheet metal manufacturing services can accelerate the prototyping and launch of high-quality consumer products in different fields, obtain best-in-class custom manufacturing of consumer products, provide competitive prices and fast turnaround times. We are committed to providing innovative metal manufacturing to the consumer goods industry. Our modern laser cutting technology, attention to detail and state-of-the-art machinery enable us to support consumer product manufacturers in multiple markets including lighting, custom deck railings, metal signage, fencing, metal home furniture, bed frames and beds Headers, specialty stores, jewelry, office furniture, decorative metalwork, bakeware, shelving, containers and packaging.

Contract manufacturing of consumer goods components

Consumer product sheet metal manufacturing is a broad industry that encompasses everything from large household items to handheld devices. With such a diverse range of products, it’s also likely that the goods you produce are part of a highly competitive market. Differentiating your products through value and quality can set you apart.

Elimold can help as a premium partner for sheet metal fabrication services. Our industry experience and expertise will help you gain a competitive advantage with custom component solutions designed to precise specifications.

Working with us for contract manufacturing gives you many benefits, such as saving money, access to expertise, and fast order turnaround. We have the facilities, equipment, workforce and skills available to serve your consumer metal fabrication needs from a single source. These advantages make us a cost-effective alternative to investing your company’s resources to gain these advantages. Overall, you’ll spend less money to complete your project while getting high-quality sheet metal parts.

Add value to your consumer products with quality sheet metal fabrication services

Our engineers can help you add value to your products by developing and assembling durable components for your manufacturing process. We use the highest quality materials and most efficient methods to reduce production costs and ensure results are precise every time.

The best way to build relationships with consumers is to offer high-quality products that are durable, functional, and visually appealing. At Elimold, we focus on manufacturing the highest quality parts and products quickly in order to build you a loyal customer base.

Consumer Products Manufacturing Services

Designing

You are concerning the complex geometry and design, or tight tolerances? Our teamwork with you from design, prototype to resolve the technical challenge till production.

Finishing Process

Elimold offers the appearance of your product aesthetic with the high standard finishing process, anodizing, Brushing, painting, sanding, polishing, black oxide, PFTE coating, and Alodine, etc.

Inspection

Our quality team will be 100% inspect and testing your products during and after production based on ISO standard, to ensure all of the quality of the parts meet compliance.

Delivery

Any of your urgent projects? our teams will be closely work with you together to resolve out, Flexible working time and put the urgent project priority to ensure delivery on time.

our capabilities

For consumer products, Elimold offers high-quality metal fabrication and custom wire forming with tight tolerances and repeatability.

- Accommodates short and long production runs

- Rigidly tests all parts for quality and safety

- Ensures fast turnaround from design to delivery

- Provide sturdy, safe packaging and shipping

- Adhere to our own strict quality control standards

- Offer in-house design and engineering services

- Provide competitive pricing

We also feature a selection of custom finishing options to ensure your product is visually appealing and meets the highest standards for hygiene and safety.

- Plating (zinc, nickel and chrome)

- Powder coating

- Electropolishing

- Vinyl coating

- Nylon coating

Consumer electronics manufacturing for prototypes and low-volume production

The success of companies bringing consumer electronics products to different markets depends on the speed of development and the creation of well-designed, user-focused end products. Leveraging technology-driven manufacturing processes not only speeds up design cycles and reduces development costs, it also facilitates support for a wider range of SKUs and meets growing consumer demand for product customization. Whether in airplanes, cars or hospitals, electronics play a ubiquitous role, delivering value and enhancing user experience through advanced functionality.

Consumer & Commercial Prototyping

Fuyu delivers swift and efficient rapid prototyping solutions across a range of professional domains. Our diverse clientele operates in various sectors, including commercial, consumer products, instruments, product prototyping, appliance prototyping, digital products prototyping, and communications products.

Office Automation prototyping

Fuyu possesses technical capabilities tailored for office automation systems. Our prototypes adhere to precise specifications, mirroring the authentic attributes of the final product. We meticulously ensure dimensional accuracy for mating parts, guaranteeing a proper fit and enhancing structural stability.

Digital & Appliance prototyping

We conduct rapid and cost-effective prototyping for our digital and appliance products. Our accomplished team of industrial designers, mechanical engineers, and marketing professionals actively utilizes the prototypes we create to gain a deeper understanding of their functionality and aesthetic appeal among potential end-customers.

Benefits of Sheet Metal Processing for Consumer Goods Manufacturing

There are many benefits to using sheet metal fabrication to manufacture consumer products. Firstly, sheet metal is a durable and long-lasting material that is resistant to corrosion and wear, making it suitable for manufacturing products that are long-lasting. Second, sheet metal can be easily formed into complex shapes and designs, allowing manufacturers to create unique and beautiful products. Additionally, sheet metal is lightweight and easy to transport and install, making it an ideal material for building consumer products that are easy to handle and use. Finally, sheet metal fabrication allows for consistent and precise production, ensuring every product is of high quality and meets required specifications. Ultimately, the benefits of using sheet metal fabrication to create consumer products are durable, beautiful, easy-to-use and high-quality products.

Consumer Goods Metal Manufacturing Applications

If you can envision a metal part, Elimold can make it. Our field engineers are proficient in popular design software programs such as 3D CAD and CAM to help turn your concepts into reality. We are also flexible enough to meet different production needs from small batches to large batches. Projects we help realize include:

- Audio and video system components

- Large and small household appliances

- Electronic devices like handheld gaming systems

- Outdoor equipment and furnishings

- Battery parts like brackets, clips and contacts

- Small hardware like nuts, bolts and screws

- Computers, Phones, & Tablets

- Cookware

- Kitchen Appliances

- Sinks

- Washers and Dryers

- Electronic devices

- Personal wellness products

- Athletics and sporting equipment

- Cookware products

- Wearable devices

- Accessory components

- Virtual reality products

- Home Furnishings

- Smart home products

Ready for a free quote?

We are proud to serve all regions around the world. Just one minute! Select the service you want, upload your design and our online instant quote system or a member of the team will respond as soon as possible with a free quote. If you don’t have a design model, or need some help figuring out a design, we’d be happy to help! Just give us a call and a member of our team will be happy to answer any questions you may have.