Aerospace Plastic Injection Molding

Elimold has the capabilities and experience to handle the most complex projects in aerospace injection molding. Our state-of-the-art facility features a variety of injection molding machines to achieve the tight tolerances and unique specifications required for aerospace projects. We offer flexible, customizable injection molding services to create a finished product that meets or exceeds your expectations. Contact us now for a free, instant quote.

Plastic Injection Molding Company for the Aerospace Industry

Elimold has been in the aerospace injection molding business since its inception. We follow the key principles of on-time delivery, quality, and affordable prices. We work diligently, leaving ample time to complete orders. We offer competitive pricing and deliver exceptional products every time. We are ISO9000 certified and AS9100 compliant, and our machines feature the latest aerospace injection molding technology.

Elimold is involved in manufacturing from the first step to the final product, with the ability to manufacture custom molding tools and the parts made with those molds. This provides a great advantage to customers who are caught up in disputes between toolmakers and molding companies. In addition to facilitating the process as much as possible, the company prides itself on its ability to communicate with customers through excellent customer service. The molding and tooling teams work with customers to get the best possible product. To learn more about Elimold’s aerospace plastic molding services, contact us today and let us know how we can help you.

Elimold Aerospace Injection Molding Facility

We provide precision injection molding and mold making for aerospace applications. We have the capabilities and experience to handle the most complex projects in aerospace injection molding. Our in-house mold design and manufacturing at our state-of-the-art facility in Shenzhen, China, gives us complete control over mold quality, reliability, and performance. This capability gives us a distinct advantage over other suppliers when it comes to molding critical components for the stringent requirements of the aerospace and aviation industries.

Our in-house facility offers world-class injection molding, overmolding, insert molding, and micro-molding services to create the parts you need. We also offer a variety of value-added ancillary services to take the quality of these injection molded products to the next level. At Elimold, we work with a wide variety of materials, which allows us to select the perfect plastic to meet your aerospace injection molding needs. We use a variety of thermoplastic resins in our injection molding process that have high temperature and tensile load ratings to withstand the rigors of aerospace applications. We will work with you to find the material with the ideal properties for your project. In addition to molding, we also provide in-mold decoration, assembly, ultrasonic welding, adhesive application, printing, and packaging.

Providing High-Quality Plastic Injection Molding Solutions For The Aerospace Industries

Elimold proudly provides aerospace plastic injection molding for manufacturers creating parts for airplanes. While we don’t provide fully functioning, life-sized 3D printed airplanes, we can use our injection molding capabilities to manufacture parts on a wide spectrum of materials that are used for aerospace projects and aircraft prototypes.

As the commercial airplane industry has boomed, so has the demand for fly-friendly functions for passengers. We have helped develop injection molding parts that are vital to aerospace safety protocols and functionality. From helping companies with their emergency exit plan to designing new overhead bins, our aerospace plastic injection molding parts serve as a vital component in the aerial design process.

Every year, we broaden our offerings to improve our injection molding services for the aerospace industry. If you’re looking for aerospace plastic injection molding for aircraft, contact our team so we can discover the best way to help you finish your new innovation in the aerospace industry.

Grow your report

Plastic Injection Molding

Overmolding

Insert Molding

Micromolding

Gas-Assisted Injection Molding

Large Part Injection Molding Services

Nylon Injection Molding Services

Liquid Silicone Rubber Molding

For your aerospace parts, trust Elimold

Our experienced design, tooling, molding and assembly teams and the latest molding technology provide aerospace manufacturers with the ability to outperform competitors with the highest quality aerospace plastic injection molded parts in a highly demanding market.

Parts manufactured for the aerospace industry require expertise in aesthetics and demand strict and specific requirements. Our molding processes and procedures ensure repeatability for each project. The Elimold quality department takes careful consideration when recording validation documentation. With over 22 years of experience, you can be assured that our team has extensive experience molding commonly used aerospace engineering polymers such as PPO and PTFE.

Elimold provides turnkey solutions for aerospace plastic injection molding needs

We are proud to be a single-source provider of conventional and two-shot molding services, cleanroom molding, 3D printed steel mold inserts, in-house tool maintenance and repair, and a variety of ancillary services for aerospace companies. Our capabilities are also very broad, so whether you need micro components or large parts, small batches or large quantities, we can provide you with everything you need to get the job done. Join us today.

One-stop aviation parts manufacturing service

In addition to injection molding, we also provide a range of other services, including mold design and manufacturing, CNC machining and 3D printing. Our comprehensive solutions cover the entire production chain, from product design to final delivery, providing you with efficient, precise and consistent manufacturing support. We are your trusted partner in the field of aerospace parts manufacturing.

Product Design

Our comprehensive product design service ensures that we work with customers from the beginning to improve all technical drawings, including 2D and 3D files, to ensure the best results for each project.

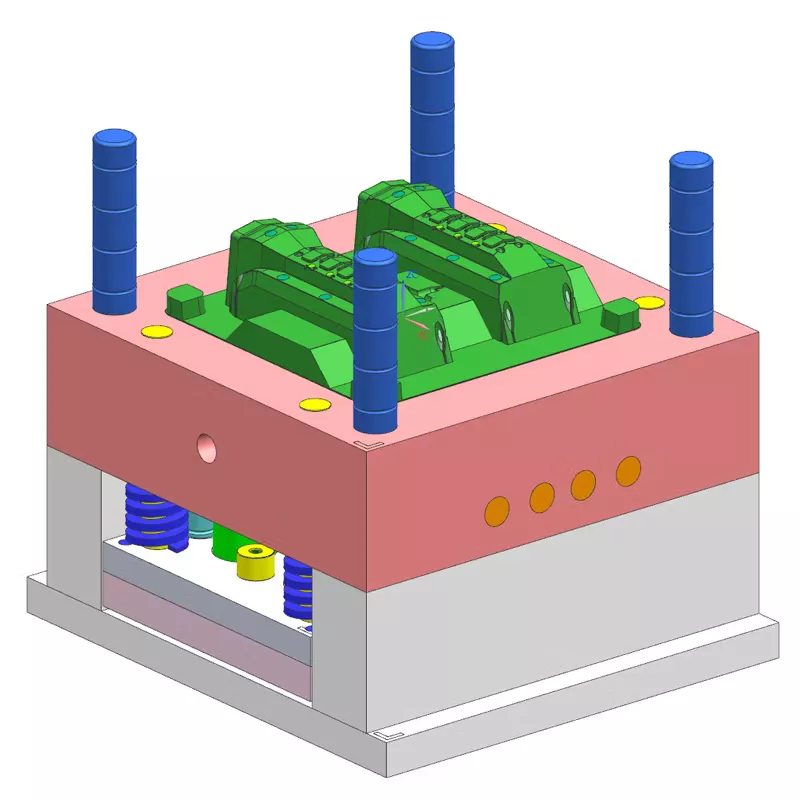

Mold Design

We specialize in custom mold design for aerospace components. Our experienced engineering team uses advanced CAD software and simulation tools to ensure accuracy, durability and cost-effectiveness. By focusing on reducing production time and improving product quality, we provide reliable solutions that meet the strict standards of the aerospace industry.

3D Printing

Elimold uses cutting-edge 3D printing technology to manufacture high-quality, low-volume plastic parts for prototyping and production. Our printers can print complex geometries, fine details, and custom textures and finishes. We can process a variety of 3D file formats and offer a wide range of materials for you to choose from.

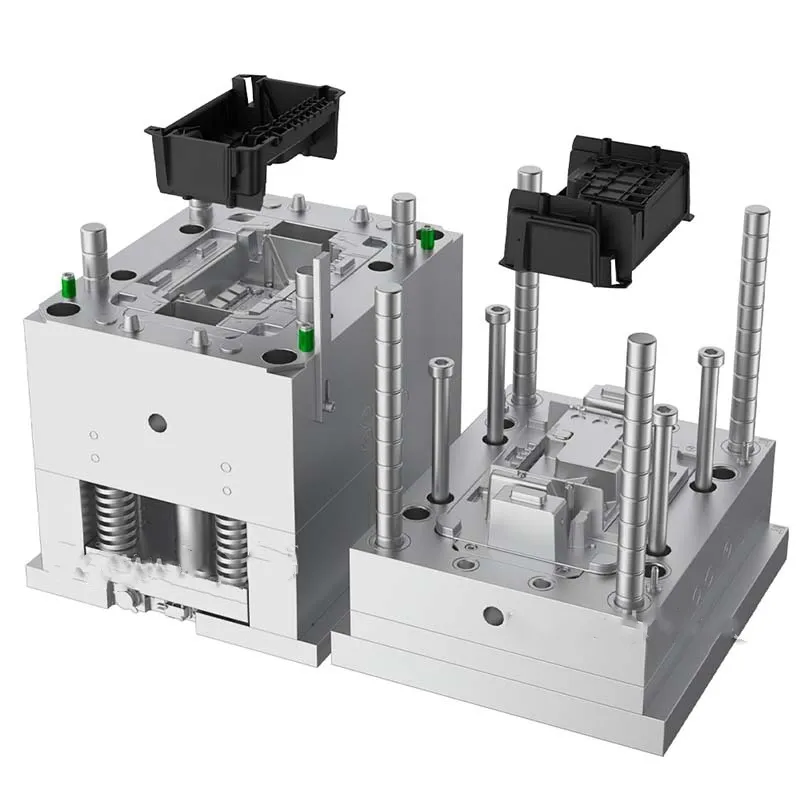

Mold Manufacturing

We specialize in providing high-precision mold manufacturing services for the aerospace industry. Using advanced five-axis CNC machining centers and Sodick mirror EDM technology, we ensure that the mold processing accuracy reaches ±2 microns, meeting the strict requirements of aerospace components for complex geometries and sizes. Our capabilities include molds as small as 5mm and as large as 1500mm.

CNC Machining

We provide high-precision CNC machining services to the aerospace industry, dedicated to producing parts that meet stringent accuracy and performance requirements. With advanced five-axis CNC machining centers and an experienced technical team, we are able to machine complex geometries and tight tolerances to ensure quality and consistency in every product.

The Role of Plastic Injection Molding and Prototyping

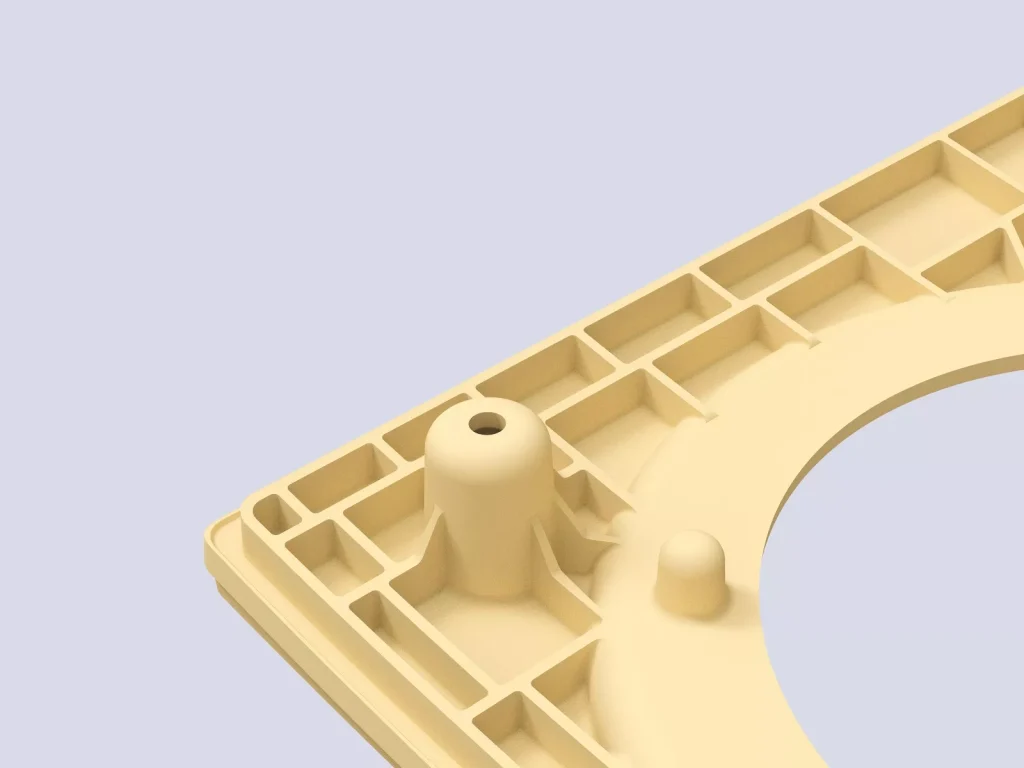

Prototype parts are essential for validating product designs. Some prototypes enable verification of fit and finish while others are needed for functional testing. While dimensionally accurate pieces can be 3D printed or machined from a solid, these options typically lack the look, feel and mechanical properties of molded parts.

Injection molding and plastic part prototyping offer multiple advantages over the services that other aerospace additive manufacturing companies provide, including:

- Better testing: Get parts made in the actual grades of material specified by the design team that are ready to test.

- Sleeker appearance: Molded parts have the required surface finish and appearance.

- No resolution limitations: Many additive techniques have clear layering that affect the appearance and possibly the function of a component, whereas injection molding does not.

- Production-grade parts: In addition to prototyping, injection molding is ideal for short-run aerospace parts manufacturing with production-grade materials, capable of producing lightweight parts for critical aerospace applications.

Quality Inspection Capabilities

We have an in-house quality control lab equipped with CMM, projector, pressure tester, tensile tester, flame retardant tester, UV tester and many other equipments to conduct in-house testing on our products from raw materials, finished product dimensions to surface finish. Our professional quality control team will monitor the quality of the products during production and perform ISO9001-2015 and TS 16949 upon delivery of goods with all quality control reports. We ensure the manufacture of high quality injection molded parts that meet industrial strength, durability, aesthetics, functionality and tight tolerances.

- ISO 9001-2015 and TS 16949.

- Own in-house quality control lab.

- Raw material testing and reporting

- Molds are regularly maintained and serviced.

- PPAP, APQP and 8D reports

High Production Standards

A long-time leader in cutting-edge plastics, Elimold is committed to providing the precision and flexibility required in today’s aerospace manufacturing industry. We apply a rigorous quality control process to aerospace projects, ensuring absolute quality and consistency in every custom molded product. We have the ability to mold nearly all custom plastic aerospace parts in-house, including complex geometries and intricate aerospace part designs that require extremely tight tolerances. Plus, with cleanroom and controlled environment molding and assembly, we meet all regulatory requirements for the aerospace industry. In fact, it is our rigorous quality management program that we are most admired for.

Communicating Quality and Regulatory Compliance

All tools and parts produced by Elimold undergo a variety of tests and quality control measures. We adhere to the strict standards of the aerospace industry, thereby ensuring that our products meet or exceed the most stringent commercial and military aviation standards. Elimold believes that constant communication is the true cornerstone of any successful collaboration.

We discuss every component of a project closely with our customers to meet your needs. We are committed to full transparency and detailed dialogue in our collaboration, placing your insights and requirements at the center of the design and manufacturing process. Together, we can turn your vision into reality, bit by bit.

Work with our efficient team

Learn how we run your project, work with an efficient technical team, and ensure that you receive the product and mold within the scheduled delivery time.

- Provide real factory quotation within 2 hours.

- DFM report feedback

- Model flow analysis support

- Optimize product design plan.

- Drawing of product design files.

- Mold design and manufacturing solutions.

- Sample testing within 15 days

- Small batch production within 5 days.

- Complete all tests and submit reports within 3 days.

- Arrive in 5 days by express delivery and 30 days by sea.

Mold design

Mold design for the aerospace sector starts with the customer’s ideas, needs and basic requirements. Precisely for this reason, at Elimold we directly involve the customer to better understand the most important details of the project. This allows to reduce costs and time and avoid subsequent redesign interventions. Mold design is carried out using advanced CAD/CAM/CAE software and molding simulation systems, which allow to analyze the mold in a very precise way, avoiding errors or problems.

Mold realization

The realization of the injection mold starts with a 3D model realized during the design phase, using the latest generation of materials and machines. The main goal is to avoid transcription or measurement errors and obtain an extremely precise and high-quality product, usually made of steel or cast iron. Elimold also offers the opportunity to realize prototypes and trial molds, a particularly effective solution to verify the feasibility of the project and reduce investment risks.

Mold maintenance

At Elimold, every customer can benefit from a mold maintenance and repair service for the aerospace industry. In fact, it is possible to repair any damage or machining errors, or restore recessed or worn areas. How is it done? Elimold uses a new laser welding machine to repair the mold and restore it to its original state in a short time. This is a particularly advantageous processing method because it avoids the need for direct mold replacement, is fast – only 24/48 hours – can be operated accurately and does not overheat the entire mold. Do you need to produce plastic parts for the aviation industry? Choose Elimold’s precision.

Ready to get started on your custom aerospace injection molding quote?

Aerospace Rapid Tooling

To make your injection molding project a success, you need a well-designed and manufactured rapid mold/tool. Our design team will initially come together for a design review to ensure your project is a success, especially when it involves complex geometries. They will make recommendations to ensure your plastic part excels.

Other injection molding companies are often not capable or willing to handle complex designs. As a result, they will often greatly simplify your design, limiting your fit and functionality. Once our designers have completed their review and have your project ready, Elimold has a highly skilled toolmaking team who know exactly how to bring your design ideas to life. Fabricating precision molds/tools is a difficult skill, especially when it comes to finalizing your project if your design requires a Class A surface or other pleasing aesthetic features.

Optimizing Additives

In addition to producing complete products, we can also optimize existing plastic aerospace products by adding additives. This could be, for example, an additive with a flame retardant effect, or an “antistatic” additive that prevents static electricity from building up on the plastic surface. Elimold works with the latest and innovative materials, so we also offer antimicrobial additives to prevent the spread of viruses and bacteria inside the aircraft!

Reverse Engineering Aerospace Parts

In addition to serial production, Elimold also excels in making specialty series products. We do this through “reverse engineering”. In this process, we deconstruct the product to reveal its inner workings. We can then build a new product for you based on this information. To do this, we use materials such as PC, PP, and any other technical plastics required for the product. This also includes soft materials such as TPU or TPE for armrests and seat components.

Materials

- Nylon (polyamide)

- Acetal (polyoxymethylene)

- Lexan (polycarbonate)

- Torlon (Polyamide-imide)

- Ultem (polyetherimide)

- Acrylic

- Polypropylene

- Polystyrene

- Polyethylene

- ABS (Acrylonitrile butadiene styrene)

- Ryton (polyphenylene sulfide)

- TPU (thermoplastic polyurethane)

- PEEK (polyetheretherketone)

- Thermoset

Injection Molded Aerospace Components & Parts

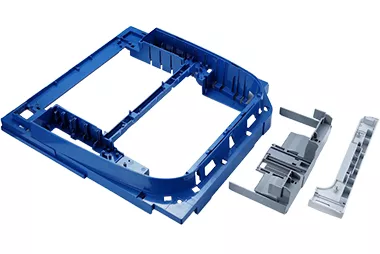

Plastic products and components in the Aerospace Industry that we are proud to supply include:

- Radomes of all shapes and sizes

- Plastic aerospace parts and components used in unmanned aircraft

- Battery housings

- Circuit boxes

- Spacers

- Knobs

- Spinners

- Connectors

- Pitot tubes

- Enclosures

Advantages Of Aerospace Injection Molding Solutions

In this age of technological advancement we propel our selves across the sky and beyond at breakneck speed. Defense aviation, commercial aviation, unmanned aviation, and satellite deployments are in need of manufacturers that understand the complexity of product engineering and the stringent compliance specifications that co-pilot each project. At Elimold we know that design, engineering, and materials are put through some of the harshest conditions imaginable subject to temperatures in excess of 3000 degrees and speeds in excess of Mach 25 (17,000mph). Our “CFT” (Cross functional Team) management model means that our clients are assigned dedicated engineers and project managers for each phase of the product life-cycle. The individuals that comprise that team are well-versed in the state of art, and are present from the very first meeting and remain in tune and available during development, production and delivery phases. Let Elimold plastic injection molding be an extension of your company and be assured that our success depends solely on yours.

Cost efficiency through functional integration / complex geometries

Complex assemblies of dissimilar materials and components are expensive and require precise matching of designs to ensure system fit and performance. With injection molding, we realise complex geometries with the highest precision in a cost-effective manner. By using technologies such as insert and overmolding, we integrate functionalities and replace assembly operations. Our solutions improve engineering strength and sustainability while reducing the total cost of ownership.

Molding Short Runs

For short run molding (only 100 pieces per year), Elimold can meet your project needs. Our short run injection molding capabilities are supported from design to distribution, and our commitment to quality control and customer service is the same as for high run molding.

Elimold’s short run injection molding meets the same stringent time-to-market standards and helps us serve customers across a wide range of industries. We carefully manage our processes to reduce lead times by using quick changeover tooling to reduce setup time and costs. Flexible work cells also minimize operations, ensuring short run molding projects remain cost-effective. Similar to our high run molding, our short run injection molding projects take advantage of full in-house engineering and tooling care services. We also offer overmolding, insert molding, and secondary operations for short run molding.

Large Part Molding

Elimold is a leader in large part molding with a team of engineers with over 30 years of experience and 160 presses ranging from 900 tons to 3000 tons. Our Shenzhen, China facility is purpose-built for large part molding with a custom underground material handling system, including 6 silos that can hold up to 1 million pounds of raw materials. We optimize the material handling, part handling, quality, appearance, and logistics required for large part molding. All of these components help produce parts that keep your manufacturing projects on schedule and to exacting standards. In injection molding, especially when dealing with large part molding, choosing the right partner can be the key to the success of your work. Elimold’s large tonnage molding capabilities make us uniquely qualified to handle all of your large projects.

Ready for a new Custom Aerospace project?

Tell us about your project needs and help you complete more competitive, high-quality injection molded products efficiently and more easily.You’ll benefit from cost-effective factory price quotes.