Polyjet 3D Printing service

PolyJet is a powerful 3D printing technology that produces smooth, accurate parts, prototypes, and tooling. With microscopic layer resolution and accuracy down to 0.014 mm, it can produce thin walls and complex geometries using the widest range of materials available with any technology.

PolyJet 3D Printing Service

Elimold uses advanced 3D printing machines for rapid prototyping and creating of solid parts with intricate forms and shapes. When your projects need realistic models made of multiple Polyjet 3D printing materials in varied colors with high precision, thermal resistance, and smooth surface finish, we are here to provide efficient solutions.

With our PolyJet 3D printing technology, you will get the most accurate, durable, and realistic models for your needs. Furthermore, we can offer you a whole range of materials for 3D printing with PolyJet technology: from transparent to opaque, from rigid to flexible, from low-temperature to high-temperature plastics. We can also organise any special material on request without any MOQ.

We are an ISO 9001-2015 certified company catering to all your manufacturing needs. Whether you need rapid prototyping services or batch production, we’ve got you covered. Our team of engineers is experienced in multiple manufacturing domains and is always happy to help with any questions.

PolyJet Technical Specifications

Maximum Accuracy |

0.1-0.3 mm |

Layer Resolution |

16 microns, or 0.016mm/0.0006″ X/Y resolution of 0.0017 |

Minimum Wall Thickness |

1mm |

Maximum Part Dimensions (Single Build) |

490 x 390 x 200 mm (19.3 x 15.35 x 7.9 in.) |

Shore Hardness Ranges |

27A – 95A |

Finishes |

matte or glossy, additional finishes available as a service |

PolyJet 3D Printing Technology

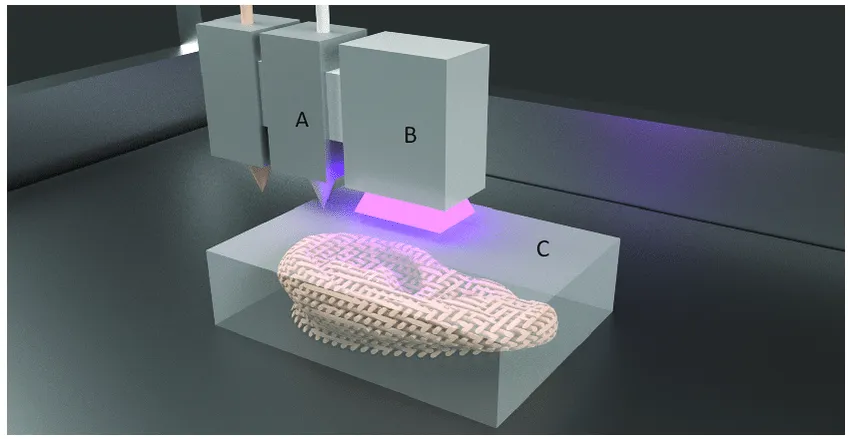

PolyJet technology is renowned for its outstanding realism and breathtaking aesthetics. The technology works similarly to traditional inkjet printing. Instead of jetting ink onto paper, a print head jets liquid photopolymers onto a build tray where each droplet cures in a flash of UV light.

Every PolyJet 3D Printer offers sharp precision, smooth surfaces and ultra-fine details. And, by combining a variety of photopolymers in specific concentrations and microstructures, the most sophisticated PolyJet systems can simulate everything from plastics and rubber to human tissue — and produce a full gamut of colors. You can now create prototypes, models, textures, and incredibly detailed patterns, and with 1000s of material options to choose from, you can incorporate various material properties and aesthetics.

Our PolyJet™ 3D Printing Services

- Rapid Prototyping: We can quickly make your functional prototype or concept model and deliver it to you in as little as 2 days!

- Additive Manufacturing Production: We make end-use parts, too, across various applications for industries like Aerospace, Automotive, Medical, Energy, and Consumer Products.

- Manufacturing Tooling: 3D printing with PolyJet allows you to incorporate multiple materials into a single print, resulting in quick production of realistic parts and design iterations early in the product development life cycle.

PolyJet 3D Printing Technology

There are plenty of materials available for this technology. We offer 4 standard materials. Besides the ‘pure’ materials, it is possible to ‘blend’ materials during the print process. As an example, Tango with a shore hardness of around A25 can be mixed during the print process with traces of Vero, to create a digital material with a final shore hardness of A 50 or higher. Based on this method, soft materials can be created with a shore hardness range from ~A25 – 95.

- Digital Materials

- Digital ABS

- Helios

- VeroClear

- Vero

- Rigur

- TangoPlus

- MED610

- VeroDent

PolyJet 3D Printing Design Guide

Engineers and Designers who are planning to produce PolyJet 3D Printed parts benefit greatly from the extreme design freedom that this process affords with materials like VeroBlack. Unlike traditional manufacturing processes like injection molding and CNC machining where there are limits on what features can be designed into a part due to cost, set up, or tooling restrictions. PolyJet 3D Printing is an additive manufacturing process and therefore you are only limited by your imagination and a few very basic guide lines.

| Possible to print rubber like materials targeting a specific Shore A hardness | PolyJet parts can have threaded brass inserts glued into them | Can print with a layer thickness as small as .0006″ |

| No draft required on the part | Individualized serial numbers can be printed into each piece that is being made | Can print multi-materiel parts, for example: VeroBlack and TangoBlack to simulate a hard part body with TPU overmolding on it |

| Smooth finish on “Class A” surfaces | PolyJet does a great job with assemblies, living hinges, snap fits, and pin hinges. | Parts are great for model making activities like clear coated lenses and “Class A” finishes |

| High-resolution, high-accuracy prototypes | PolyJet is able to print models in full color, no need for sanding or painting | Very smooth surface; fine layer lines can be easily removed |

Ideal Applications of polyjet 3D Printing

PolyJet printing process is ideal when multiple materials are necessary for printing parts. They are best for rapid prototyping and production of parts in small numbers. This technology is widely used for creating high-precision parts for aerospace, automotive, electronics, medical, and consumer goods industries. Designers, engineers, and manufacturers prefer PolyJet printing for parts with high accuracy and fine details for several uses.

Some of the key PolyJet applications are:

- Prototyping: PolyJet is used extensively for rapid prototyping. It helps in creating models and prototypes quickly and easily. In addition, the smooth finish and accuracy of parts printed using this technology make it an ideal choice for producing high-quality prototypes.

- Medical devices: This additive manufacturing technology is used to produce medical devices and implants. The accuracy and fine details achieved with this technology help make medical devices according to industry standards.

- Dental applications: PolyJet is also used for printing dental applications. It helps produce dental implants, crowns, and other dental products with great accuracy and detail.

- Consumer goods: PolyJet is used to produce goods such as eyeglasses, watches, and other small accessory parts. This technology’s high level of accuracy and detail helps 3d print high-quality consumer products.

What is PolyJet 3D Printing?

Polyjet 3D Printing Basics

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions, producing parts with incredible precision and speed. It also supports a wide variety of build materials.

How Polyjet Works

PolyJet 3D printed parts are built using photopolymer liquid resin. The printer places layers of photocurable resins onto a build tray in extremely fine layers. As the layers are placed, they are simultaneously cured via exposure to ultraviolet (UV) light, solidifying them into solid material matching the programmed CAD file. This process repeats itself until the entire part has been constructed. In the case of complex geometries, support structures are added to the part to ensure a successful build and manually removed during the finishing process.

Benefits of Polyjet 3D Printing

Eliminates the multi-stage processes of traditional manufacturing, such as tooling, milling, and creating molds.

Creates complex shapes with a high degree of precision that would otherwise be impossible to build via traditional manufacturing processes.

PolyJet 3D can build vastly different part geometries, unlike traditional processes that would necessitate a complete retooling of an assembly line to produce a different part.

Offers a vast material selection with a range of properties and the ability to print multiple materials and simulate overmolds.

Because PolyJet 3D can create complex and multi-material parts in a single operation, significantly less build time is needed vs traditional manufacturing. We can have parts to you in as fast as 1 day.

Are your looking for a Polyjet 3D printing service?

Whether you’re looking for an initial prototype or ready for small-batch production, send us what you’re looking for and we can begin. Fill out our online order form for a free quote for your project. If you have questions regarding any part of our PolyJet 3D printing service, please feel free to reach out to us.