Precision Machining

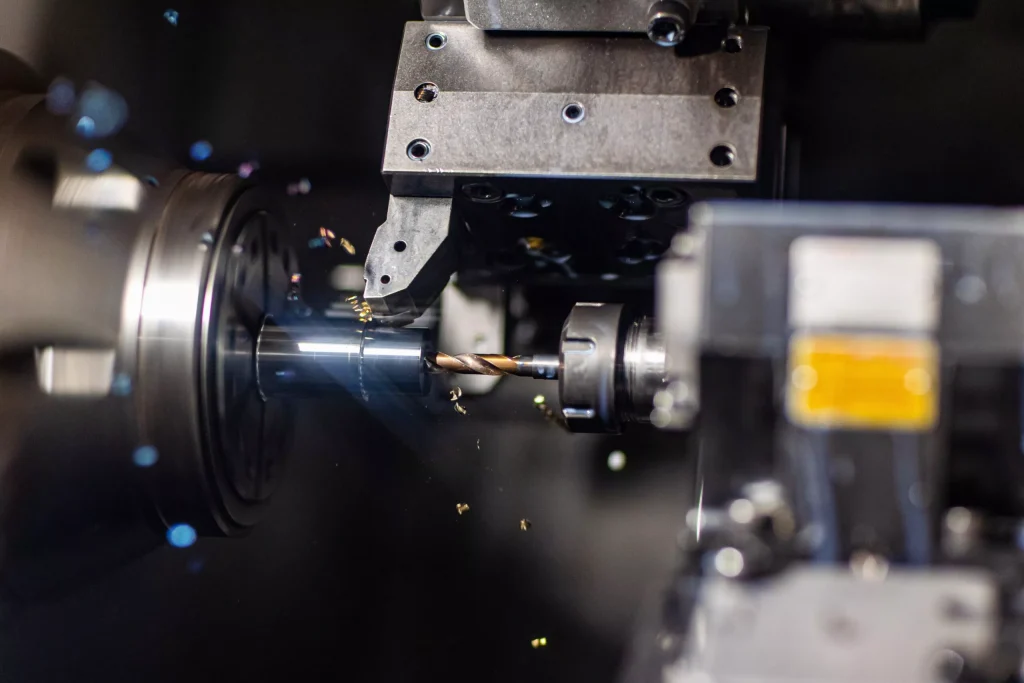

From prototype manufacturing to production machining projects, the Elimold Company produces precision parts of the highest quality and consistency. We strive to ensure on-time delivery and competitive pricing. Whether it’s a complex, custom-machined aerospace part or an intricate component for the semiconductor sector, absolute attention to detail and unparalleled quality remain our primary focus.

Precision machining, manufacturing and testing

Elimold’s precision machining center offers center-boring, deep-hole drilling, robotic rotary stub welding, straightening, hammer peening and roller burnishing, milling and turning up to 6 axis, lathe turning, honing, wire EDM, ECM deburring and laser engraving all under one roof. This results in superior process control for all of our standard and custom products. Our fully equipped clean room and lab can build any downhole or surface assembly.

Precision Every Time

Our commitment to success for our customers goes beyond hard work and dedication — it means precision every time. As one of North America’s leading precision machining companies, Elimold has invested in some of the industry’s most powerful automation for precision machining.

From integrated robotic cells to 100-plus vertical, horizontal, and 5-axis machining solutions, our climate-controlled, 24/7 lights-out capabilities can accommodate project runs of all sizes. Our experience manufacturing complex precision-machined parts and our substantial investment in state-of-the-art machinery make us the perfect partner for your next program. With our complete breadth of capabilities, we can scale your programs as they grow.

Materials

Regardless of the material required for your products, Elimold’s state-of-the-art machine shop is fully equipped to provide the flexibility your precision parts require. We offer the capability to fabricate custom parts in almost any configuration, size, or weight. We have extensive experience in machining a wide range of production materials, including stainless steel, copper, molybdenum, titanium, aluminum, as well as a number of specialized exotic materials.

- Low Carbon Steel – 1020, 1018, A36, 12L14

- Alloy Steel – 4130, 4140PH, 4150PH, 4340, 1044, 1045

- Tool Steels – O1, A2, H13, D12, D2, P20, S7, W1,

- Stainless Steels – 303, 304, 316, 316L, 416, 420, 17-4PH

- Aluminum – 6061, 7050, 6013, 3003, 6063, MIC-6, APT5, ALCA5

- Bronze – 954, 936, 932, 360

- Titanium – Grade 5, Grade 2,

- Plastic – Delrin, Acetal, UHMW, ABS, PVC, Nylatron , G10, PEEK, Garolite(LE), Teflon, PTFE, Carbon Fiber, Nylon

Finishing

Our Precision Machining parts can be finished using:

- Black Oxide

- Anodization

- Hard Coat Anodization

- Hard Chrome Plating

- Electro Polishing

- Nickel Plating

Benefits of precision machining

While there is a cost associated with precision advanced machining, industries such as aerospace, robotics, and automotive, along with surgical device manufacturers, require complex parts fitting and functioning together flawlessly.

High dimensional accuracy

Tight tolerances are the name of the precision machining game. With specialized tools and processes, precision machining can achieve tolerances as close as ±0.0001 inch (0.0025mm) from a 3D model’s ideal dimensions.

Consistency

Besides achieving the industry’s tightest tolerances, precision machining can also reliably replicate those results at scale, making each part in a run as close to identical as possible.

High volume capability

While precision machining is used for prototypes and custom, small-batch parts, it can also fulfill high-volume orders to the same exacting specifications.

Material and process versatility

Precision machining works with a wide range of materials—many types of metals, plastics, and composites, as well as wood and glass—on a variety of milling, turning, grinding, drilling, laser, and multi-axis CNC machines.

Efficiency

Thanks to highly automated and accurate processes, precision machining contributes to a factory’s productivity with high production speeds, efficient use of the workforce, and low defect rates.

Safety

With highly automated, computer-controlled precision machining, workers stay clear of dangerous cutting and grinding operations and can focus on valuable higher-level skills like CNC programming.

Precision Machining Services for All Industries & Applications

Our state-of-the-art precision machining shop located in China serves customers throughout the world and throughout the United States. We provide high-speed precision CNC machining services for a wide range of industries and applications, including:

- Optical industry

- Medical device manufacturing

- Electronics

- Computer technology

- Marine equipment OEMs

- Mining industry

- Food processing

- Fastener industry

- Aircraft/aerospace

- Military machining

- Sports & recreation industry

- Semiconductor manufacturing

- Testing equipment

- and many others

Superior Custom Machining Services

Our precision machining experience ranges from cutting-edge aerospace, defense, and semiconductor applications to a wide range of industrial products. Get in touch to discover all of the advantages that Elimold Company can provide to your custom machining project.