How much does a mold cost for plastic injection? This question is often asked by people who want to adopt this technology. Plastic injection molding is a popular manufacturing process for making many parts. Injection molding projects require manufacturing a corresponding injection mold at the outset. Therefore, it is critical to understand the cost of producing injection molds before considering this process for your manufacturing operation.

This article explores the cost of injection molds. Understanding injection mold costs will help you estimate the cost of your injection molding project.

Let’s get to the heart of the matter and answer the question: How much does an injection mold cost?

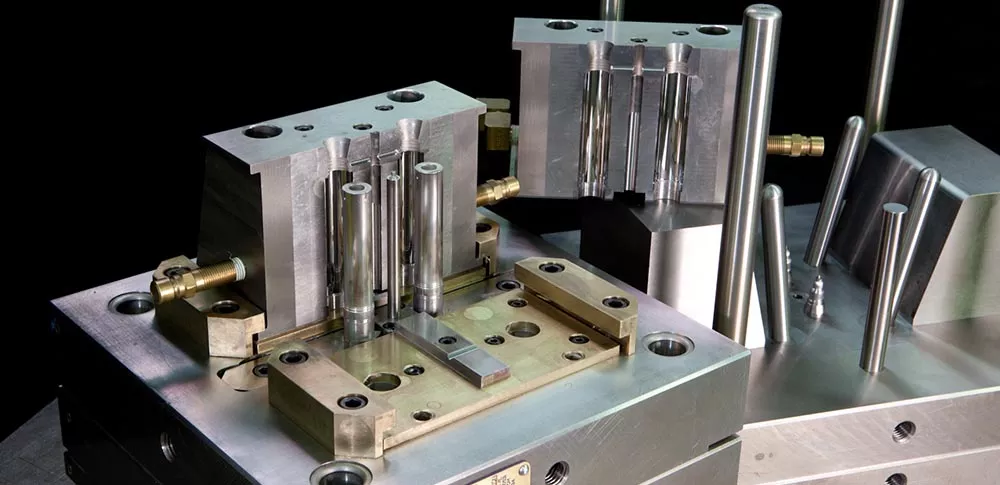

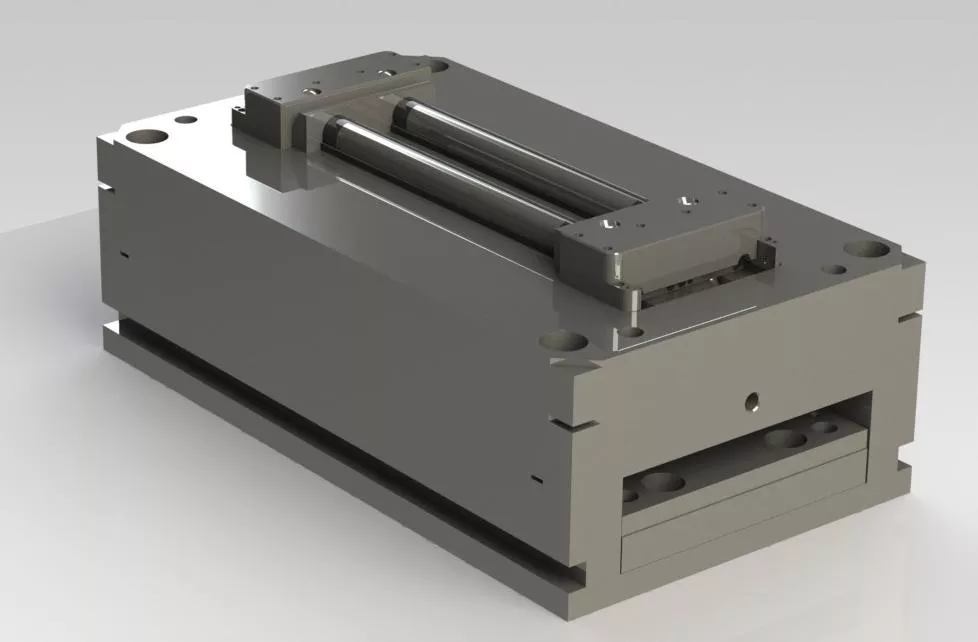

Cost of Manufacturing Injection Molds

The cost of a mold is determined by a combination of part size, complexity, material, and expected quantity. Plastic injection molding processes can cost anywhere from $3,000 to $100,000. Simple molds typically cost between $3,000 and $6,000, while larger, more complex, high-volume, or multi-cavity molds can cost $25,000 to $50,000 or more.

For example, if you need 1,000 parts per year, we recommend a single-cavity mold, which produces one part per machine cycle. In this case, the price of the mold might be $1,000-$2,000.

Alternatively, your order quantity of about 10,000-20,000 small parts could cost as much as $10,000-50,000 for an injection mold with a multi-cavity design that molds multiple parts simultaneously. The cost can be upwards of $100,000 for more complex geometries and larger orders.

Mold costs depend on the complexity or size of the part. Considering all the variables involved will help determine the overall injection mold cost. It is important to weigh the cost of the mold against the number of parts produced. Higher volumes will reduce the final cost per part per unit because the total injection mold cost can be spread over hundreds or thousands of parts. While the upfront cost of injection molding can be high, it is still the fastest and most economical way to produce large quantities of plastic parts.

If your part is complex (for example, if it has complex geometry or dense walls), the manufacturer may need to use special (i.e., more expensive) molds to complete your order. The cost to you will be higher.

Conclusion

Injection mold prices vary from project to project. Knowing what factors affect cost will help in many ways. For example, it can help you communicate better with your mold maker. It is important to understand the impact of certain product features and decisions. This can help you decide which design will meet your product needs. But there is no need to spend money on unnecessary features. For one thing, the mold is too weak to meet your production needs. In addition, you can have a very strong mold that can only accommodate a small percentage of its features.

Elimold offers professional, cost-effective, and efficient mold-making services. Contact us today to discuss your injection molding project and receive a free quote.