Various 3D printing technologies are currently popular in manufacturing and used in different fields and for different purposes. Among them is selective laser sintering (SLS). Selective laser sintering (SLS) 3D printing is trusted by engineers and manufacturers in different industries for producing robust and functional parts.

The development of selective laser sintering (SLS) technology began with the foundation of powder bed melting techniques developed by two PhDs at the University of Texas at Austin in the 1980s, incorporating the use of lasers to enable these techniques to be manufactured using a wide range of materials from polymers to metals.

Selective laser sintering (SLS) is an additive manufacturing process that belongs to the powder fusion family. In the selective laser sintering 3D printing process, a laser selectively sears polymer powder particles, fusing them and building the part layer by layer. SLS is a versatile solution, especially if you want to defer injection molding and its high start-up costs and test your product’s or technology’s performance before manufacturing expensive molds and tooling. It is cost-effective to produce less than 1,000 products using this technology.

Learn the basics of selective laser sintering (SLS 3D printing). Learn how SLS 3D printing works, the advantages and disadvantages of SLS technology, and the various materials suitable for your part or project.

What is Selective Laser Sintering 3D Printing?

One of the technologies used in today’s 3D printers is Selective Laser Sintering (SLS). Selective laser sintering is one of the additive manufacturing (AM) technologies, and the SLS process was developed and patented by then-University of Texas undergraduate Carl Deckard and his mechanical engineering professor, Joe Beaman, in the 1980s.

The main principle of SLS technology is to use a high-powered laser to sinter polymer powder particles to form a solid three-dimensional object. SLS uses a co2 laser, while DMLS uses an ND: YAG fiber laser. Both are identical in principle, drawing slices of the CAD model on the material bed and fusing micron-sized material particles one layer at a time.

SLS does not require the support structure of DMLS, and unlike stereolithography (SLA), SLS primarily uses engineered nylon to create fully functional parts. Although SLS technology is far from new, it is still used primarily for industrial applications. The precision laser used in the SLS process enables high-precision manufacturing, even of complex parts. As a result, SLS is widely used for rapid prototyping and producing small quantities of custom parts.

How does SLS 3D printing work?

SLS works by sintering powders at high temperatures using a laser that heats the powder to slightly below its boiling point (sintering) or above its boiling point (melting), thereby fusing the particles in the powder together to form a solid form. Selective laser sintering makes it possible to print functional objects without using an intermediate binder or through an assembly stage.

The selective laser sintering process is similar to other powder bed fusion techniques in the following ways. As with all 3D printing methods, the overall printing process has the following steps:

1. The designer generates a 3D model using a computer-aided design (CAD) program.

2. The design is divided into thin (2D) layers.

3. The split design is sent to the SLS printer.

4. A leveling roller spreads a thin layer of powder material on the printer’s build platform.

5. The CO 2 laser traces a cross-section of the material, heats, and fuses it.

6. Once a layer is completed, the build platform is lowered to make room for the next layer of powder.

7. Any unused material is recycled after each layer is completed.

8. The SLS process is repeated, building layer by layer until the part is complete.

During the printing process, the SLS part is surrounded by un-sintered powder. This additional powder supports the part during the printing process, thus eliminating the need for a support structure. Unlike other 3D printing methods, such as stereolithography or fused deposition modeling, which typically require such support, these methods are more time-consuming than SLS.

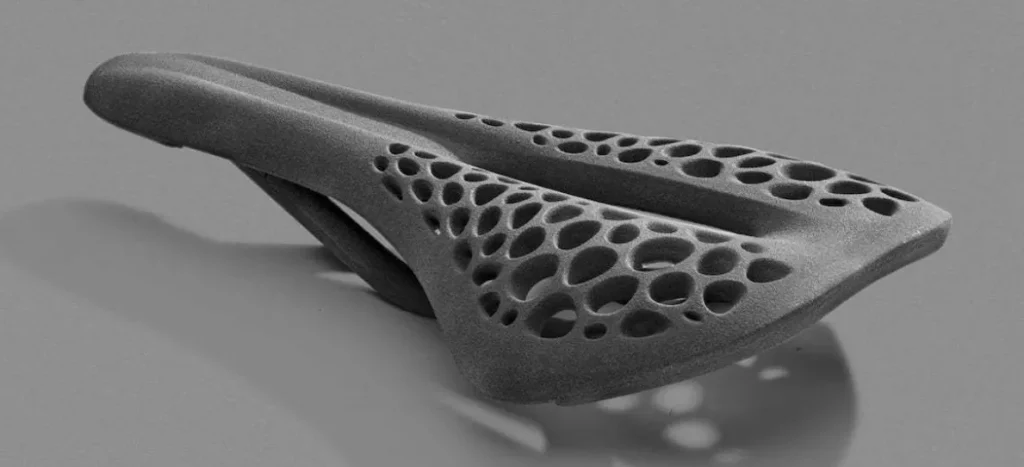

Also, no dedicated support structure is required because the unmelted powder supports the part during printing. This makes SLS well-suited for complex geometries, including internal features, undercuts, thin walls, and negatively shaped features.

SLS requires very little additional tooling after the object is printed, meaning that objects typically do not need to be sanded or altered after they come out of the SLS machine. The same allows SLS 3D printing to produce parts with excellent mechanical properties similar in strength to injection molded parts.

Materials Available for SLS 3D Printing

Selective laser sintering (SLS) 3D printing technology is available in a wide variety of materials, with the most common material being polyamide PA12, also known as nylon 12. nylon is ideal for complex components and durable parts with high environmental stability. SLS 3D-printed nylon parts are strong, tough, robust, and durable. The final part is impact resistant and can withstand repeated wear and tear. Nylon is resistant to UV, light, heat, moisture, solvents, temperature, and water. 3D-printed nylon parts are also biocompatible and non-allergenic. While SLS technology refers to plastic polymers, powder melting technology can be applied to many materials. These include polypropylene, aluminide, carbamide, PEBA, PA11, and PEEK for manufacturing products. Other additives can also be added to the fibers of materials such as carbon fiber, glass, or aluminum to improve the part’s mechanical properties. Among them, polyamide powder can be added to various additives to improve the mechanical and thermal properties of the produced SLS parts.

Depending on the project, all powders used in selective laser sintering can be modified for specific applications to achieve the mechanical properties required for the model. TPU combines the high tear strength and elongation at the break of rubber materials with the versatility of SLS 3D printing, making it ideal for producing flexible, skin-safe functional prototypes and end-use parts that meet the demands of everyday use.

Taken together, the real potential of SLS 3D printing lies in new materials with customized properties (conductivity, heat resistance, water resistance, you name it!) of new materials. In the opinion of many futurists, additive manufacturing is a production technology that will surely transcend the future!

Applications of SLS 3D printing

SLS 3D printing technology benefits from the ability to print parts in various materials, thus accelerating innovation and providing quality parts for various industries, including engineering, aerospace, manufacturing, and healthcare.

In the case of the aerospace industry, aircraft are generally manufactured in very small quantities and have long life cycles. Aircraft manufacturers who use solid molds directly to produce aircraft parts can result in high overall project costs. This is also because solid molds are costly to manufacture and require long-term storage and protection from damage and corrosion, which would otherwise require remanufacturing the molds. If SLS printing technology is used to build prototypes of aircraft parts using only polymer materials, significant savings in tooling costs can be realized.

In addition, SLS machines can also print high-quality materials ranging from flexible plastics to food-grade ceramics, so SLS technology can also be applied to the medical device field for prototyping or small batch technology validation of products and parts such as hearing aids, dental fixators, and prosthetics.

Combining the advantages offered by SLS printing technology, manufacturers producing multiple types of low-volume parts (rapid prototyping) can save money with SLS, primarily because it allows for easy production of multiple industries and types of parts without the expense of extensive tooling. In addition to the applications described above, common use cases include:

- custom tools and fixtures

- gasoline drums

- air ducts

- architectural models

- Flight-rated components for UAVs

- car design

- art sculpture

Advantages and Disadvantages of SLS

What are the advantages of SLS 3D printing

1. SLS parts have good isotropic mechanical properties, making them ideal for functional parts and prototypes.

2. when manufacturing SLS parts, the hollow space is filled with un-sintered powder. SLS does not require support, so designs with complex geometries can be easily generated.

3. Because no support structure is required, designers can create parts that achieve their goals without worrying about manufacturing feasibility. As a result, many parts considered “impossible” due to the limitations of traditional subtractive manufacturing techniques can now be manufactured using SLS additive manufacturing.

4. Because the nylon powder used in SLS requires only a very short laser exposure to the sinter, SLS printing is one of the fastest 3D printing technologies available. Unlike other technologies, such as FDM, there is little trade-off between printing speed and ensuring high quality.

5. All remaining un-sintered powder is collected and can be reused.

6. SLS prints are naturally porous and readily absorb moisture and other liquids. This porous nature makes SLS parts ideal for coloring, especially when using a hot water bath.

What are the disadvantages of SLA 3D printing?

1. The porous nature of SLS parts can compromise their structural integrity. While SLS parts typically have excellent tensile strength, they lack flexibility and can fail at relatively low levels of deformation. For this reason, SLS printing is often used as a proof-of-concept prototype, and SLS-produced parts may also have rough surface finishes.

2. The nylon powder used in SLS is subjected to high temperatures during the sintering process and then cools rapidly. As the part cools, it also shrinks, leading to inaccurate printed parts – often with sharp edges and corners.

3. SLS parts have a grainy surface finish and internal porosity and may require post-processing if a smooth surface or water tightness is desired.

4. While SLS-printed powders can be reused, most SLS experts recommend using up to 50% recycled powder in future prints, as described above. Therefore, there is always an element of waste in the SLS printing process.

5. Large planes and small holes cannot be printed accurately with SLS because they are prone to distortion and over-sintering.

What is the next step in SLS?

Currently, selective laser sintering (SLS) 3D printing technology is mainly used in industry, mainly limited by the high price of SLS 3D printer equipment and the limitations of laser usage and powder materials. Like all AM technologies, SLS depends on the manufacturer’s ability to produce high-precision parts and optimize 3D models. The other thing is that SLS technology cannot print thin-walled and sharp-edged parts, and certain software features are critical to creating and optimizing these models.

For an in-depth look at SLS 3D printing technology and how SLS technology can help you get efficient solutions for rapid prototyping and low-volume part production, contact us today.