CNC machining is one of the more common manufacturing processes. This is mainly due to its high accuracy, precision, and tight tolerance ranges. In fact, through CNC machining, it is possible to accurately manufacture parts of the same size in small batches, while achieving tolerances as small as tenths of a millimeter. There are many types of CNC machining; the common ones are CNC milling and CNC turning. This article will mainly introduce the characteristics of CNC milling and what parts are suitable for CNC milling.

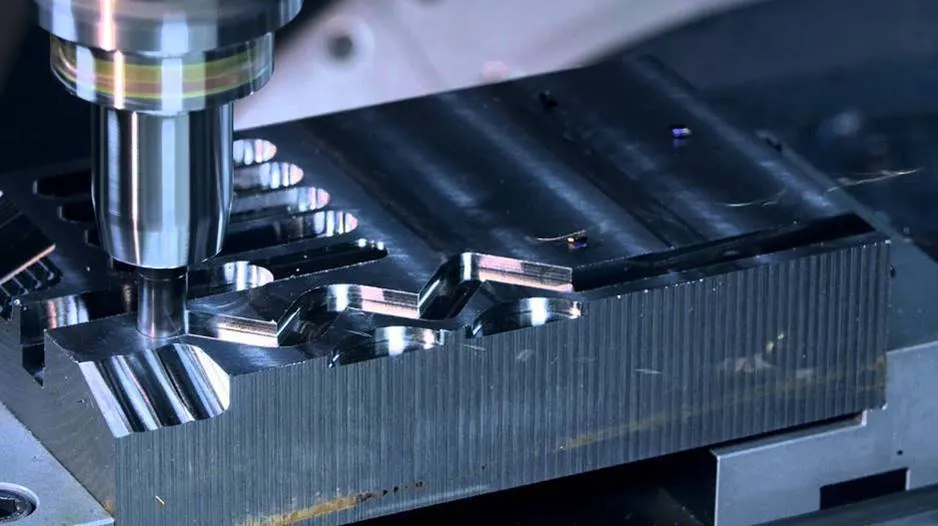

CNC milling is a machining process that uses a rotating tool to remove excess parts of a block of material until the desired custom shape is formed. In addition, CNC milling can machine very complex parts while meeting the strict tolerance requirements of the parts. CNC milling has been continuously adapted and refined to produce precision parts that meet the exacting demands of today’s demanding industries.

CNC milling is mainly used in subtractive manufacturing. The parts to be milled are fixed in the fixture on the CNC worktable. Then the raw materials are processed through the CNC milling machine’s X, Y, and Z axes, and the tool spindle is rotated at a very high speed to cut the material to achieve the ideal parts.

Features of CNC Milling

The application of CNC milling has the characteristics of flexibility and variety. It is used to process various parts with different structures and complex shapes. On the CNC machine, drilling, boring, plane milling, end-face milling, tapping, and other processes can be completed. In addition, CNC milling has high precision and repeatability, which can meet the requirements of high-quality machining. CNC milling avoids operator errors and maintains the consistency of part dimensions during small-batch processing.

The CNC milling machine has the functions of a drilling machine and a boring machine simultaneously. On the multi-variety and small-batch production line, CNC milling is used to centralize the processing procedures, improving production efficiency and reducing the error rate of parts clamping. In addition, CNC milling also has the function of fast forward, backward, and fast positioning of the tool holder, thereby reducing maneuvering time.

CNC milling can also process complex profiles that are difficult to machine by CNC lathes and even the plane curve contours and spatial surface contours of parts. This is because CNC milling has the characteristics of multiple feed coordinates and feed axis linkage.

What are the parts suitable for CNC milling

Compared with conventional machining, CNC milling has the characteristics of high machining accuracy, complex shape parts, and wide machining range. According to the characteristics of CNC milling, the parts suitable for milling mainly include the following types.

1. Parts with complex structures such as curve contours or curved surfaces: the plane curve contour of the part, that is, the part has a complex curve with internal and external contours, and the processing surface is parallel or perpendicular to the horizontal plane. In three-dimensional space coordinates, the surface of a part is usually a point variation on the surface. Mathematical models usually design it. During the machining process, the milling cutter is always in point contact with the machined surface. The part’s surface is usually processed by three-coordinate CNC milling because it needs to be programmed with the help of the CNC system.

2. The structure of parts that are difficult to be processed by ordinary milling: For parts that are difficult to observe and control, such as size, scribing, detection, etc., because ordinary milling machines do not have CNC system additional processing. Therefore, choosing a CNC milling machine for these parts is very suitable.

3. Ordinary milling machines cannot achieve precision and accuracy: Due to the errors caused by human factors in ordinary milling, it is difficult to ensure the dimensional accuracy, shape accuracy, and surface roughness of the parts. Therefore, if the precision of the parts is high, it is necessary to use a CNC milling machine for processing.

What are the classifications of CNC milling machines and machining centers?

Currently, CNC machine tools used in the machinery manufacturing industry can be roughly divided into CNC milling machines, CNC machining centers, CNC lathes, CNC grinding machines, CNC wire cutting machine tools, etc. The following briefly introduces the classification of CNC milling machines and machining centers.

First, the type of CNC milling machine

CNC milling machines can process various parts with flat contours and solid surfaces. CNC milling machines can also perform drilling, expanding, reaming, boring, and tapping. CNC milling machines are divided into vertical CNC milling machines and horizontal CNC milling machines. CNC milling machines have different grades such as 2-axis linkage, 3-axis linkage, 4-axis linkage, and 5-axis linkage. The most widely used CNC milling machine is 3-axis linkage, and 4-axis linkage and 5-axis linkage are generally used in the military industry. , automotive and aerospace industries.

Second, the type of machining center

The difference between the CNC machining center and the general CNC machine tool is that the CNC machining center is equipped with a device that can automatically change the tool and a tool magazine system. The tool magazine stores several tools prepared in advance, which can process the workpiece in multiple processes. Machining centers are also divided into vertical and horizontal machining centers.

A vertical machining center refers to a machining center with a vertical spindle. Its structure is mostly fixed columns, and the worktable is rectangular, without indexing and rotating function; it is suitable for processing discs, sleeves, and plate parts. It generally has three linear motion coordinate axes, and one can be installed on the worktable. A rotary table with a rotating shaft is used to process helical parts.

The vertical machining center is easy to install, operate, observe the processing situation, and debug the program, has a simple structure, small footprint, low price, and is widely used. However, due to the limitation of the height of the column and the tool-changing device, parts that are too high cannot be machined. The chips are not easily discharged when machining a cavity or a concave profile. In severe cases, the tool will be damaged, the machined surface will be damaged, and the smooth processing will be affected.

- Horizontal machining center

A horizontal machining center refers to a machining center with a horizontal spindle. Horizontal machining centers usually have an automatic indexing rotary table, which generally has 3 to 5 motion coordinates, and the common one is 3 linear motion coordinates plus 1 rotary motion coordinate. Machining of the remaining 4 surfaces, except for the mounting surface and the top surface, is most suitable for machining box parts. Compared with the vertical machining center, the horizontal machining center easily removes chips during machining, which benefits the machining. Still, the structure is complicated, and the price is higher.

- Gantry-type machining center

The gantry machining center refers to the CNC center with large processing specifications. The main shaft is mostly vertical. In addition to the automatic tool changer, it also has replaceable spindle head accessories. The functions of the CNC device are also relatively complete and can be used for multiple purposes in one machine. , especially suitable for processing large workpieces or workpieces with complex shapes, such as in the aerospace industry and the processing of certain parts on large steam turbines.

- Virtual axis machining center

The virtual axis machining center changes the structure of the traditional machine tool in the past. Through the movement of the connecting rod, it realizes the movement of the spindle with multiple degrees of freedom. It completes the processing of the complex curved surface of the workpiece.

The article mainly introduces the characteristics of CNC milling. Read the full text to understand that the application of CNC milling is flexible and diverse. It is used to process various parts with different structures and complex shapes. Drilling and boring can be completed on a CNC milling machine. , milling plane, milling end face, tapping, and other processes. In addition, the article also introduces that CNC milling is suitable for machining complex structures such as curved contours or curved surfaces, as well as parts that are difficult to machine by ordinary milling machines.