What is metal 3D printing? How does this additive technology work? This article describes the basic process of metal 3D printing, several common metal 3D printing techniques, and their main advantages and limitations.

Whenever the technology of 3D printing is mentioned, we naturally think of printing plastic-related parts, not metal parts. Can 3D printing cannot print metal materials? Anyone who knows a little about 3D printers knows that metal 3D printing is as popular a manufacturing method as any other 3D printer technology. And the current metal 3D printing technology is still the most significant investment currency and the fastest-growing 3D printing technology in the manufacturing industry. This technology can be used independently for rapid prototyping and finished product production and in conjunction with other manufacturing technologies. This technology is comparable to CNC machining in manufacturing certain parts.

This technology is commonly used in various industries for rapid prototyping, aerospace, mechanical engineering, and other industries in large numbers in the application. Compared to other subtractive metal manufacturing processes, metal 3D printing can reduce production ramp-up costs, shorten design cycles, and speed up time to market.

Metal additive manufacturing has unlimited possibilities.

Metal additive manufacturing (MAM) is a disruptive manufacturing technology compared to other 3D printing technologies, and its creation brings unlimited possibilities to custom manufacturing. This disruption is not only in terms of design freedom but also in the choice of metal materials available to metal 3D printers.

As an example, machining titanium alloys on traditional processes are costly. But metal additive manufacturing allows for the direct processing of this advanced material. Especially for alloys that can only be manufactured at high cooling rates. Thus, the birth of metal additive manufacturing will open a world of new applications and opportunities for the custom manufacturing industry.

This technology enables lightweight engineering and design, whether in automotive, aerospace, or other fields where mass reduction is becoming increasingly important. It can also cost-effectively customize products related to the medical field, save energy in the production process at a specific cost, and can reduce manufacturing costs while achieving product performance.

3D metal printing technology has opened a new world for the custom manufacturing industry. It eliminates spending on tooling, reduces product production costs, and the additive manufacturing process offers unlimited geometric freedom.

Shortly, metal 3D printing technology will be automated, and we can directly control 3D printers to produce parts based on design files automatically. At that time, the production efficiency and cost of products would surprise everyone.

What is metal 3D printing?

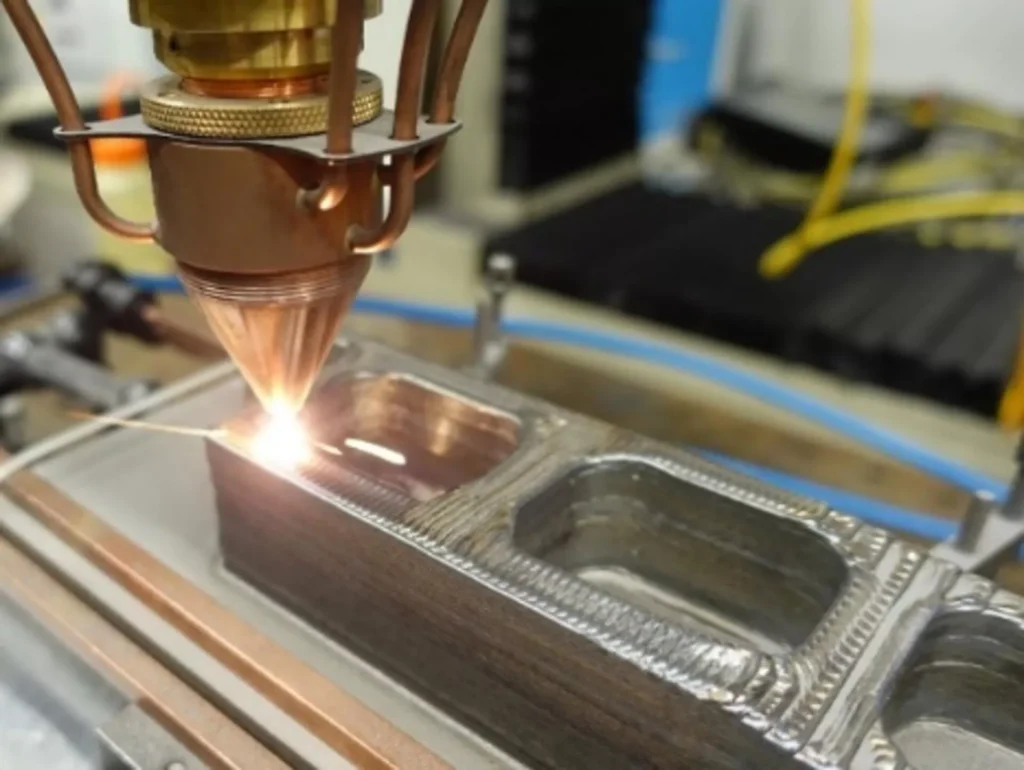

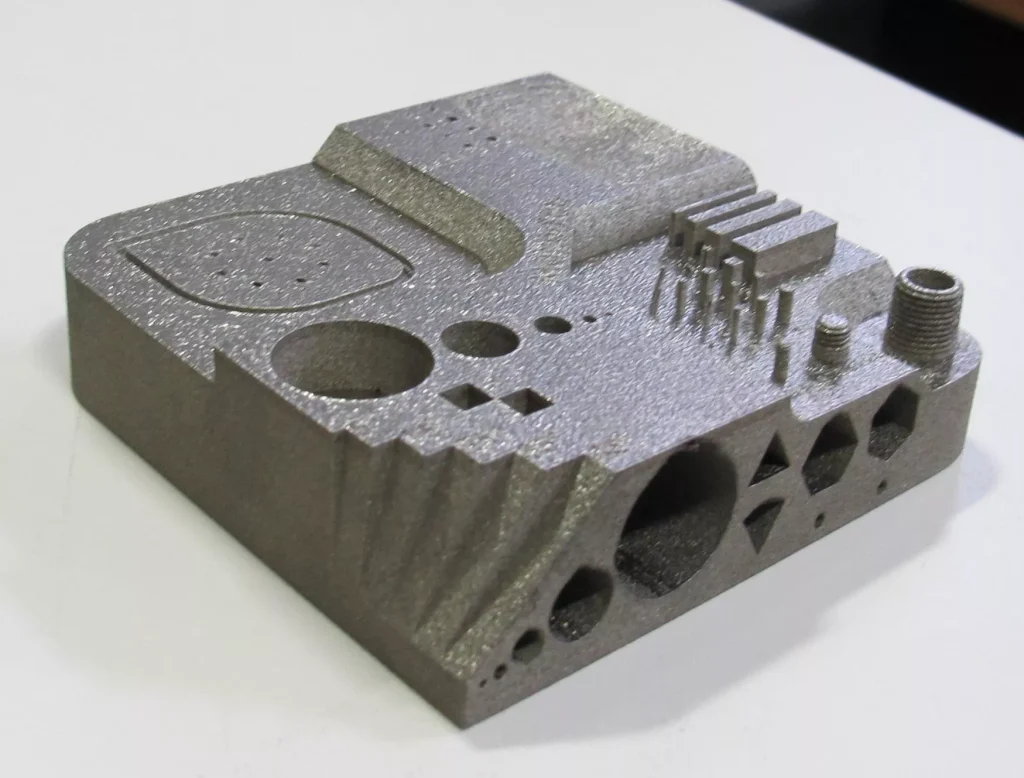

Metal 3D printing is a revolutionary technology with similar basic principles to other additive technologies. It allows for producing parts with a high degree of design freedom based on the provided design data. The basic process is manufacturing metal parts through any by-layer sintering, melting, and welding of metal or metal powder. The main advantages of the process are the ability to produce robust. The main advantages of the process are the ability to produce robust, complex geometries, internal lattice structures, shape-following cooling channels, and exotic designs that traditional machining methods cannot manufacture. Current metal 3D printing techniques typically create prototypes and final products using materials such as stainless steel, aluminum, bronze, and titanium alloys.

What are the disadvantages of metal 3D printing?

Metal 3D printing is not a perfect technology, and it has drawbacks. It is less efficient and cheap than traditional manufacturing methods for making common parts. And with the current state of technological development, it is not feasible to use metal 3D printing technology to mass produce products.Main disadvantages:

- metal powder is much more expensive than “normal” coarse metal

- The manufacturing speed of general products is relatively slow

- Metal 3D printers are expensive

- errors and accuracy tend to be lower than in CNC machining

- may require additional heat treatment when printing products

- Cannot make large parts

What are the advantages of metal 3D printing?

CNC machining can make all types of products. CNC machining cannot produce parts with “unique designs.” As it happens, this is the advantage of metal 3D printing. It is possible to produce almost unlimited products with complex or unique designs. Key Benefits:

- 3D printers can produce intricate details much faster than traditional manufacturing methods.

- Can combine 3D printed details, ultimately saving time and money.

- Can design quickly while minimizing material waste and maximizing strength simultaneously.

- Follower-shaped cooling channels dramatically improve performance and resistance to thermal stress, making it ideal for aerospace and automotive applications.

- enables multiple identical parts to be built simultaneously on a single platform, significantly improving the production efficiency

- of metal 3D printing with little to no material waste

A few of the most common metal additive manufacturing processes

The leading metal 3D printing technologies. There are three types of DMLS (Direct Metal Laser Sintering), LMS (Metal Laser Sintering), and EBM (Electron Beam Melting). Selective laser melting (SLM) and direct metal laser sintering (DMLS) are two metal additive manufacturing processes in the powder bed fusion 3D printing family. There are also several other metal 3D printing technologies:

- Powder Bed or Powder Bed Fusion process

- Binder Jetting

- Direct Metal Deposition (DMD) or Direct Energy Deposition (DED)

- Metal Extrusion or Material Extrusion

Will metal additive manufacturing become a mainstream manufacturing technology?

Metal 3D printing has many advantages over plastic 3D printing – strength, high melting point, and flexibility are just a few. However, metal 3D printers have always been costly. This has also limited the application of this technology to the general consumer sector. It is currently used mainly for rapid prototyping in companies. However, based on our current scenario of using metal 3D printing technology for actual production inferred: with the breakthrough of 3D printing technology, it is believed that this technology will be widely used and even become a common and popular manufacturing technology.

Although metal additive manufacturing is currently only being adopted by companies focused on innovation and creating new value. It also has some challenges that must be overcome, including education around applications, design for additive manufacturing (DFAM), industry standards, regulations, certifications, and metal material quality to accelerate its widespread adoption. But shortly, there will undoubtedly be a place for metal 3D printing in custom manufacturing.

In Summary

Metal 3D printing is a relatively new technology based on existing technologies. While it has proven to be very valuable in the prototyping process, the high cost is currently a limiting factor for its widespread adoption, as the relatively low accuracy of small-scale production and the high cost of final parts.

With the continuous development of technology, all the above problems can be solved. Finally, metal 3D printing technology is something to look forward to.

If you need metal 3D printing services to create rapid prototypes for you or need other manufacturing processes, contact us today.