The plastic molding industry is not well understood by many people, especially those not in the industry. It may be difficult to understand the difference between plastic and injection molding. However, you should know that plastics are used in many products and industries we come into contact with and use daily. Almost all plastic products or parts should be made through plastic molding and processed by different processes according to different designs. For example, injection, blow molding, rotational, extrusion, roto casting, etc. Of these, the most widely used is injection molding.

Plastic molding in Wikipedia explains that plastic molding is making plastic in various forms (powders, granules, solutions, and dispersions) into products or blanks of the desired shape. There are up to three dozen process methods for plastic molding. The choice of different processes for plastic molding is mainly based on the type of plastic (thermoplastic or thermosetting), the starting form, and the shape and size of the product. Commonly used methods for processing thermoplastics include extrusion, injection molding, calendering, blow molding, thermoforming, etc. Processing thermoset plastics is generally done by molding, transfer molding, and injection molding. Lamination, molding, and thermoforming are to make the plastic molded on a flat surface. The above methods of processing plastics can be used for rubber processing. In addition, casting, etc. uses liquid monomers or polymers as raw materials. Among these methods, extrusion and injection molding are the most used and most basic molding methods.

Now you have some understanding of plastic molding. But as a newcomer to this industry, what do you do when you develop new projects that require plastic injection molding? You can contact Elimold to help you solve the problems you are experiencing with your project.

According to the above explanation of plastic molding, injection molding is among the most popular and widely used of over thirty plastic molding processes. Injection molding is a manufacturing process that requires melting thermoplastic plastic at a certain temperature (driven by high pressure) to process plastic products. The molten liquid plastic is injected under high pressure into a temperature-controlled metal mold and cured in the mold. The injection molding process is very fast, taking only a few seconds to complete and begin the next cycle. Now you can look around and see plastic cups, cell phone protectors, cup lid dispensers, cell phone cases, printer housings, etc. These are all made by the injection molding process, and products molded by injection molding are everywhere, and you can find injection molded plastic products everywhere.

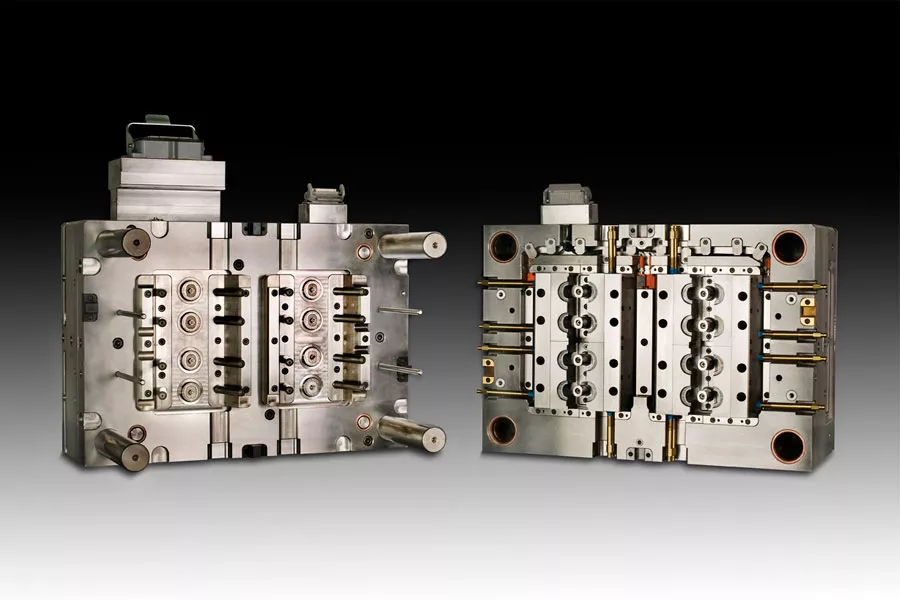

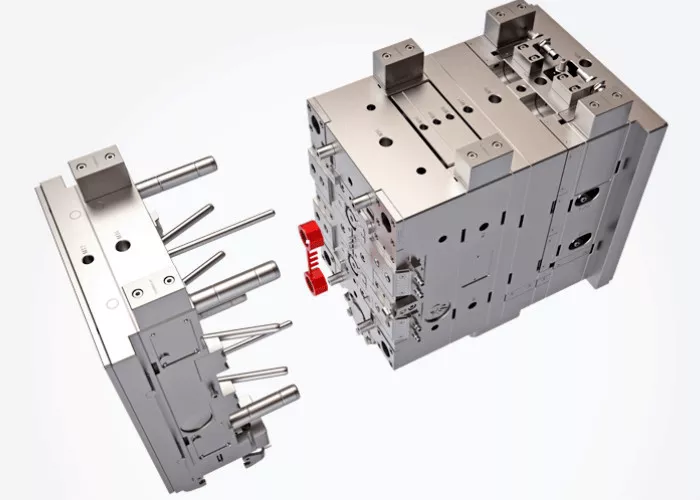

Supplementary note: injection molding used for the metal mold is a plastic mold; plastic molds include injection molds, extrusion molds, and suction molds. Injection molding is mainly used in injection molding; injection mold can also be understood as an empty mold and then a fixed hole in the body, through which the molten thermoplastic material will be injected into the metal mold after high-temperature heating, cooling molding, open the mold, and finally get the product.

Elimold is a custom manufacturer, and we can custom fabricate metal and plastic parts. Whether you are a startup or an established business, we have the capabilities to work with you. Our services cover injection molding, mold design and manufacturing, CNC machining, 3D printing, and other custom manufacturing techniques. We can help you with rapid prototyping and mass production of parts. If you need, you can contact our team at any time; we will give you the best service.