The first CNC machines were invented in the 17th century but were not widely used. It was only in the 1940s that engineers began to use CNC technology extensively for machining parts. As digital applications became more widely used, machine tools were computer-controlled, reducing the chance of human error, which allowed for the production of complex precision parts.

Despite the development of 3D printing and its applications, it still has yet to shake the position of CNC machining in the custom parts manufacturing industry. The two operations are different, as 3D printing is an additive manufacturing type, and CNC machining is a subtractive manufacturing type. However, 3D printing is preferred for producing plastic and low-quality required parts, especially for some simple, rapid prototyping needs to verify the performance of the parts. It is also because the cost of 3D printing services is unsuitable for mass production, while CNC machining is just the opposite.

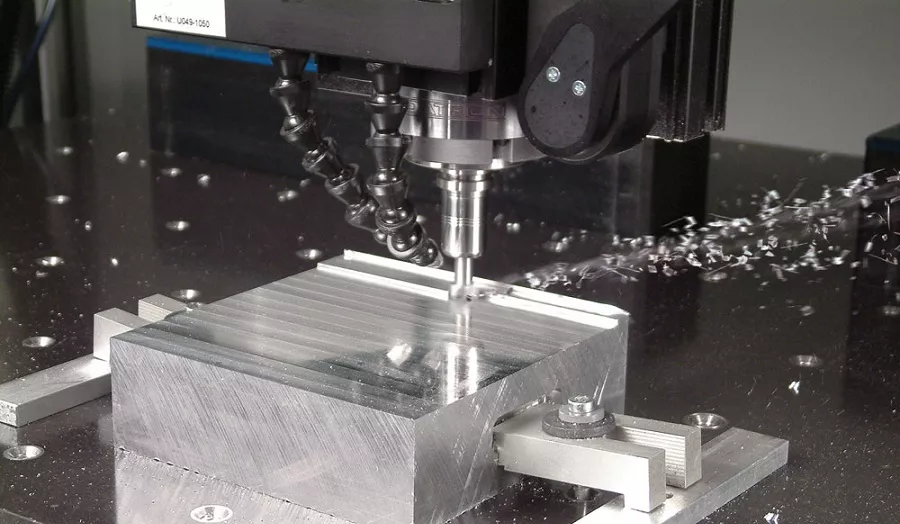

CNC machining is now the most widely used part machining technology in the world, but many customers may need help understanding the cost of CNC machining. If you think CNC machining is necessary to make your parts, read this article. This article will give you an idea of the cost of CNC machined parts.

How to Calculate the Cost of CNC Machining Custom Parts

CNC machining is the most common technique for manufacturing complex parts from metals and engineering plastics. When deciding to machine a part this way, the first question that often arises is, “How much will it cost? Below is a price reference for standard CNC machining services. You can estimate the cost of machining a part.

Different types of CNC machines exist, including 3-axis, 4-axis, and 5-axis. Different types of machines can perform different processes and make different parts.

A 3-axis machine, including a CNC milling machine, costs about $40 per hour. A CNC lathe is also a 3-axis machine and costs about $35 to run. CNC milling machines are slightly more expensive and cover the cost of operator wages.

Multi-axis machines, including 5-axis machines, are more expensive because they cost more to run. Typically $75-$120 per hour. Since prices can exceed that average, you should get a quote before agreeing to any work.

Factors that affect the price quoted by CNC machining service providers

When we start needing CNC machining services at the beginning of a custom machined part project, we should know the cost of CNC machining services, which generally varies depending on the material, size, quantity, complexity, and type of machine used.

1. CNC Machine Costs

The cost of machining varies with the type of machine. The cost of the machine depends on the size, weight, speed, power, and machine configuration of the machine. Generally, the CNC machining service provider will select the correct type of CNC machine to manufacture our custom parts based on the material and part design engineering drawings and quality requirements and provide experienced engineers to help determine the best CNC machining method to choose to have the best cost and quality. When deciding which type of CNC machine to use to machine our custom parts, the primary considerations are accuracy and cost per hour. Below are typical CNC machine costs.

- Typical cost rates for 3-axis CNC milling machine machining services are approximately $30 to $40 per hour, including operator wages

- 3-axis CNC lathes are relatively low, typically $35 per hour.

- The average cost of CNC machining for four axes or 5+ axes is about $75-$130 per hour. The high price of multi-axis CNC machining is due to the high mechanical cost and complexity of the operation of such machines.

2. Material cost

We will purchase them for you and charge an 8% markup, or you can supply them yourself. In addition, more rigid materials take longer to machine. expected metal costs for CNC machined parts are

- 6061 aluminum costs about $25 per piece

- 075 aluminum costs about $80 per piece

- Stainless steel 304 costs $90 per piece

Most materials can be CNC machined to different custom designs, and in addition to metals, plastic materials can also be machined. To find out more about the cost of materials, please get in touch with us to provide you with detailed information.

3. Tolerances

The more precise you want your part, the more you will pay. Each custom part has different characteristics and specified extreme tolerances, both critical and non-critical, that can significantly increase the cost of a CNC part. There are several reasons for this; the first is that machining complex parts requires different tooling setups and extended machine time to ensure high accuracy; the second is the additional labor time required to manually check each feature of each part and the tolerances for compliance.

4. Engineering

If you have a napkin sketch with incomplete dimensions/tolerances, we will have to draw it to the real thing, which will incur additional costs. In addition, if your design and material applications need to meet the performance requirements of the part design, our engineers will help you refine the drawing and improve the design. While most CNC machining service providers do not charge for this, refining drawings and improving designs means modifying 3D CAD design models and G-code programming, which adds cost and is generally charged on a case-by-case basis.

5. Quantity

The cost of machining 100 parts per part is much lower than machining two parts. The total number of parts that need to be machined affects the total cost of the CNC part. The unit cost of making parts of different designs and one-off parts will be higher than making multiple parts of the same design. This is because different parts must be reprogrammed, and different fixtures must be designed. Therefore, the larger the number of machined parts of the same design, the lower the part unit cost.

6. Surface finish

Parts machined by CNC usually have machining lines visible to the naked eye, which is characteristic of CNC machining because CNC machining is subtractive and formed when the tool removes material. Although it does not affect the dimensional accuracy of the part, the surface treatment of the part can improve the appearance of the part and its resistance to harsh environments. For many reasons, CNC machined parts with specified finish requirements can also affect the final cost of CNC machined parts. If surface finishing is required directly on the CNC machine, specialized tooling and longer machining times are required, which can further increase costs.

Machine and labor time is usually the biggest factor in part pricing; how long does it take to run? Most companies operate on a price/hr basis. We will look at the drawing, estimate the machine/labor time for each part, multiply it by the number of parts, and then multiply it by the “shop productivity” (which varies not only from shop to shop but also depends on the number of parts). Our company rates range from $60/hour for our valued customers to $150/hour.

Your ideal CNC machining solution: Elimold

Do you want to get a quality CNC product at an affordable price? Or are you unfamiliar with the CNC process and want a company that can deliver a top-notch product? At Elimold, we provide you with top-notch CNC machining processes.

With us, your CNC machining costing becomes a breeze. With our management mechanism, all you need to do is send a drawing to us at [email protected], and our engineers will analyze your design and send feedback within 12 hours.

Elimold has established a coordinated service system with feedback and timely progress communication. With this, you can rest assured that we will deliver your product on time and with high manufacturing quality.

Conclusion

CNC machining is expensive due to the equipment’s complexity and the machine operators’ wages. However, cost optimization is easy once you get the hang of the process. With an optimized process, the cost and quality of CNC machining are unparalleled.