Injection molding is a common manufacturing technique for making large quantities of plastic parts.

In our lives, we see products made of plastic as far as the eye can see. From children’s toys to airplanes flying in the sky, there are parts made of plastic. Plastic parts made by injection molding are often used to protect, reinforce, and construct various products due to their reliability and high quality. This makes injection molding the most common manufacturing process for producing plastic parts. It works by injecting molten plastic raw material into a mold, which is then cooled and molded to obtain the final product.

Plastic injection molding lives with us daily, so what is injection molding? What materials does it use? What is the leading workflow? This article will explain several central questions about the injection molding process.

What is plastic injection molding?

The injection molding process was born in the United States in 1872 and is now the world’s most widely used plastic manufacturing process. Plastic injection molding is simply injecting a hot, molten plastic material into a metal mold at high pressure and then cooling and curing it to produce a molded end product. The primary process is that materials such as synthetic resin (plastic raw material) are first heated and melted, then injected into a metal mold at high pressure to cool and form the designed shape. Then the machine automatically opens the mold and drops out the finished part. This is a cyclical process from mold closure to plastic injection to part drop-out. High-volume plastic parts manufacturing is the repetition of numerous injection molding machine work cycles.

What is an injection molding machine?

The first plastic injection molding machine was developed and patented in 1872 by American inventor John Wesley Hyatt. Since its introduction, the machine has met market demand and led to the rapid development of plastic injection molding.

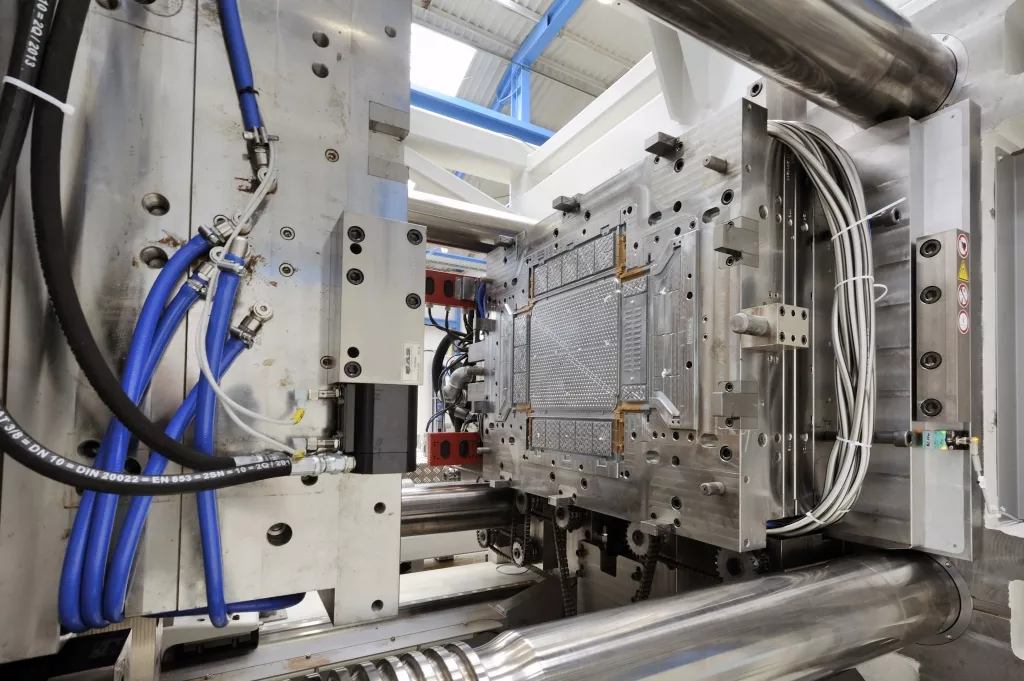

Plastic processing requires a particular injection molding machine (MIM) to complete the manufacture of plastic parts, and the clamping force tonnage mainly determines the size of the machine. Various types of injection molding machines have been developed.

- Servo motors drive electric injection molding machines

- Hydraulic motors drive hydraulic injection molding machines.

- A combination of servo motors and hydraulic motors drives hybrid injection molding machines.

Depending on the tonnage of the clamping force of the injection molding machine, there are injection molding machines ranging from micro-injection molding machines with only a few tons to giant injection molding machines with a clamping force of over 3000 tons. Therefore, the injection molding process can produce from tiny parts to the manufacture of extensive parts, such as plastic drive gears for toy cars to front dashboards or bumpers for automobiles.

Main working principle and process of injection molding machine

In recent years, CNC has been increasingly used in injection molding machines, and high-speed injection molding machine types under program control have become increasingly popular. On the other hand, many specialized machines are also used, for example, to form models for LCD light guide panels.

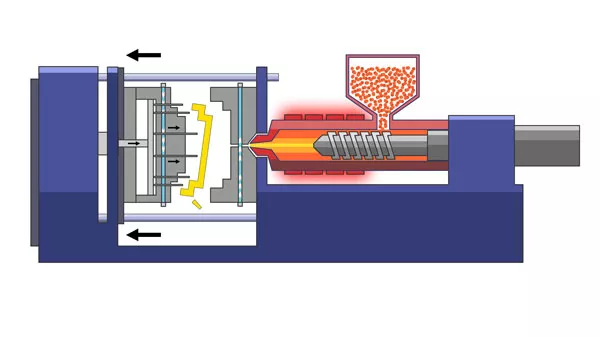

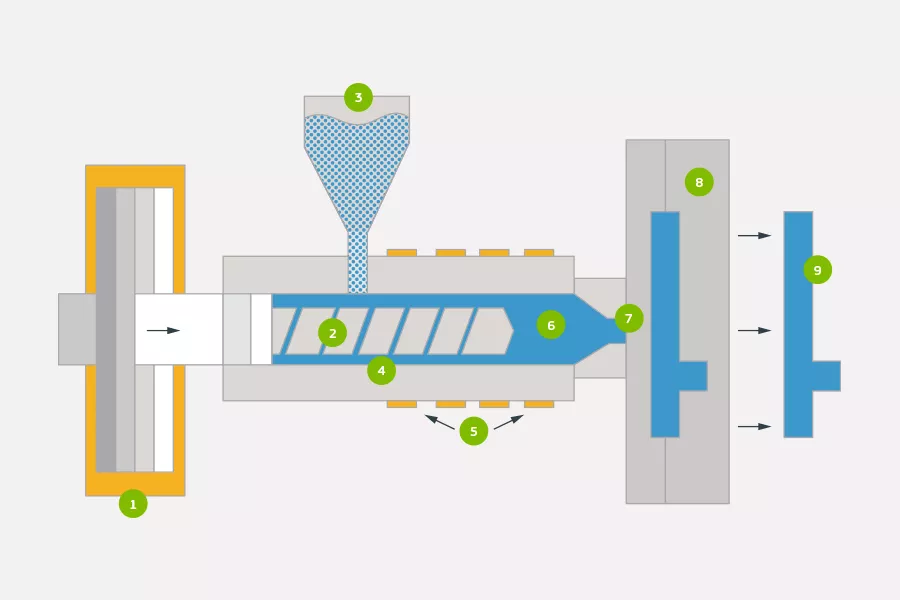

The structure of an injection molding machine can be summarized as consisting of an injection unit that feeds molten material into the mold and a clamping unit that operates the mold.

The injection molding machine is divided into two central units: clamping and injection units.

The function of the clamping unit is to open and close the mold and eject the product. There are two mold closing methods: the elbow joint type and the direct-acting hydraulic type, which opens and closes the mold directly with a hydraulic cylinder.

The function of the injection unit is to melt the plastic by heat and then inject the molten plastic into the mold. Workers feed plastic pellets from a hopper into a barrel to begin the plastic injection molding process. The barrel contains an internal auger. The auger is an auger-like device that feeds the material by rotating it. A heating band on the outside of the barrel heats the barrel and screws to melt the plastic into a molten state. The melted plastic accumulates in front of the screw (metering). The injection process begins when the required amount of molten plastic has been accumulated.

As the machine cycle begins, the mold closes, and the drill is inserted forward under high pressure, like a giant plunger in a syringe.

In less than a few seconds, the internal auger injects the molten plastic into the empty part of the mold (called the cavity). A coolant (usually water) flows through channels in and around the mold to quickly cool the molten plastic, much like an engine block. It usually takes less than 60 seconds for the plastic to solidify the shape of the molding cavity.

As molten plastic flows through the mold, the machine controls the screw movement or injection rate speed. On the other hand, it controls the holding pressure after the molten plastic fills the cavity.

The position of change from speed control to pressure control is set where the screw position or injection pressure reaches some fixed value.

After the plastic part has solidified, the mold opens, and the part is ejected. Once the plastic injection molding machine ejects the solidified plastic part, the process can begin again.

Main Materials Used in Injection Molding

The most commonly used materials for injection molding are thermoplastics. Using the correct thermoplastic testing tools by custom plastic part manufacturers is critical to ensuring that the final assembly has the correct properties. Thermoplastics are polymers that melt at high temperatures and cure at low temperatures. Each thermoplastic has different properties, high-temperature, and pressure resistance due to its molecular structure. Semi-crystalline plastics have an ordered molecular structure, and amorphous plastics have a looser structure. Plastics typically used for injection molding are plastic pellets and can be mixed consistently with colorants, recycled materials, and other specialty additives.

Custom plastic part manufacturers select plastics with different properties depending on the performance requirements of the mold and part. The correct selection of the final thermoplastic determines whether the final component performs as required. The injection molding process can begin once the correct thermoplastic and mold have been tested and selected. The most common types of thermoplastics used by plastic parts manufacturers include the following categories:

1. acrylonitrile butadiene styrene (ABS)

2. polycarbonate (PC)

3. Aliphatic polyamides (PPA)

4. polyformaldehyde (POM)

5. Polymethyl methacrylate (PMMA)

6. Polypropylene (PP)

7. polybutylene terephthalate (PBT)

8. polyphenyl sulfone (PPSU)

9. polyetheretherketone (PEEK)

10. Polyetherimide (PEI)

In addition to the materials listed above, there are many other material types. Suppose you want to know the characteristics of each plastic material. In that case, you can search through Google according to the listed names or contact our engineers directly on the Elimold website to answer your questions.

What does an injection molding manufacturer do?

Injection molding manufacturers vary in their capabilities and services. Some companies use only pre-existing designs, while others provide support throughout product development. As a full-service plastic injection molding manufacturer, Elimold offers a full range of mold-making and production capabilities. From consulting to product packaging, our customers benefit from our long list of in-house capabilities, including

- part design

- rapid prototyping

- mold design

- mold manufacturing

- injection molding production

- pad printing

- assembly

- Packaging & Stamping

Elimold is an owned and operated full-service parts custom contract manufacturer. Based in Shenzhen, China, we have a long history of working with large companies and start-ups. Contact us today to determine if this process suits your idea or company. You can also submit online quotes for plastic injection molds, CNC machining, 3D printing, and more.

Conclusion

Injection molding has a wide range of applications in manufacturing plastic parts, especially in producing high-volume parts. While upfront mold design, machining, and molding testing can be expensive, high-volume manufacturing costs are low. Injection molding can produce nearly identical parts and can be used to produce parts in various material types.

You can learn more about Elimold’s manufacturing production support services here.