Introduction: In recent years, wind power has been developed worldwide to provide a more sustainable alternative to electricity production. In the United States, for example, total annual electricity generation from wind power has increased from 6 billion kilowatt hours in 2000 to about 380 billion kilowatt hours in 2021. According to the U.S. Energy Information Administration (EIA), this represents about 9.2% of total utility-scale electricity generation in the United States. There are still many challenges to overcome, but progress is worth acknowledging. Among these challenges, some customers argue that wind turbines cannot be built unconditionally while also considering the recyclability of the blades produced.

From Waste to Wind, Antarctic Bear has learned that a Belgian association was formed to address these challenges. It uses additive manufacturing technology, primarily fused deposition modeling (FDM), to design wind turbines from recycled plastic. Bram, the founder of the nonprofit From Waste to Wind, had gained valuable experience researching the environmental impact of large wind turbines in the Flemish government sector. From Waste to Wind has already received an international award and additional support from the Antwerp Climate Fund in Belgium.

Background on the creation of From Waste to Wind

While working for the Flemish government, Bram noticed that there was still a lot of resistance to the rollout of wind turbines. Although there were already fairly strict rules in place to limit wind turbines’ environmental impact, people were unaware of them. They feared that wind turbines would cause noise pollution and block their view, so they didn’t want them in their gardens. Bram started experimenting with old barrels for wind turbines and magnets from old hard drives and met like-minded partners on the Internet to get people to look at wind power differently.

Bram now works with Time Circus, a charity group that makes all sorts of things from recycled materials, and they also run Loods 21 and Bar Paniek in Belgium. Time circus’s original homemade wind turbine blades were made from PVC sewer pipe, which was not very U.V. resistant, and the blades had broken, causing the power failure. Eventually, Bram bought a printer for 200 euros and repaired the blades using 3D printing.

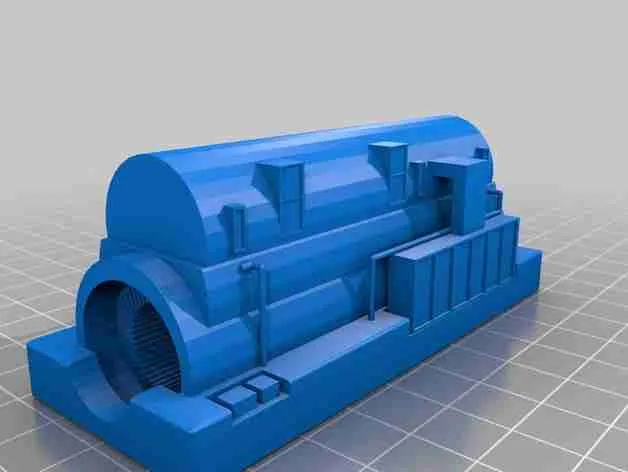

Plastic printing is sometimes not as easy as it looks; it can shrink and warp, and it took Bram several months to get it right. Later, Bram printed a completely custom wind turbine measuring 20x20x20 cm. This wind turbine worked well for several months, and it won Bram a $10,000 prize at Hackaday, an international platform for innovative creators, which was a great encouragement for them.

Bram created the From Waste to Wind Association to break down barriers to renewable energy, especially small-scale wind energy, and bring energy production closer to people. The company’s current business model focuses on researching and raising awareness, which they do with prizes and subsidies. In addition, they have received a grant from the City of Antwerp Climate Fund, which greatly boosts the company’s philanthropic goals.

3D printing for sustainability

Recycling blades for wind turbines has been a big problem, as the fibers and resin cannot be separated when they reach the end of their service life after 20 years. The only thing that can be done is to grind them up and put them in landfills or reuse them in asphalt. In the U.S., they are often buried in landfills.

Pure plastic blades can be fully recycled, unlike the glass fiber-reinforced blades used by other manufacturers. Bram deliberately chose to print reinforced plastics without added fibers. Because with today’s recycling methods, plastics are still “contaminated” and have much less potential for reuse. Today, much plastic waste is generated during the printing process, and there is an unclear material origin. For example, PLA biomaterial may be produced somewhere and then shipped to another industrial facility where it is processed into filament. Bram chose to use rPET, made from recycled PET, the same plastic used in plastic bottles. It has to be recycled anyway, and it’s already available locally and has better mechanical properties than PLA.

From Waste to Wind’s future projects

From Waste to Wind plans to create larger wind turbines, up to 4 meters long, which will generate 50% of the energy needed to complement photovoltaic power in an average home. They also plan to connect all the wind turbines to a computer so that the consumer can always see how much energy his wind turbine produces and safety parameters such as vibrations. Currently, From Waste to Wind is developing its MPPT controller, which will be open source.