Recently, researchers at MIT demonstrated a 3D printed plasma sensor for orbiting spacecraft, and 3D Science Valley has learned that these 3D printed plasma sensors work just as well as more expensive semiconductor sensors. These durable, accurate sensors can be used effectively on lightweight satellites known as CubeSats, often used for environmental monitoring or weather forecasting.

These 3D printed plasma sensors, also known as potentially delayed analyzers (RPAs), are used by orbiting spacecraft such as artificial satellites to determine atmospheric chemistry and ion energy distribution. These sensors are well suited for CubeSats because of their low cost and fast production rate. These inexpensive, low-power, lightweight satellites are typically used for communications and environmental monitoring in the Earth’s upper atmosphere. And the 3D-printed sensors developed at MIT can be produced for tens of dollars in a few days.

3D printing of light-cured ceramics

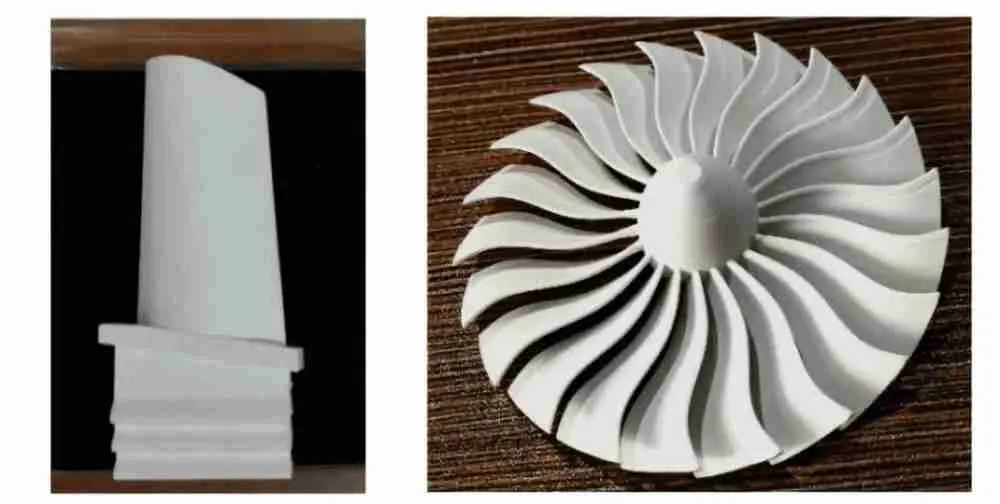

Researchers developed the RPA using a glass-ceramic material that is more durable than traditional sensor materials such as silicon and thin-film coatings. by using glass-ceramics in a manufacturing process developed for 3D printing of plastics; it was possible to create complexly shaped sensors that can withstand the wide range of temperature fluctuations encountered by spacecraft in low Earth orbit. The 3D printing process for ceramics typically involves hitting ceramic powders with a laser to fuse them into shape. Still, the process typically leaves the material rough and creates weak spots due to the high heat from the laser. Instead, MIT researchers used a light-curing 3D printing process, a popular process marketed decades ago for resin additive manufacturing.

With the DLP photopolymerization 3D printing process, a resin material containing ceramic material is cured with UV light after adding each layer. Each layer is only 100 microns thick (about the diameter of a human hair) to create smooth, nonporous, complex ceramic shapes. The refractive index difference between the ceramic and resin has the greatest effect on the depth of cure, followed by the particle spacing and, finally, the ceramic particle size. Although particle size has little effect on the depth of cure, it significantly affects paste rheology and post-processing properties and must therefore be carefully controlled. In a 3D printed digital manufacturing process where the product’s design can be very complex, the high precision achieved with light-cured 3D printing has allowed researchers to create machining paths with unique shapes to perfectly align the holes of the plasma sensor when set inside the housing. This allows more ions to pass through, resulting in higher-resolution measurements.

Regarding design iterations, the MIT team simultaneously produced prototypes of four unique designs because the 3D-printed sensors were so inexpensive and fast to manufacture. It was found that while one design is particularly effective at capturing and measuring a variety of plasmas, such as those encountered by satellites in orbit, another design is well suited to sensing extremely dense and cold plasmas that can typically only be measured using ultra-precise semiconductor devices. This high precision could allow 3D-printed sensors to be applied to fusion energy research or supersonic flight. According to MIT’s findings, the rapid prototyping process enabled by 3D printing could spur more innovation in satellite and spacecraft design.

Often innovation is intertwined with the frustration of failure, and innovation requires researchers to be able to fail and take risks. However, 3D printing-additive manufacturing cleverly defuses the frustration, and 3D printing is a very different way to build space hardware. Researchers can build space hardware; if it fails, that’s okay because 3D printing allows for a new version to be made quickly and cheaply with a fast iterative design. For researchers, it’s an ideal tool. Next, MIT scientists hope to improve the manufacturing process in the future, where reducing the layer thickness or pixel size in the aggregation process can create more accurate and complex hardware. In addition, the ability to fully 3D print-additive manufacturing sensors will allow scientific research to interface with space manufacturing. Scientists also want to explore the use of artificial intelligence to optimize sensor design for specific scenarios, such as greatly reducing the mass of a sensor while ensuring that it remains structurally sound.

Multifunctional sensors

The Plasma Sensor-Delayed Potential Analyzer (RPA) was first used on a space mission in 1959. The sensor detects the energy in ions or charged particles that float in plasma, a superheated mixture of molecules in the Earth’s upper atmosphere. On orbiting spacecraft like CubeSat, the multifunctional instrument measures energy and performs chemical analyses that can help scientists predict the weather or monitor climate change. The sensors contain a series of electrically charged grids dotted with small holes. As the plasma passes through the holes, electrons and other particles are stripped away until only ions remain. These ions produce the currents that the sensor measures and analyzes.

The key to the success of a plasma sensor-delayed potential analyzer (RPA) is the housing structure that aligns the grid. It must be electrically insulated while also withstanding sudden and drastic temperature fluctuations. Undoubtedly, ceramic 3D printing opens up a winding path for manufacturing multifunctional sensors. According to 3D Science Valley’s “3D Printing Ceramics White Paper,” ceramic 3D printing companies focus on developing production-grade ceramic 3D printing systems and materials. Lower-cost and higher-precision 3D printing technologies are entering the market. As ceramic additive manufacturing technology and materials technology continue to develop, applications based on light-curing, binder injection, and material extrusion 3D printing technologies will be enhanced to varying degrees. They will gain deeper development in several fields, such as automotive, dental, energy, and electronics.