Fused Deposition Modeling (FDM) 3D Printing Service

Reduce costs and shorten development timelines by 3D printing your parts out of real thermoplastic materials using fused deposition modeling (FDM).FDM printing is best suited for non visible parts where surface finish is not critical. FDM prototype parts are porous but can be sealed using different processes or chemicals. Sparse build technology can also be used to reduce cost or weight of parts.

- Low Volume Production of complex end-use parts

- Prototypes for form, fit, and function testing

- Casting Foundry Patterns

- Master Patterns for Sculpture Industries

- Pre-Surgical Planning Bone Model

- Mock up models for Retail space

FDM Additive Manufacturing

Fused deposition modeling (FDM) is the most widely used 3D printing process because of its ease of use and ability to run real engineered plastics. FDM, also referred to as Fused Filament Fabrication or FFF, works be extruding materials layer by layer.

FDM is a popular method for additive manufacturing but has its own specific benefits. FDM is more widely known and affordable than HP MJF or Carbon DLS due to the availability and low cost of entry with desktop 3D printers. The Elimold has the capabilities to manufacture 3D printed parts with FDM technology for your projects.

Our industrial FDM machines offer more repeatability for industrial, aerospace and medical prototyping and production. Today, there are hundreds of FDM and FFF 3D printers available in all different sizes, for different materials and applications.

Like all our additive manufacturing machines, FDM runs 24/7 but is easier to operate and post-process which allows for low-cost parts and quick turnarounds in as little as 1-2 days.

What is FDM 3D printing used for?

FDM is the most cost-effective way of producing custom thermoplastic parts and prototypes. FDM 3D printers can be used with multiple materials (FDM filaments can be made of ABS, PLA, PETG, ULTEM, or metal). At Elimold, we offer three options: PLA, Ultrafuse® 316L, and Ultrafuse® 17-4. While using FDM 3D printing with plastic filament such as PLA appears to be a great process to improve your rapid prototyping process and create reliable, functional prototypes. Our PLA plastic or polylactic acid material uses a Big Rep 3D printer, allowing us to print large parts of 1x1x1m with a good resolution.

But this additive manufacturing technology is not only using plastic materials. Metal is becoming a natural alternative to manufacturing objects with higher performances. Using metal filament, our FDM process is the perfect choice for tooling, jigs and fixtures, molds, and other functional parts, where resistance and durability are needed. Ultrafuse materials are great solutions for medical, automotive, or aerospace industries to create functional prototypes and series production.

Technical Specification

| Standard lead time | Minimum of 4 working days, depending on part size, number of components and finishing degrees Minimum of 2 working days for parts with dimensions smaller than 200 x 100 x 100 mm |

| Standard accuracy | ±0.15% (with a lower limit on ±0.3 mm) |

| Layer Resolution | 0.05 to 0.3 mm |

| Minimum wall thickness | Not lower than 1.5 mm |

| Maximum build dimensions | Dimensions are unlimited as components may be composed of several sub-parts. The build area of our largest machine is 600 x 600 x 600 mm |

| Surface structure | Unfinished parts typically have a rough surface but all kinds of fine finishes are possible. FDM parts can be smoothened, painted, and coated |

| Number of Printers | More than 30+ Printers |

FDM Design & Build Guideline

Each 3D printing technology is a little different, here are standard guidelines to consider when choosing FDM as your 3D printing process:

- FDM Build Layers

- 0.007” Build Layers = Best part finish, accuracy, detail, and strength but increases cost and build times (Ultem not available)

- 0.010” Build Layers = Best balance of finish, accuracy, detail, and strength with cost and build times

- 0.013” Build Layers = Best for quick low-cost parts but finish, accuracy, detail, and strength are reduced

- Minimum Wall Thickness & Features = .71-1.32mm (0.028”-0.052”) based on layers

- Standard Finish = Level 1 Support Removal Finish

- Standard Lead Time = 1-3 days

- Tolerances = +/- 0.005” for first inch then +/- 0.002” per inch thereafter

- Inserts = Preferred for threads, install in post-processing with heat stake or adhesives

- Holes = Drill, Ream, and Tap (Print threads then chase or ream in finishing)

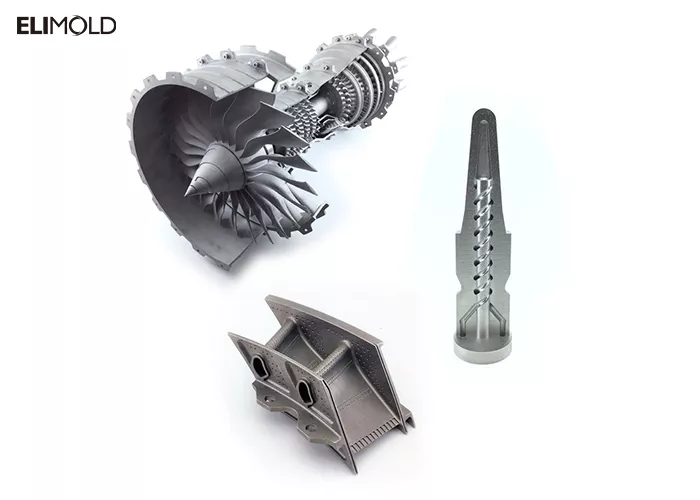

Part manufactured using fused deposition modeling 3D printing technology

Get Your Printed Parts Into Production Runs Today

From design to prototype and production, our team of engineers is ready to help bring your idea to life with 3D printing.Send your CAD files, Receive your customized custom Fused Deposition Modeling (FDM) printing quote. Choose from a variety of process materials to suit your needs.

Benefits of Fused Deposition Modeling (FDM)

Elimold uses the most advanced industrial FDM 3D printers designed to meet tolerances of +/- a single build layer thickness for the first inch and +/- .002” for every inch thereafter.

FDM printed parts are available in a variety of high-performance plastics for applications that require resistance to the elements.

Elimold can produce FDM parts with large build volumes up to 24″ x 36″ x 36″.

FDM parts do not require tooling which reduces the manufacturing lead time from weeks to days.

FDM has the highest variety of real engineered thermoplastics.

FDM is capable of producing end-use parts on-demand, increasing throughput and helping you get to market faster.

The Materials Available By FDM 3D Printing At Elimold

| MATERIALS | DESCRIPTION |

|---|---|

| TPU 92A (thermoplastic polyurethane elastomer) |

|

| Antero™ 800NA (polyetherketoneketone) |

|

| ULTEM™ 1010 resin (polyetherimide) |

|

| ULTEM™ 9085 resin (polyetherimide) |

|

| FDM Nylon 12™ (polyamide 12) |

|

| FDM Nylon 12CF™ (polyamide 12CF) |

|

| PC (polycarbonate) |

|

| PC-ISO™ (polycarbonate – ISO 10993 USP Class VI biocompatible) |

|

| PC-ABS (polycarbonate – acrylonitrile butadiene styrene) |

|

| ASA (acrylonitrile styrene acrylate) |

|

| ABS-ESD7™ (acrylonitrile butadiene styrene – static dissipative) |

|

| ABS-M30™ (acrylonitrile butadiene styrene) |

|

0.005 inch (0.127 mm) layer thickness not available for Stratasys F900.

See individual material spec sheets for testing details.

Annealed

Actual surface resistance may range from 109 to 106 ohms, depending upon geometry, build style and finishing techniques.

Available only on the Stratasys F370

Download the FDM Material Specification PDF and consult a Elimold expert for details on different materials.

For additional flexible 3D printing options // TPU 88A for SLS, PolyJet, and Urethane Casting

Order Material Samples // Keychains and Kits

Why do our clients prefer FDM technology?

- FDM fused deposition modeling technology is easy to use.

- It reduces the production cost associated with 3D printing technology.

- The lead times for this manufacturing process are comparatively shorter.

- It is easy to deal with complicated cavities and geometries with FDM technology.

- There are several high-performance options that need element resistances.

- Our professionals can produce on-demand parts.

Available Finishes for FDM Parts

| Spray painting | Get painted according to the color pattern provided by the customer (Including matte paint, high-gloss paint, electroplating-imitation paint, varnish, leather paint,etc). |

| Polished | The surface texture is polished in a variety of ways to meet the actual needs of customers. The transparent parts can be polished accordingly to improve transparency and light transmittance. |

| Electroplating | Provide electroplating services, improve the overall strength of the parts, provide metal-like surface texture, and make it have certain metal characteristics. |

| Inlay nut | At the specific bottom hole position that needs to be processed, the internal thread is processed. |

| Glazing assembly | The surface of the part is glazed to better imitate the appearance of handicrafts. Have mature assembly experience to ensure the overall display of the product. |

| Reinforced coating | The unique outer coating processing ability improves the strength of the product structure, reduces external wear, and can better avoid damage caused by normal storage and use. |

| Testing Service | A variety of measuring equipment provides reasonable measure services according to the actual needs of customers. |

Are you looking for more information or want to get an accurate quotation?

Are you looking for the top source of FDM 3D Printing Services? Is it difficult to choose from the market’s many manufacturers? Elimold offers the greatest 3D Printing Services in the world, with high precision, durability, and dependability. Elimold’s services are designed to be fast, cost-effective, and high-quality. We use only the best materials and the latest 3D Printing technology to ensure that every product they produce is of the highest standard. We also offer a wide range of materials to choose from, including ABS, PLA, TPU, Nylon and more. With our expertise, they can help you to create prototypes that are accurate, functional, and visually appealing.